Method for preventing slipping of lower belt of blast furnace groove

A belt slippage and blast furnace slot technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of the relative displacement of the belt and the driving pulley, the complex detection of the device, and the incomplete use, and achieve the failure rate. Low, simple device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

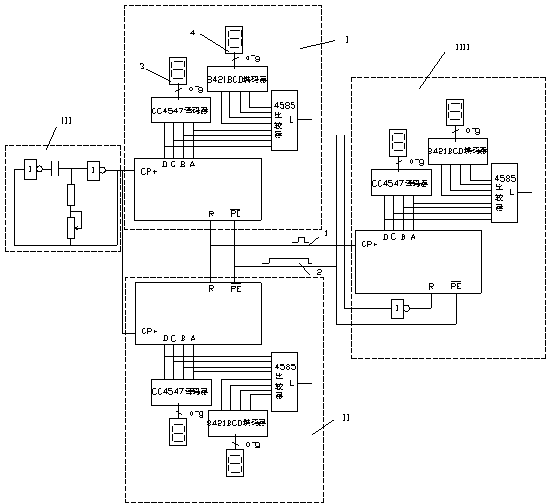

[0013] In order to deepen the understanding of the present invention, below in conjunction with appendix figure 1 The present invention will be further described.

[0014] When the belt is out, the control system sends a belt running signal "1" that is figure 1 The operation signal of the control technology device output by the central 2 centralized control center is sent to the speed detection device. This signal is sent to the PE terminal in the device. The function of the high potential of this terminal is to make the 40192 counter immediately figure 1 I, II, and IIII are counted. When the PE terminal is set to "1", the ring oscillator is figure 1 Middle III starts pulse counting according to the set frequency. If the set pulse interval is 0.1 second, then a clock counting with 0.1 second as the unit is formed. Only when the device is running, the device will work. The accumulated time is output through the A, B, C, and D terminals of the 40192 counting module, and all th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com