Method for partial oiling by using hollowed-out lining paper

A kind of lining paper and local technology, which is applied in the post-processing of printing, general parts of printing machinery, printing and other directions, can solve the problem of high cost, and achieve the effect of delaying production, reducing cost, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

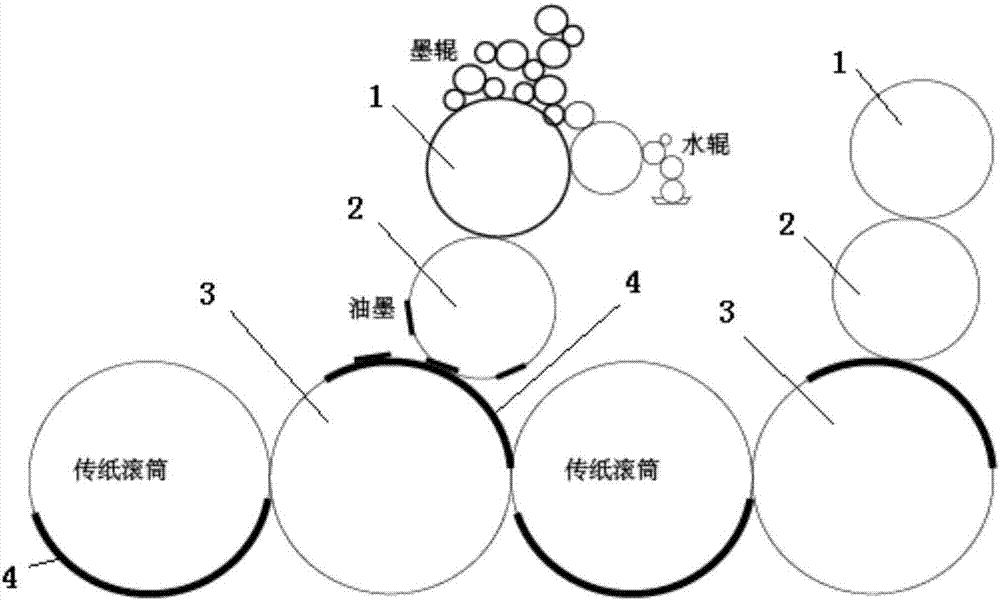

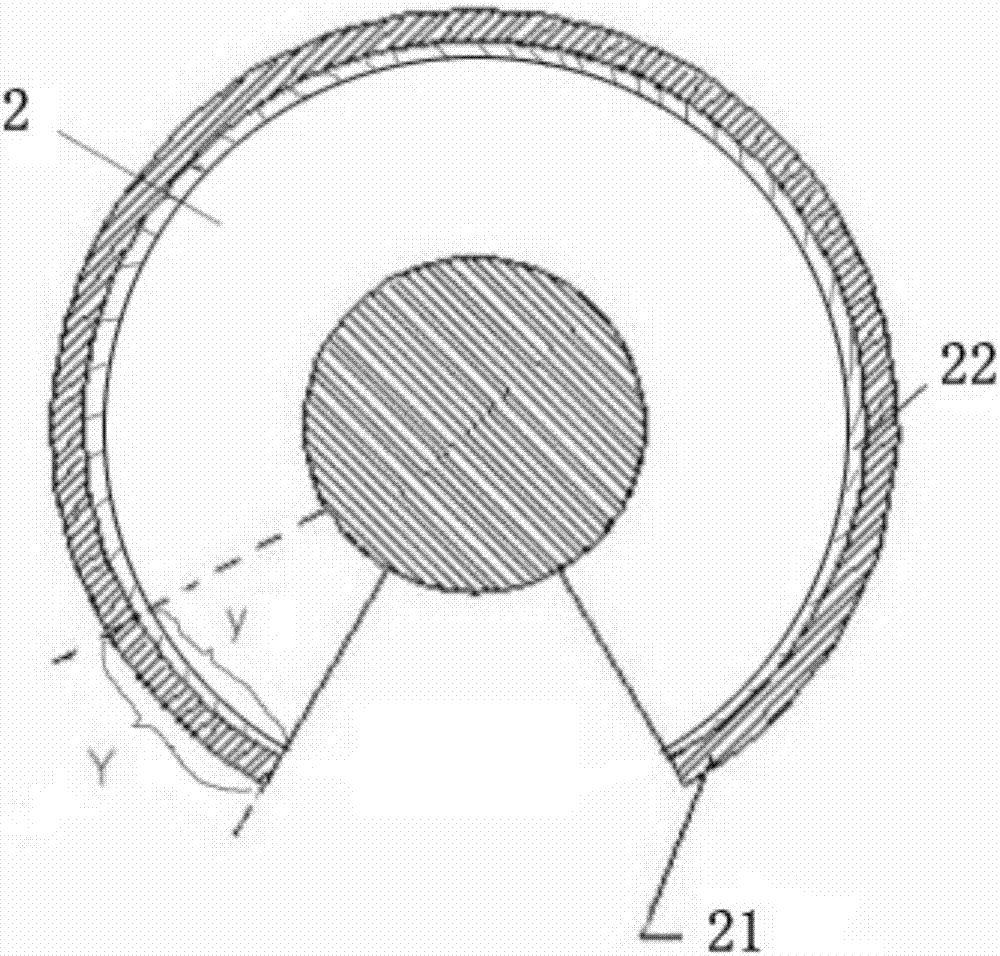

[0028] In this embodiment, the process of using the hollow backing paper for partial oiling is as follows:

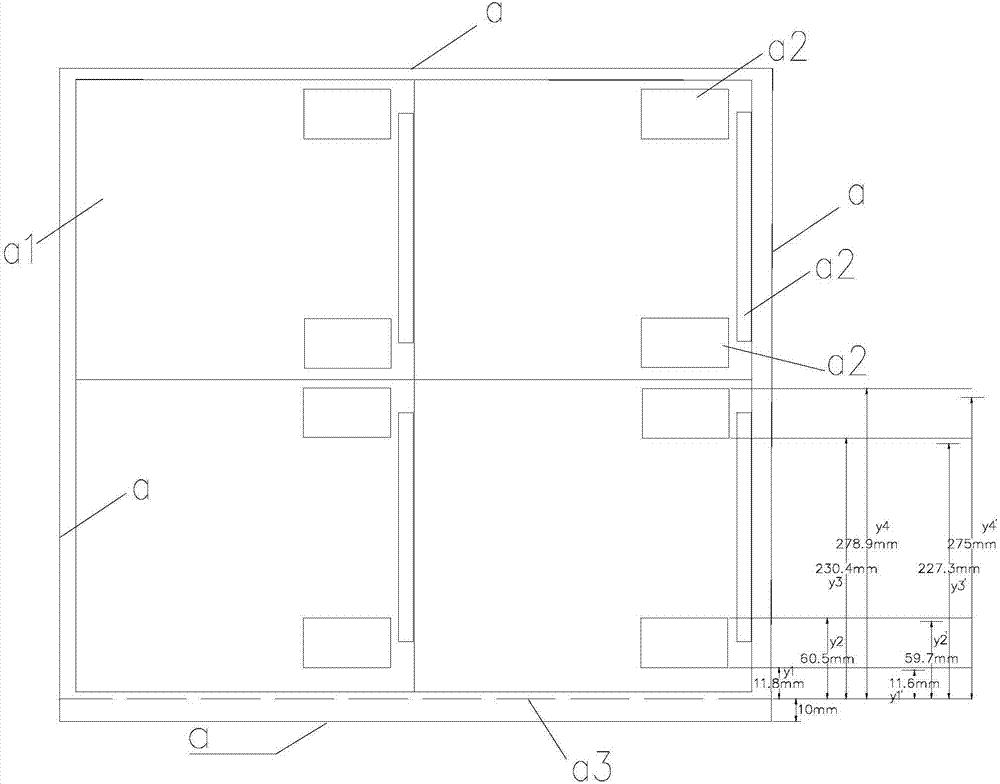

[0029] Step 1) as in figure 2 As shown, a large version is formed according to the specifications of the lining paper. The box ɑ in the figure indicates the line of the lining paper, and ɑ1 indicates the layout of the carton. figure 2 The medium and large version includes the layout of 4 cartons ɑ1, ɑ2 indicates the reserved white area, and then releases the large version PDF and puts it into AI (abbreviation of Adobe Illustrator) software to be processed (easy to process).

[0030] Step 2) Determine the coordinates of the reserved white area ɑ2 on the large version:

[0031] Step 2-1) Set the starting point of the horizontal coordinate, that is, the X coordinate, at the position where the positioning line is 0, namely fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com