Pressure maintaining and leakage testing method of purification changeover valves for oxygen generation

A switching valve and leak testing technology, applied in the testing of mechanical parts, the testing of machine/structural parts, and the measurement of the acceleration and deceleration rate of fluids, etc., can solve the problem of reducing the lifting work of disassembling the valve, the time-consuming and laborious disassembling of the valve, and the increase of equipment costs. Costs and other issues to achieve the effect of saving labor costs, speeding up work, and reducing system downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

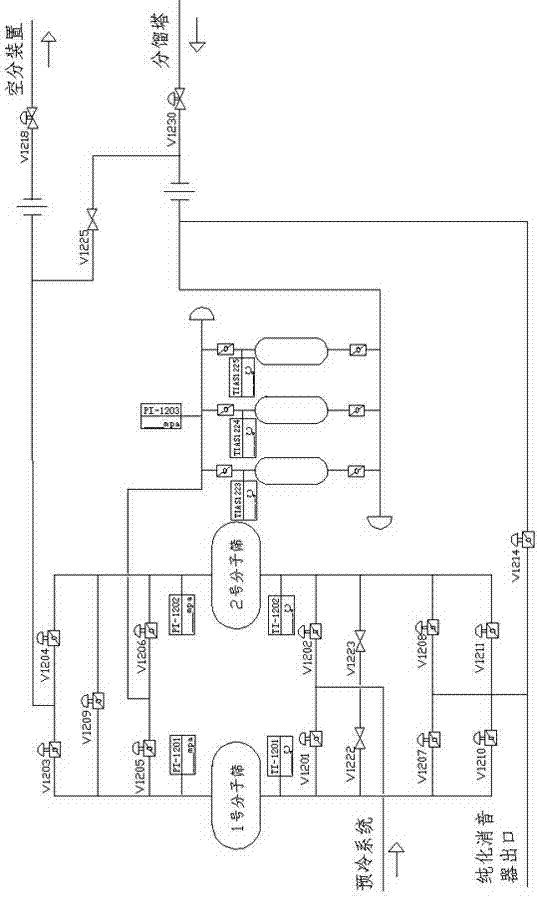

[0029] The invention provides a method for pressure maintaining and leak testing of an oxygen purification switching valve, comprising the following steps:

[0030] 1) After the air separation plant is shut down, the air compressor does not stop, all valves are fully closed, and the pressure of the air compressor is kept at 0.45mpa. Observe the PI-1201 and PI-1202 pressure measuring instruments to judge whether the valve is leaking, and check the next valve Switch adjustment and change of pressure measuring instrument to detect whether the valve is leaking;

[0031] 2) Keep the pressure of the fractionation tower at 0.1-0.2mpa, prevent the normal temperature valve from being closed tightly, and the low-temperature gas backflow, causing damage to the fractionation tower or causing shutdown accidents, and observe whether the pressure of No. 1 and No. 2 molecular sieves rises for 20 minutes. If 1, If the pressure of the No. 2 molecular sieve does not rise, it means that there is ...

Embodiment 2

[0041] The present invention also provides a pressure-holding and leak-testing method for an oxygen purification switching valve, comprising the following steps:

[0042] 1) After the air separation unit is shut down, the air compressor does not stop, all valves are fully closed, and the pressure of the air compressor is kept at 0.45mpa, and the PI-1201 and PI-1202 pressure measuring instruments are observed to determine whether the valve is leaking;

[0043] 2) Keep the pressure of the fractionation tower at 0.1-0.2mpa, and observe whether the pressure of No. 1 and No. 2 molecular sieves rises for 20 minutes. If the pressure of No. 1 and No. 2 molecular sieves does not rise, then the v1201 valve and v1202 valve will not leak. If the pressure rises, the v1201 valve leaks, and if the pressure of No. 2 molecular sieve rises, the v1202 valve leaks;

[0044] 3) Open the v1201 valve of No. 1 molecular sieve, and observe whether the pressure of No. 2 molecular sieve rises. If it ris...

Embodiment 3

[0053] The present invention also provides a pressure-holding and leak-testing method for an oxygen purification switching valve, comprising the following steps:

[0054] 1) After the air separation unit is shut down, the air compressor does not stop, all valves are fully closed, and the pressure of the air compressor is kept at 0.45mpa, and the PI-1201 and PI-1202 pressure measuring instruments are observed to determine whether the valve is leaking;

[0055] 2) Keep the pressure of the fractionation tower at 0.1-0.2mpa, and observe whether the pressure of No. 1 and No. 2 molecular sieves rises for 20 minutes. If the pressure of No. 1 and No. 2 molecular sieves does not rise, then the v1201 valve and v1202 valve will not leak. If the pressure rises, the v1201 valve leaks, and if the pressure of No. 2 molecular sieve rises, the v1202 valve leaks;

[0056] 3) Open the v1201 valve of No. 1 molecular sieve, and observe whether the pressure of No. 2 molecular sieve rises. If it ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com