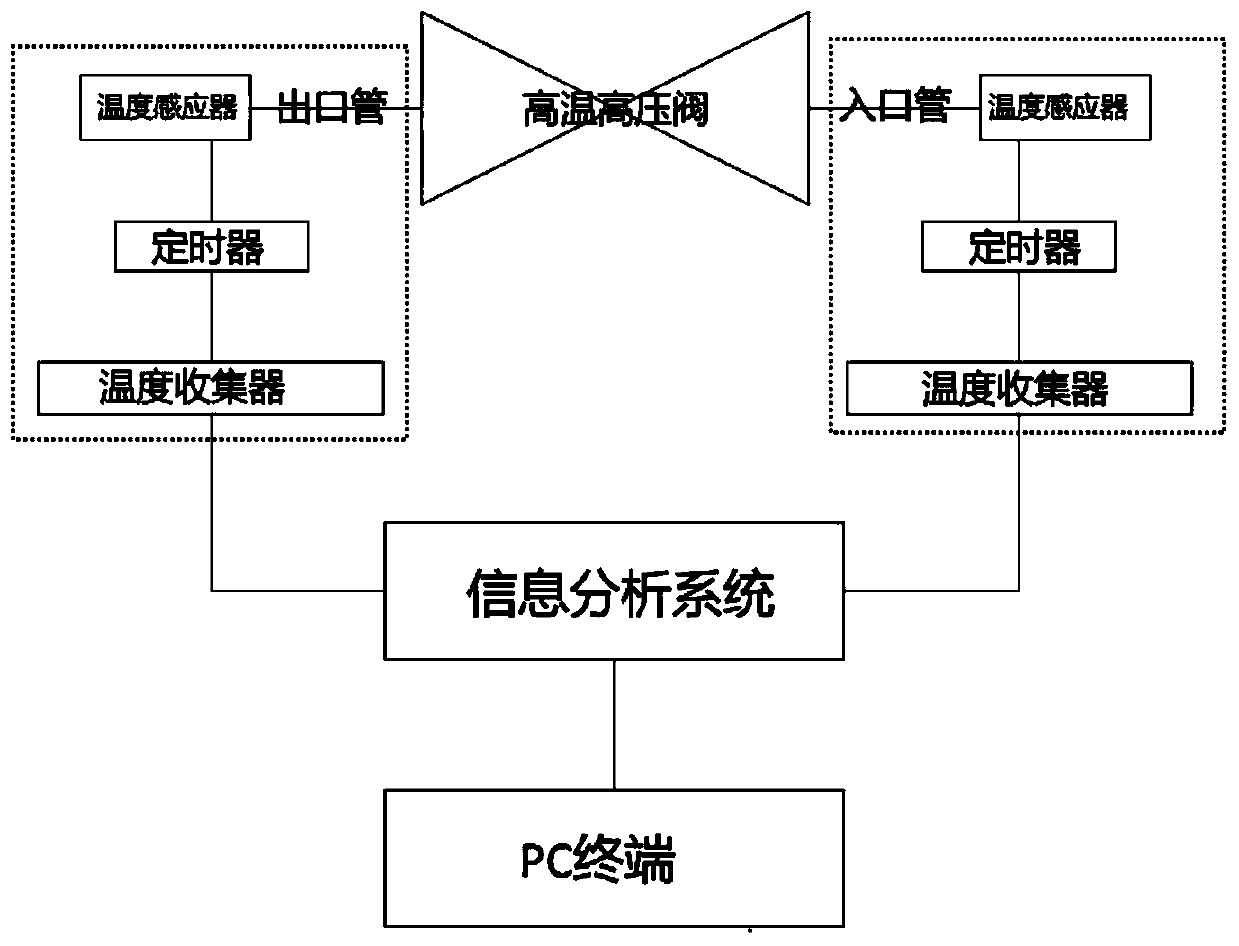

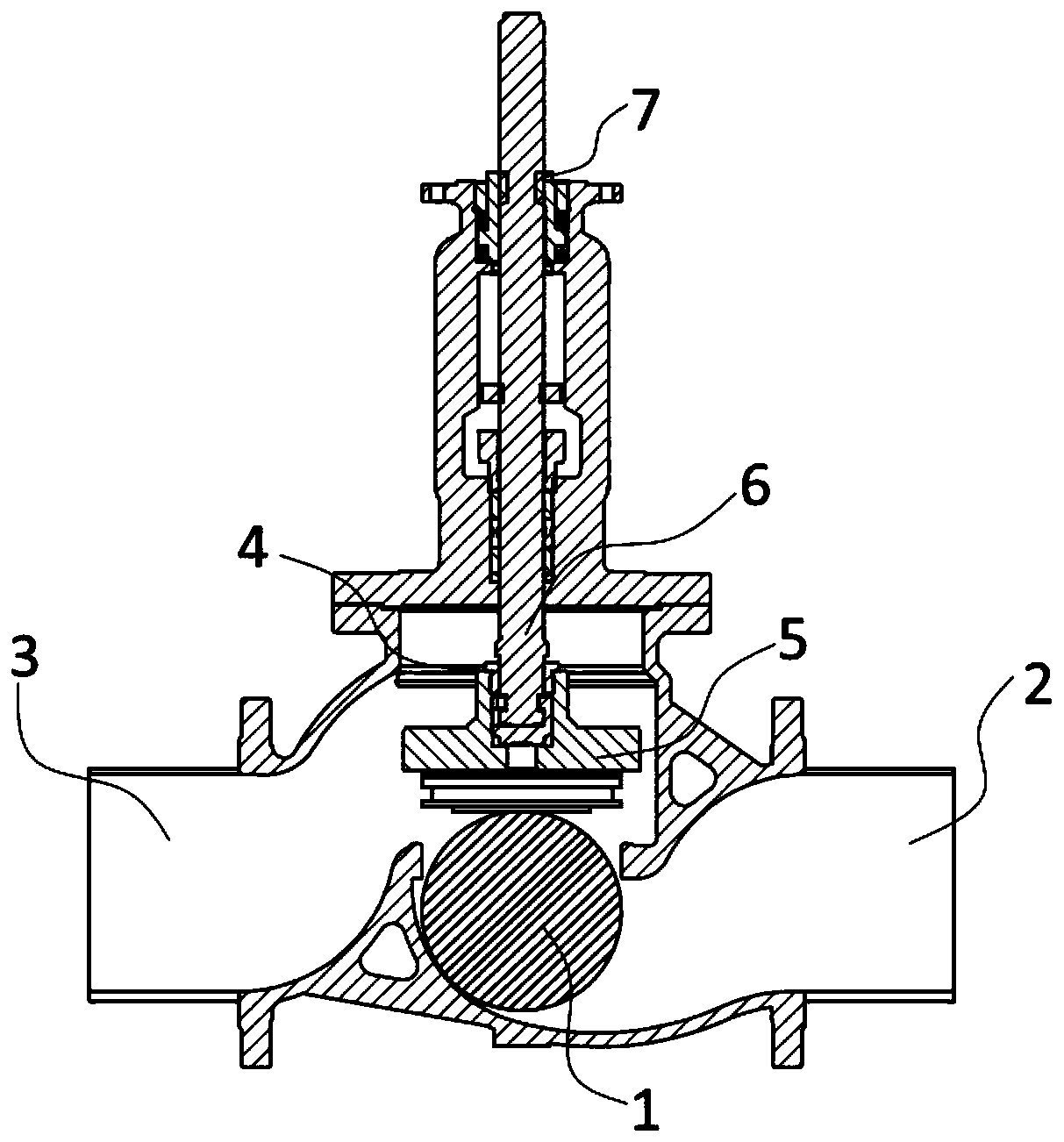

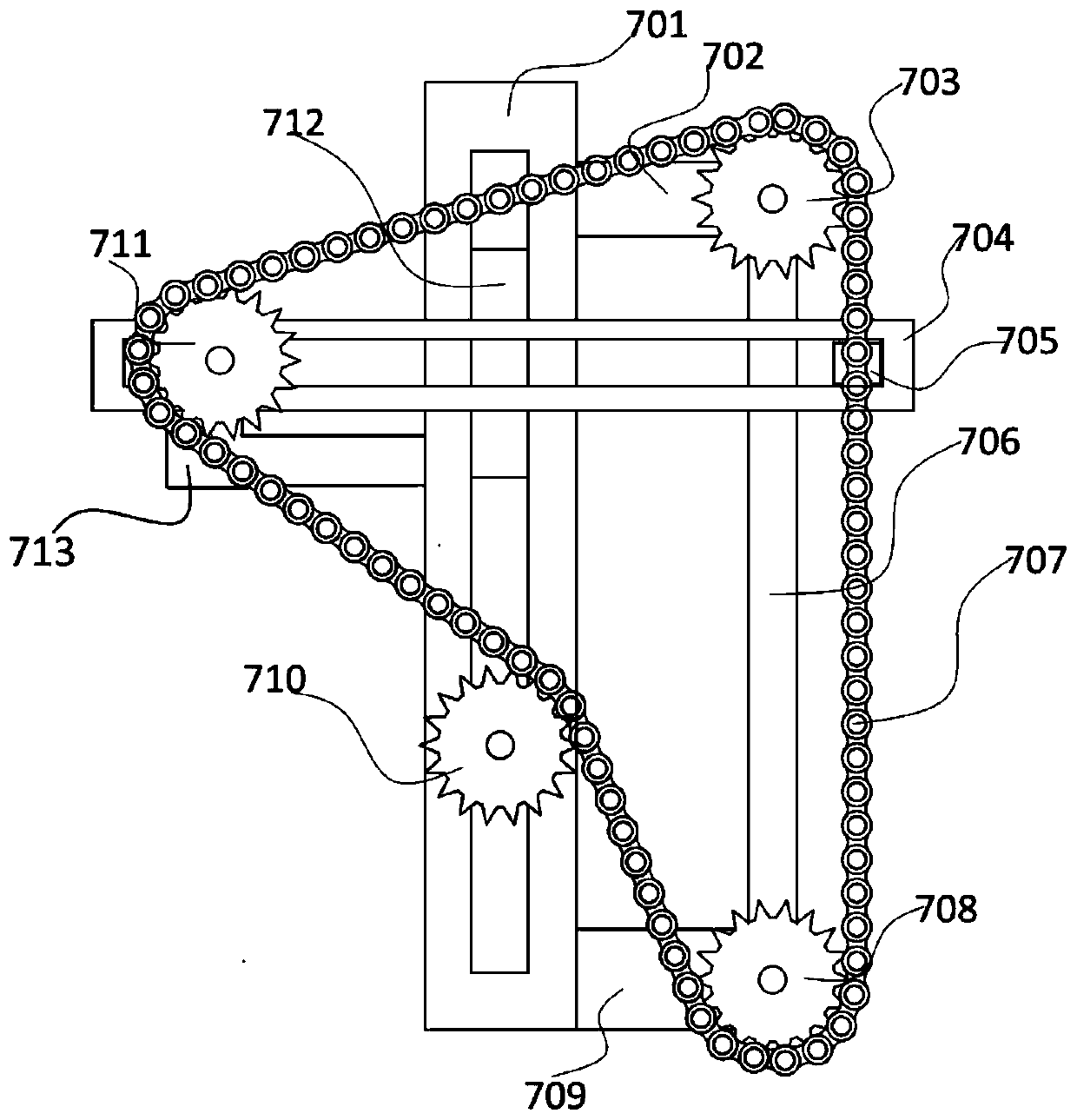

An automatic analysis system and analysis method for internal leakage of high temperature and high pressure valves in power plants

An automatic analysis system, high temperature and high pressure technology, applied in geometric CAD, design optimization/simulation, computer aided design, etc., can solve problems such as economic losses of enterprises, differences in valve sealing performance, internal leakage, etc., and achieve time saving and temperature measurement range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0028] After the research and analysis of the applicant, the reason for this problem (the internal leakage of the valve brings economic losses to the enterprise, and there is also the safety of the system operation) is that the internal leakage of the valve cannot be judged correctly from the appearance, and most of them now use ultrasonic testing. The sound environment required for ultrasonic testing is relatively high. In thermal power plants where there are many and complicated noise sources, ultrasonic testing equipment cannot normally collect effective info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com