Denitrification SCR ammonia injection control system and workflow thereof

A control system and workflow technology, applied in the field of SCR denitrification, can solve the problems of high labor intensity, high labor cost, large error and delay, etc., and achieve the effect of reducing labor intensity, high degree of intelligence, and simple workflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

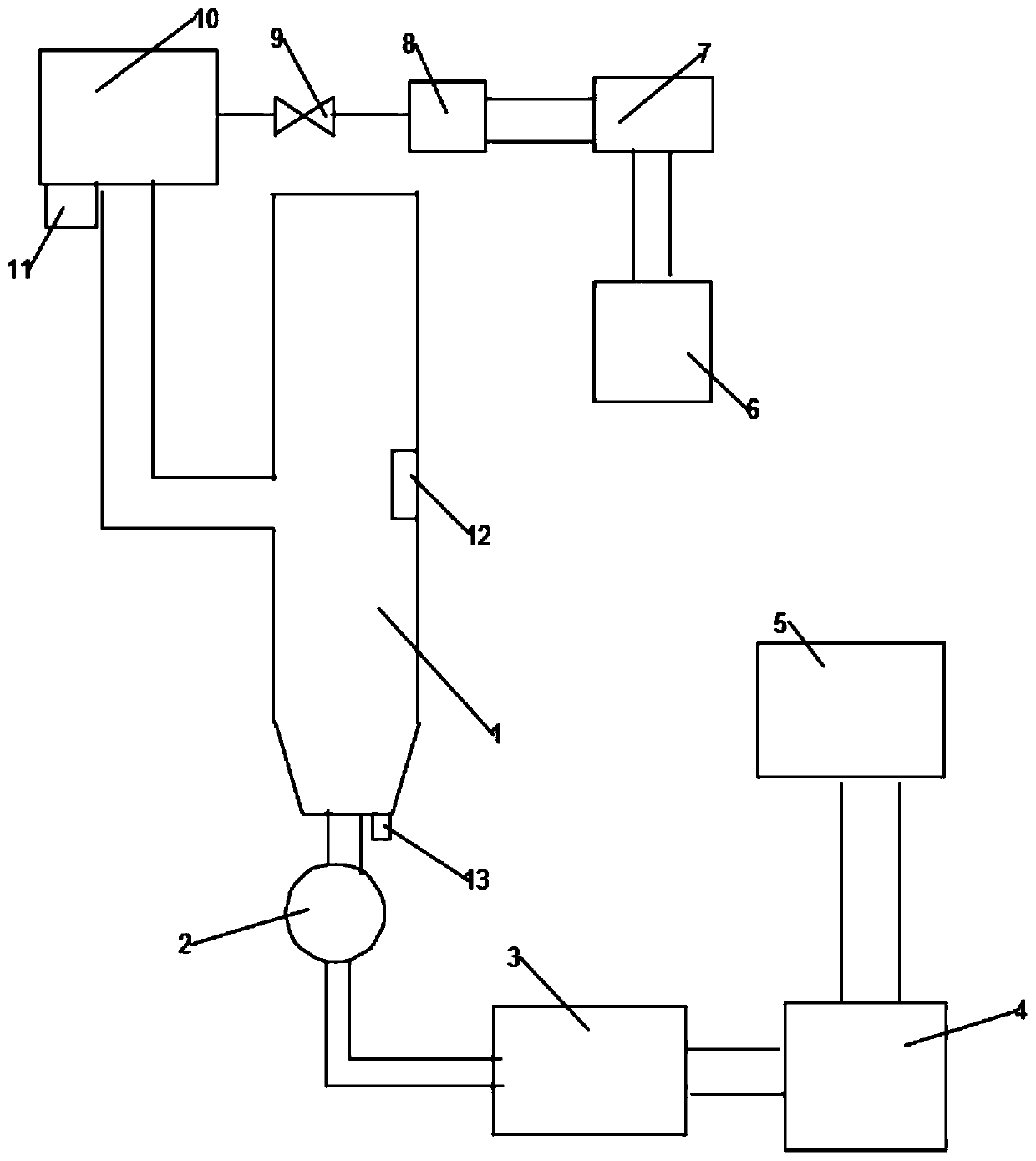

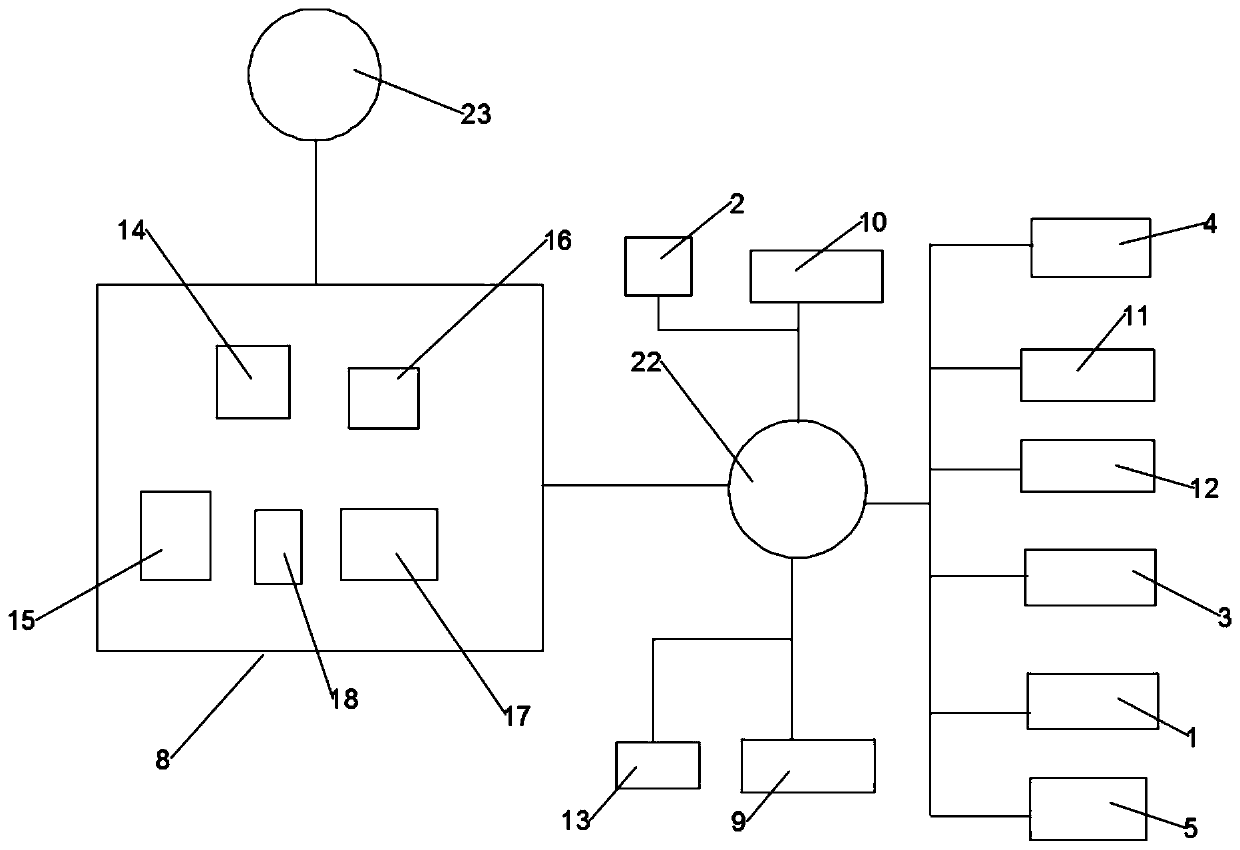

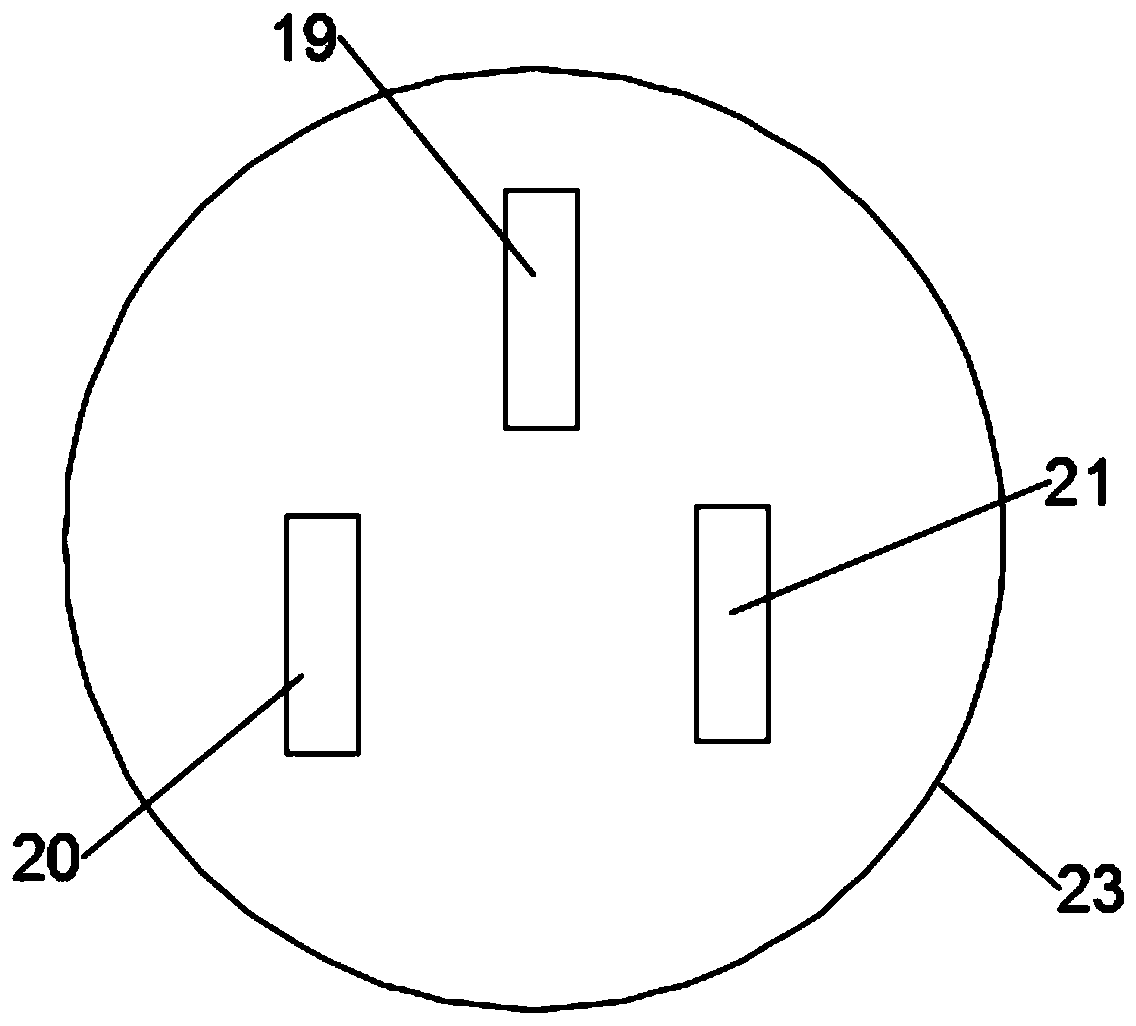

[0028] Example 1, such as Figure 1-3 As shown, a denitrification SCR ammonia injection control system according to an embodiment of the present invention includes: a control terminal 8, a mixing flowmeter 11, a thermometer 12, a flue gas flowmeter 13 and a solenoid valve 9, and the mixing flowmeter 11 is installed on the mixer 10 At the outlet of the mixer 10, the flow rate of the mixture of ammonia and air can be measured. The thermometer 12 is installed inside the SCR reaction tower 1 to control the reaction temperature. The solenoid valve 9 is located between the mixer 10 and the evaporator 7 to control whether Connected, the flue gas flowmeter 13 is located at the outlet of the SCR reaction tower 1, and measures the flue gas flow at the outlet in real time. The control terminal 8 communicates with the mixing flowmeter 11, the thermometer 12, the flue gas flowmeter 13 and the solenoid valve through the communication module 22 respectively. 9 connected. The control termina...

Embodiment 2

[0035]Embodiment 2, a denitrification SCR ammonia injection control system according to the embodiment of the present invention, including: control terminal 8, mixing flow meter 11, thermometer 12, flue gas flow meter 13 and solenoid valve 9, mixing flow meter 11 is installed in the mixer At the outlet of 10, the flow rate of the mixture of ammonia and air in the mixer 10 can be measured, the thermometer 12 is installed inside the SCR reaction tower 1, and the reaction temperature can be controlled, and the solenoid valve 9 is located between the mixer 10 and the evaporator 7, which can control Whether it is connected, the flue gas flowmeter 13 is located at the outlet of the SCR reaction tower 1, and measures the flue gas flow at the outlet in real time. The control terminal 8 communicates with the mixing flowmeter 11, the thermometer 12, the flue gas flowmeter 13 and the electromagnetic Valve 9 is connected. The control terminal 8 is also connected to the SCR reaction tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com