Welding repairing restoration method for beryllium bronze metal accessory

A metal part and repair method technology, applied in the field of welding and repairing metal parts, can solve the problems of low maintenance cost, high price, poor use effect, etc., and achieve the effects of reduced scrap loss, simple operation, and timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Select welding parameters, these parameters include welding parameters known to those skilled in the art such as welding current, welding wire and the distance between the welding torch of the welding torch and the metal part substrate. The welding parameters are mainly based on the welding technology to select the distance between the welding torch of the welding torch and the metal part substrate, and the welding wire and welding current are selected according to the substrate material.

[0015] Take repairing beryllium bronze punch as example below to further illustrate the present invention.

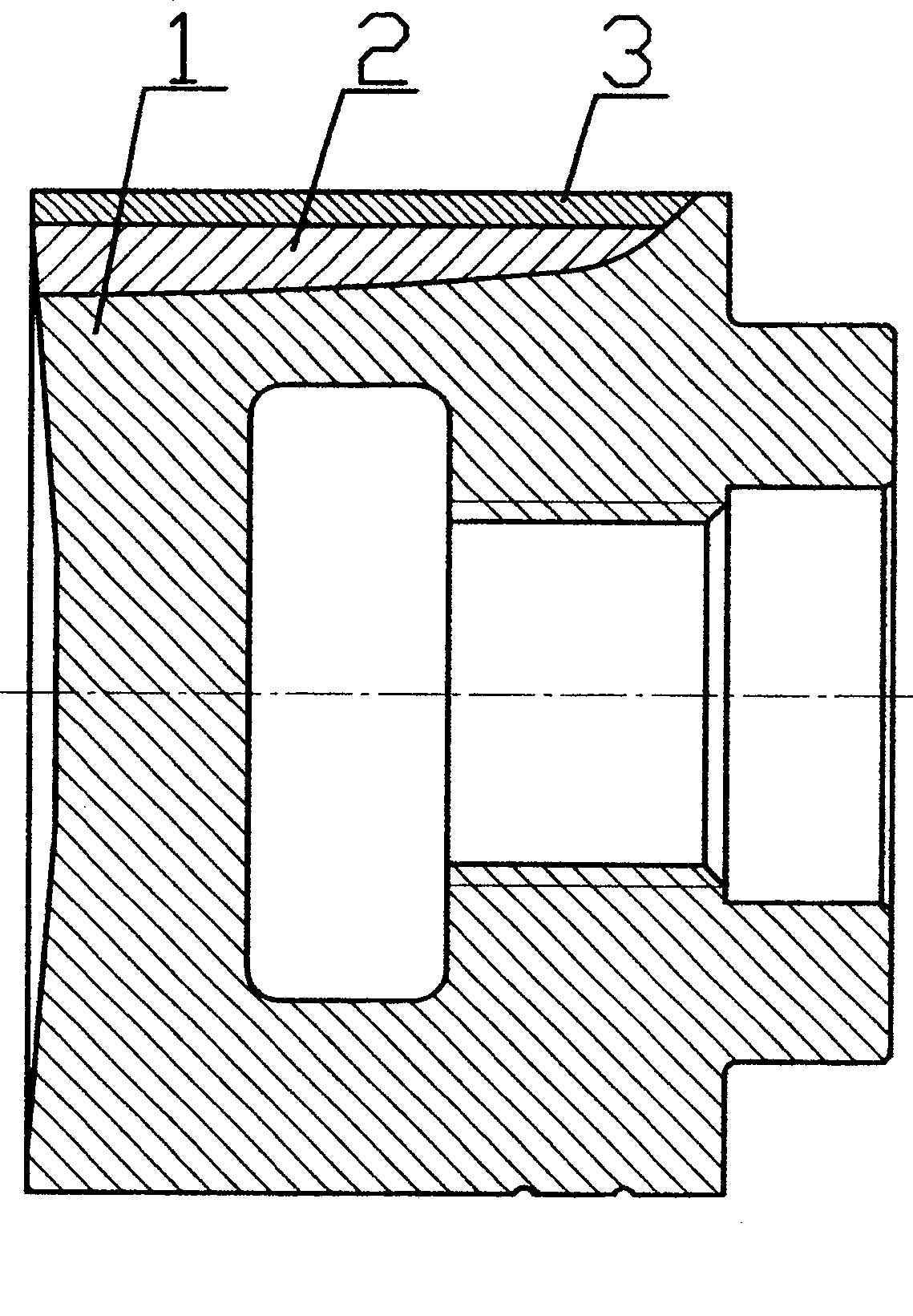

[0016] Referring to the accompanying drawings, use a conventional method to clean the surface of the beryllium bronze punch 1 to be repaired, heat it up to 300°C for 2 to 3 hours with the furnace, and then take it out of the furnace for welding.

[0017] When welding, the angle between the welding torch and the surface of the beryllium bronze punch is kept at about 80°, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com