Rail structure of high-speed rail transportation

A high-speed track and track technology, applied in tracks, roads, buildings, etc., can solve the problems of reducing the service life of track structures, poor adjustability of support methods, and affecting structural safety, so as to improve lateral stiffness, speed up production progress, and save The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

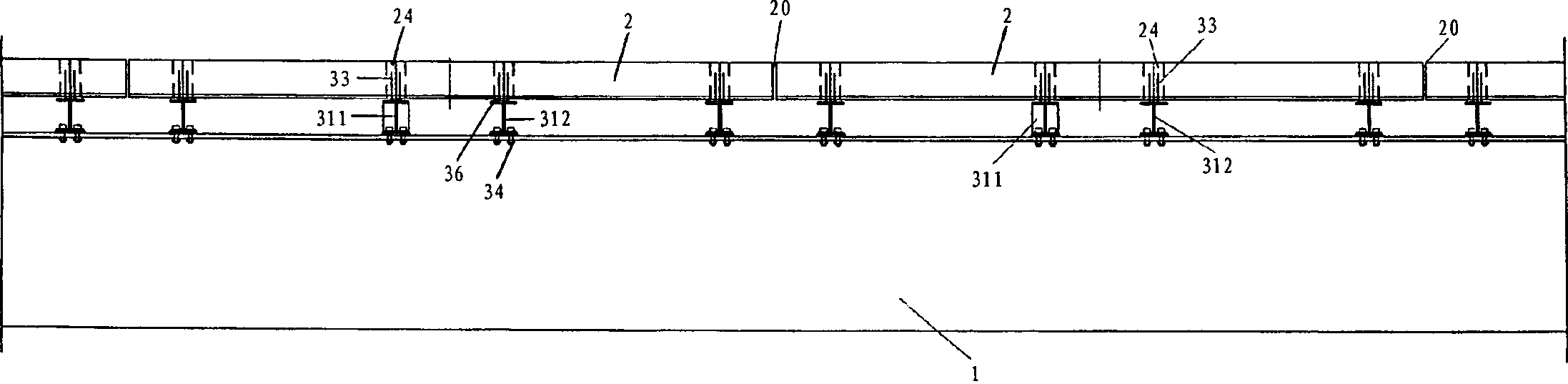

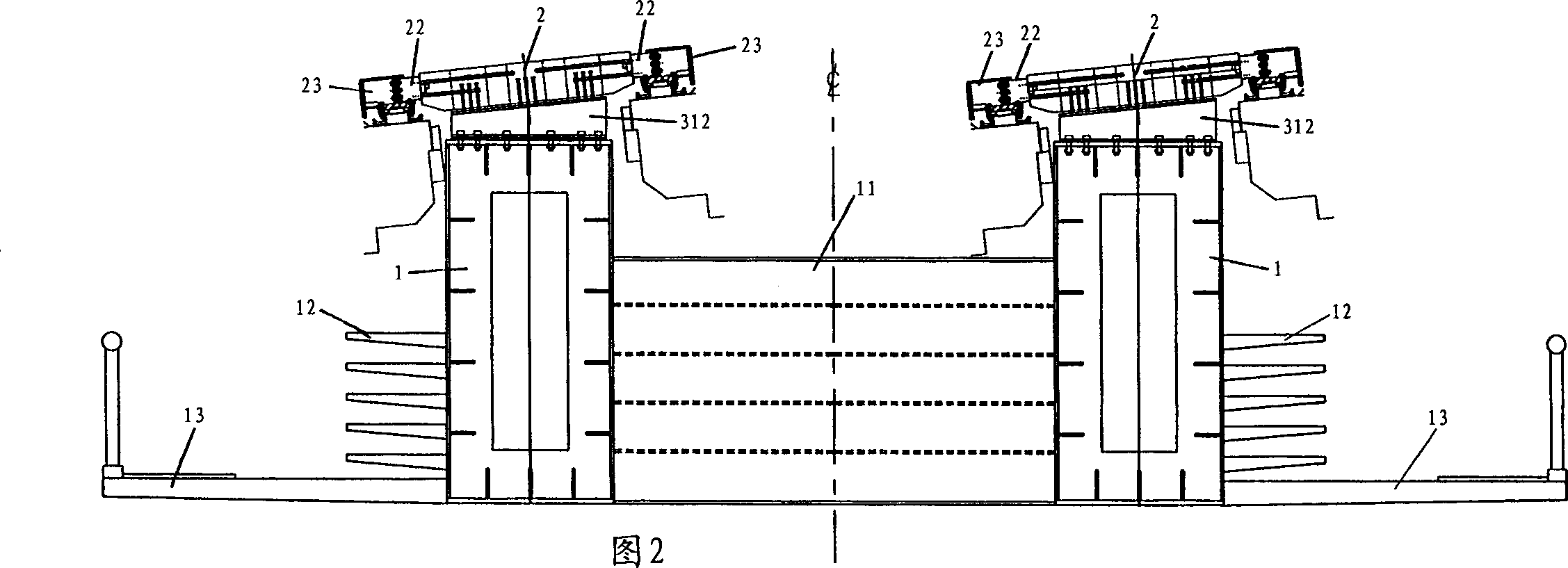

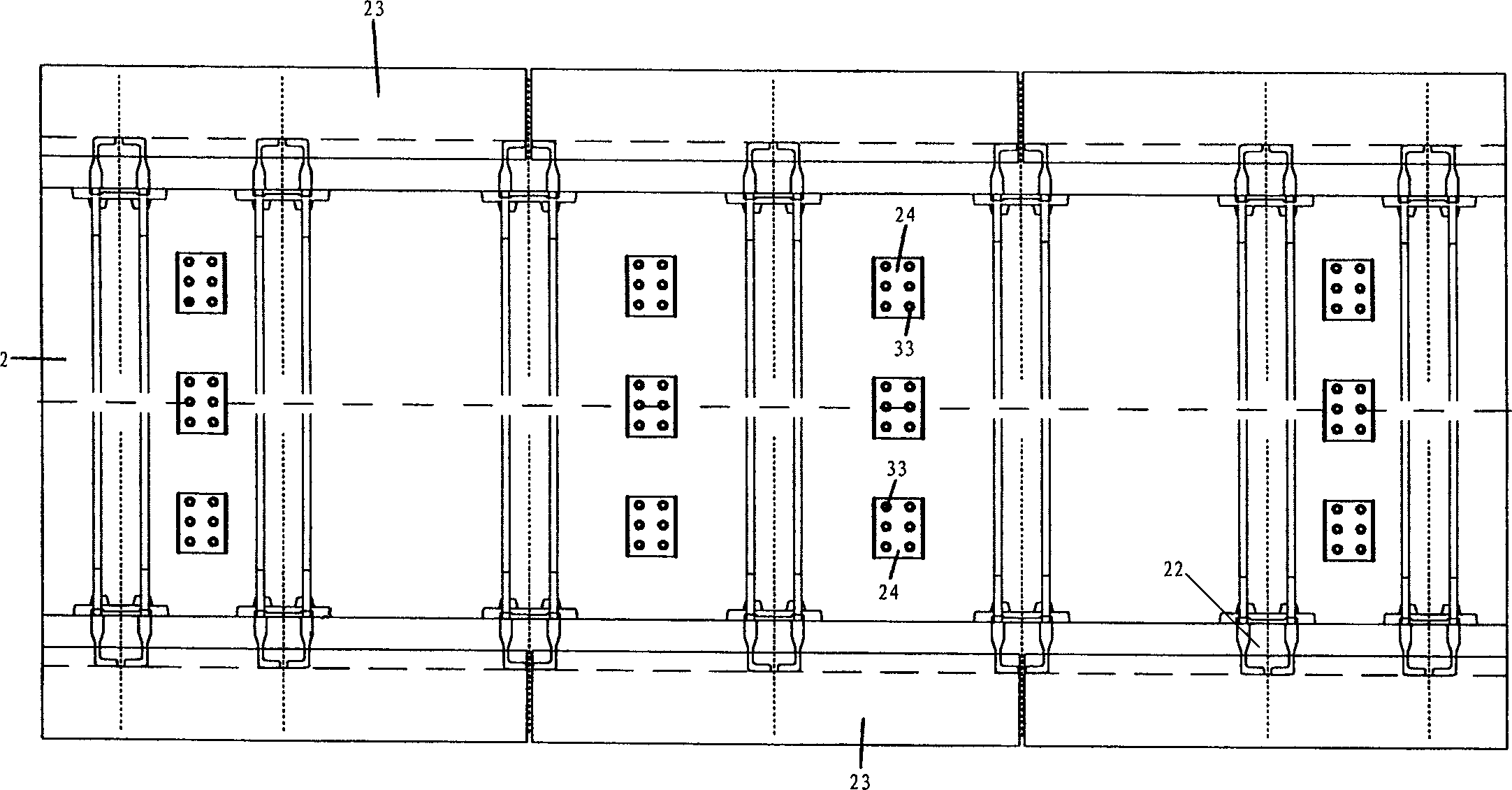

[0046] figure 1 The overall layout of the double-deck track structure of the present invention is shown in , from the elevation, the reinforced concrete slab girder 21 (hereinafter referred to as member 21) of the upper layer rail surface structure and the lower load-bearing main beam 1 are connected as a whole through a connecting mechanism 3, and the member 21 It is a small component whose length can be one to two times the length of a single functional part (3.096m). Multiple components 21 are vertically erected on the lower support structure along the line, and a certain telescopic gap 20 is left between the two components 21 to meet Longitudinal and transverse live load deformation and component temperature expansion and contraction deformation. The purpose of adopting a smaller size for the longitudinal direction of member 21 is mainly to reduce the difficulty of making and processing the upper rail surface structure. The weight of a single member 21 is relatively light,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com