Double-end tapping device for sphygmomanometer watchcase

A technology of tapping device and sphygmomanometer, which is applied to thread trimming devices, thread trimming machines, metal processing equipment, etc., can solve the problems of workpiece affecting machining accuracy, low machining efficiency, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

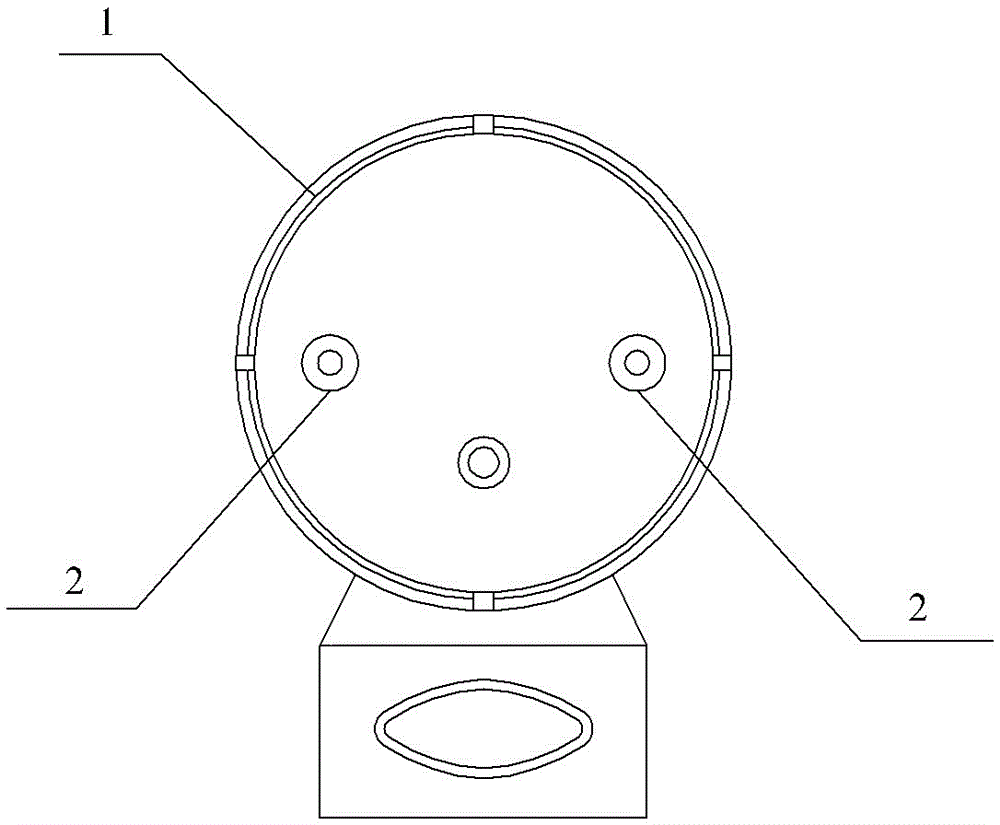

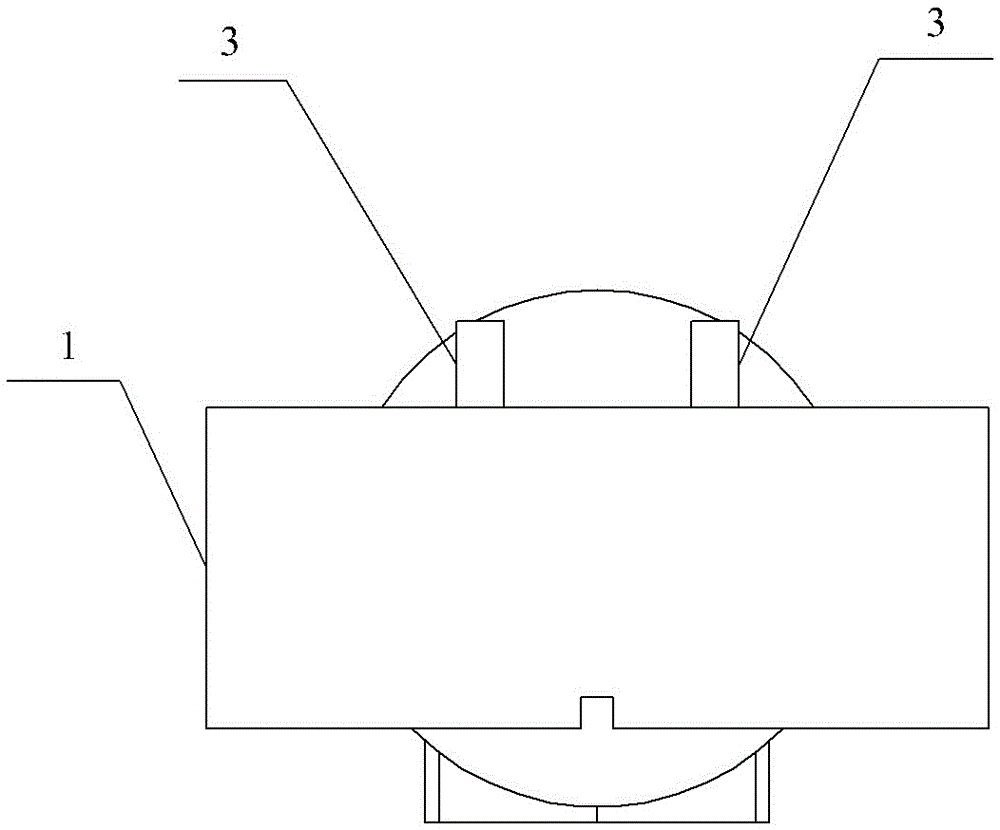

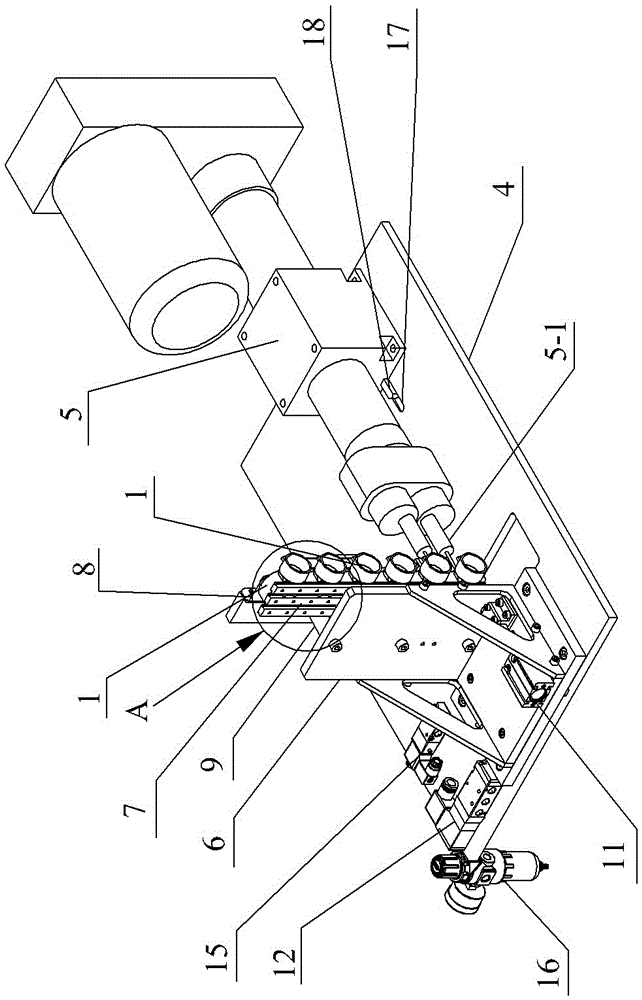

[0016] See Figure 1-6 , a double-head tapping device for a sphygmomanometer watch case of the present invention includes a base plate 4, a double-head automatic tapping machine 5 and a PLC control system, the base plate 4 is fixedly connected with a bracket 6, and the front end of the bracket 6 is provided with a vertical setting The workpiece limit groove is enclosed by the slide rail 7 and the front baffle 8. The slide rail 7 is fixed on the bracket 6, and the front baffle 8 is arranged in parallel with the slide rail 7 and is fixed by the connecting rod 9 On the bracket 6, a workpiece limiting groove is formed between the front baffle 8 and the slide rail 7. The upper and lower ends of the workpiece limiting groove are the workpiece inlet and the workpiece outlet respectively. The sphygmomanometer watch case 1 is placed on the workpiece from top to bottom. In the limit groove, the two bosses 3 on the rear side wall of the sphygmomanometer case 1 are inserted into the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com