Printing deviation measuring method, printing method and printing device for solar cell plate

A solar cell sheet and printing method technology, applied in printing devices, measuring devices, optical devices, etc., can solve the problems that rotary table printing cannot meet the printing accuracy of solar cell electrodes, achieve rapid position adjustment, improve accuracy, reduce The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

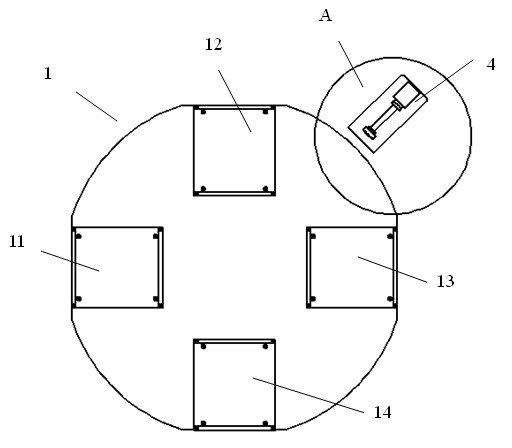

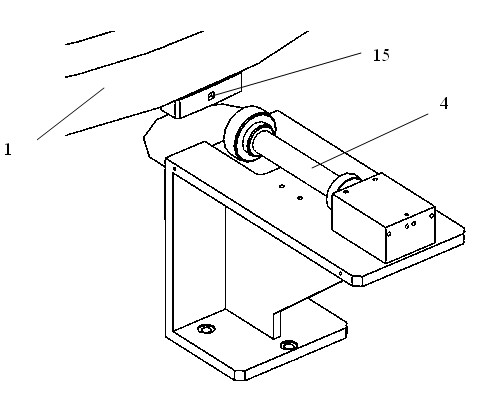

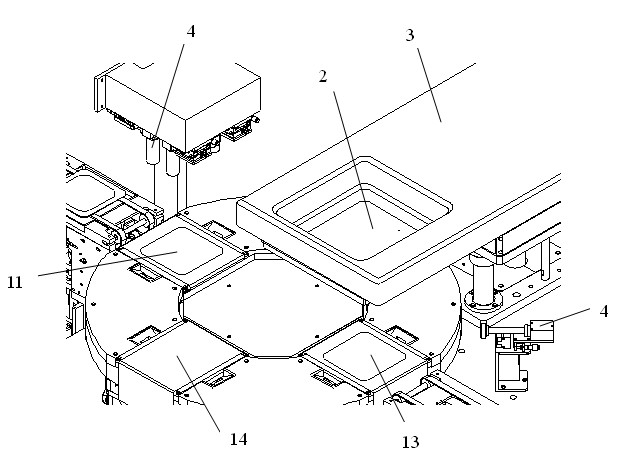

[0045] Such as Figure 1-3 As shown, the rotary table 1 of the device for solar cell sheet electrode printing in this embodiment is as figure 1 As shown (the power mechanism, control system, etc. are not shown in the figure), there are 4 stations 2 evenly distributed on the rotary table 1, followed by waiting station 11, printing station 12, film output station 13 and Scrap film station 14. At the same time, circular identification marks 15 are respectively arranged on the outer edge sides of the rotary table corresponding to the four stations. Certainly, the identification mark 15 may also be in any shape convenient for the CCD camera 4 to identify, such as square. CCD cameras 4 are arranged respectively at the same height as the circular identification marks 15 near the outer edge of the rotary table 1, for photographing the identification marks 15 and obtaining the actual position data of each station, and transmitting the data to the control system, Calculate the positi...

Embodiment 2

[0050] In this embodiment, the printing method for the solar cells on the rotary table adopts the printing device as described in Embodiment 1. Such as Figure 4 As shown, it is a flow chart from the primary printing of the silver grid lines to the secondary overprinting of the silver grid lines of the solar cells. First, after the solar cells are transported to the waiting station 11, the CCD camera 4 measures the actual position P1' of the solar cells at the waiting station 11, and at the same time, the actual position M' of the waiting station 11 is measured by the CCD camera 4 And transmit the measured data to the control system; then, the control system calculates the position deviation ΔP1 of the solar cells according to the preset position P1 of the waiting station 11 and the actual position P1'; then, the solar cells rotate with The rotation of the worktable 1 is transmitted to the printing station 12, and the actual position N' of the printing station is measured by ...

Embodiment 3

[0055] The deviation measurement method for solar cell sheet printing in this embodiment includes: firstly, the solar cell sheet is adsorbed and positioned by vacuum adsorption equipment through a plurality of micropores opened in the waiting position, and then the solar cell sheet is positioned near the waiting station 11. The actual position P1' of the solar cells and the actual position P1'' of the waiting station are captured by the CCD camera respectively, and the position information is transmitted to the control system; Calculate the positional deviation ΔP1 of the solar cells from the actual position P1′; then, after the rotary table 1 rotates 90 degrees, the CCD camera 4 arranged near the outer periphery of the rotary table 1 measures the movement of the waiting station 11 to The actual position P2' behind the printing station 12, and the position information is transmitted to the control system; the control system calculates the printing station according to the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com