Necking detection and control method of melting electrode and electric arc welding

A melting electrode, arc welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of small suppression effect and unstable welding state, and achieve the improvement of suppression effect, stable welding state, and reduced sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0079] In the necking detection control method according to the first embodiment of the present invention, the necking detection time Tn is detected for each short circuit, and when the necking detection time Tn is equal to or less than the lower limit time Lt, the count value Cn is decremented by 1, and when When the upper limit time Ht is longer than the upper limit time Ht, 1 is added to the count value Cn, and when the count value reaches the negative reference value Lc, the necking detection reference value Vtn is decreased by the decrease value Δd, and the count value Cn is reset to 0. When the count value Cn When the positive reference value Hc is reached, the constriction detection reference value Vtn is increased by the increment value Δu, and the count value Cn is reset to 0, and the above-mentioned correction of the constriction detection reference value Vtn is continued during welding. Hereinafter, this Embodiment 1 will be described.

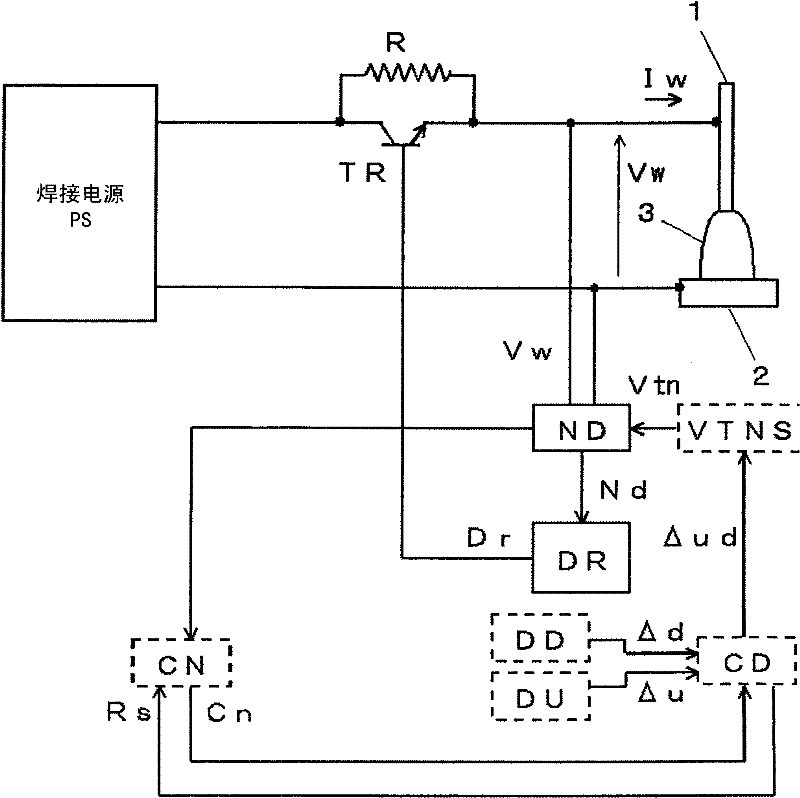

[0080] figure 1 It is a bl...

Embodiment approach 2

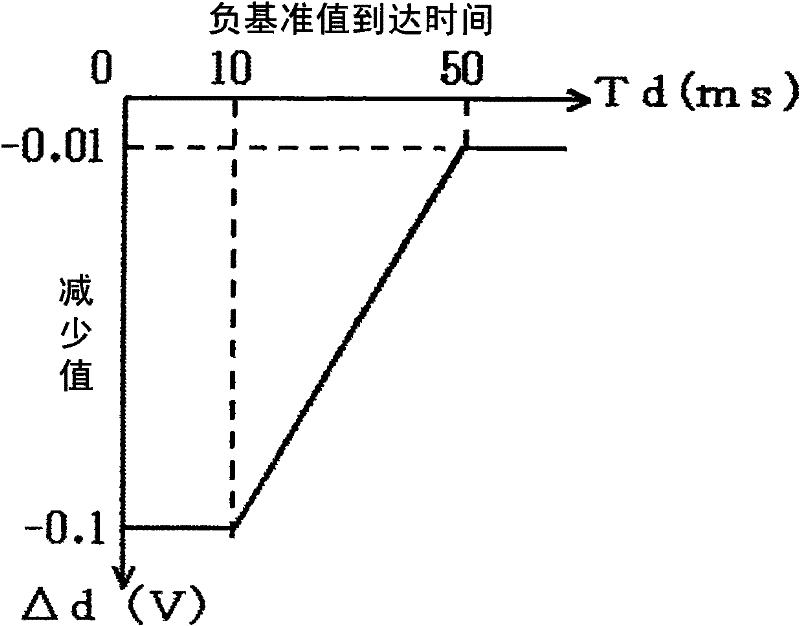

[0093] In the necking detection control method according to the second embodiment of the present invention, the decrease value Δd is made to correspond to the negative reference value arrival time Td from the time when the count value Cn is reset to 0 until the negative reference value Lc is reached. The above-mentioned increment value Δu is changed according to the positive reference value arrival time Tu from the time when the above-mentioned count value Cn is reset to 0 until the above-mentioned positive reference value Hc is reached. Hereinafter, the second embodiment will be described.

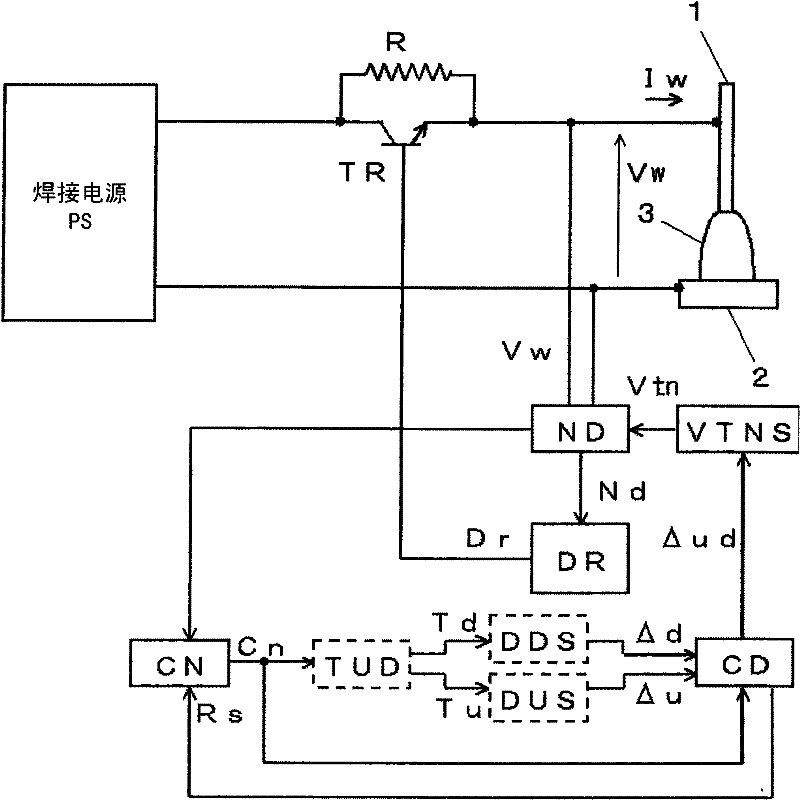

[0094] figure 2 It is a block diagram of the welding apparatus for implementing the necking detection control method of the fusion electrode arc welding of Embodiment 2. FIG. This figure is the same as the above Figure 5 as well as figure 1 Correspondingly, the same symbols are assigned to the same modules, and their descriptions are omitted. The figure is in figure 1 The referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com