Krah tube electric hot melting connecting device and method

A connection device and carat tube technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of inability to determine whether the fusion of pipes is sufficient, the quality of pipe welding cannot be guaranteed, and affect construction efficiency, etc., to achieve good adaptability, Effect of reducing impact and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

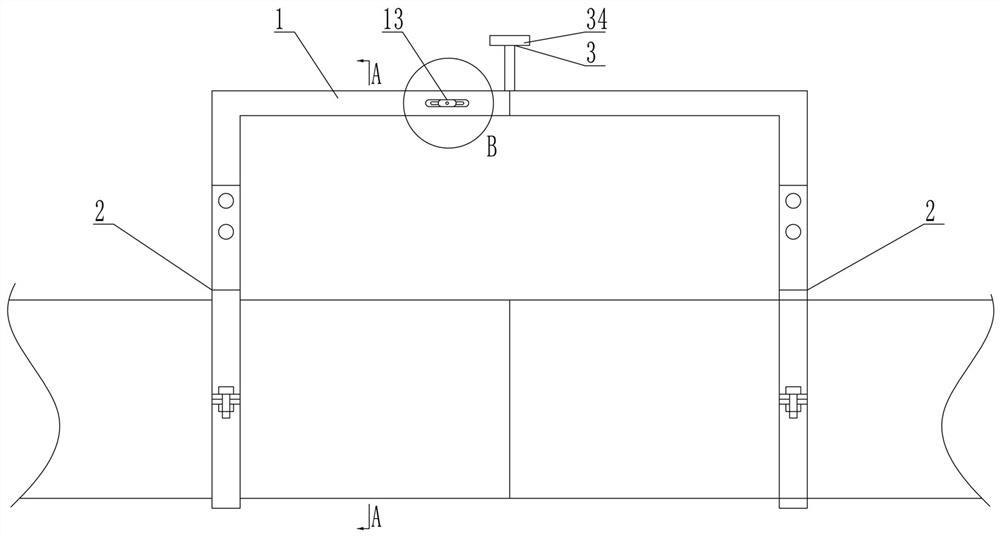

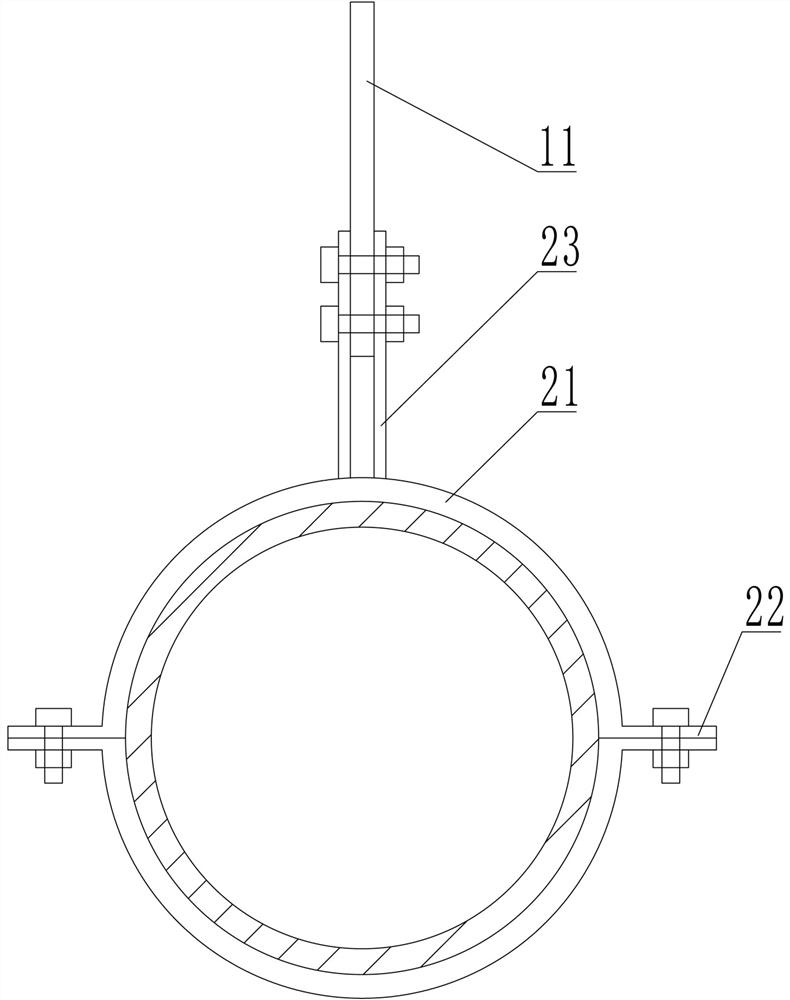

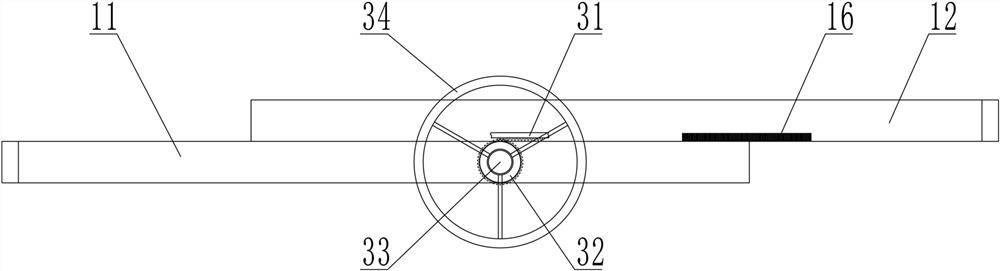

[0034] Such as Figure 1~Figure 5 Among them, an electrothermal fusion connection device for carat tubes, which includes an adjusting arm 1, a clamping part 2 and a driving mechanism 3; the connecting plate 23 of the clamping part 2 is respectively connected to the left arm 11 and the right arm 12 of the adjusting arm 1 , the left arm 11 and the right arm 12 of the adjusting arm 1 slide and cooperate with each other, the two semicircular arc plates 21 of the clamping part 2 form a circular clamping ring, and the circular clamping ring is located at the lower part of the adjusting arm 1, and the driving mechanism 3 The rack 31 and the gear 32 are respectively connected with the left arm 11 and the right arm 12 of the adjusting arm 1, and the driving mechanism 3 drives the two clamping parts 2 to approach or move away from each other. The structure is simple. When in use, the two clamping parts 2 respectively clamp the two ends of the two carat tubes, and the driving mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com