Substation secondary wire straightening and bending device and wire fixing tightness commissioning method

A technology of secondary wiring and bending device, which is applied in the direction of cable installation device, switchgear, cable installation, etc. It can solve the problems of limited construction time, time-consuming protection screen, power supply failure of substation, etc., and achieves high efficiency and time-saving angle Labor-saving, easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

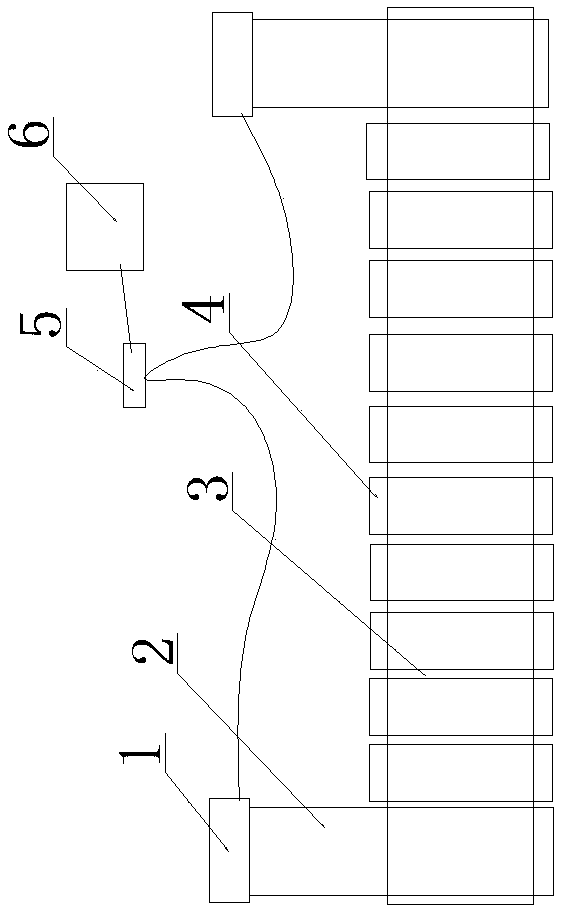

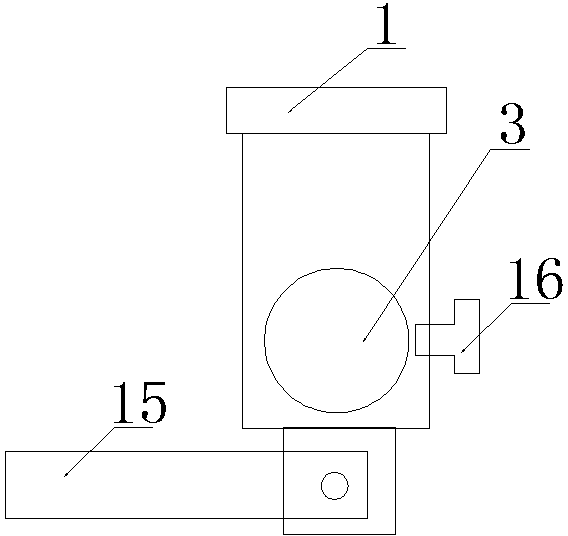

[0031] Embodiment 1: as figure 1 , 2 As shown in . and 3, a straightening and bending device for secondary wiring of a substation includes a cylinder 3, two ends of the cylinder 3 are provided with movably connected legs 2, and one end of the legs is provided with a magnet.

[0032] Described magnet adopts electromagnet 1.

[0033] The electromagnet 1 is connected with a sliding rheostat 5 in series.

[0034] The straightening, bending and fixing effect test mechanism 4 is set on the cylinder body.

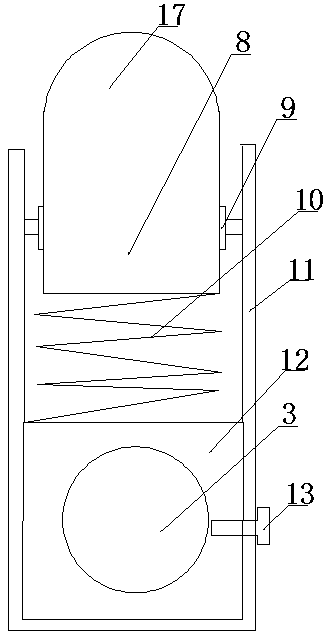

[0035] The wire straightening and bending and fixing effect testing mechanism 4 includes several sliding sleeves 12 sleeved on the cylinder body 3, an electromagnetic sleeve 11 arranged on the sliding sleeve 12 and perpendicular to the legs 3, located in the electromagnetic sleeve 11 and The bottom of the electromagnetic sleeve 11 is connected to the magnetic push rod 8 by the spring 10 , and the bending part 17 is arranged on the upper end of the magnetic push rod 8 and has a ...

Embodiment 2

[0048] Embodiment 2: as figure 1 , 2 As shown in . and 3, a straightening and bending device for secondary wiring of a substation includes a cylinder 3, two ends of the cylinder 3 are provided with movably connected legs 2, and one end of the legs is provided with a magnet.

[0049] Described magnet adopts electromagnet 1.

[0050] The electromagnet 1 is connected with a sliding rheostat 5 in series.

[0051] The straightening, bending and fixing effect test mechanism 4 is set on the cylinder body.

[0052] The wire straightening and bending and fixing effect testing mechanism 4 includes several sliding sleeves 12 sleeved on the cylinder body 3, an electromagnetic sleeve 11 arranged on the sliding sleeve 12 and perpendicular to the legs 3, located in the electromagnetic sleeve 11 and The bottom of the electromagnetic sleeve 11 is connected to the magnetic push rod 8 by the spring 10 , and the bending part 17 is arranged on the upper end of the magnetic push rod 8 and has a ...

Embodiment 3

[0068] Embodiment 3: as figure 1 , 2 , 4, and 5, a substation secondary wiring straightening and bending device includes a cylinder 3, two ends of the cylinder 3 are provided with movably connected legs 2, and one end of the legs is provided with a magnet.

[0069] Described magnet adopts electromagnet 1.

[0070] The electromagnet 1 is connected with a sliding rheostat 5 in series.

[0071] The straightening, bending and fixing effect test mechanism 4 is set on the cylinder body.

[0072]The wire straightening and bending and fixing effect testing mechanism 4 includes several sliding sleeves 12 sleeved on the cylinder body 3, an electromagnetic sleeve 11 arranged on the sliding sleeve 12 and perpendicular to the legs 3, located in the electromagnetic sleeve 11 and The bottom of the electromagnetic sleeve 11 is connected to the magnetic push rod 8 by the spring 10 , and the bending part 17 is arranged on the upper end of the magnetic push rod 8 and has a semicircular cut su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com