A plasma-submerged arc hybrid welding system and its welding method

A plasma arc and plasma welding technology, which is applied to plasma welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of difficult to guarantee welding quality, reduce welding production efficiency, and reduce welding penetration, so as to improve joint structure and Mechanical properties, material saving, less welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

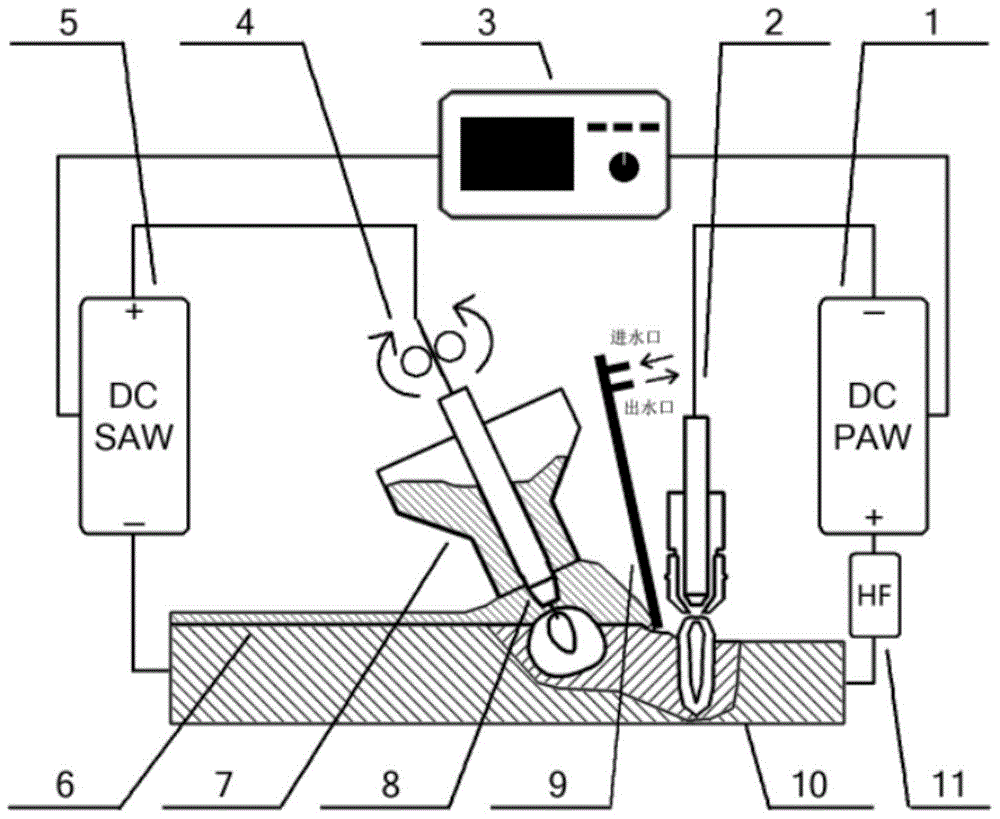

[0021] combine figure 1 ~2, the welding system of the present invention is mainly composed of a submerged arc welding power supply 5, a plasma arc power supply 1, a high-frequency arc starter 11, a wire feeding mechanism 4, a plasma welding torch 2, a submerged arc welding torch 8, a solder guide groove 7, and a water-cooled copper partition Board 9 and control device 3 etc. constitute. Before welding, the plasma welding torch 2 and the submerged arc welding torch 8 are combined to form a composite welding torch, the angle α between the axes of the two welding torches is 15-75°, and a water-cooled copper partition is placed between the two welding torches to block the surrounding area of the submerged arc welding torch The flux can prevent the flux from entering the plasma arc area, which will affect the stable burning and deep penetration ability of the plasma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com