Miniature open type device with adjustable air gap for underwater local dry method welding and welding method

A local dry method and air gap technology, used in welding equipment, welding accessories, arc welding equipment, etc., can solve problems affecting arc stability and weld formation, insufficient welding flexibility and applicability, affecting welding process stability, etc. problems, to achieve a wide range of engineering applications, improve arc stability, low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described below based on the embodiments, and those of ordinary skill in the art should understand that the drawings provided again are for illustrative purposes and are not necessarily drawn to scale.

[0023] Unless clearly required by the context, words such as "including", "comprising" and the like throughout the specification and claims should be construed in an inclusive rather than an exclusive sense: that is, "including but not limited to" meaning.

[0024] Note: In this application, the up and down direction is defined as: figure 1 In the axial direction of the welding torch, the direction close to the workpiece is down, and the direction away from the workpiece is up. In addition, the radially outer side of the welding gun in the figure is defined as the outer side, and the radially inner side of the welding gun is defined as the inner side.

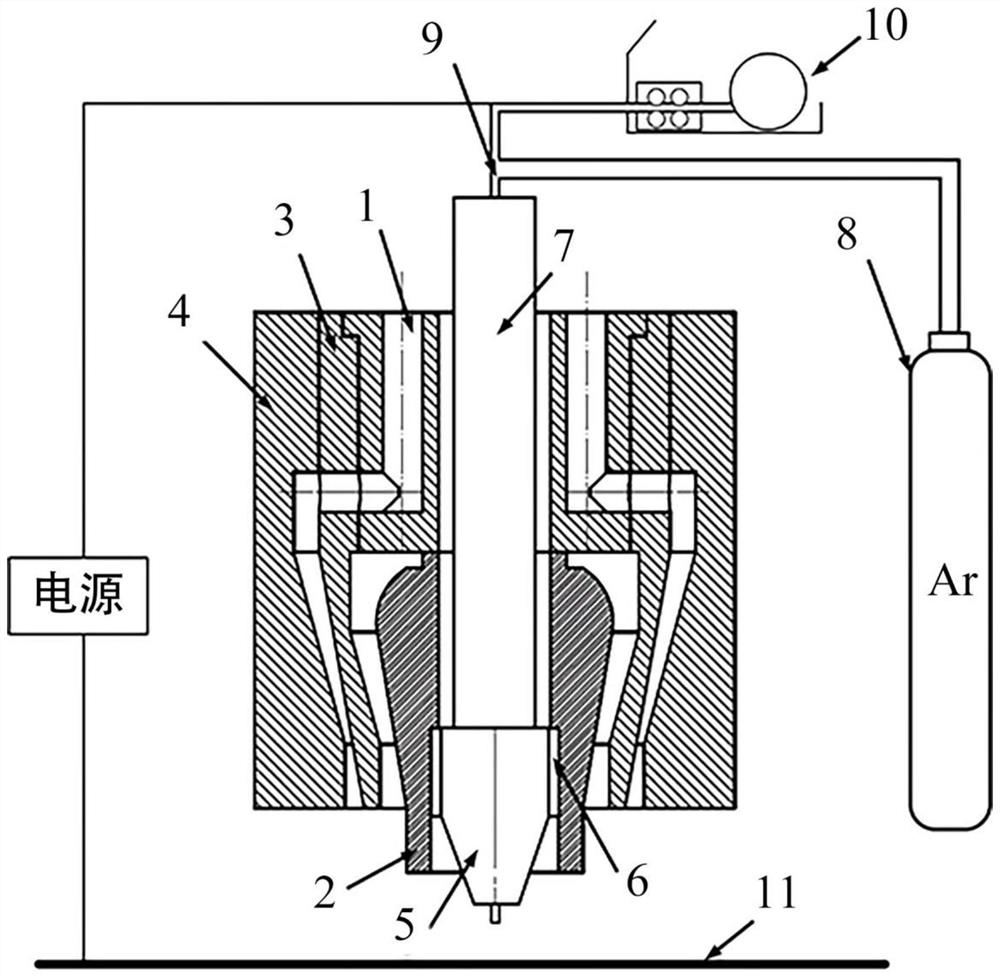

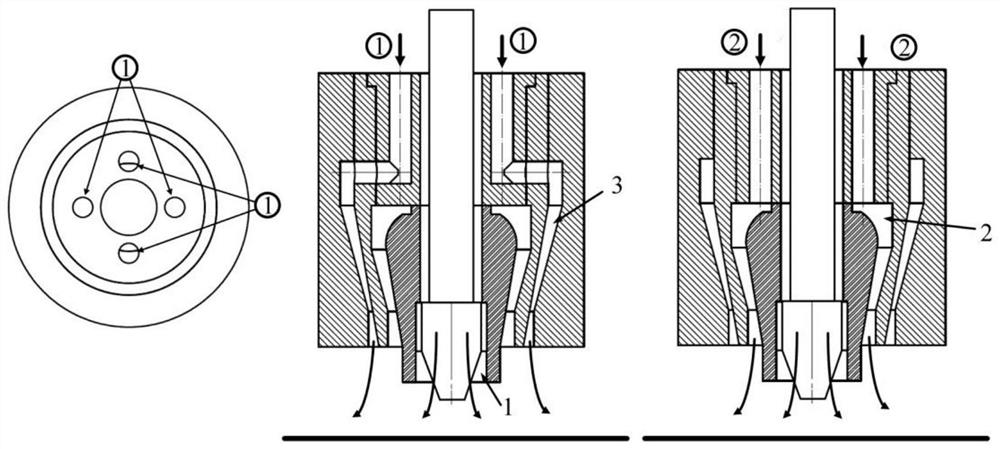

[0025] like figure 1 , 2 As shown, the present invention includes a welding torch nozzl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com