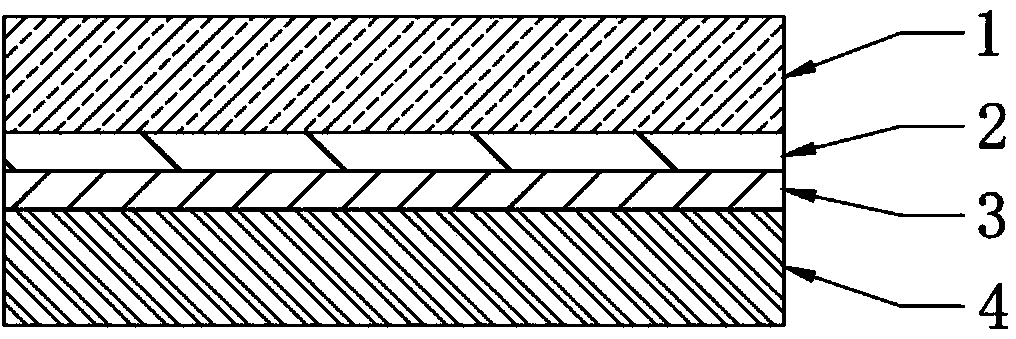

Preparing method for double-layer high-entropy alloy diffusion barrier layer

A high-entropy alloy and barrier layer technology, used in coatings, metal material coating processes, ion implantation plating, etc. Reduce energy consumption and save the effect of sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

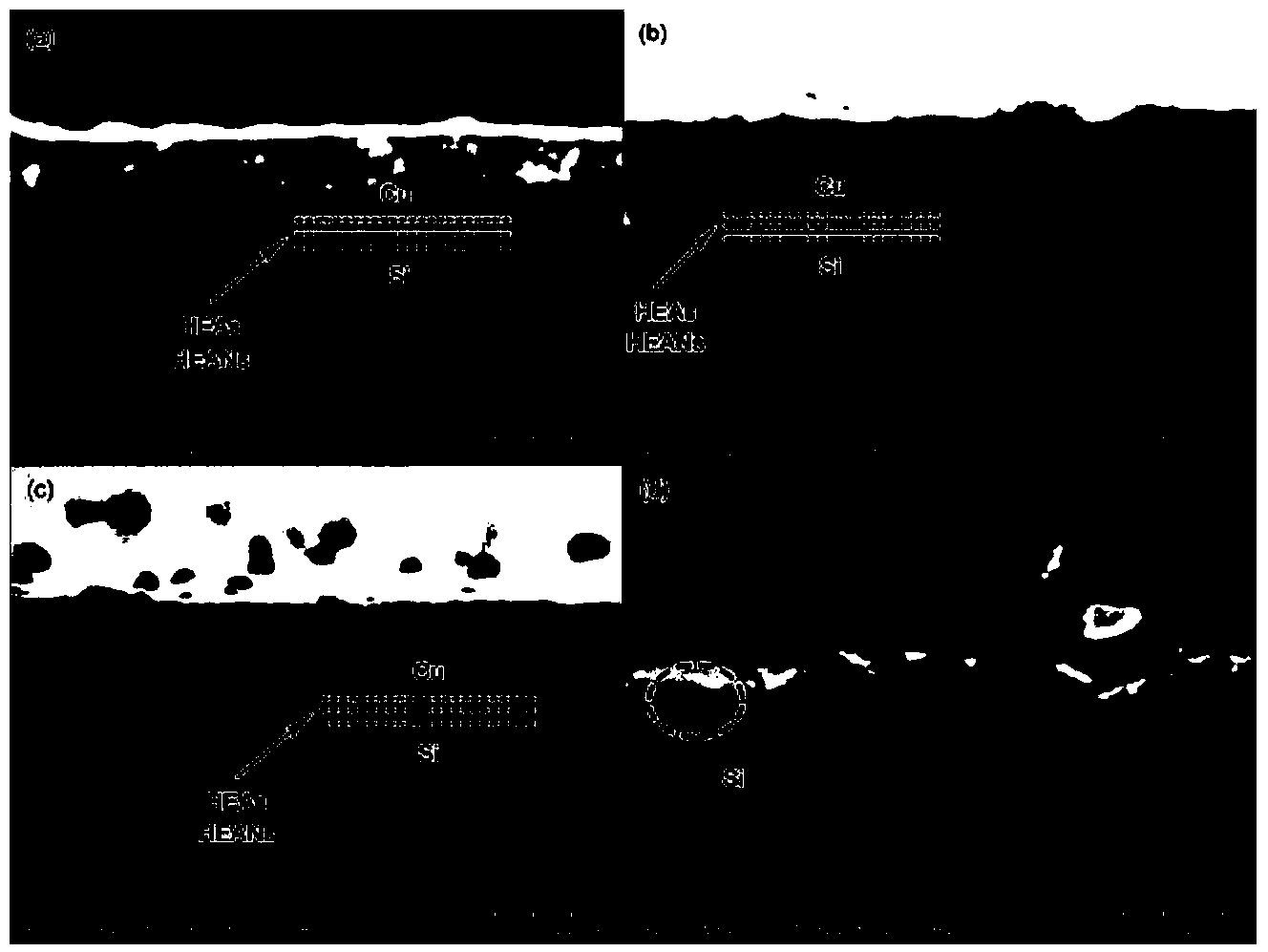

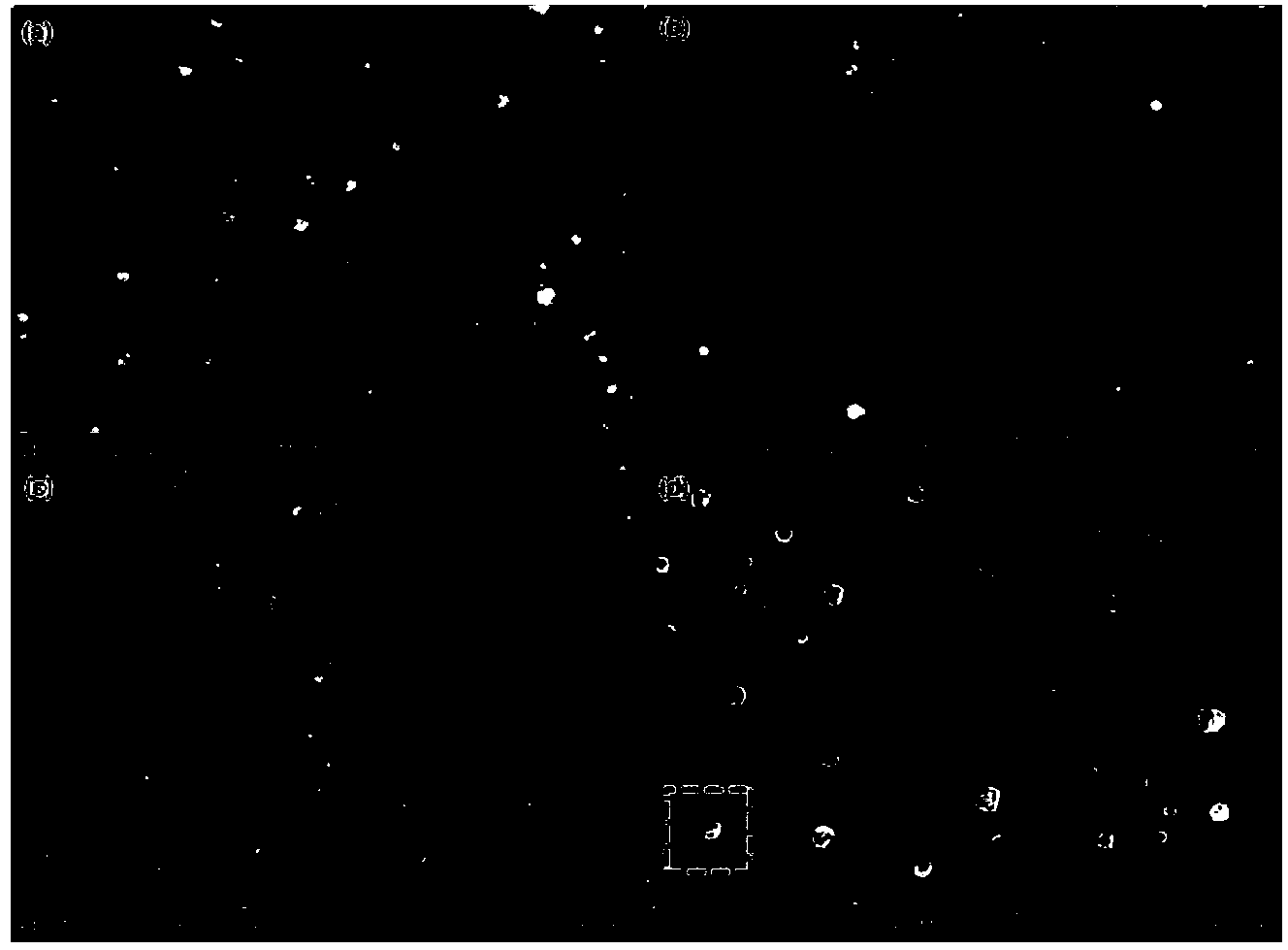

Examples

Embodiment 1

[0051] (1) Place the N-type single crystal Si substrate with a crystal orientation of [100] in acetone and then in absolute ethanol for about 20 minutes of ultrasonic cleaning, and take it out and dry it for later use;

[0052] (2) Put the single crystal Si substrate cleaned in step (1) and the Ta target, Al target, and Cr target as the target material into the magnetron sputtering coating vacuum furnace, and place the Ni target sheet on the Cr target. The Ti target is placed on the Ta target, and the Ni target and the Ti target only occupy part of the Cr target and the Ta target; vacuumize the magnetron sputtering coating vacuum furnace to 4.0×10 -4 After Pa, Ar was introduced as the working gas, and the impurities in the single crystal Si substrate were removed by reverse sputtering cleaning. The power of reverse sputtering cleaning was 200W, and the bias voltage was -700V; Impurities, the power of pre-sputtering cleaning is 60W; the operating pressure of reverse sputtering ...

Embodiment 2

[0064] (1) Place the N-type single crystal Si substrate with a crystal orientation of [100] in absolute ethanol and then in acetone for about 30 minutes of ultrasonic cleaning respectively, and take out and dry for later use after thorough cleaning;

[0065] (2) Put the single crystal Si substrate cleaned in step (1) and the Ta target, Al target, and Cr target as the target material into the magnetron sputtering coating vacuum furnace, and place the Ni target sheet on the Cr target. The Ti target is placed on the Ta target, and the Ni target and the Ti target only occupy part of the Cr target and the Ta target; vacuumize the magnetron sputtering coating vacuum furnace to 1.2×10 -4 After Pa, Ar was introduced as the working gas, and the impurities in the single crystal Si substrate were removed by reverse sputtering cleaning. The power of the reverse sputtering cleaning was 160W, and the bias voltage was -800V; Impurities, the power of pre-sputtering cleaning is 100W; the opera...

Embodiment 3

[0071] (1) Place the N-type single crystal Si substrate with a crystal orientation of [100] in acetone and absolute ethanol for about 25 minutes for ultrasonic cleaning respectively, take it out and dry it for later use after thorough cleaning;

[0072] (2) Put the single crystal Si substrate cleaned in step (1) and the Ta target, Al target, and Cr target as the target material into the magnetron sputtering coating vacuum furnace, and place the Ni target sheet on the Cr target. Place the Ti target on the Ta target, wherein the Ni target and the Ti target only occupy part of the position on the Cr target and the Ta target; vacuumize the magnetron sputtering coating vacuum furnace to 4.0×10 -4 After Pa, Ar was introduced as the working gas, and the impurities in the single crystal Si substrate were removed by reverse sputtering cleaning. The power of reverse sputtering cleaning was 240W, and the bias voltage was -700V; Impurities, the power of pre-sputtering cleaning is 80W; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com