Welding method of plasma pole noble gas protection

A plasma metal, inert gas technology, applied in welding equipment, metal processing equipment, arc welding equipment, etc., can solve problems such as inability to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

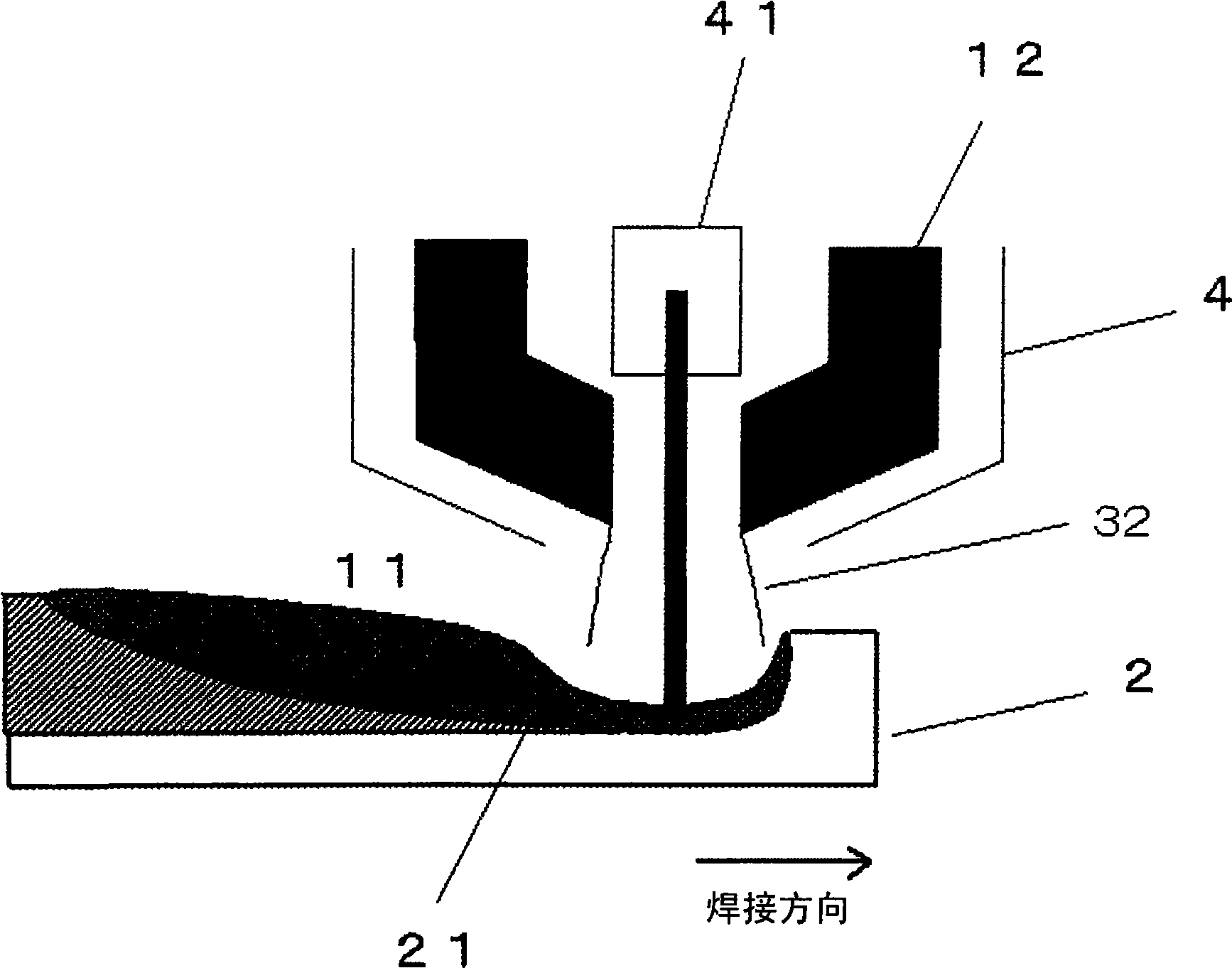

[0049] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

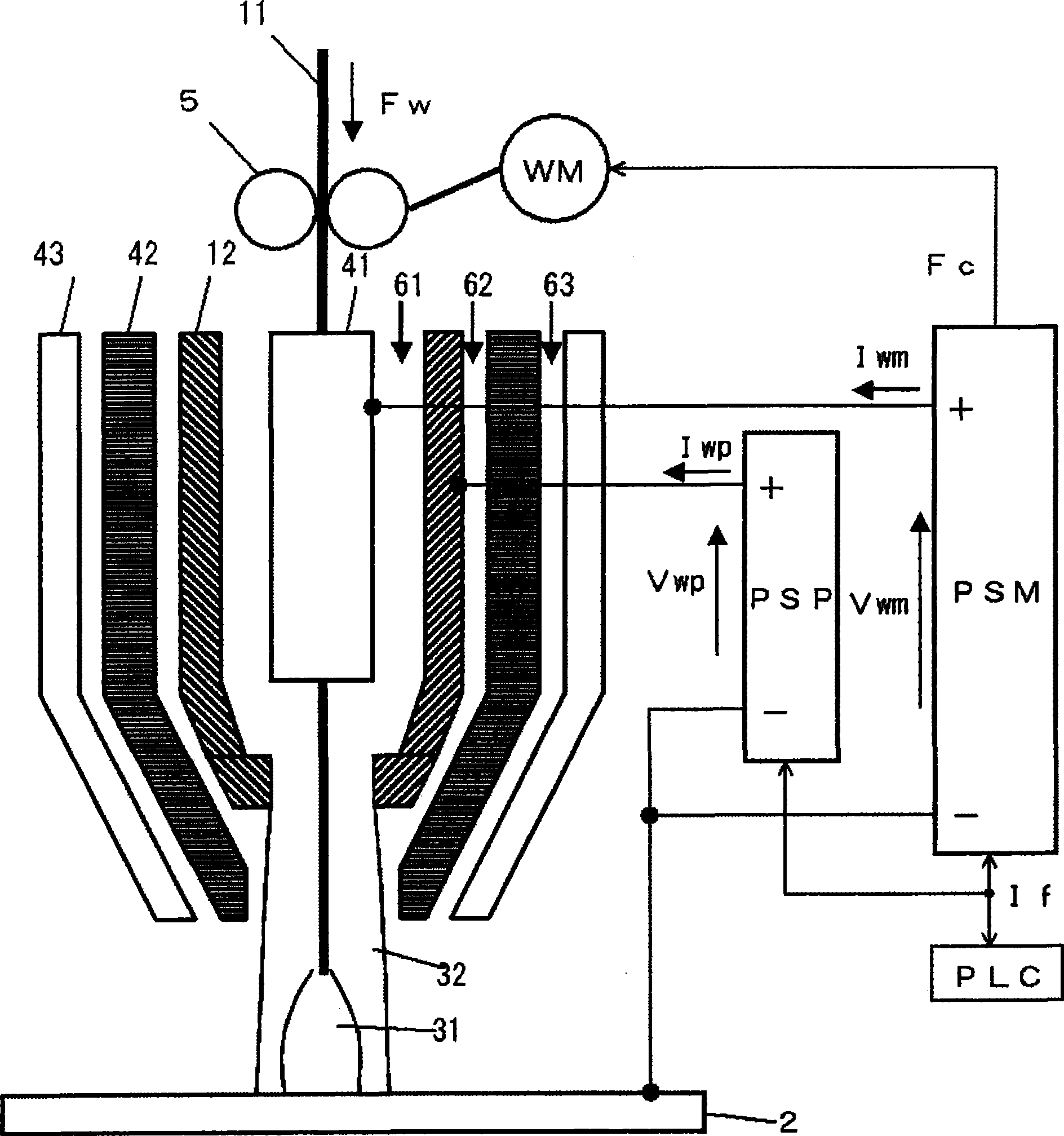

[0050] figure 1 It is a structural diagram of a welding device for implementing the plasma metal inert gas shielded welding method related to the embodiment of the present invention. Hereinafter, each configuration will be described with reference to this figure.

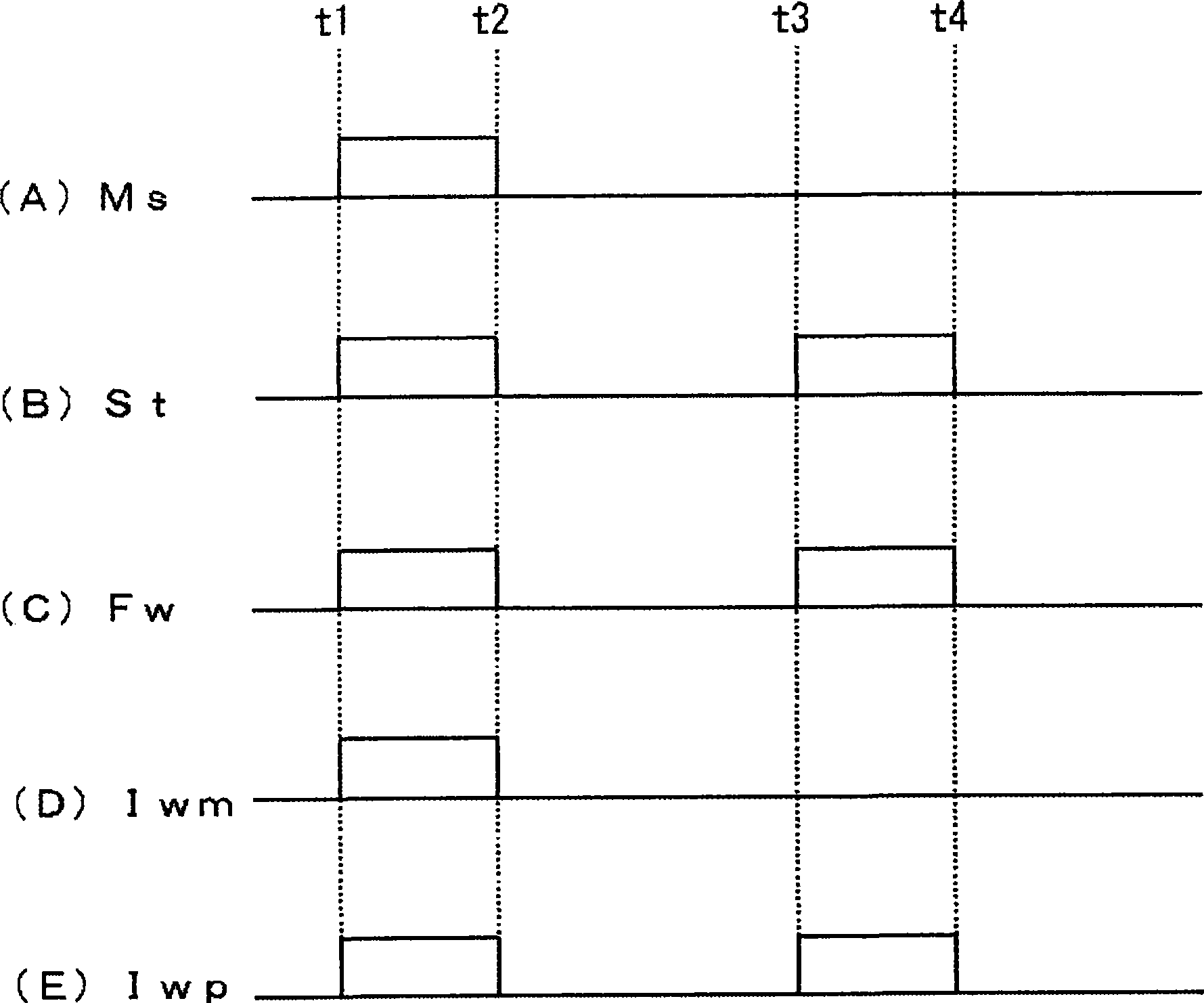

[0051]The sequence control device PLC sends an interface signal If including a welding mode selection signal Ms, a welding start signal St, a metal inert gas welding voltage setting signal, a metal inert gas welding current setting signal, and a plasma current setting signal. The sequence control device PLC is a programmable logic controller (Programmabol Logic Controller), and corresponds to a robot control device or the like during robot welding. The metal inert gas welding power supply PSM receives the above-mentioned interface signal If, and when the above-mentioned welding mode selection signal Ms is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com