Consumable electrode type arc welding method and device therefor

An arc welding method and arc welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of unstable arc, large sputtering, large welding current, etc., and achieve the effect of stable arc state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

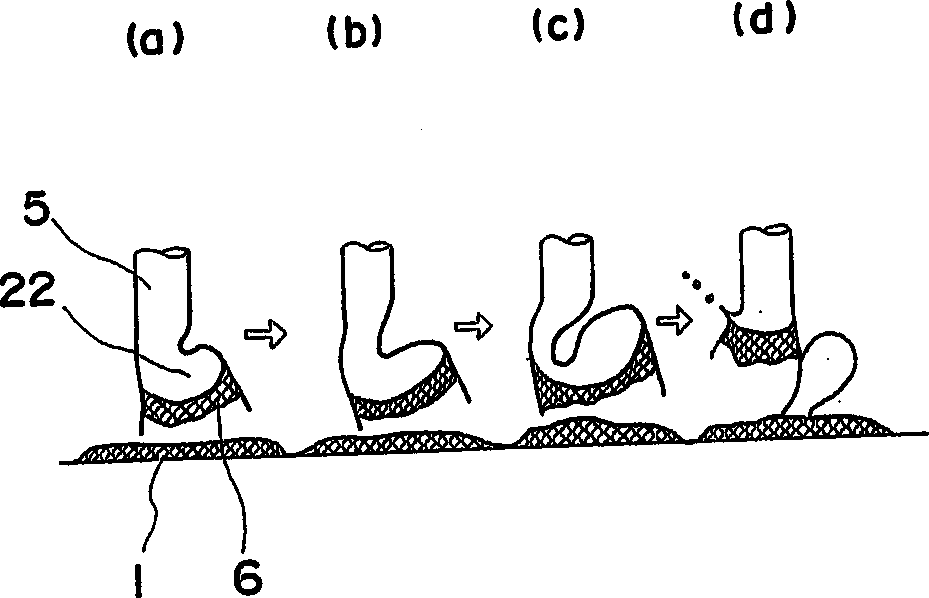

[0030] Hereinafter, examples of the present invention will be described. Figure 4 It is a relational diagram of welding voltage, welding current, welding wire feeding speed, and droplet movement in the present invention.

[0031] Such as Figure 4 As seen in , if a short circuit occurs, the voltage drops from a set value, and a short circuit is detected, then, after a predetermined delay time, the welding current is increased to release the short circuit. In addition, by decelerating the welding wire feed speed in synchronization with short circuit detection, molten metal flow or surface tension in the molten pool effectively plays a role in detachment of the droplet from the wire tip and promotes short circuit release. After the short circuit is released, the welding wire feeding speed is accelerated to prevent the droplet from breaking away from the generated arc fragments, and the movement to the arc and the formation of the droplet are performed rapidly. Here, by equali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com