Plasma processing apparatus and plasma processing method

一种等离子体、处理装置的技术,应用在真空容器内进行清洁领域,达到抑制损伤、溅射作用降低、高电子密度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

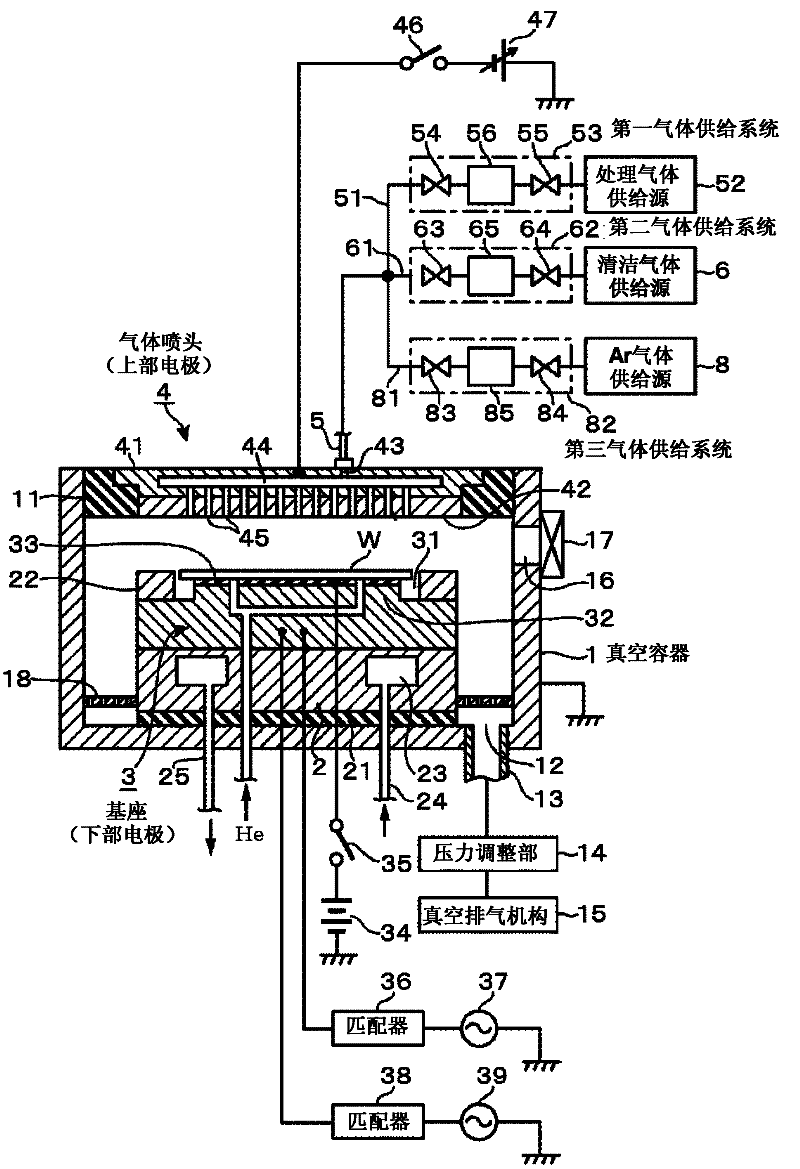

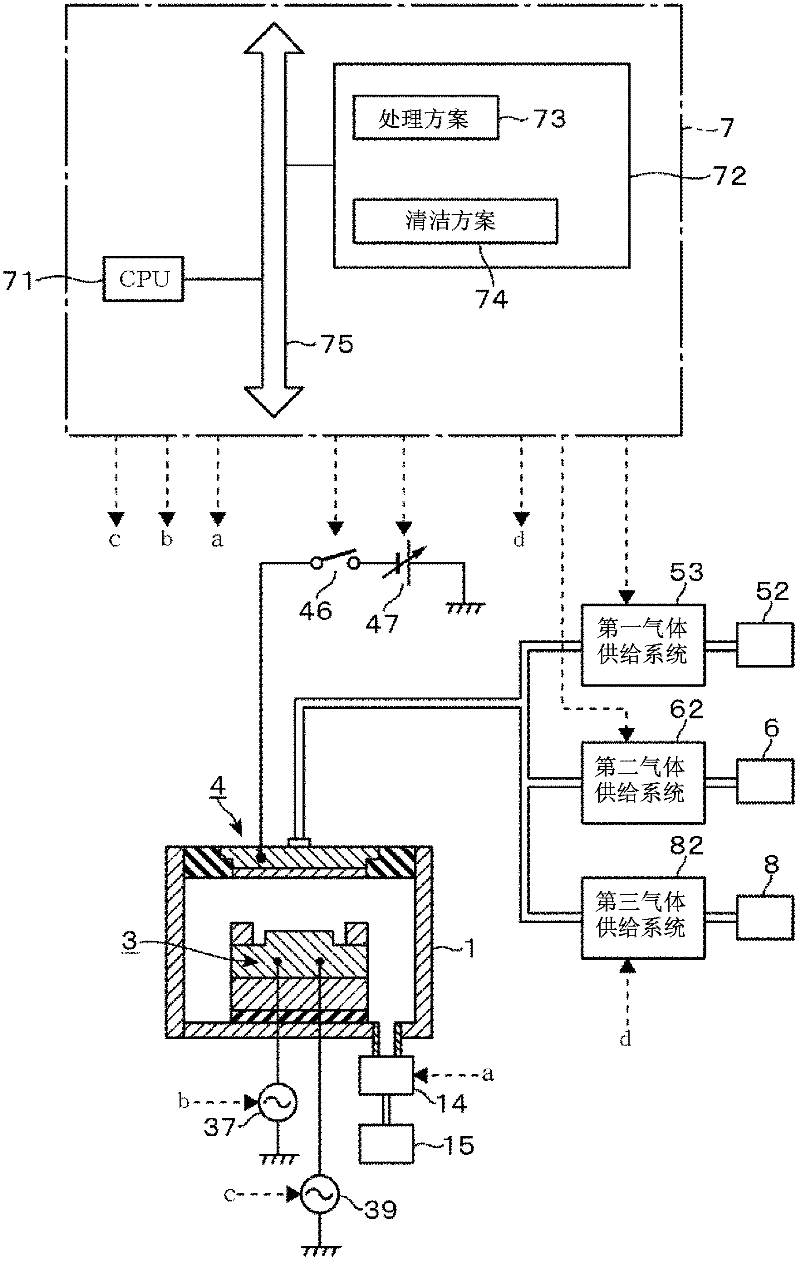

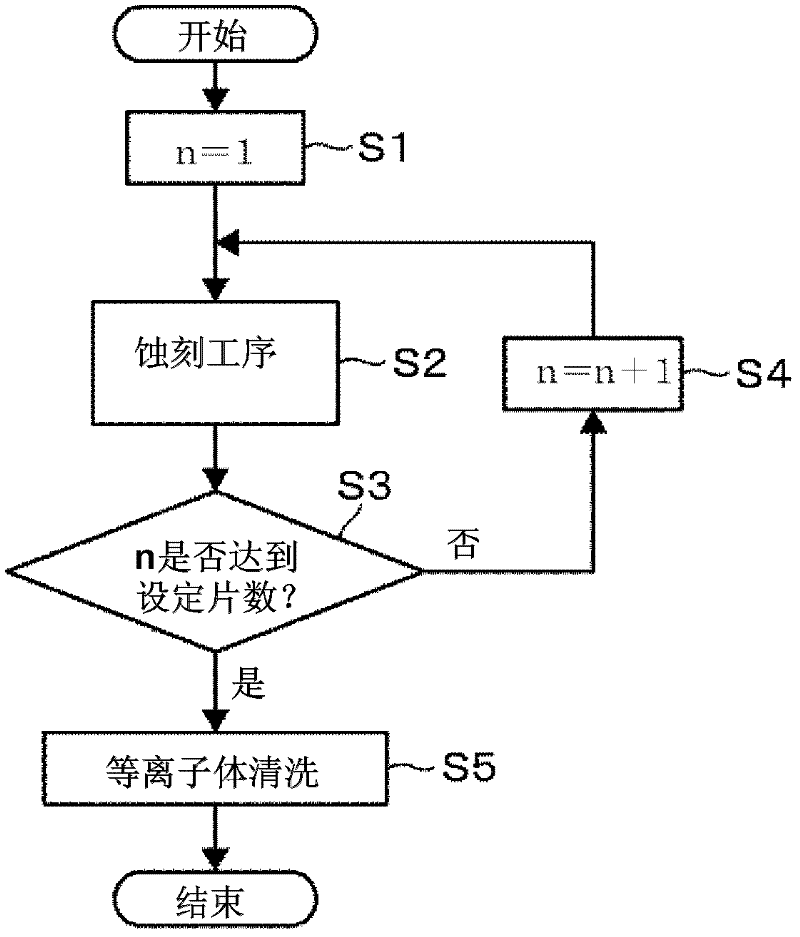

Method used

Image

Examples

Embodiment 1

[0069] Both the surface roughness and the diameter of the island-shaped portion 91b of Example 1 were approximately equal to those of Reference Example 1, but compared with Example 1, the surface roughness of Comparative Example 1 was increased and the diameter was decreased. From this, it was confirmed that in the plasma cleaning process not using the dummy wafer, damage to the surface of the electrostatic chuck 33b can be reduced by applying a DC voltage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com