Hollow fiber type composite nano-filtration membrane and preparation method thereof

A technology of composite nanofiltration membrane and fiber membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

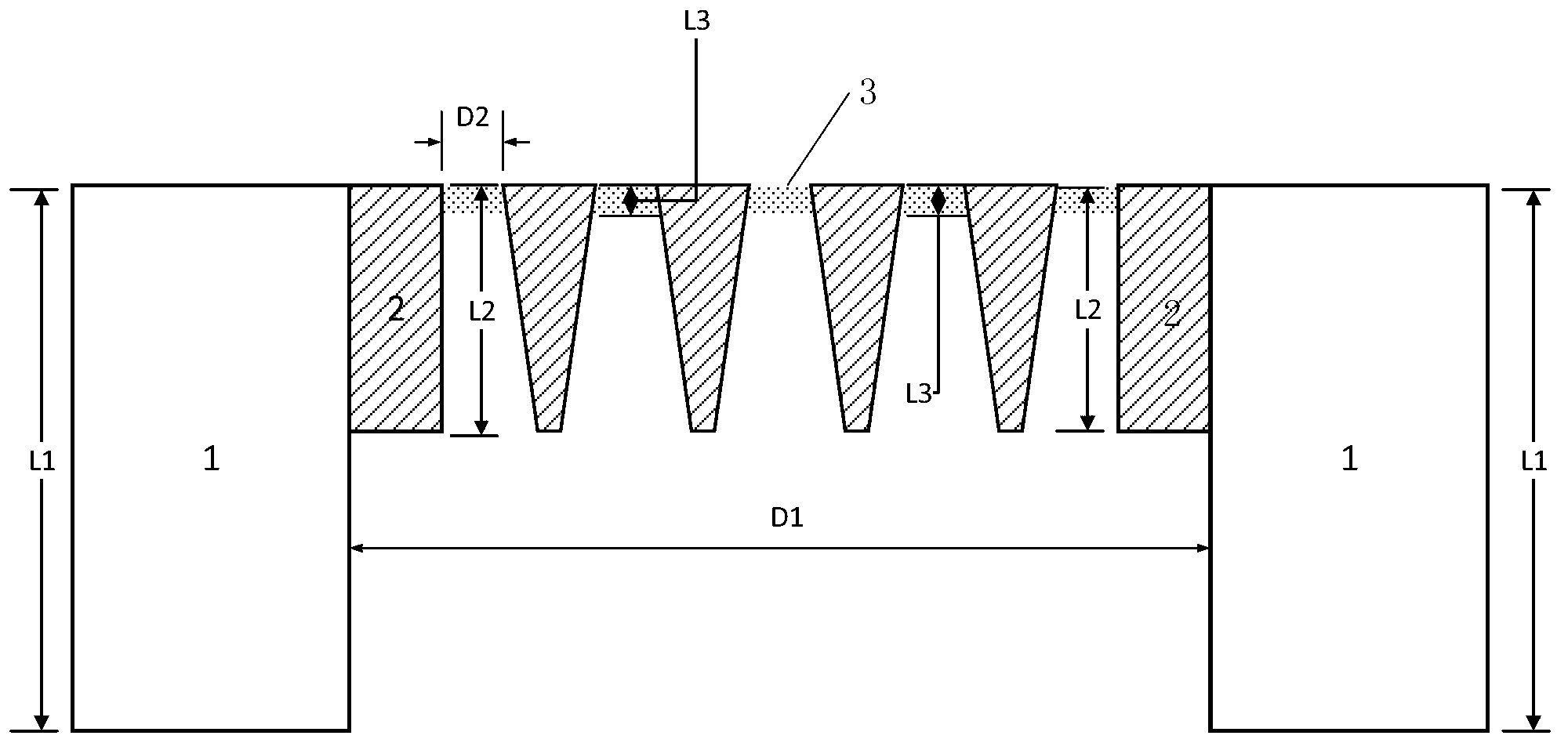

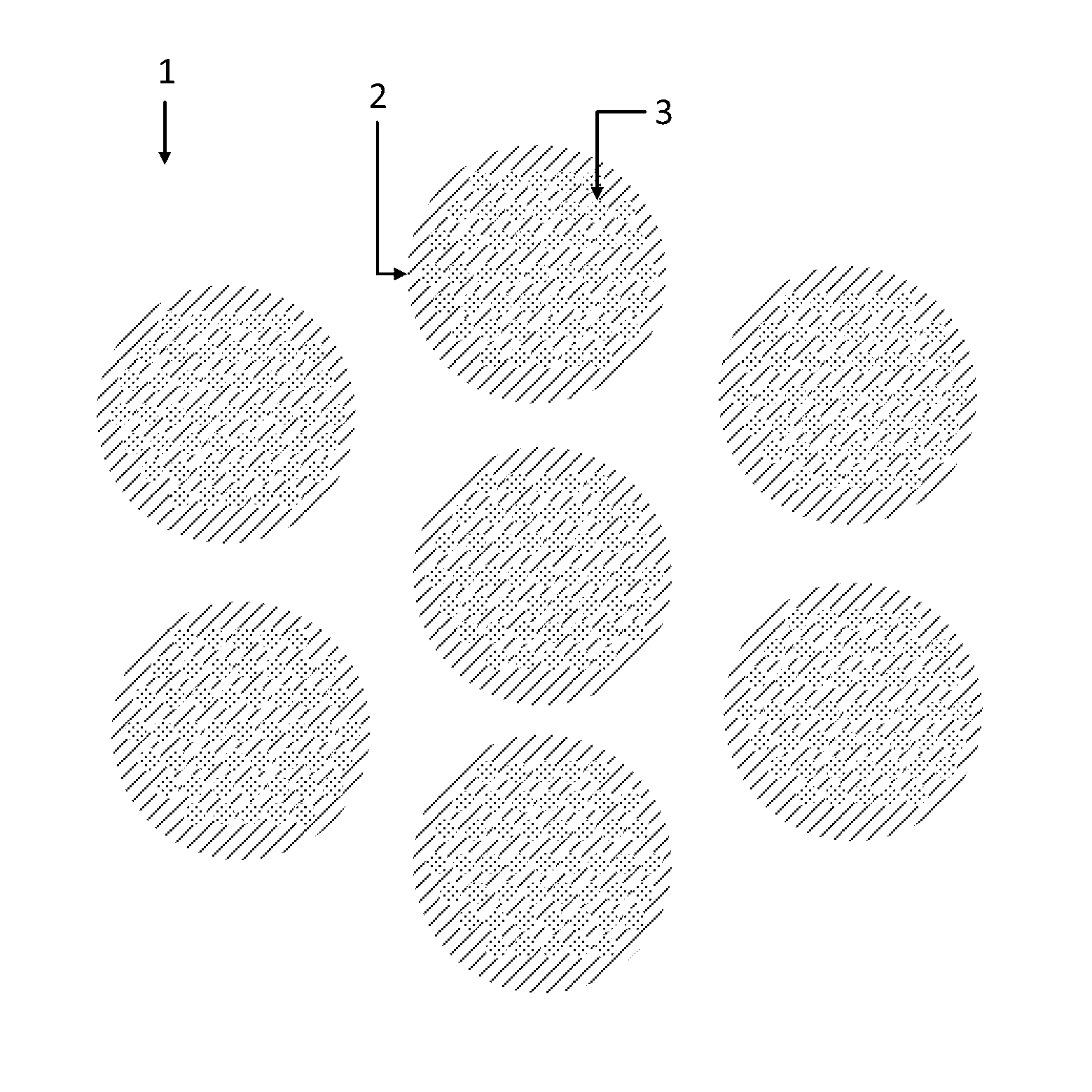

Method used

Image

Examples

Embodiment 1

[0072] A polyolefin hollow fiber membrane with an outer diameter of 1.2mm and an inner diameter of 0.8mm was prepared by thermally induced phase separation as the base membrane. The alcohol bubble point is 0.24-0.25MPa, the tensile strength is 9.5MPa, and the operating pressure is 1150.6L at 0.01MPa. m -2 h -1 The pure water flux, the elongation at break is 150%.

[0073] Prepare a nitrogen-methylpyrrolidone (NMP) solution of polysulfone polymers, prepare 25mL casting solution with a concentration of 2w / v%, stir at room temperature for 24 hours to fully dissolve, and then vacuum oven at 0.09MPa for 30min to defoam. Cast the casting solution on a clean glass plate, rotate the hollow fiber membrane on the edge of the casting solution on the glass plate, so that the micropores of the membrane are soaked in the solution, and the membrane is immersed in deionized water for 1 hour to fully exchange the solvent, take it out, and dry it at room temperature Use after drying.

[0074...

Embodiment 2

[0077] The same base film as in Example 1 was used.

[0078] Prepare a polysulfone polymer dimethyl sulfoxide (DMSO) film casting solution with a concentration of 10w / v%, stir at room temperature for 24 hours to fully dissolve, and then vacuum oven at 0.09MPa for 30min to defoam. The membrane filaments were immersed in the casting solution for 5 minutes, so that the pores of the membrane filaments were infiltrated with the solution, and the membrane filaments were immersed in deionized water for 2 hours to fully exchange the solvent, then taken out, and dried at room temperature before use.

[0079] Prepare a polyvalent diamine solution containing 2w / v%, and a polyacyl chloride oil phase solution containing 0.1w / v%. Four 10cm-long membrane filaments coated with a transition layer were made into a membrane device, and the aqueous phase solution was passed through the membrane filaments inside the membrane filaments for 5 minutes under a pressure of 0.2 MPa. Then the membrane d...

Embodiment 3

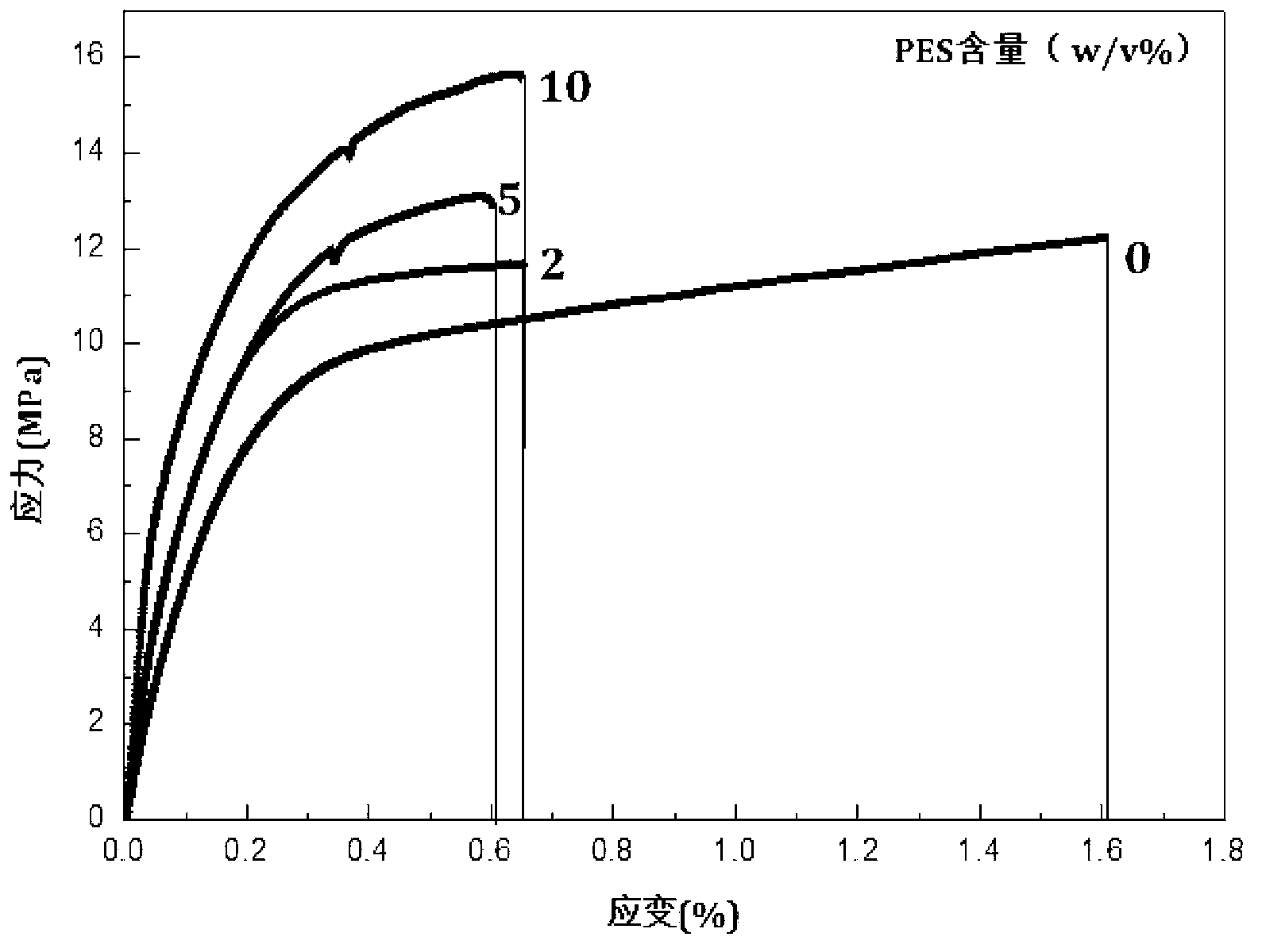

[0083] Compared with Example 1, except that the immersion time of the membrane filaments in the casting solution was changed, other reaction conditions were the same. The relationship between the obtained nanofiltration membrane pure water flux and the 2000ppm rejection rate is shown in Table 1. Impregnation of PES into the micropores improves the support of the membrane pores to the composite layer and increases the rejection rate; when the immersion time is too long, the NMP solvent will destroy the membrane pore structure of the PVDF hollow fiber microporous base membrane, and the pore size of the support layer is too large However, the structure of the composite layer cannot be supported, and the interception performance is destroyed.

[0084] Table 1 Effect of membrane filament immersion time on nanofiltration membrane performance

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com