Double-gradient heat-insulation anti-ablative coating and preparation method thereof

An anti-ablation, double-gradient technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of thermal shock resistance, oxidation resistance, and oxidation resistance. Problems such as not being improved, to achieve the effect of improving thermal shock resistance, reducing interlayer stress, and improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

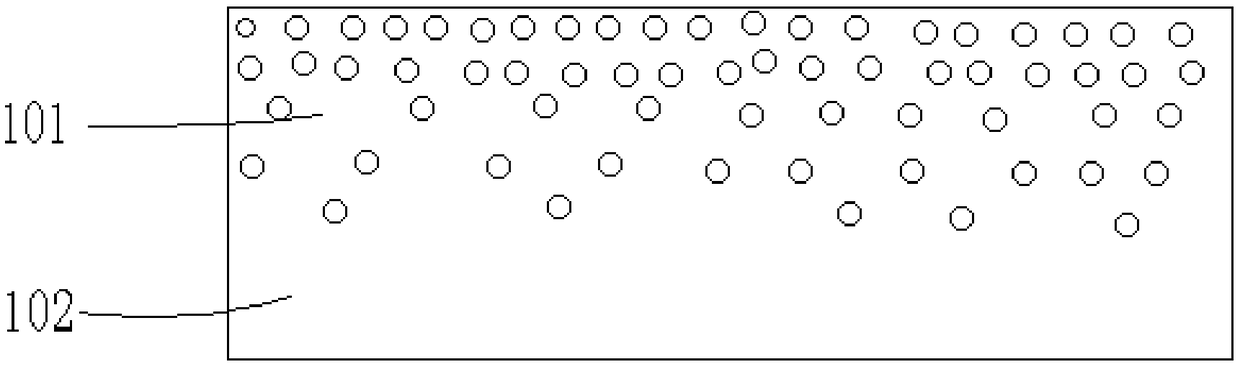

[0035] The second aspect of the present invention also provides a method for preparing the dual-gradient heat-insulating and anti-ablation coating 101, which includes the following steps: .

[0036] S01, pretreatment of the substrate 102, selecting one of alloy steel or superalloy as the substrate 102, and performing surface treatment on the workpiece to be sprayed;

[0037] S02, spraying powder pretreatment, spraying powder is two groups of materials A and B, group A material is alloy powder, which is one of NiCrAlY, CoCrAlY, NiCoCrAlY, NiCoCrAlYTa alloy, group B material is ceramic powder, which is partially stabilized by yttrium oxide Zirconia (Y 2 o 3 -ZrO 2 ), calcium oxide partially stabilized zirconia (CaO-ZrO 2 ), cerium oxide partially stabilized zirconia (CeO 2 -ZrO 2 ) and aluminum oxide (Al2O3); the alloy to be sprayed and the ceramic powder are dried in an oven; the optional implementation of this embodiment is that the alloy to be sprayed and the ceramic pow...

Embodiment 1

[0045] A dual-gradient heat-insulating and anti-ablation coating 101 provided in this embodiment and its preparation method are as follows.

[0046] 1. Substrate 102 pretreatment. Use organic solvents to clean the surface of the workpiece to remove oil and rust, and use sandblasting to roughen the surface of the sprayed workpiece after drying;

[0047] 2. Powder pretreatment. The metal alloy layer is NiCrAlY from 200 mesh to 325 mesh, and the ceramic layer is 8% Y from 200 mesh to 325 mesh 2 o 3 -ZrO 2 , the powder was dried at 80°C for 30min.

[0048] 3. Coating preparation.

[0049] The powder feeding rate of the first sublayer NiCrAlY powder is 5kg / h, 8%Y 2 o 3 -ZrO 2 The powder feeding rate is 0kg / h, the powder feeding pressure is 0.8MPa, the spraying power is 30kW, the spraying speed is 30mm / s, and the spraying distance is kept at 100mm;

[0050] The powder feeding rate of the second sublayer NiCrAlY powder is 3kg / h, 8%Y 2 o 3 -ZrO 2 The powder feeding rate is...

Embodiment 2

[0055] A dual-gradient heat-insulating and anti-ablation coating 101 provided in this embodiment and its preparation method are as follows.

[0056] 1. Substrate 102 pretreatment. Use organic solvents to clean the surface of the workpiece to remove oil and rust, and use sandblasting to roughen the surface of the sprayed workpiece after drying;

[0057] 2. Powder pretreatment. The metal alloy layer is 200 mesh to 325 mesh NiCoCrAlY, and the ceramic layer is 200 mesh to 325 mesh CeO 2 -ZrO 2 , the powder was dried at 80°C for 30min.

[0058] 3. Coating preparation.

[0059] The powder feeding rate of the first sublayer NiCoCrAlY powder is 6kg / h, CeO 2 -ZrO 2 The powder feeding rate is 0kg / h, the powder feeding pressure is 0.8MPa, the spraying power is 30kW, the spraying speed is 30mm / s, and the spraying distance is kept at 100mm;

[0060] The powder feeding rate of the second sublayer NiCoCrAlY powder is 5kg / h, CeO 2 -ZrO 2 The powder feeding rate is 1kg / h, the powder f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com