95 chromium-aluminum-zirconium brick for coal water slurry pressurized gasifier and preparation method thereof

A technology of pressurized gasification and coal-water slurry, which is applied in the field of refractory materials and can solve the problems of restricting the operating rate of gasifiers and the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

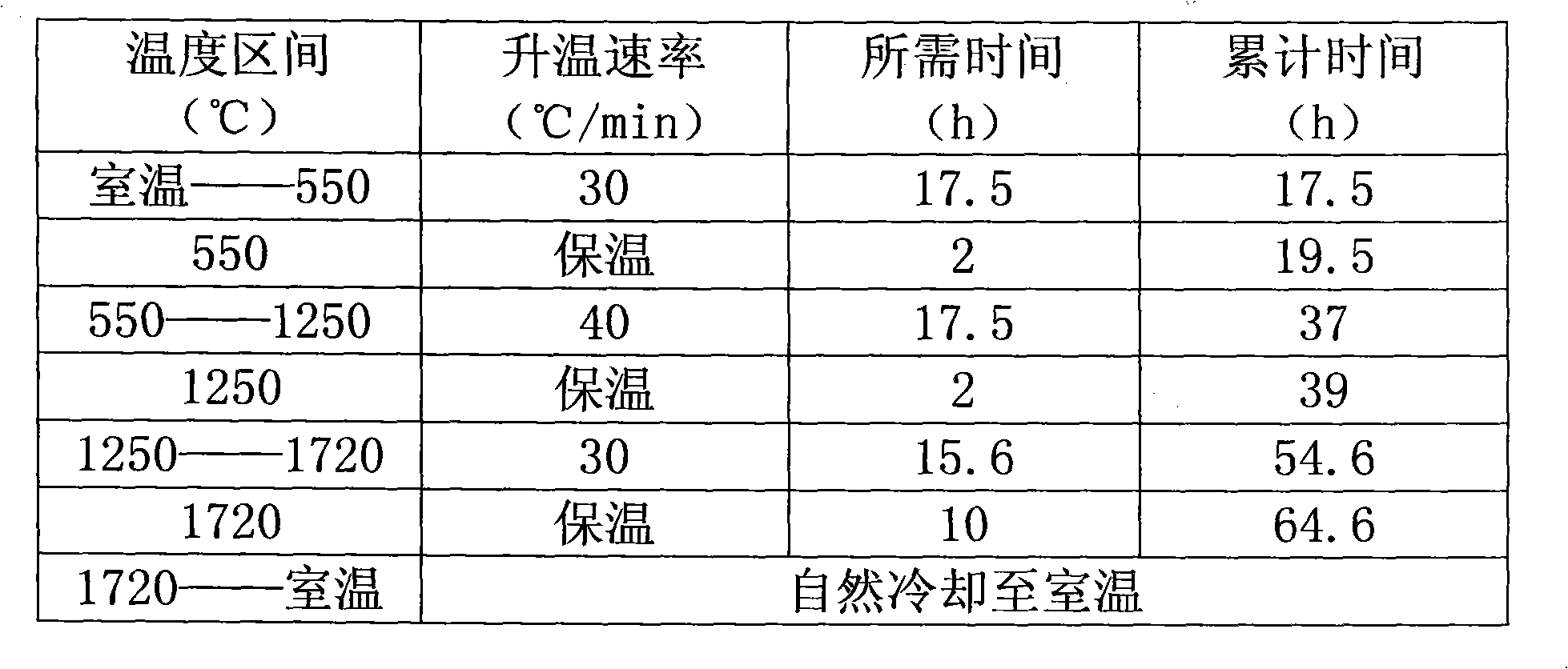

Embodiment 1

[0025] A 95 chrome-aluminum-zirconium brick for a coal-water slurry pressurized gasifier, the raw materials of which are calculated by weight percentage: fused chromium oxide 4mm-2mm 40%, fused chromium oxide 2mm-0mm 25%, fused chromium oxide ≤ 0.088 mm 23.5%, chromium oxide green 5.0%, zirconia micropowder 1.5%, α-Al 2 o 3 5.0% of fine powder; according to the percentage of the total amount of raw materials, 2.5% of aluminum dihydrogen phosphate and 0.4% of dextrin are added.

Embodiment 2

[0027] A 95 chrome-aluminum-zirconium brick for a coal-water slurry pressurized gasifier, the raw materials of which are calculated by weight percentage: fused chromium oxide 4mm-2mm 45%, fused chromium oxide 2mm-0mm 20%, fused chromium oxide ≤ 0.088 mm 22.5%, chromium oxide green 5.0%, zirconia micropowder 2.0%, α-Al 2 o 3 5.5% of fine powder; according to the percentage of the total amount of raw materials, 3.0% of aluminum dihydrogen phosphate and 0.35% of dextrin are added.

Embodiment 3

[0029] A 95 chromium-aluminum-zirconium brick for a coal-water slurry pressurized gasifier, the raw materials of which are calculated by weight percentage: fused chromium oxide 4mm-2mm 50%, fused chromium oxide 2mm-0mm 15.0%, fused chromium oxide ≤ 0.088 mm 21.0%, chromium oxide green 5.0%, zirconia micropowder 3.0%, α-Al 2 o 3 6.0% of fine powder; according to the percentage of the total amount of raw materials, 3.5% of aluminum dihydrogen phosphate and 0.3% of dextrin are added.

[0030] In the above-mentioned embodiments, the weight percentage of chromium oxide in fused chromium oxide is more than or equal to 99%; The particle composition is less than or equal to 5 μm, and the weight percentage of zirconia in zirconia powder is ≥97%; α-Al 2 o 3 Micropowder consists of particles with a particle size less than or equal to 5 μm, α-Al 2 o 3 α-Al in fine powder 2 o 3 The weight percentage is more than or equal to 99%; the aluminum dihydrogen phosphate is liquid; the dextr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com