Anti-H2S stress corrosion high pressure resistant forgings and method for manufacturing same

A technology of stress corrosion and hydrogen sulfide resistance, which is applied in the field of hydrogen sulfide stress corrosion resistant high-pressure forgings for large blowout preventers and its manufacturing field, can solve problems such as performance degradation of blowout preventers, material mechanical properties decline, corrosion cracking, etc., and achieve reduction Formation tendency of non-metallic inclusions, improvement of hardenability, and effect of increasing the density of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Its chemical composition is shown in Table 1, and the rest are Fe and unavoidable impurities;

[0054] Table 1

[0055]

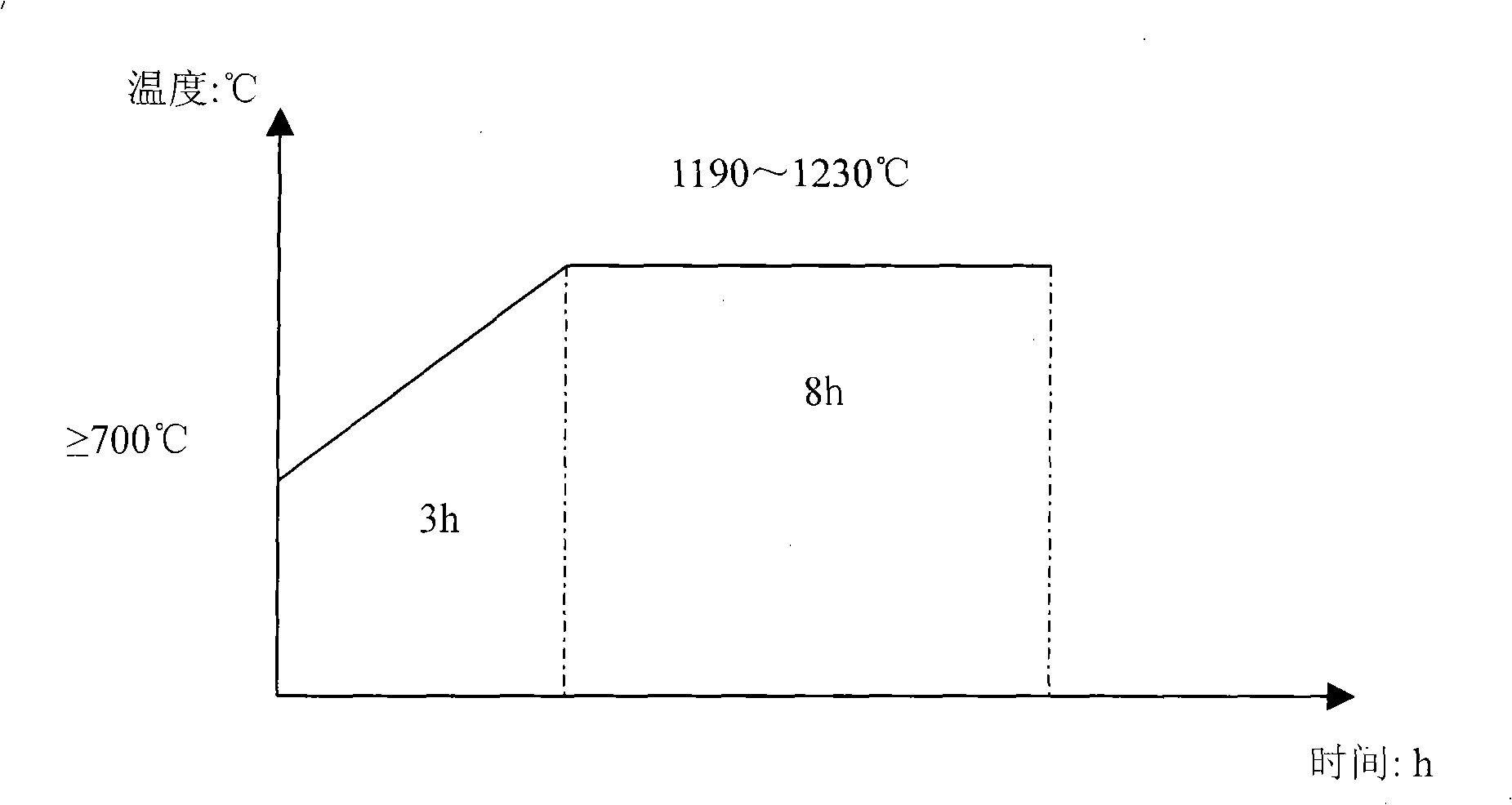

[0056] After electric furnace smelting, refining outside the furnace and vacuum degassing, 35 tons of steel ingots are poured, demoulded and sent to the fast forging heating furnace for heating 12 hours after casting. The heating rate is heated to 1210°C and then kept for 8 hours. The heating process curve is shown in figure 1 Shown; the heating rate of the steel ingot and the soaking time in the high temperature section are controlled reasonably.

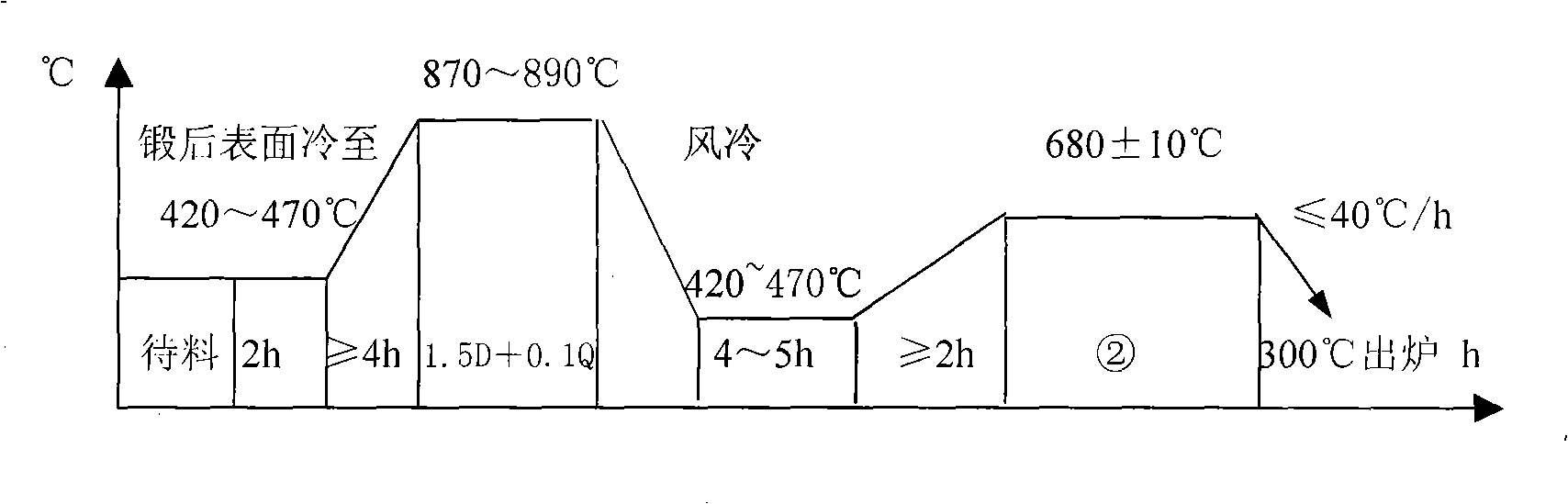

[0057] figure 2 It is a process curve diagram of normalizing and tempering treatment of forgings according to the present invention. Pre-normalizing treatment is carried out by air cooling after forging, and the temperature is kept at 420-470 ° C for 2 hours. The normalizing temperature is 870-890°C, and the holding time is 21 hours, so that the structure can be fully transformed and stable austen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com