100 L carbon fiber wrapped aluminum-lined composite cylinder and manufacture method thereof

A composite material and manufacturing method technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problem of reducing the abnormal failure of composite gas cylinders, the weight of composite gas cylinders, and the welding structure. Unreasonable design and other problems, to achieve the effect of light weight, light weight and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In these drawings, the size and relative sizes of layers and regions may be exaggerated for clarity.

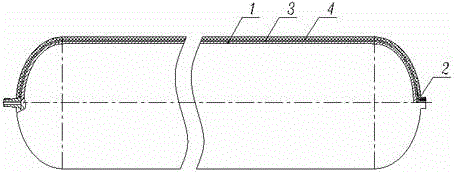

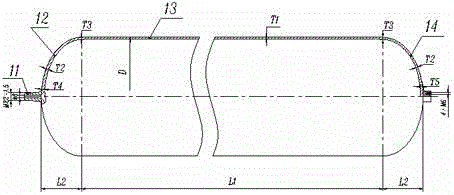

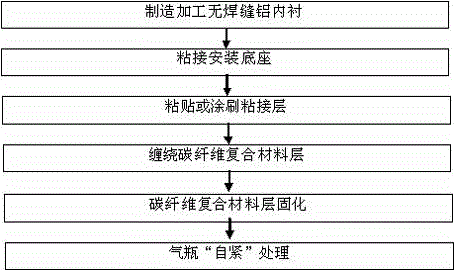

[0036] Such as figure 1As shown, a 100-liter carbon fiber-wound aluminum-lined composite gas cylinder provided by the embodiment of the present invention is mainly composed of a weldless aluminum liner 1 , a mounting base 2 , an adhesive layer 3 and a carbon fiber composite material layer 4 . The weldless aluminum liner 1 is composed of four parts: a nozzle 11, an ellipsoidal head 12, a cylindrical section 13 and an ellips...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com