Simulation experimental device for natural hydrate geological stratification

A technology for simulating experimental equipment and geological stratification, which is used in wellbore/well components, earthwork drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

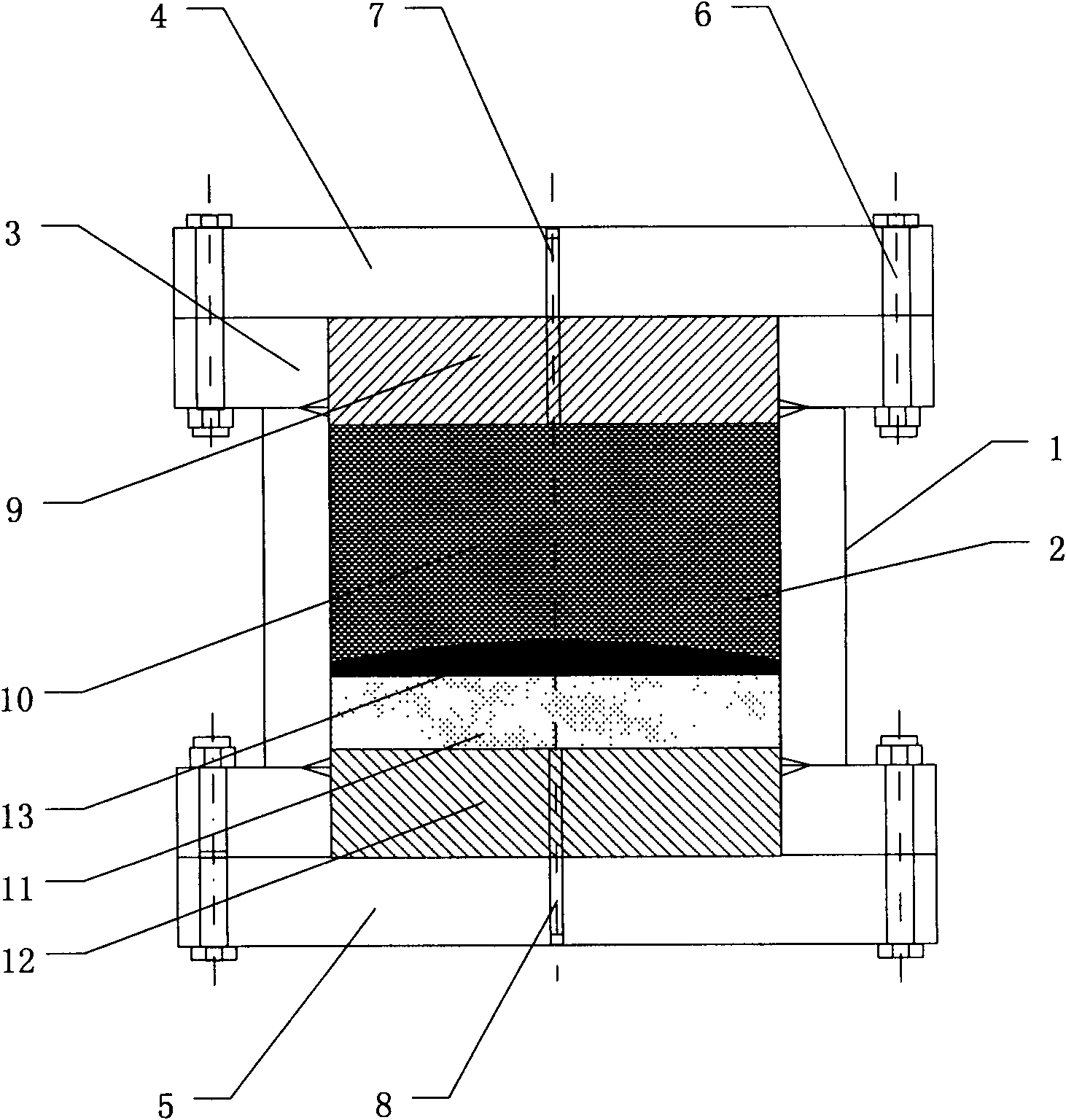

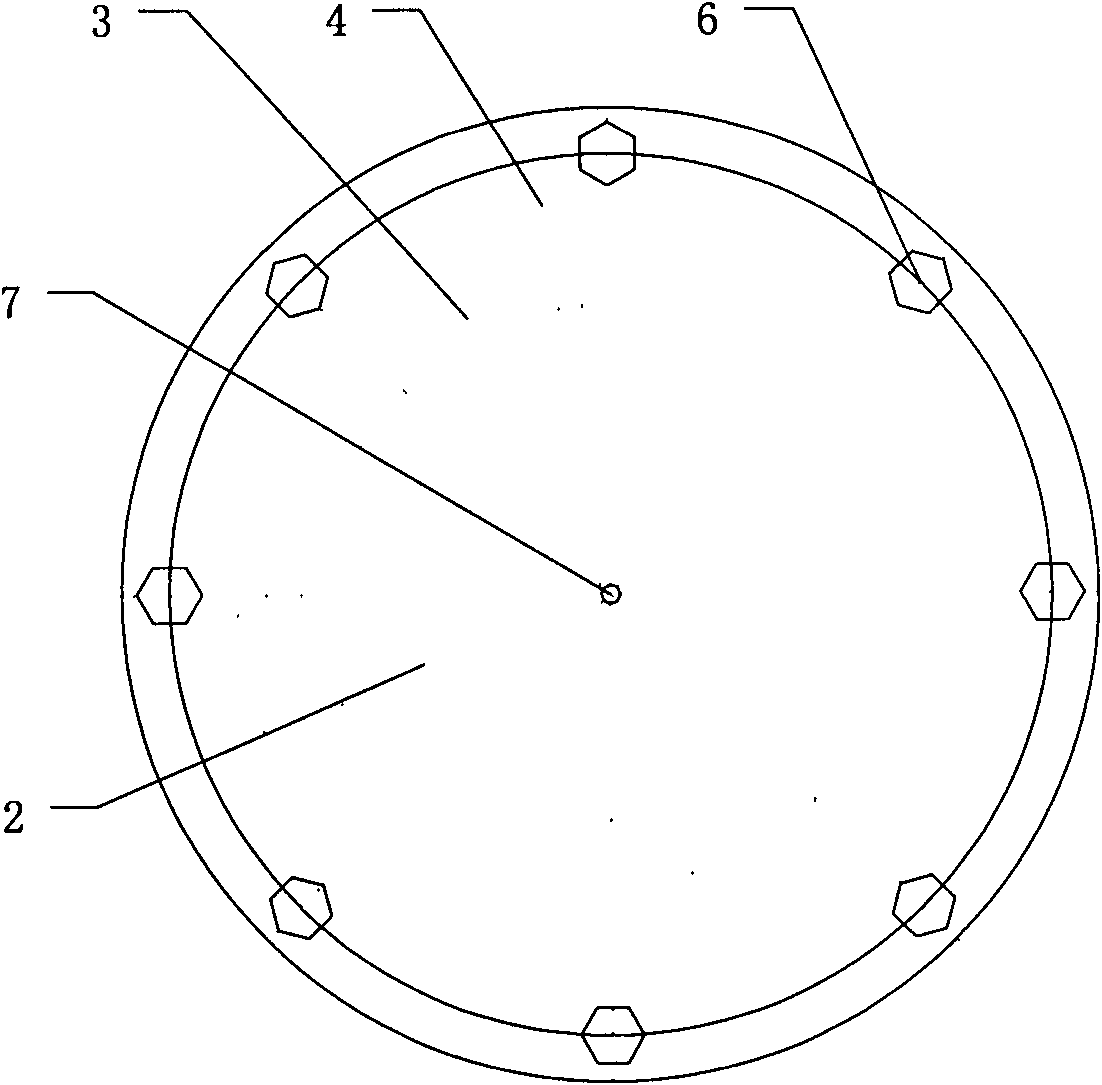

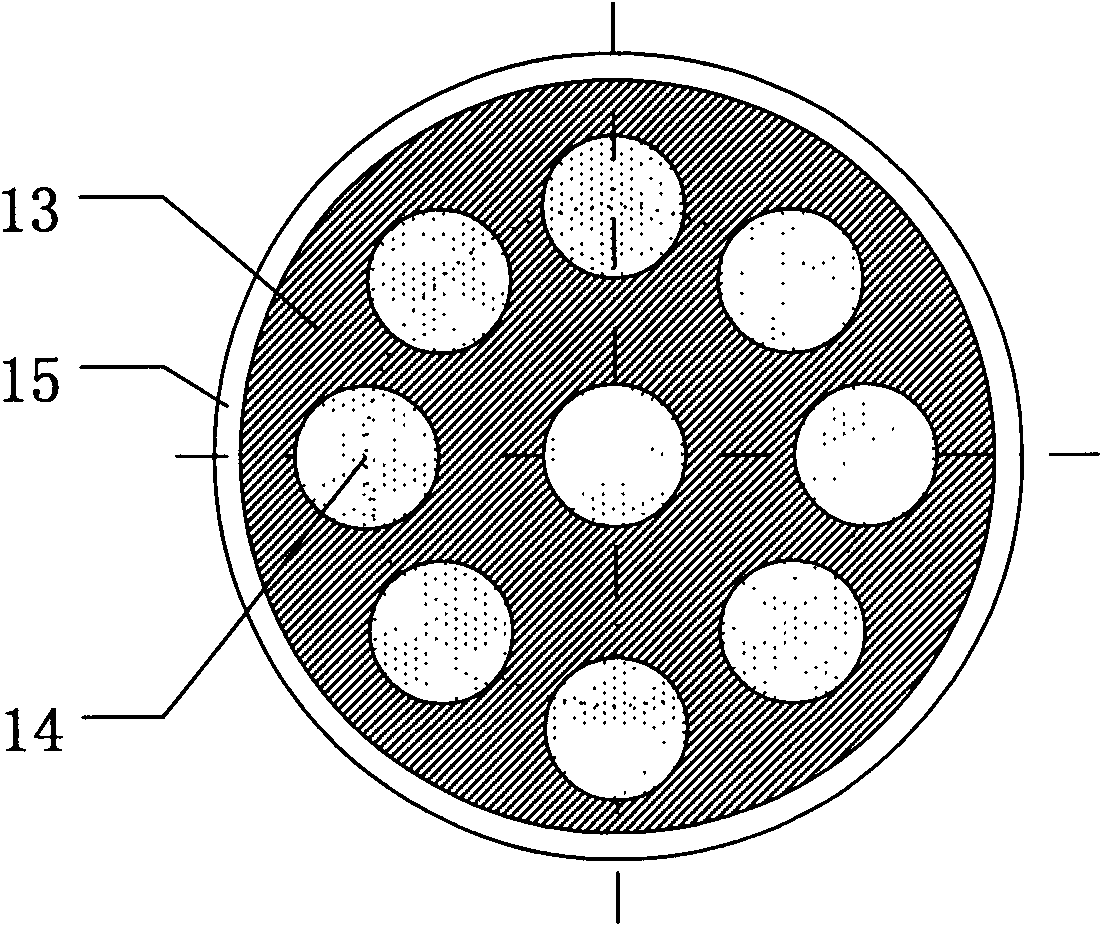

[0023] Formation type 1 gas hydrate reservoir geological stratification model:

[0024] see Figure 1 to Figure 2 As shown, the characteristics of type 1 natural gas hydrate reservoirs are that from top to bottom, the strata are mainly divided into upper caprock 9, hydrate layer 10, free gas layer below hydrate layer 10, lower caprock 12, upper caprock 9 Both the hydrate layer 10 and the free gas or water layer 11 contain sediments. In the simulation chamber 2 in the three-dimensional model 1, the semi-permeable partition layer 13 is placed between the hydrate layer 10 and the free gas layer below the hydrate layer 11, and the semi-permeable partition layer 13 that only permeates gas and does not permeate water is used. , the upper and lower surfaces of the semi-permeable partition layer 13 are respectively horizontal surfaces or arc-shaped surfaces with a high middle and low sides. Before the synthesis of natural gas hydrate, firstly, inject an appropriate amount of solutio...

Embodiment 2

[0027] Formation type 2 gas hydrate reservoir geological stratification model:

[0028] Type 2 natural gas hydrate reservoirs are characterized by the strata from top to bottom are mainly divided into the upper cap rock 9, the hydrate layer 10, the lower aquifer of the hydrate layer 10, and the lower cap rock 12, the upper cap rock 9 and the lower cap rock 12 are composed of low-permeability rocks, and the hydrate layer 10 and the free gas or water layer 11 both contain sediments. In the simulation chamber 2 in the three-dimensional model 1, the semi-permeable barrier layer 13 is placed between the hydrate layer 10 and the aquifer layer below the hydrate layer 10, and the semi-permeable barrier layer 13 that only permeates water but not gas is used. Before the synthesis of natural gas hydrate, first, inject an appropriate amount of solution into the simulation chamber 2 of the three-dimensional model 1 through the gas-liquid port 7 at the upper end. Near the interface, the in...

Embodiment 3

[0031] A type 3 gas hydrate reservoir geological stratification model is formed.

[0032] Type 3 natural gas hydrate reservoirs are characterized by the fact that the formation is mainly divided into upper caprock 9, hydrate layer 10, and lower caprock 12 from top to bottom, and the upper caprock 9 and lower caprock 12 are both composed of low-permeability rocks , the hydrate layer contains sediment. In the simulation chamber 2 in the three-dimensional model 1, the semi-permeable partition layer 13 is not used. Before the synthesis of natural gas hydrate, firstly, inject an appropriate amount of solution into the simulation chamber 2 of the three-dimensional model 1 through the gas-liquid port 7 at the upper end. Near the interface of the hydrate layer 10, the injected solution flows into the hydrate layer 10 under the action of gravity. Secondly, a certain amount of natural gas is injected into the free gas layer to a certain pressure through the gas-liquid port 8 at the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage range | aaaaa | aaaaa |

| Voltage range | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com