An electrolyte and a lithium ion battery

An electrolyte and lithium salt technology, applied in the field of electrolyte and lithium-ion batteries, can solve the problems of increased battery impedance, heating of the battery cell, strong oxidation of the electrolyte, etc., and achieve the effect of good ion conductivity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The electrolyte solution and the lithium ion battery according to the present invention will be described in detail below.

[0012] First, the electrolytic solution according to the first aspect of the present invention will be described.

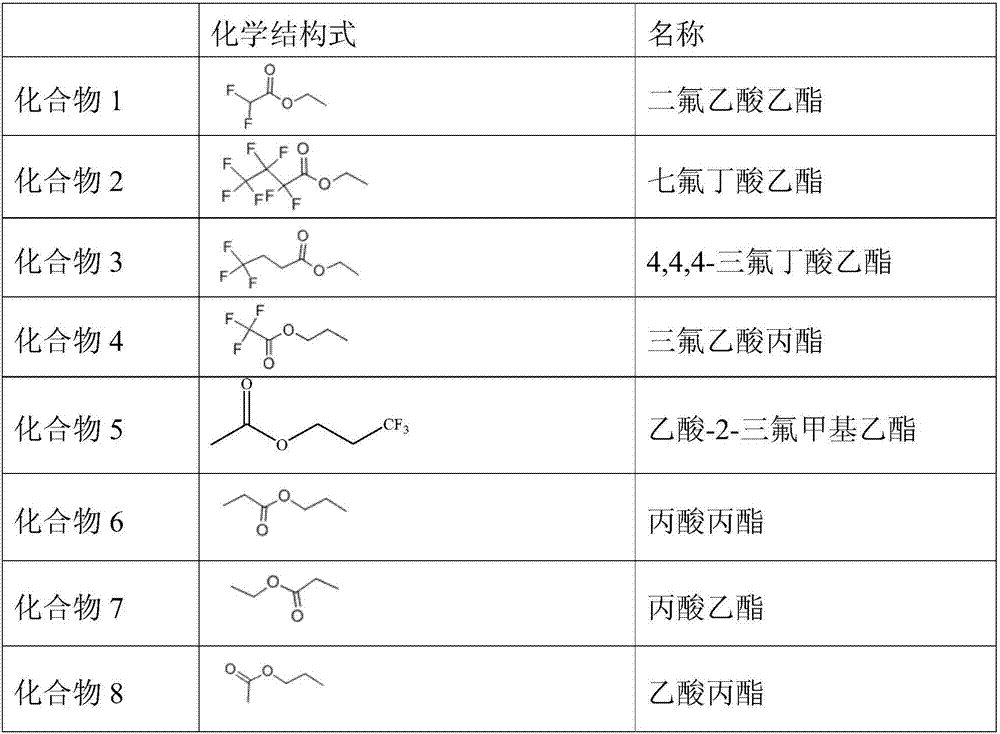

[0013] The electrolytic solution according to the first aspect of the present invention includes a lithium salt and an organic solvent. The lithium salt includes: LiPF 6 and lithium bis(trifluoromethanesulfonyl)imide (abbreviated as LiTFSI) and / or lithium bis(fluorosulfonyl)imide (abbreviated as LiFSI). The organic solvent includes: carboxylate and / or fluorocarboxylate; carbonate and / or fluorocarbonate; and sulfone. The room temperature viscosity of the carboxylate is 0.3mPa.s-0.5mPa.s. The room temperature viscosity of the fluorocarboxylate is less than 0.3mPa.s. Neither the carboxylate nor the fluorocarboxylate has a boiling point lower than 65°C under normal pressure. The weight of the carboxylate and / or the fluorocarboxylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com