Embedded waveguide printed circuit board structure

A printed circuit board, embedded technology, applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problem that the waveguide is not easy to integrate, and achieve the effect of reducing the change of dielectric loss and crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

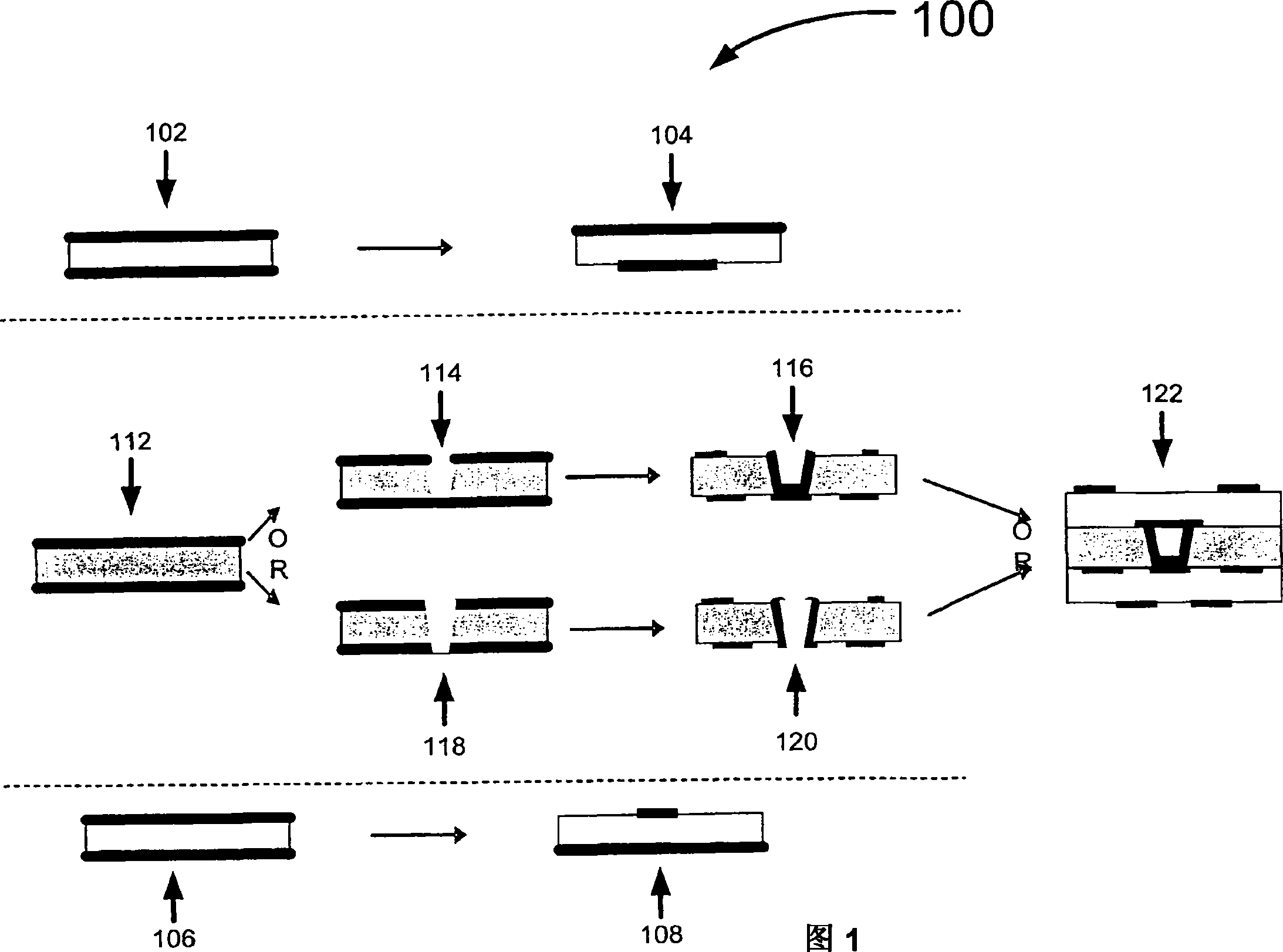

[0042] FIG. 1 illustrates a process 100 of forming waveguides in accordance with some embodiments. According to some embodiments, process 100 uses a thermoplastic cap material of thermoplastic nature to attach the top cap and / or bottom cap of the waveguide during lamination.

[0043] The top portion of the process 100 of FIG. 1 shows at 102 a copper clad thermoplastic dielectric core or multilayer structure. According to some embodiments, a copper clad thermoplastic dielectric core or multilayer structure shown at 102 has a bottom dielectric composed of thermoplastic. The bottom copper layer is imaged at 104 . The bottom copper layer, shown at 104, includes the conductors used to form the air dielectric waveguide.

[0044] Similar to the top portion of the process 100 of FIG. 1 , the bottom portion of the process 100 includes at 106 a copper clad thermoplastic dielectric core or a multilayer structure with the top dielectric being thermoplastic. The top copper layer of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com