Manufacturing method for low-speed wing flutter wind tunnel model

A manufacturing method and airfoil technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as accurate simulation of unfavorable aerodynamic shapes, influence on test accuracy, and difficulty in eliminating manufacturing errors, so as to achieve accurate geometric shapes , accurate simulation, and high structural efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

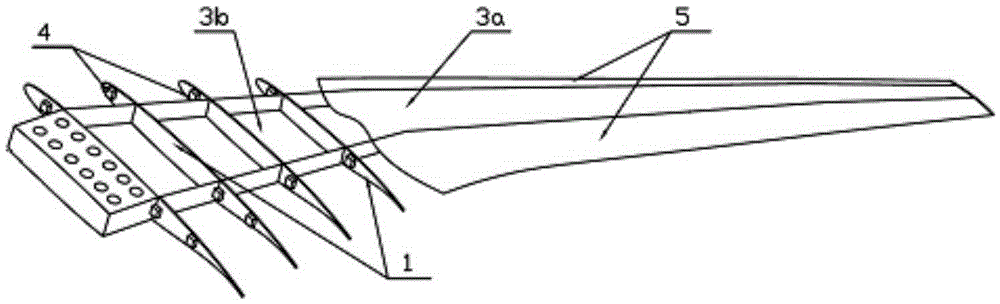

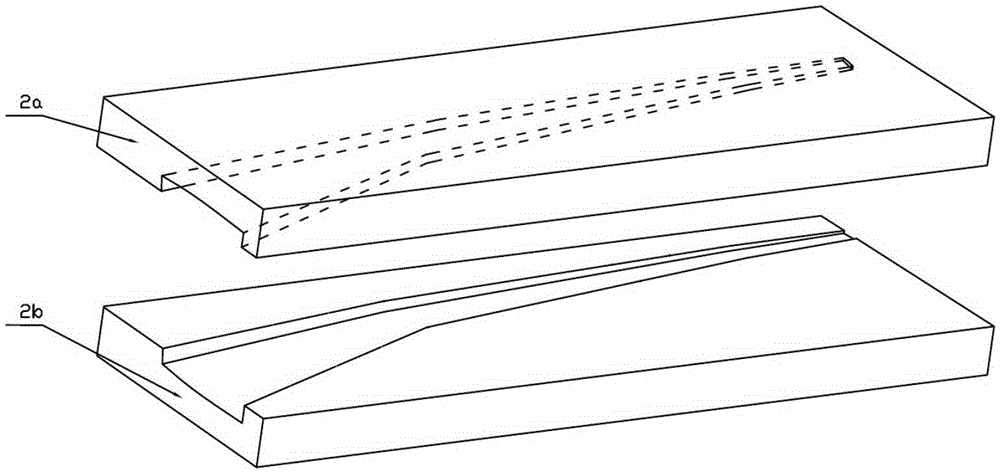

[0030] In the proposal of this application, a method for manufacturing a low-speed flutter wind tunnel model of an airfoil includes the following steps:

[0031] A method for manufacturing a wing low-speed flutter wind tunnel model, comprising the following steps:

[0032] Step 1) adopt energy method or single closed chamber profile method to extract the stiffness distribution and mass distribution of original wing;

[0033] Step 2) Select an appropriate length scaling ratio and velocity scaling ratio according to the target wind tunnel parameters, and calculate the stiffness scaling ratio and mass scaling ratio according to the similarity criterion;

[0034] Step 3) Obtain the target stiffness distribution and the target mass distribution of the flutter model according to the stiffness distribution and mass distribution and the stiffness scaling ratio and the mass scaling ratio of the original wing;

[0035] Step 4) Determine the parameters of the composite material flutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com