Built-up connection structure and built-up connection method for roof support and I-steel purlins

A combined connection and I-beam technology, which is applied to building structures, roofs, building components, etc., can solve problems such as poor technical and economic indicators and increased roofing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

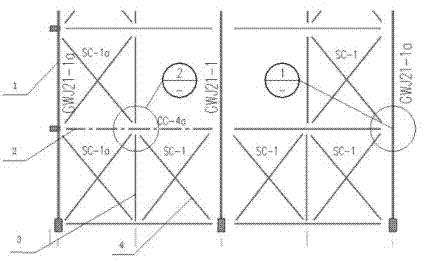

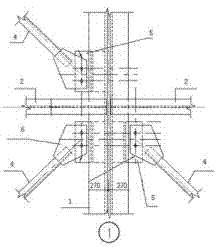

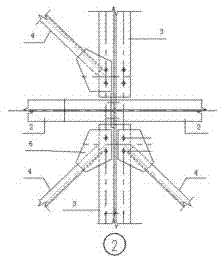

[0025] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a combined connection structure of roof supports and I-shaped steel purlins has several steel roof truss structures connected with several roof support structures to form a network connection structure. connected, and the four corners of the joints where the purlin 2 is connected to the upper chord 1 of the steel roof truss are obliquely connected to the roof support rod 4 through the steel part 5, the connecting plate 6; the roof support structure is connected vertically by the connecting beam 3 and the purlin 2, and The four corners of the node where the purlin 2 is connected to the connecting beam 3 are obliquely connected to the roof support rod 4 through the connecting plate 6;

[0026] Among them, the shaped steel part 5 of the steel roof truss structure is fixed on the upper chord 1 of the steel roof truss, and the shaped steel part 5 is connected with the upper chord 1 of the steel ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com