Parallel chord wood truss and manufacturing method thereof

A string and truss technology, which is applied in the field of parallel string truss and its production, can solve the problems of poor vibration comfort of the floor and achieve the effects of easy production, prevention of lateral instability, and improvement of bending bearing capacity and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

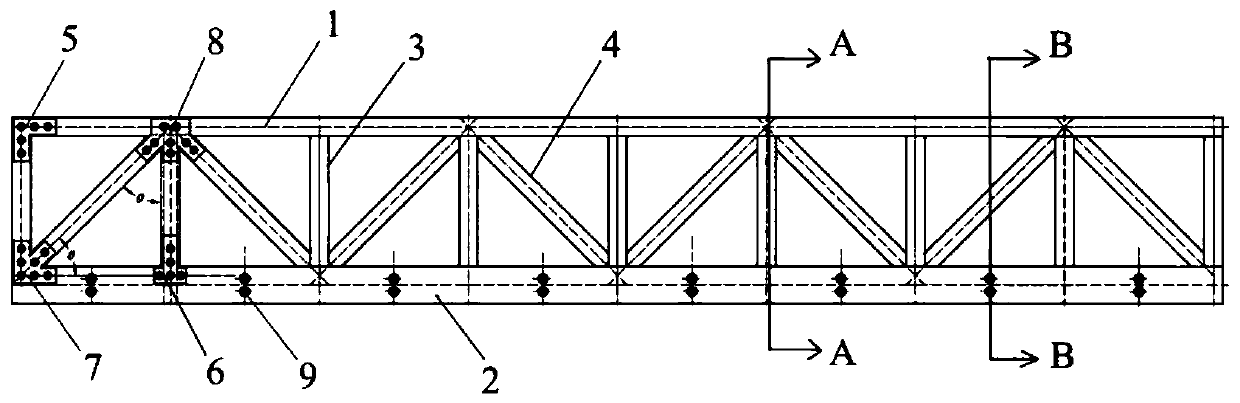

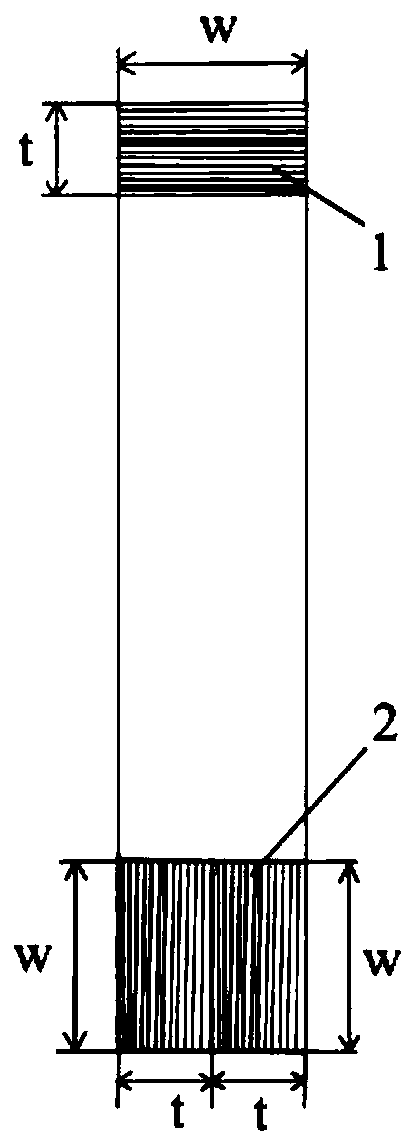

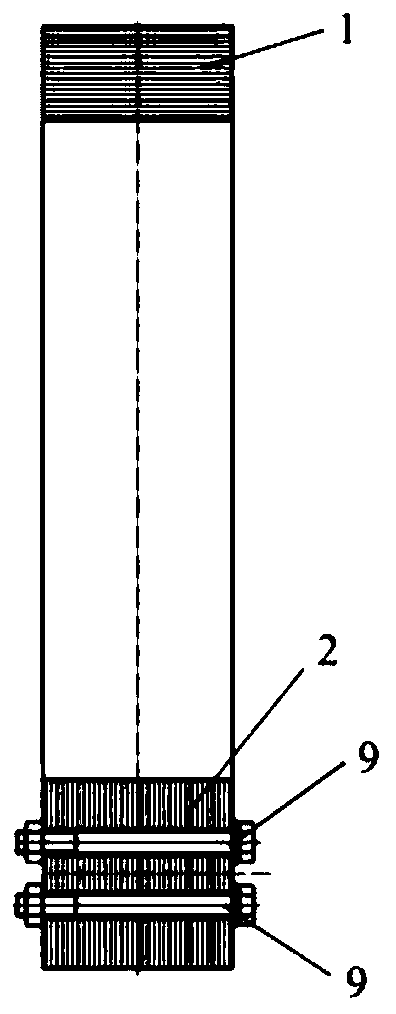

[0071] Example 1: The upper chord 1, the lower chord 2, the straight web 3 and the oblique web 4 are manufactured using LVL with a strength grade of 12E-38f. The thickness t of the LVL is 30 mm, and the width w is 60mm. The fabricated parallel-chord wooden truss has a height of 300mm, a width of 60mm and a length of 6 meters. When a uniformly distributed load of 1.9kPa is used, the mid-span deformation of the parallel-chord wooden truss is measured to be 2.7711mm. The ultimate load of this parallel-chord wooden truss is 6.97kN. The mid-span deformation refers to the deformation in the middle of the length direction of the parallel string wooden truss.

[0072] As a comparison, the tooth plate in the prior art is used to connect the wooden truss, and the sawn timber made of the wooden truss has a thickness of 38mm and a width of 60mm. The sawn timber can use SPF (Spruce-Pine-Fir, spruce-pine-fir) boards. The height, width and length of the finished wooden trusses are consis...

Embodiment 2

[0073]Example 2: The upper chord 1, the lower chord 2, the straight web 3 and the oblique web 4 are manufactured using LVL with a strength grade of 14E-42f. The thickness t of the LVL is 40 mm, and the width w is 80mm. The fabricated parallel-chord wooden truss has a height of 400mm, a width of 80mm, and a length of 8 meters. When a uniformly distributed load of 1.9kPa is used, the mid-span deformation of the parallel-chord wooden truss is measured to be 3.4321mm. The ultimate load of this parallel-chord wooden truss is 14.2kN.

[0074] As a comparison, the tooth plate in the prior art is used to connect the wooden truss, and the sawn timber made of the wooden truss has a thickness of 38mm and a width of 80mm. The height, width and length of the finished wooden trusses are consistent with the above-mentioned parallel-chord wooden trusses. When a uniformly distributed load of 1.9kPa is used, the mid-span deformation of the wooden truss is measured to be 5.8212mm. The ultima...

Embodiment 3

[0075] Example 3: The upper chord 1, the lower chord 2, the straight web 3 and the oblique web 4 are made by using LVL with a strength grade of 15E-45f. The thickness t of the LVL is 45 mm, and the width w is 90mm. The fabricated parallel-chord wooden truss has a height of 450mm, a width of 90mm and a length of 8 meters. When a uniformly distributed load of 1.9kPa is used, the mid-span deformation of the parallel-chord wooden truss is measured to be 2.6987mm. The ultimate load of this parallel-chord wooden truss is 21.84kN.

[0076] As a comparison, the tooth plate in the prior art is used to connect the wooden truss, and the sawn timber made of the wooden truss has a thickness of 38 mm and a width of 90 mm. The height, width and length of the finished wooden trusses are consistent with the above-mentioned parallel-chord wooden trusses. When a uniformly distributed load of 1.9kPa is used, the mid-span deformation of the wooden truss is measured to be 5.1932mm. The ultimate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com