Buckling-restrained steel frame beam column connecting structure

A beam-column connection and anti-buckling technology, which is applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of not making good use of the flexural bearing capacity of beams, not making full use of the advantages of beam-column joints, and not making good use of earthquake resistance, etc. , to achieve the effect of material saving, low cost and good dissipation of seismic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

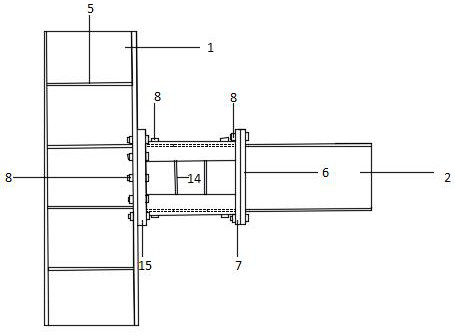

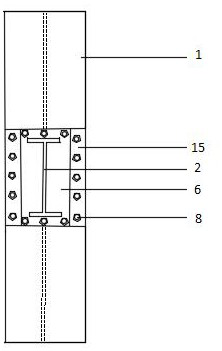

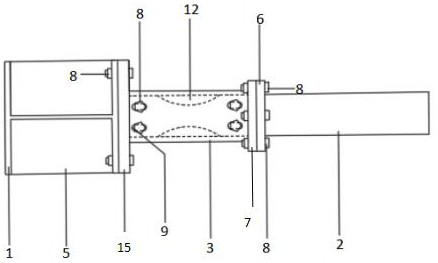

[0021] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0022] The present invention relates to a buckling-resistant steel frame beam-column connection structure, comprising an I-shaped steel column 1, an I-shaped steel beam 2, and an anti-buckling connector. The connection between the I-shaped steel column 1 and the I-shaped steel beam 2 is The anti-buckling connectors are connected, and the buckling-resistant connectors include a buckling-constrained channel steel 3, a side-constrained buckling channel steel 4, and an energy dissipator 11. The energy dissipator 11 is a section of I-shaped steel, and the The side edges of the upper and lower flange plates of the shaped steel are respectively made with arc-shaped grooves to weaken the mouth, and the four corners of the upper and lower flange plates of the I-shaped steel of the energy dissipator are respectively made with long screw holes 9, and the I-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com