Bearing type motion decoupling vertical vibration isolation device

A vibration isolation and vertical technology, applied in the direction of bearings, shafts and bearings, linear motion bearings, etc., can solve problems such as low initial vibration isolation frequency, lateral instability of coil springs, and centroid deviation of disc springs. To achieve the effect of ensuring stability, ensuring work performance, and optimizing alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present application will be further described below in conjunction with the embodiments shown in the accompanying drawings.

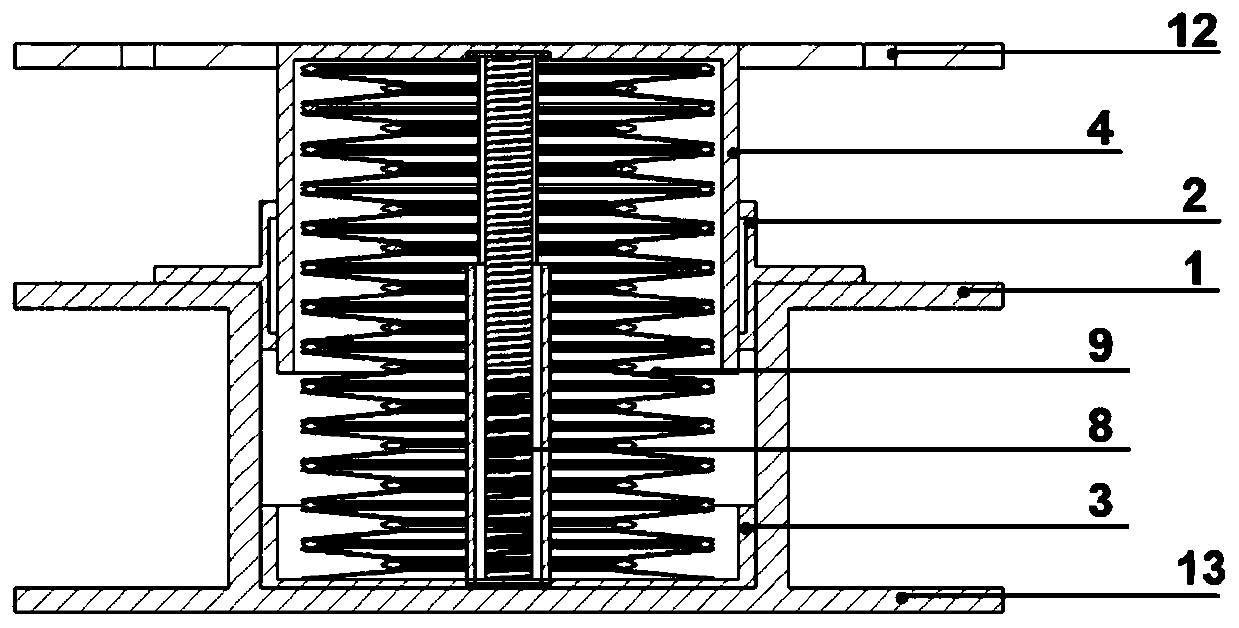

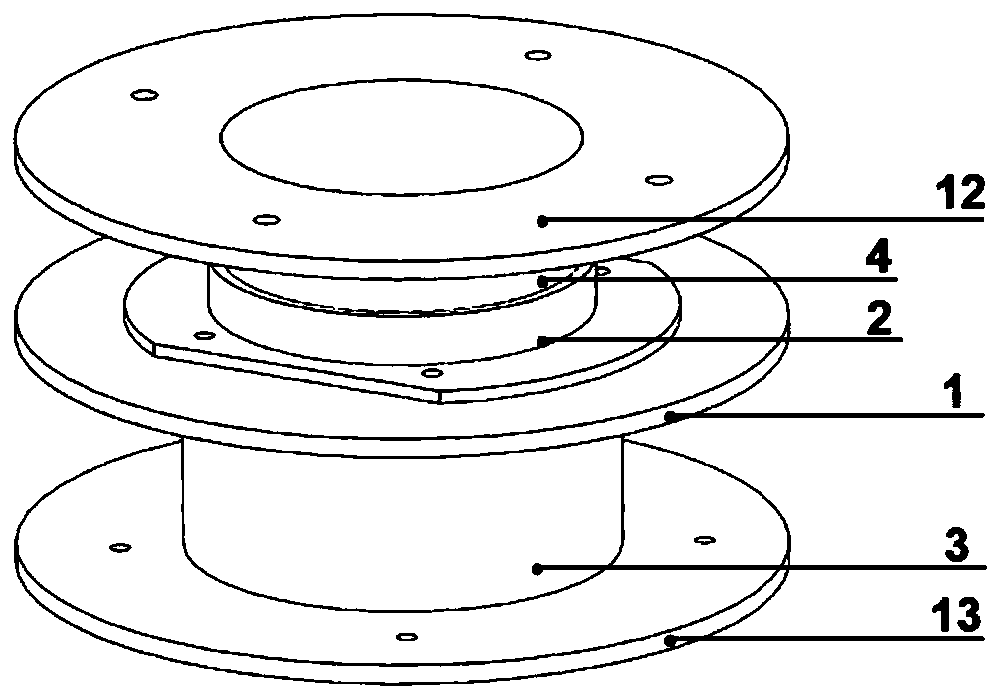

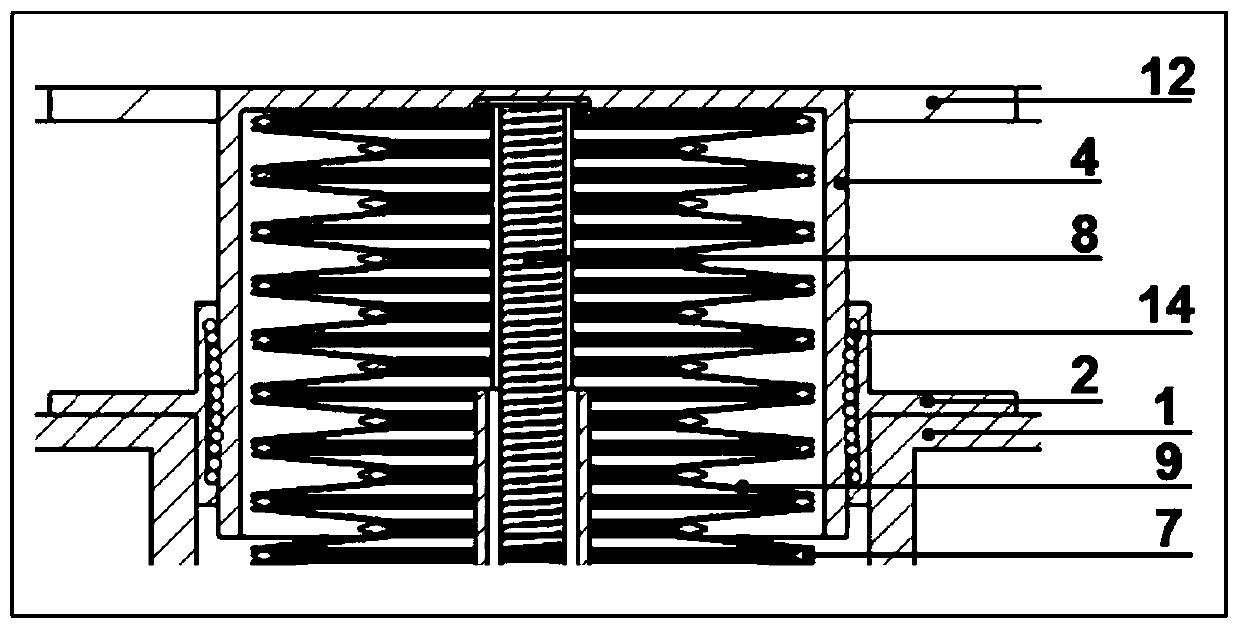

[0026] figure 1 As shown, the application includes: a vertical vibration isolation mechanism, a connection and fixing mechanism, an anti-stability mechanism, a positioning mechanism, and a motion decoupling mechanism. The vertical vibration isolation mechanism is the core mechanism located at the center of the entire device, which is responsible for providing the vertical self-adaptive stiffness characteristics required for vibration isolation; The bottom is respectively fixed on the structure, and at the same time, its top, bottom and the vertical vibration isolation mechanism in the middle realize the transmission and bearing of vertical force; the anti-instability mechanism and positioning mechanism are arranged around the elastic elements in the vertical vibration isolation mechanism , the two cooperate to ensure the stability of the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com