High-speed locomotive motor suspension device

A high-speed locomotive and suspension device technology, applied in locomotives, motor vehicles, electric locomotives, etc., can solve the problems of inability to meet the requirements of high-speed locomotives, complex elastic axle suspension structures, and overload of DC traction motors, and achieve excellent lateral dynamic performance. , Improve the lateral dynamic performance, the effect of low wheel-rail action force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

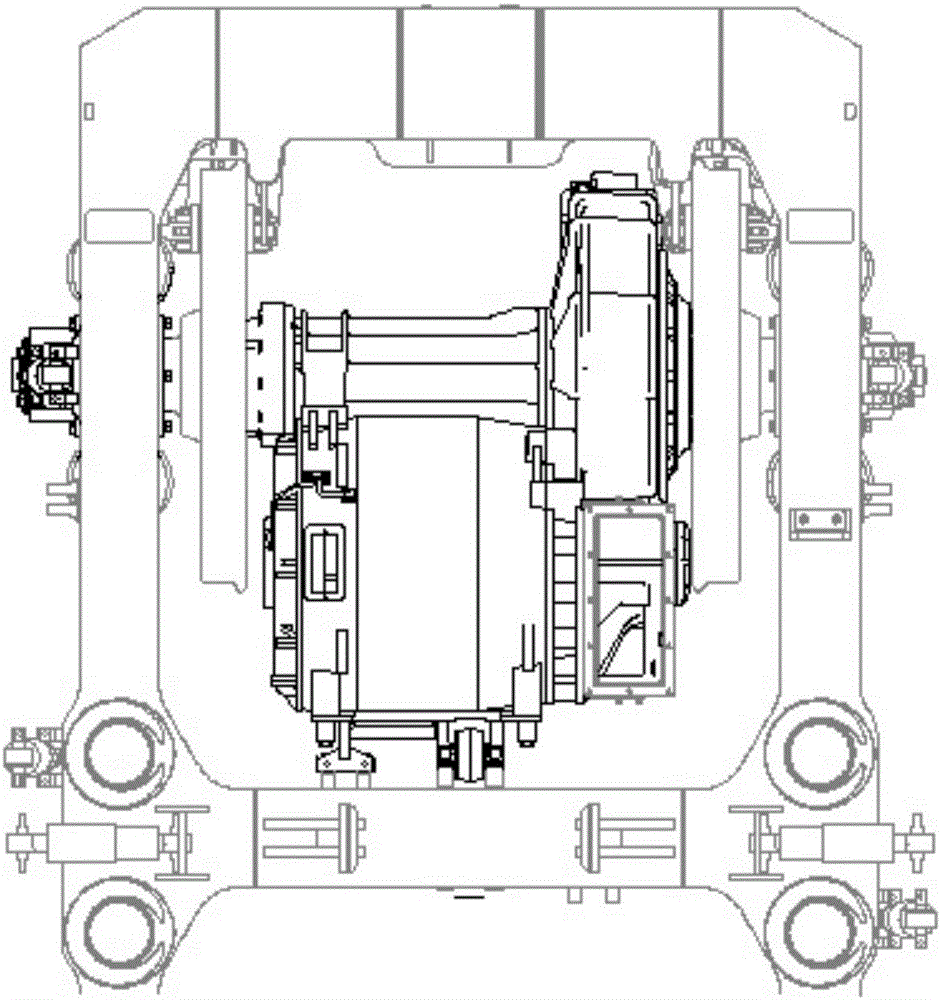

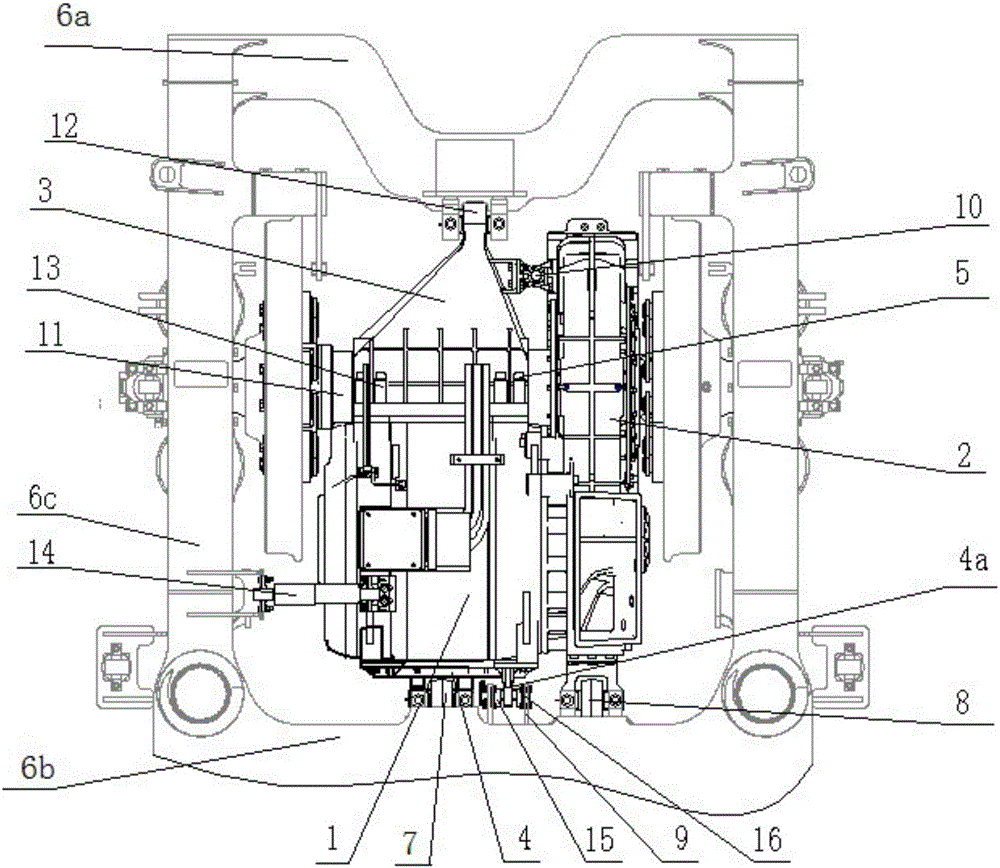

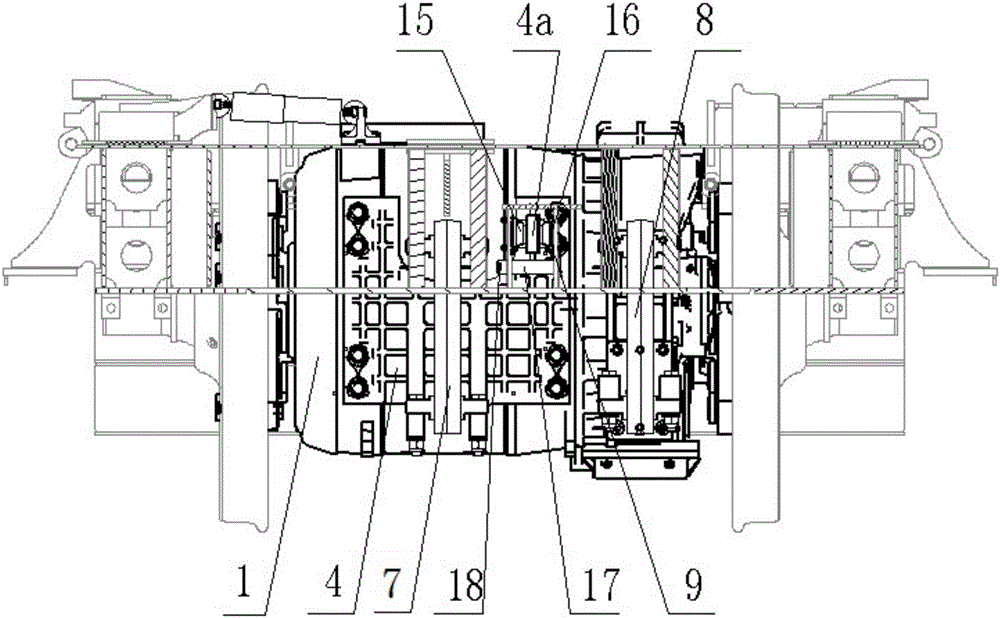

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] like figure 2 , image 3 As shown in the motor suspension device of a high-speed locomotive, the motor 1 and the gearbox 2 are rigidly connected, the motor 1 and the front support base 3 are connected by bolt sleeves 13 and hexagon socket bolts 5, and the motor 1 and the rear support base 4 are connected by anti-loosening bolts , the motor 1 is suspended on the frame front beam 6a through the front support base 3, the motor 1 is suspended on the frame beam 6b through the rear support base 4 connected to the motor suspender 7, and the gearbox 2 is suspended on the framework through the gear box suspender 8 On the beam 6b, the baffle plate 4a on the rear support seat 4 is clamped in the middle of the transverse stopper seat 9 on the frame beam 6b, and a certain gap is maintained.

[0023] The front support seat 3 is connected with the gear box 2 through the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com