Web beam structure anti-destabilization clamper under fatigue shear load effect

A technology of shear load and beam structure, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as lateral instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

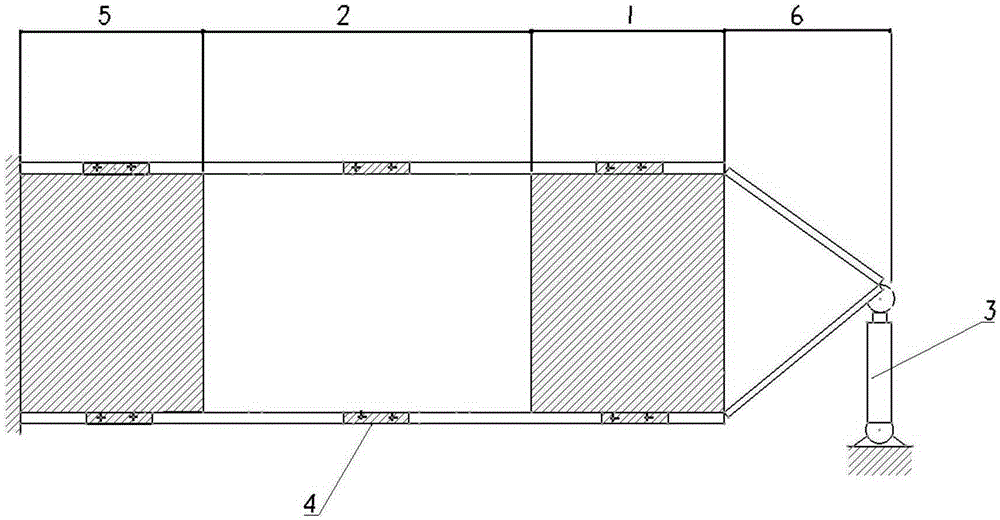

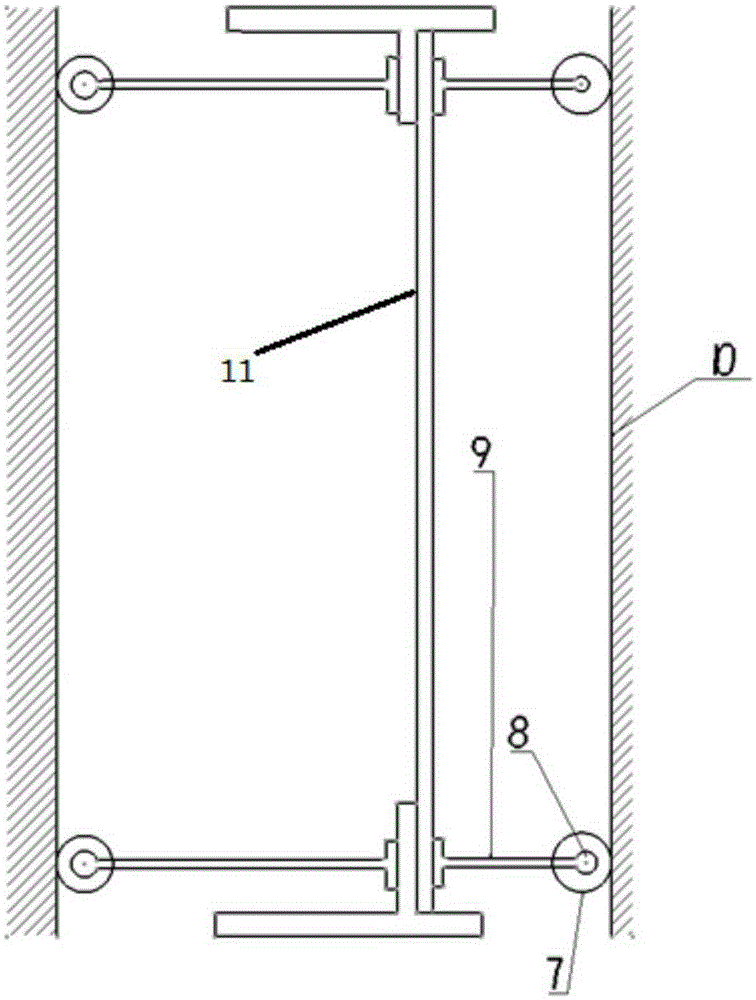

[0015] Before the test, select the largest unit fatigue load for analysis, determine the deformation of the test piece, and then determine the size of the clamping plate, so that the rollers have enough space to roll on the clamping plate to prevent the rollers from slipping out due to excessive deformation Clamping plate; at the same time, calculate and analyze to determine the load on the fixture, which is used to select rollers, spherical hinges, brackets, etc. that meet the requirements. When the test piece is installed, adjust the bracket to ensure that the rollers are in close contact with the clamping plate.

[0016] During the fatigue test, the load acts on the web beam test piece. Because of the roller 7, the anti-instability fixture can move in the web surface together with the test piece. When the plate is deformed outside the plane, the bracket 9 (rigid support rod) limits the out-of-plane deformation of the flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com