Industrialized assembling type special-shaped column steel structure-steel plate shear wall steel structure system

A steel plate shear wall and industrial assembly technology, applied in the direction of walls, columns, pier columns, etc., can solve the problems of environmental pollution, slow construction speed, large deformation, etc., and achieve the effects of ensuring construction quality, increasing net height, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing:

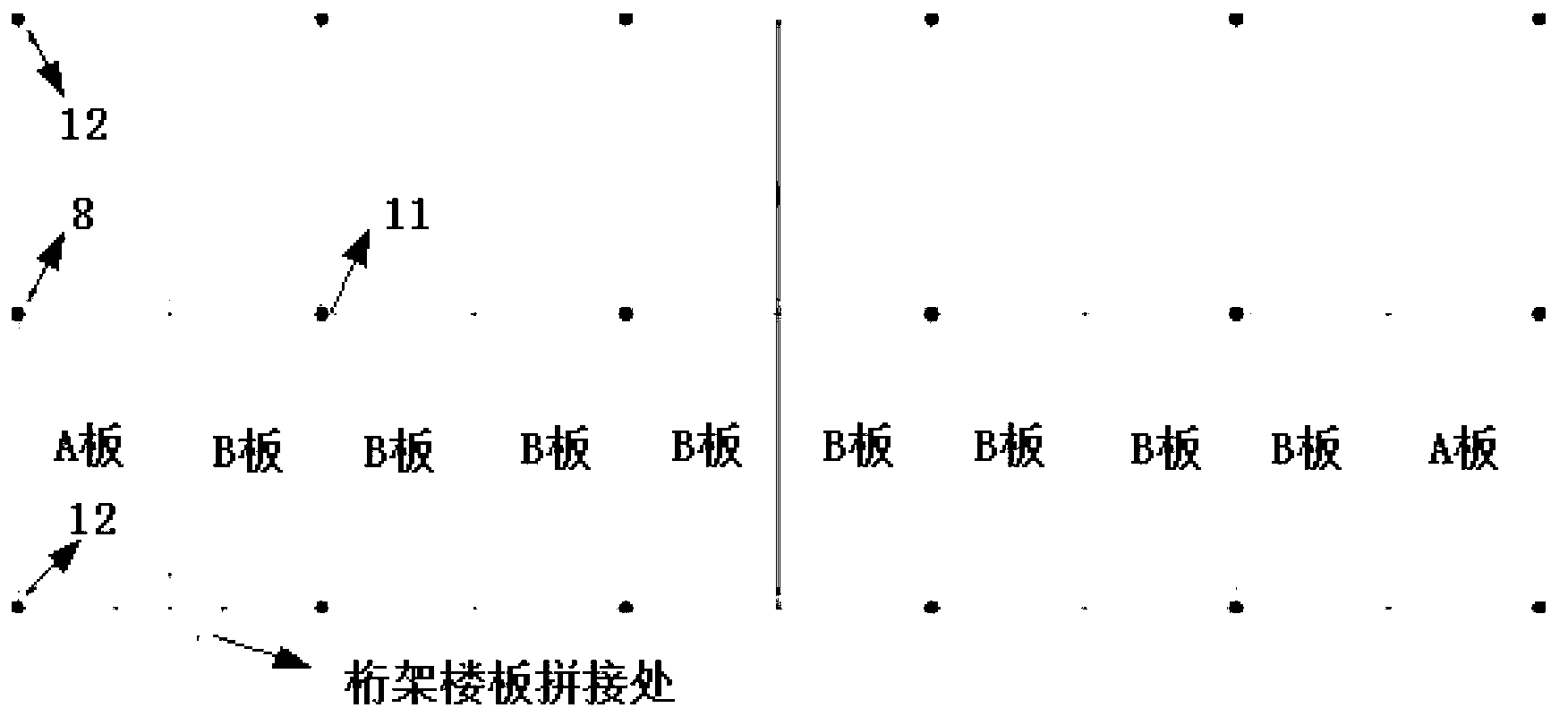

[0050] as attached figure 1 As shown, the assembled truss plate of the present invention is spliced with the assembled column in the manner of ABB···BBA.

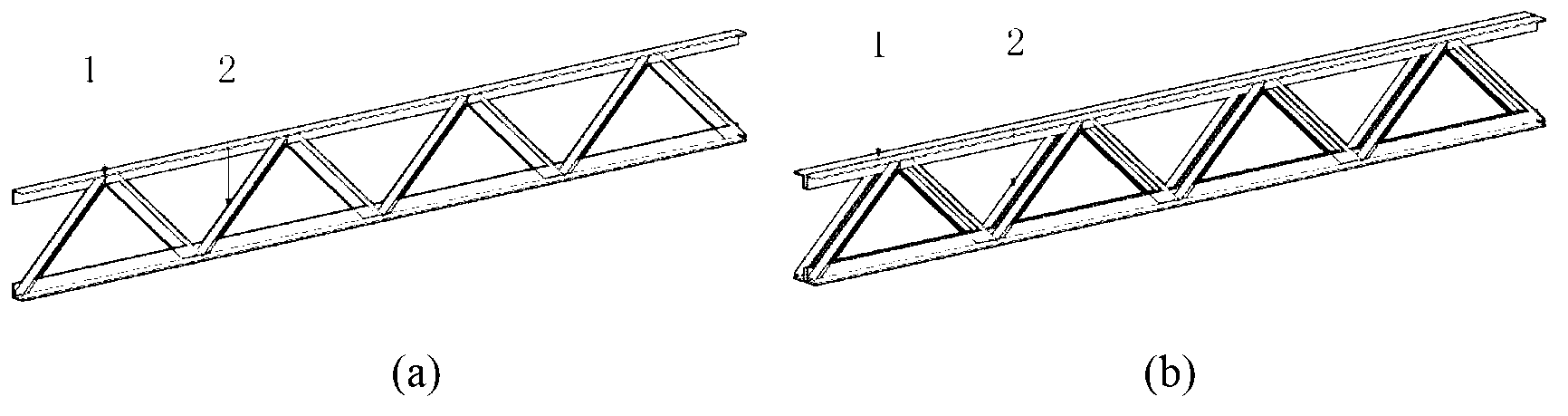

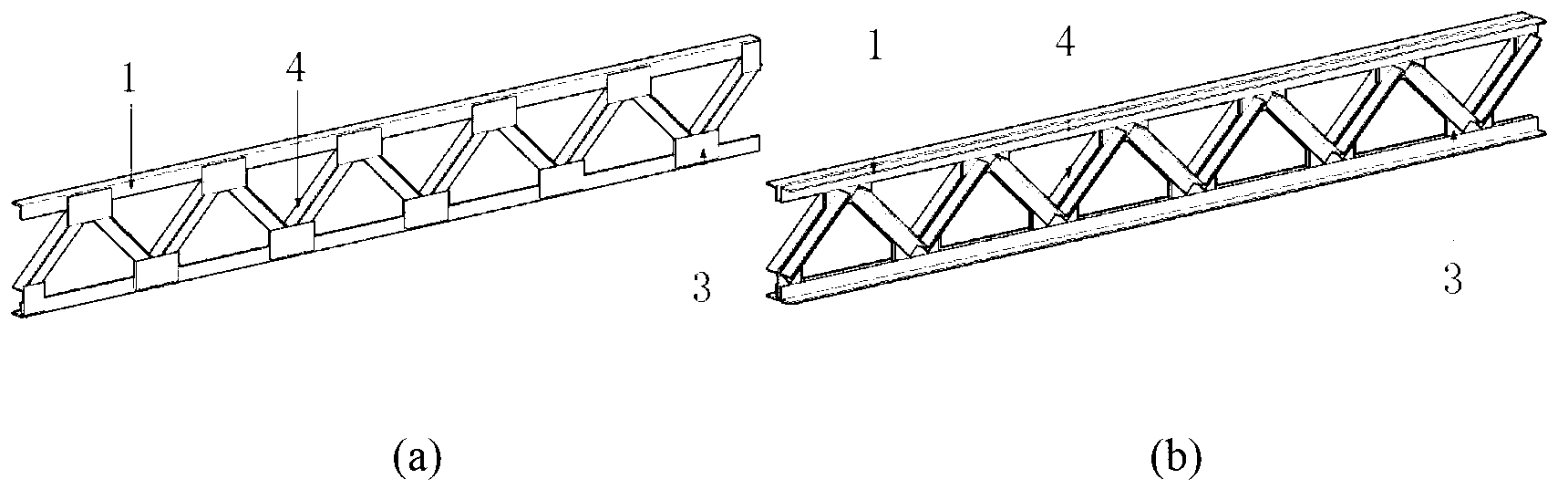

[0051] as attached Figure 4 As shown, in the industrialized assembled special-shaped column frame-steel plate shear wall steel structure system described in the present invention, the involved beam is a truss beam composed of channel steel and angle steel splicing, including upper and lower chords 5 and webs 4, wherein The upper and lower chords 5 are made of channel steel, and the web members 4 are made of angle steel, which are divided into single-channel steel beams and double-channel steel beams. The single-channel steel beams are provided with connecting holes at intervals of a fixed distance, so that the two plates can be connected by bolts when splicing the plates. Single-channel steel beams are spliced into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com