Patents

Literature

76results about How to "Reducing Hazardous Accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

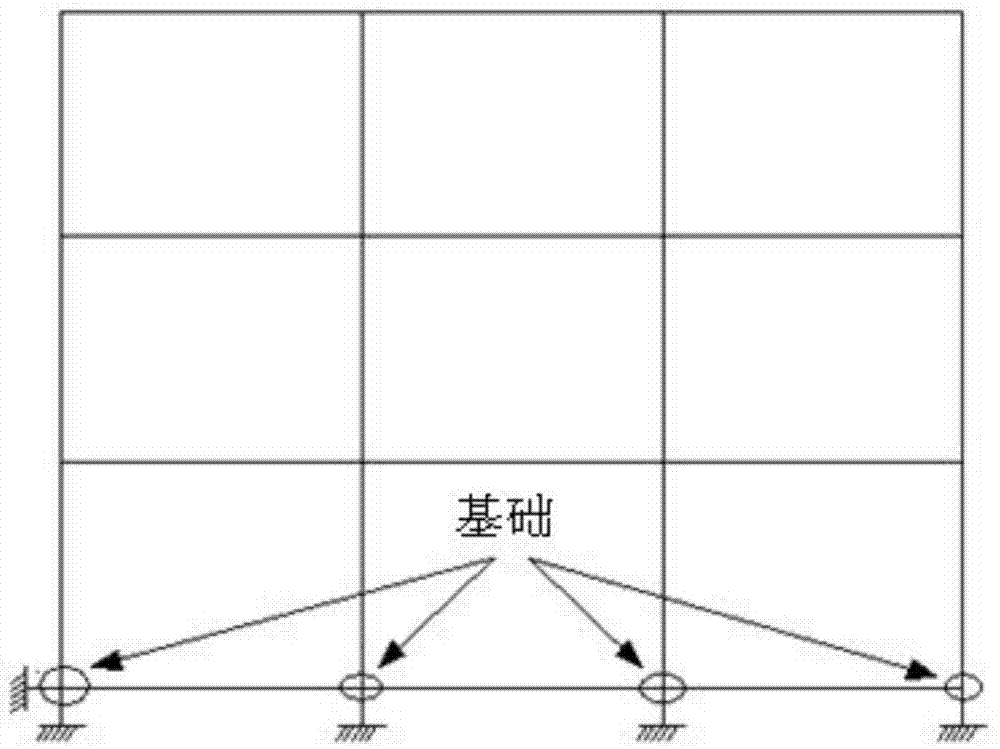

Industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system

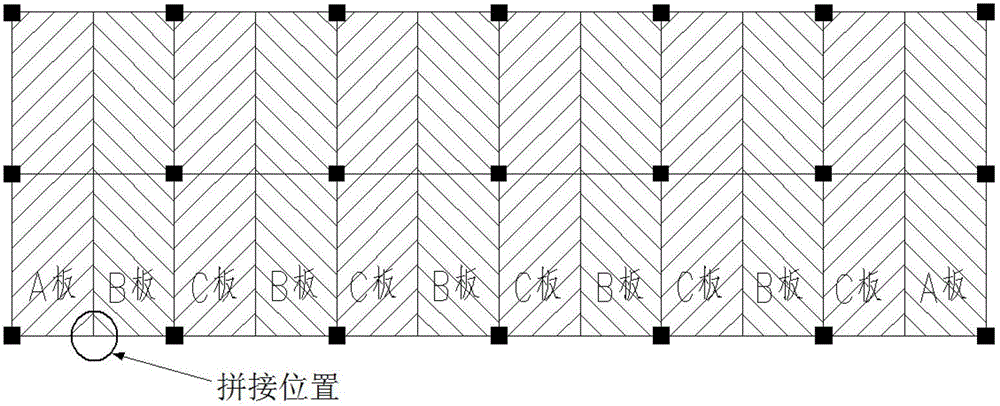

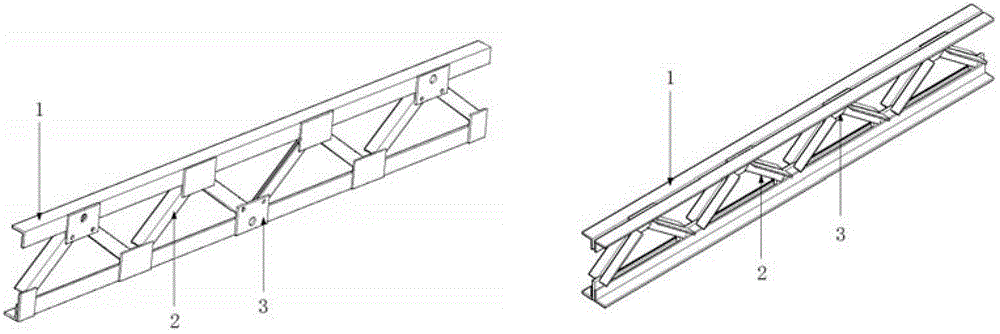

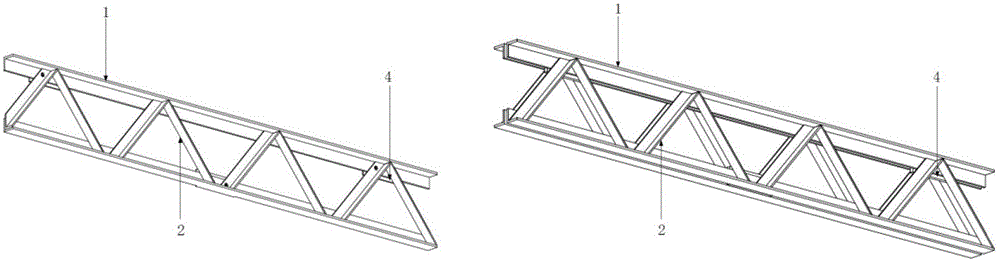

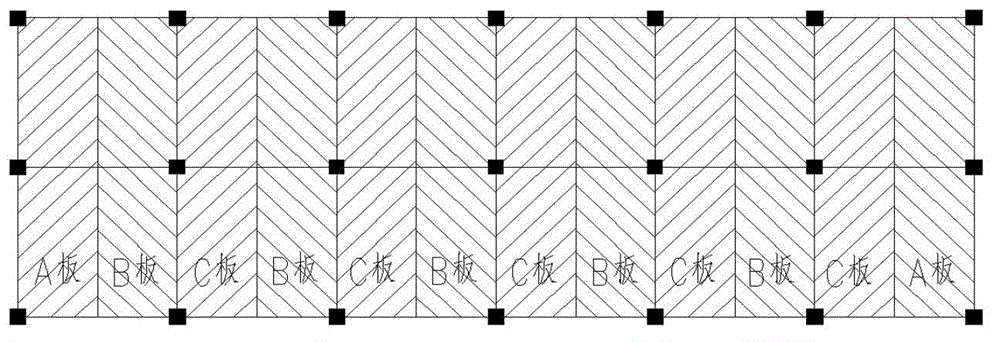

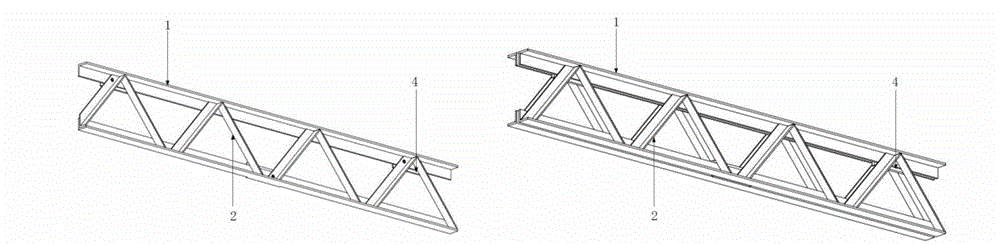

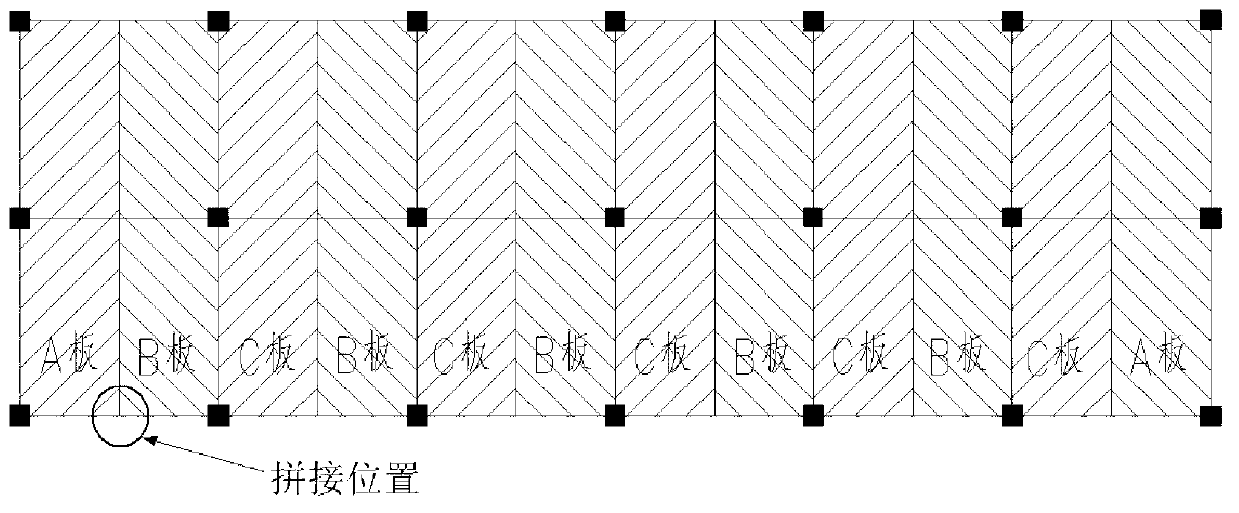

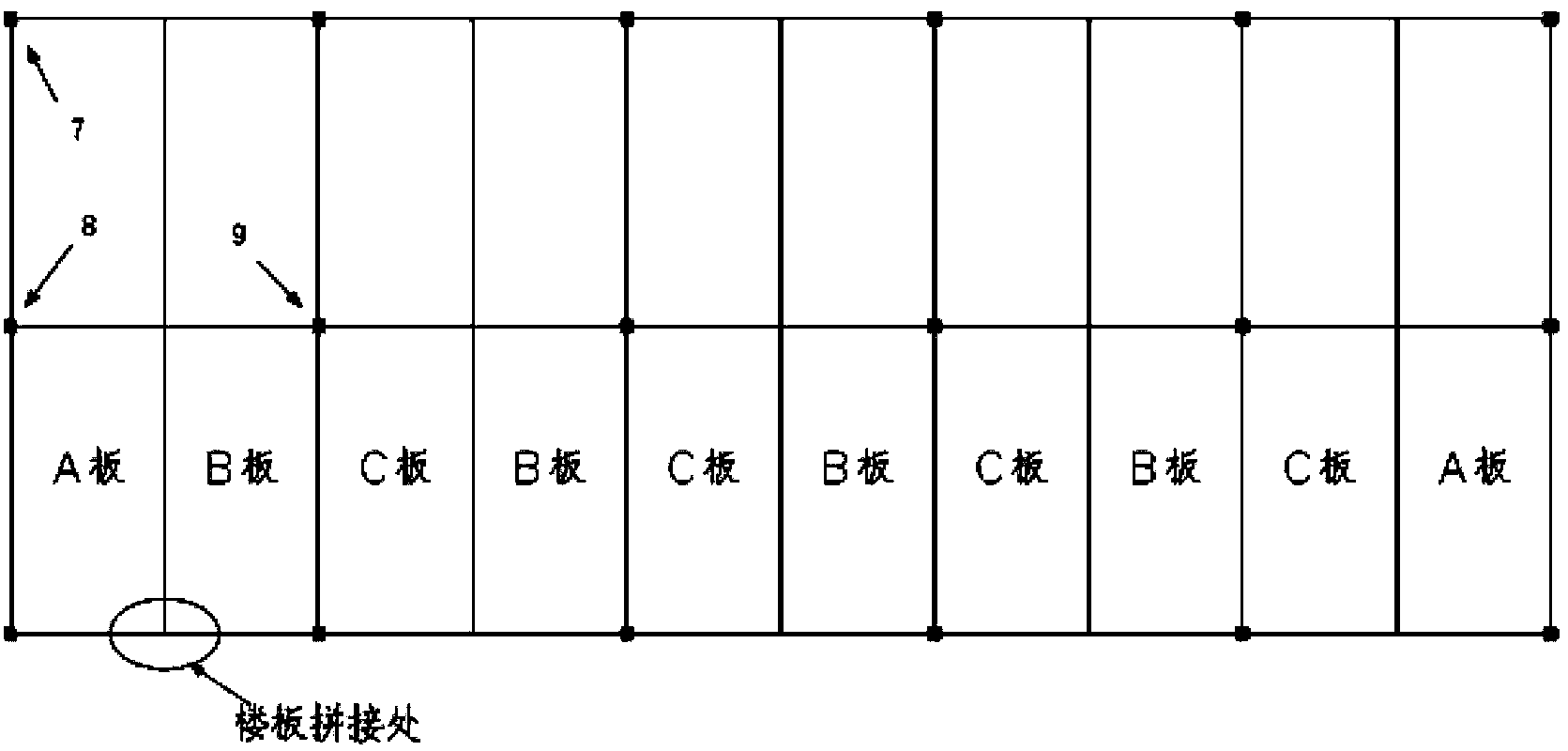

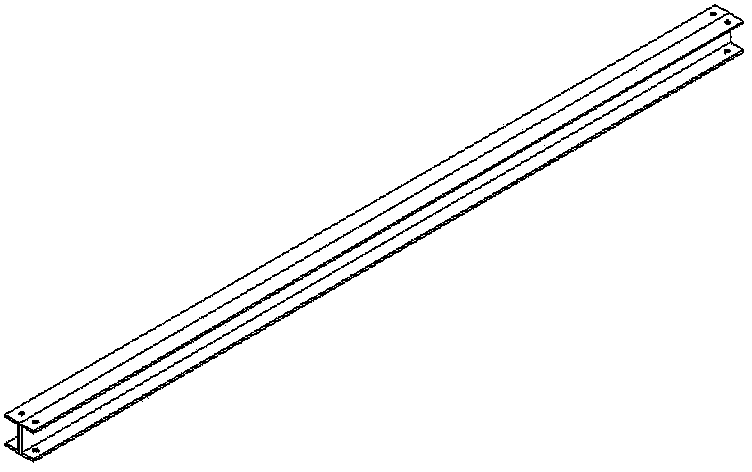

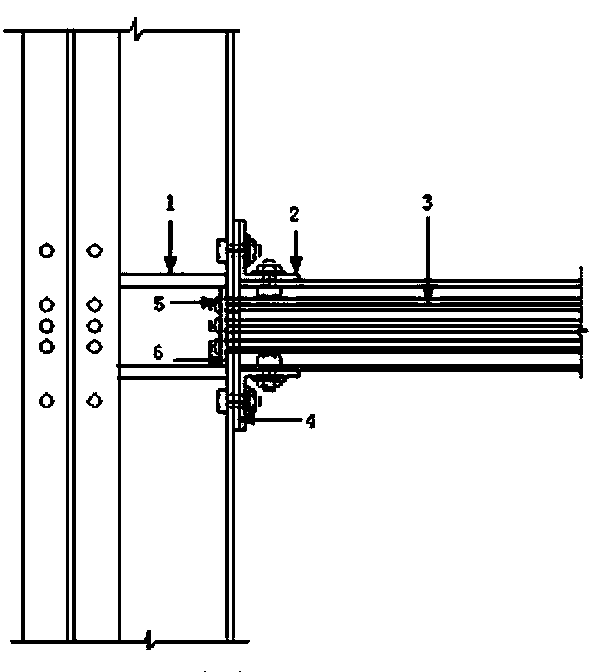

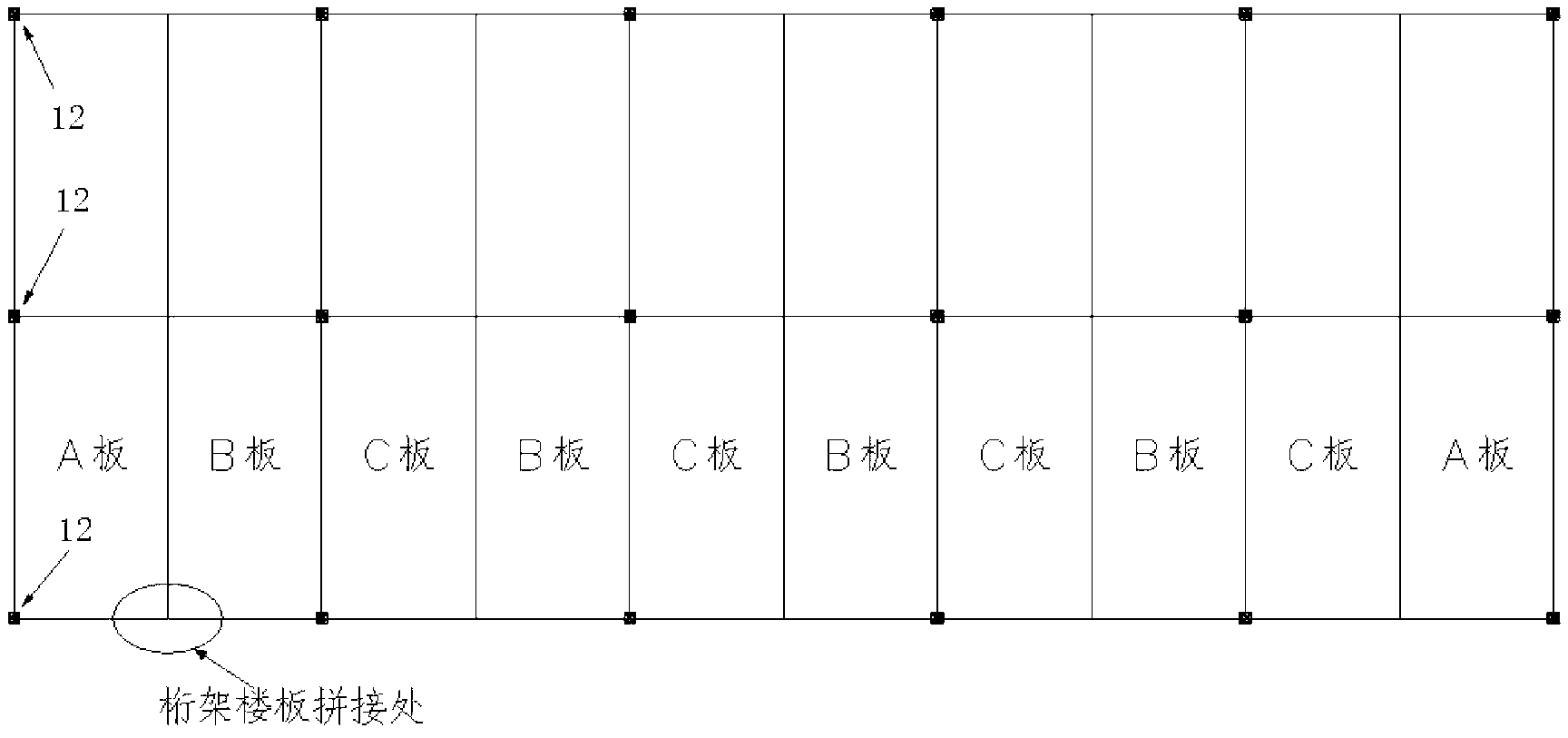

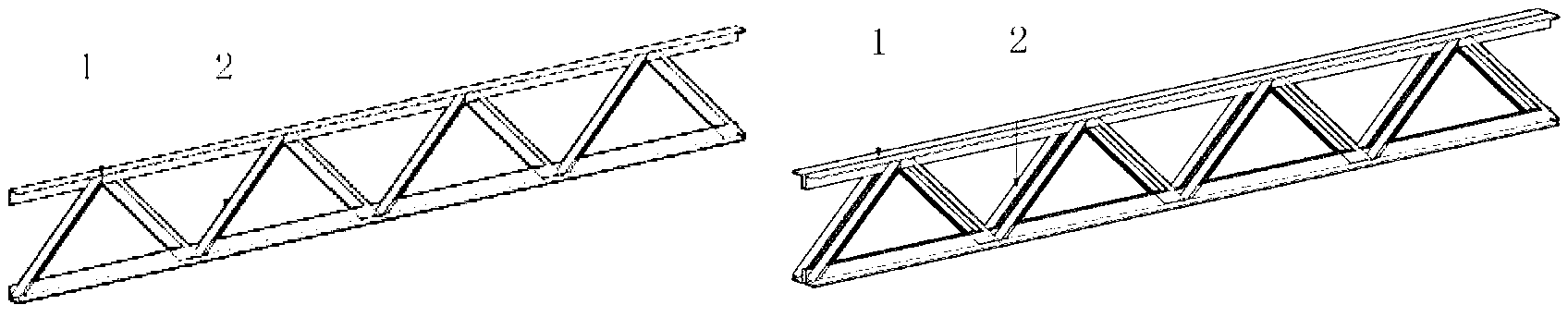

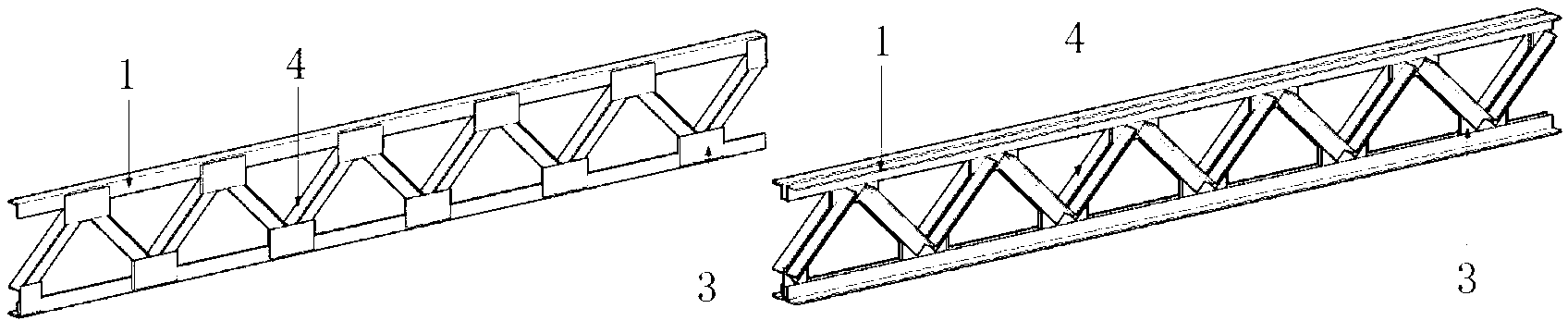

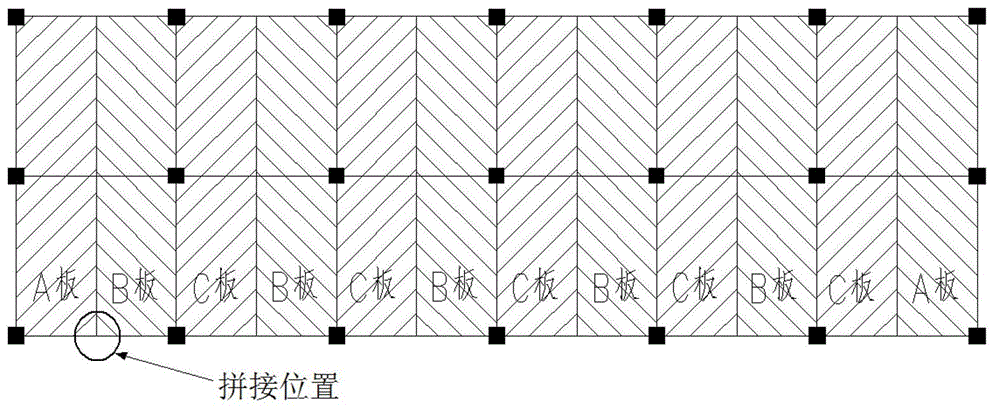

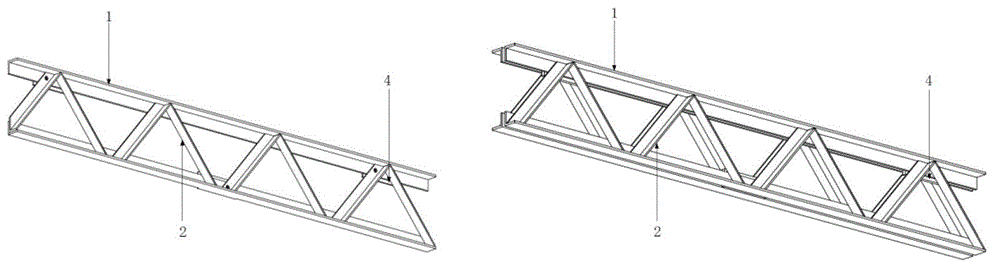

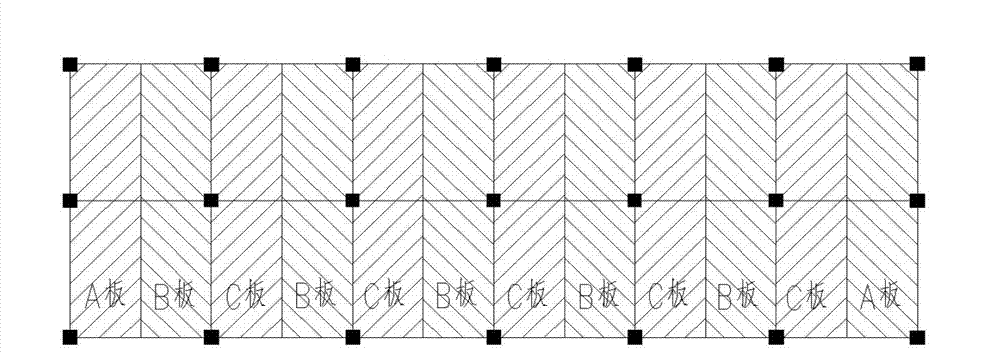

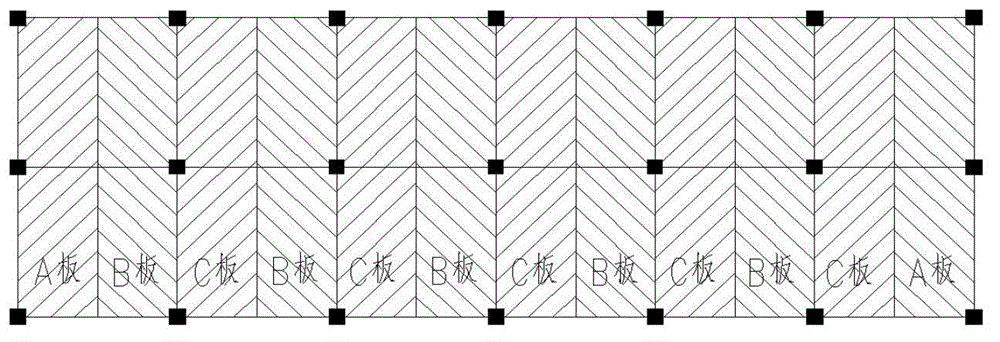

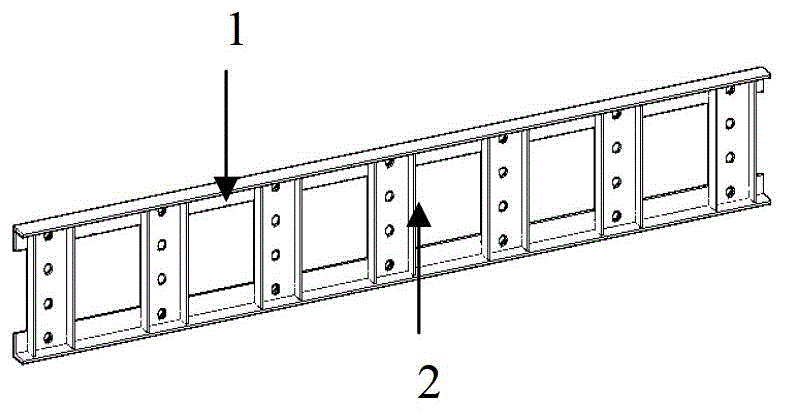

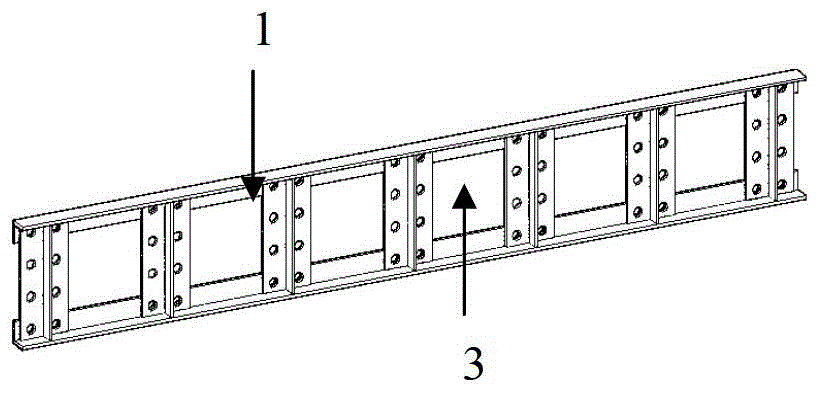

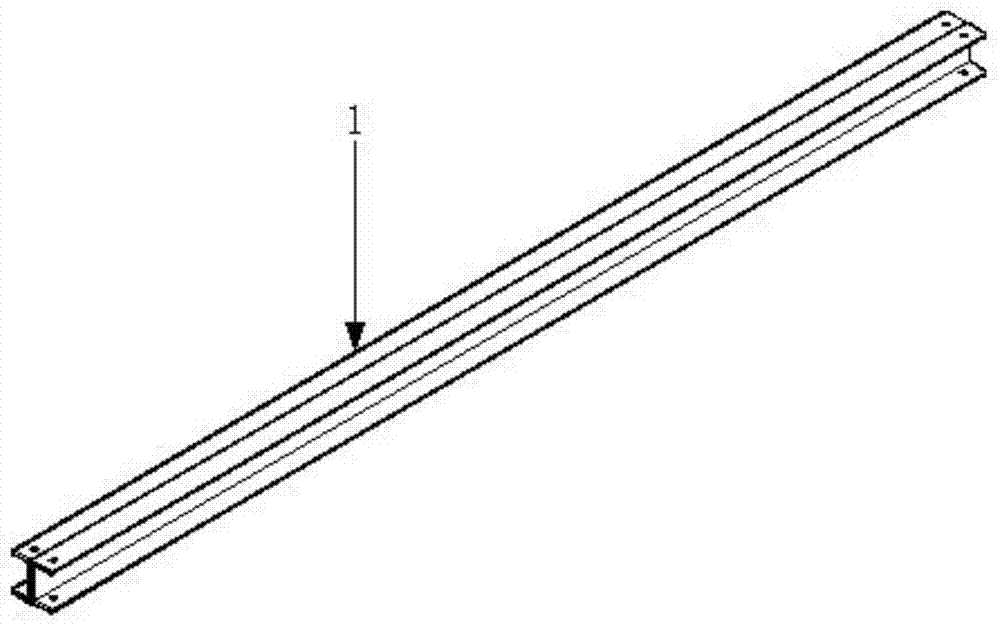

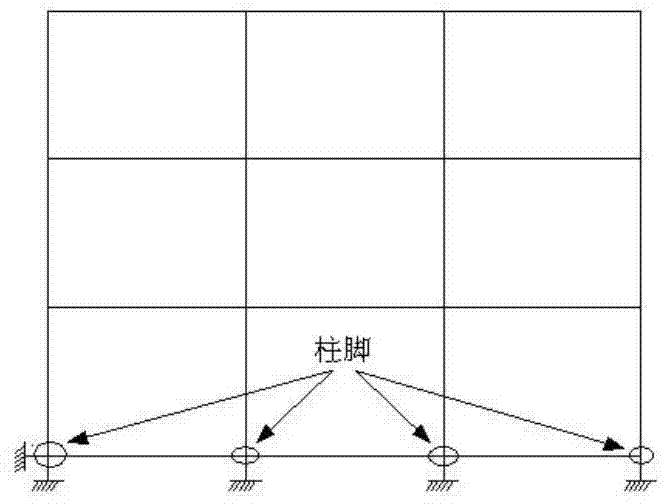

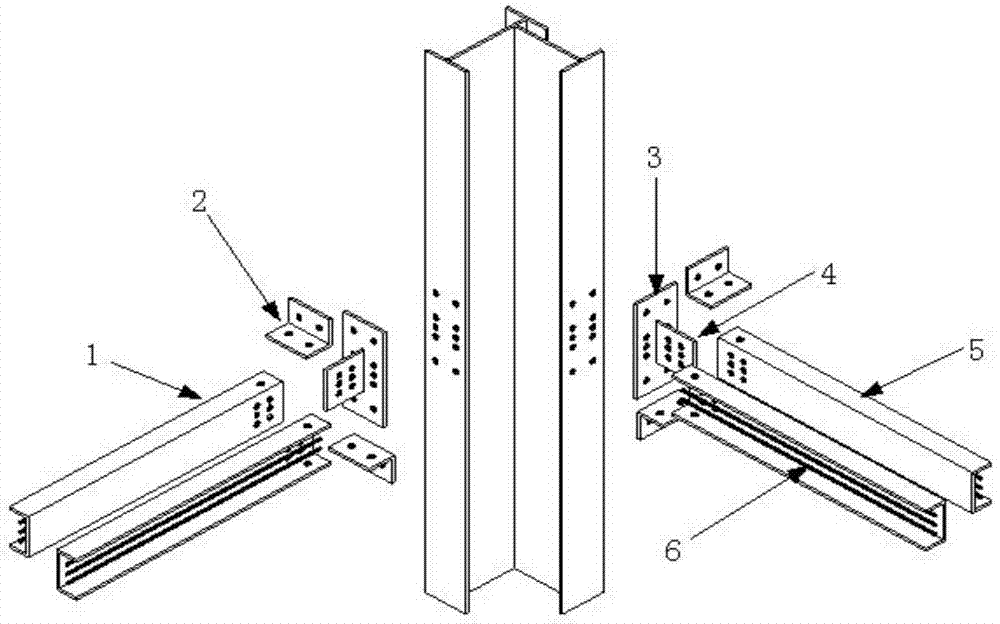

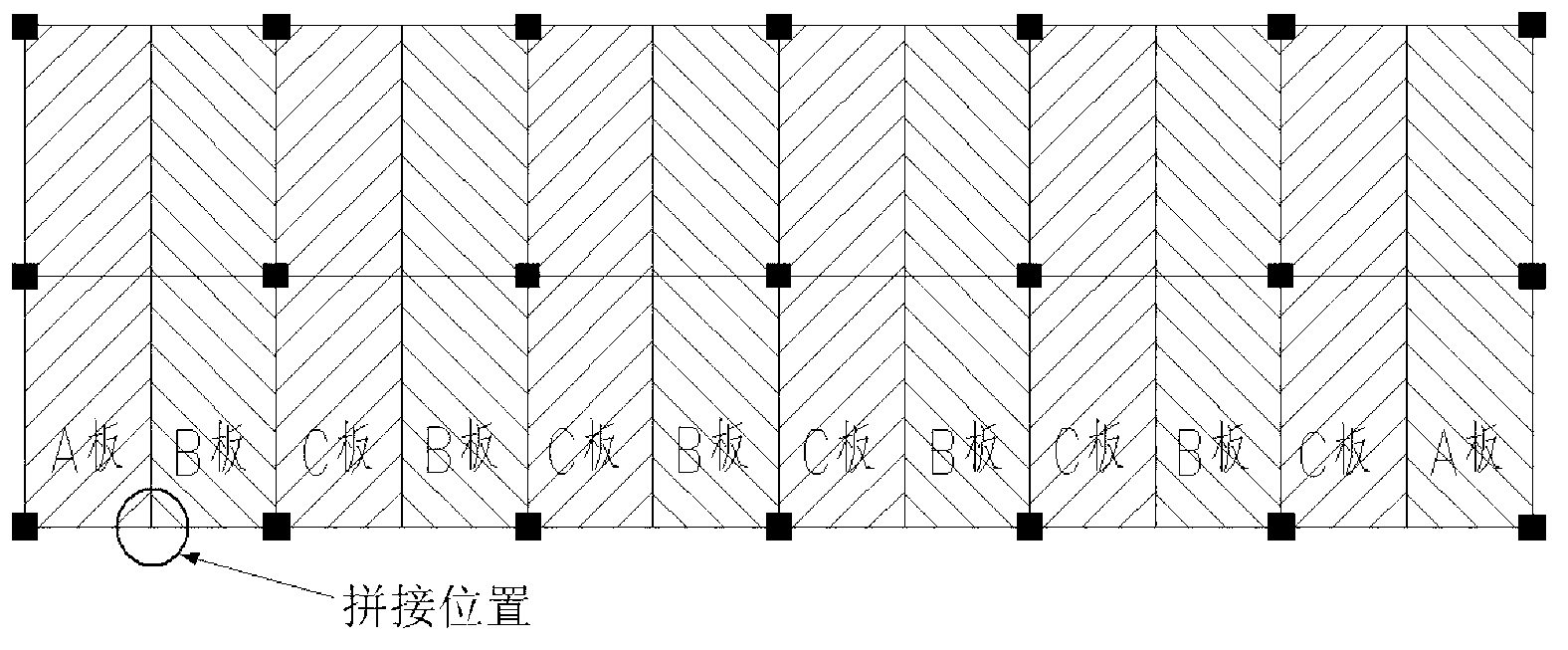

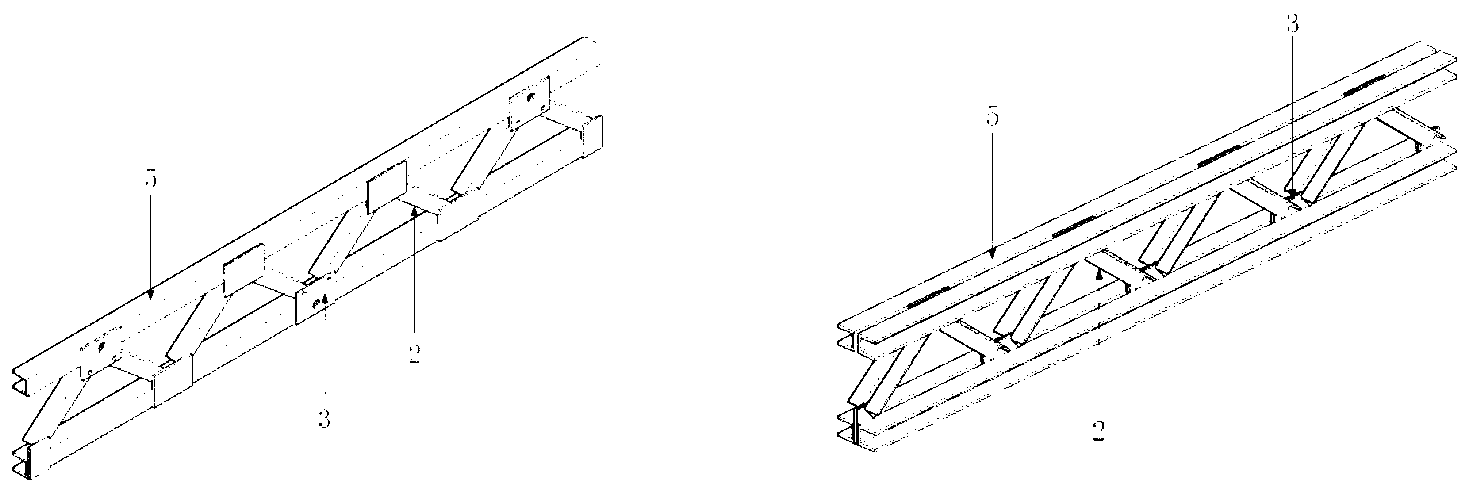

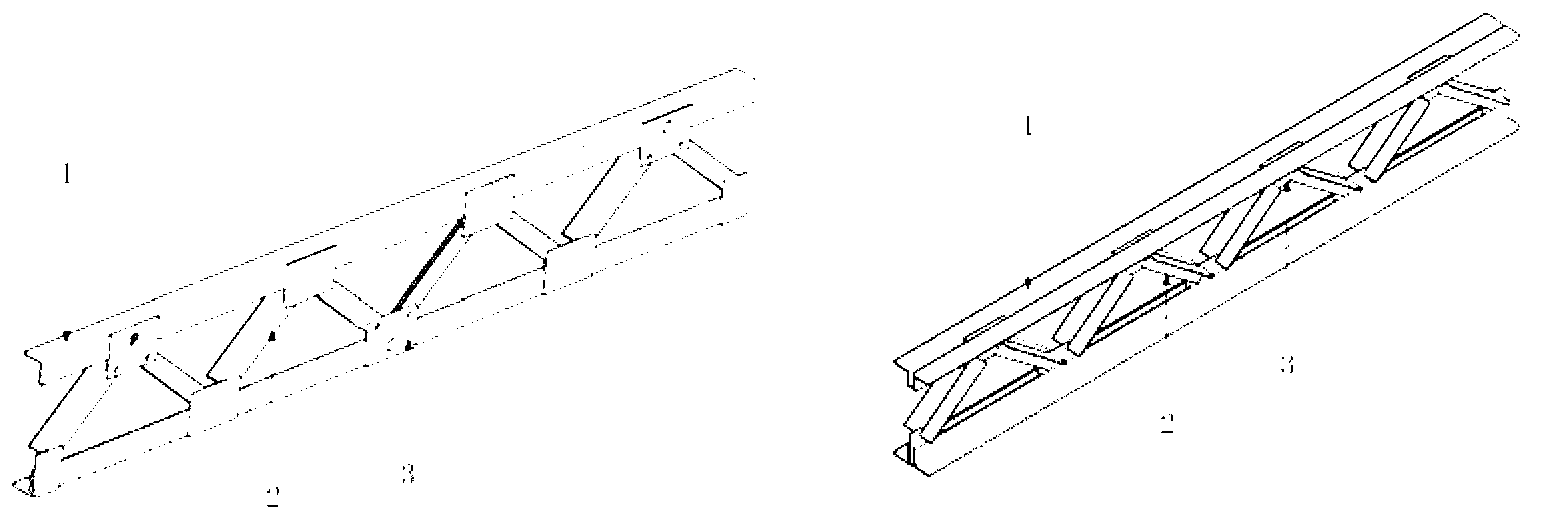

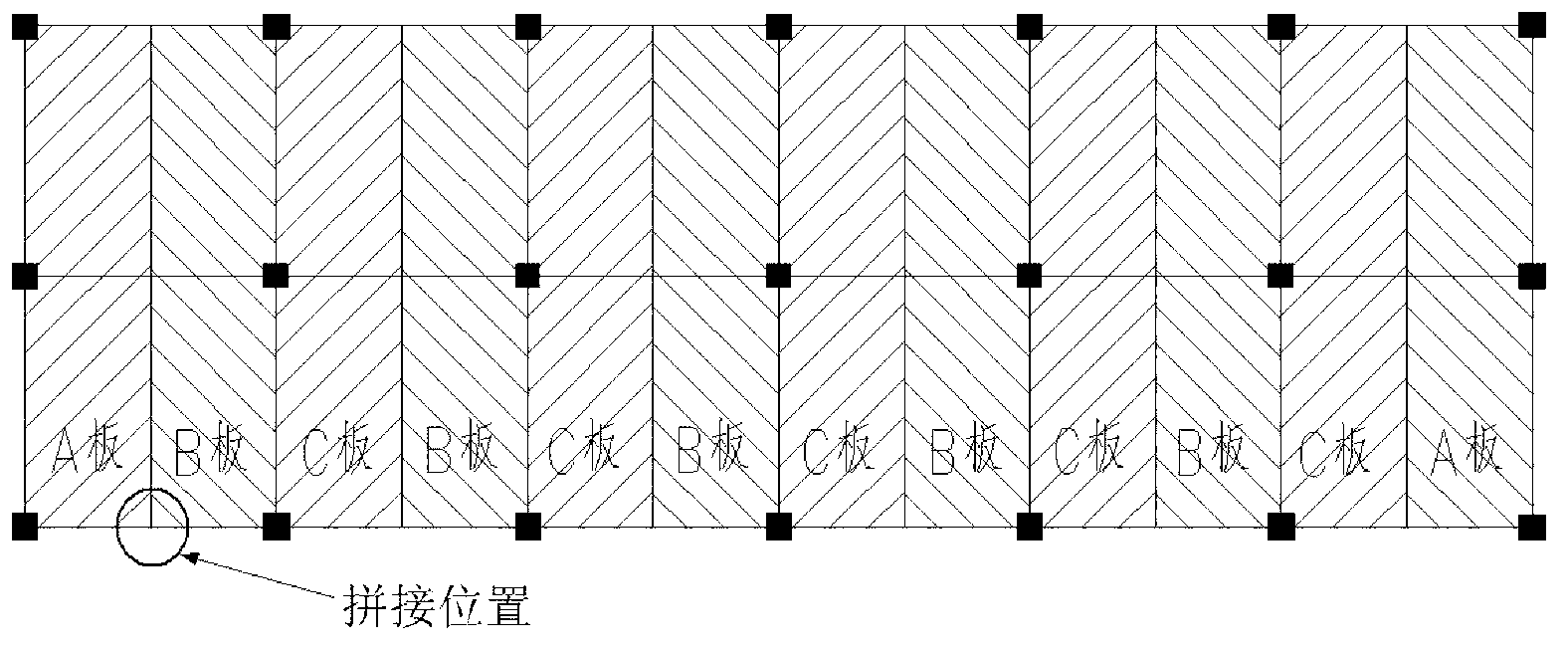

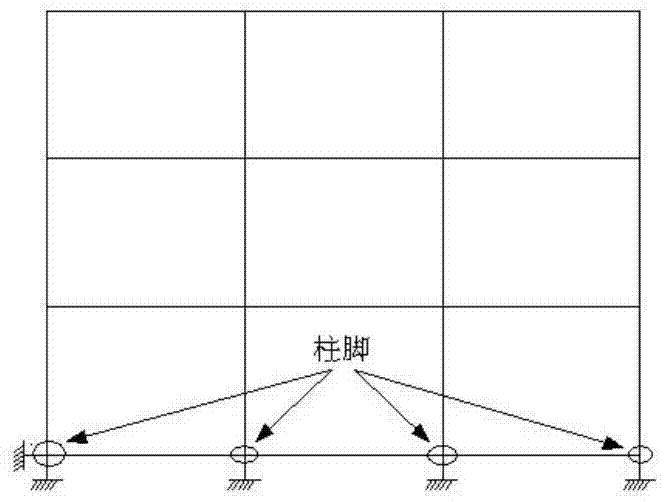

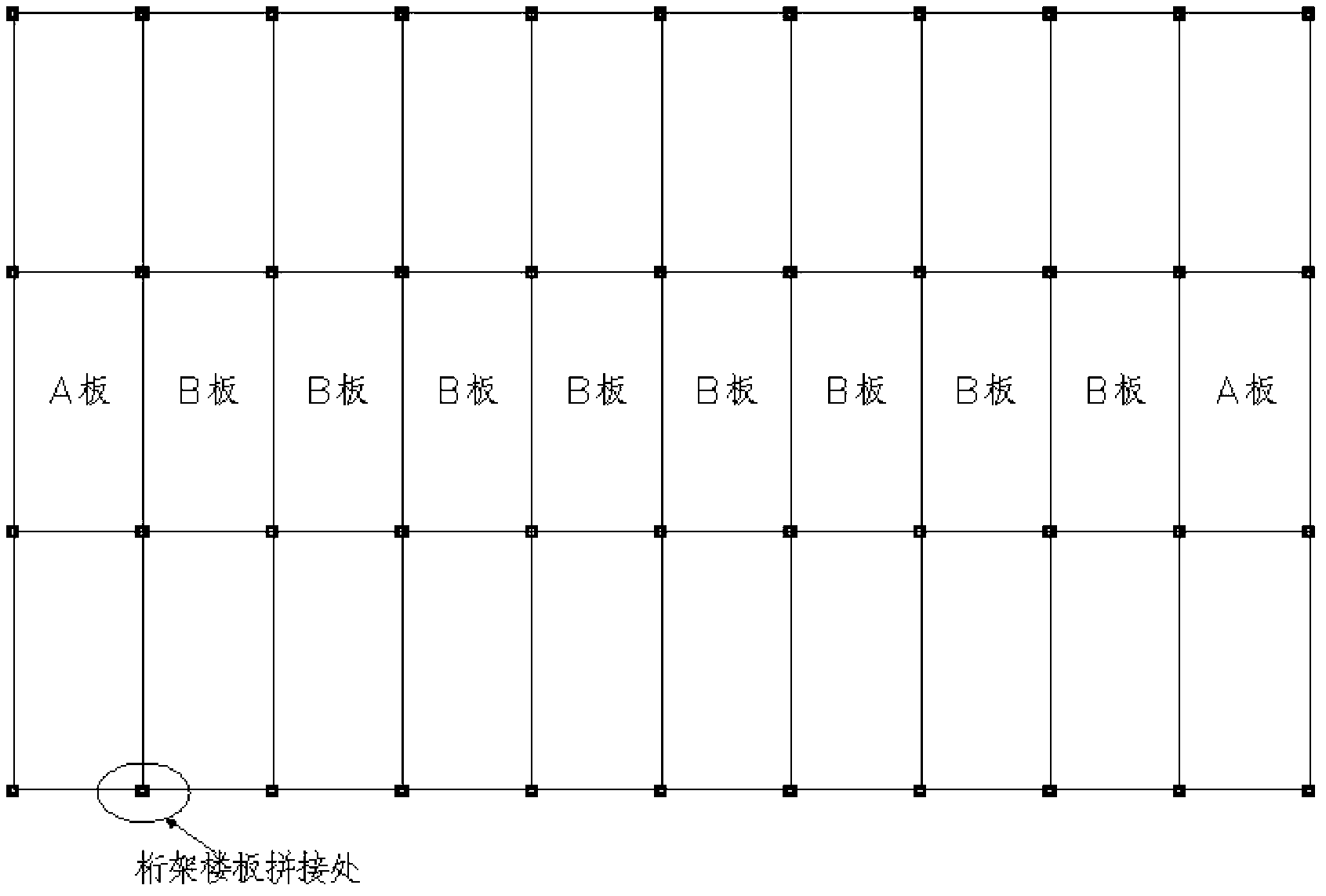

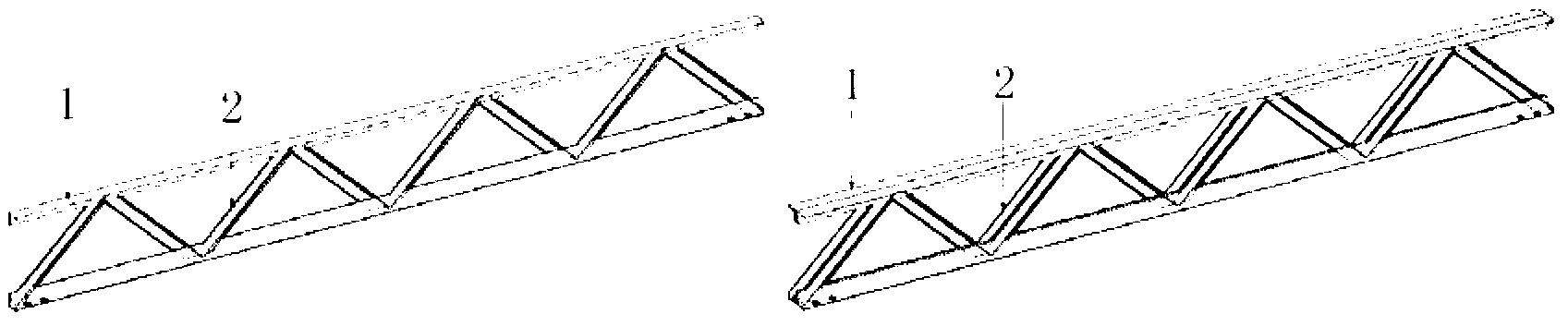

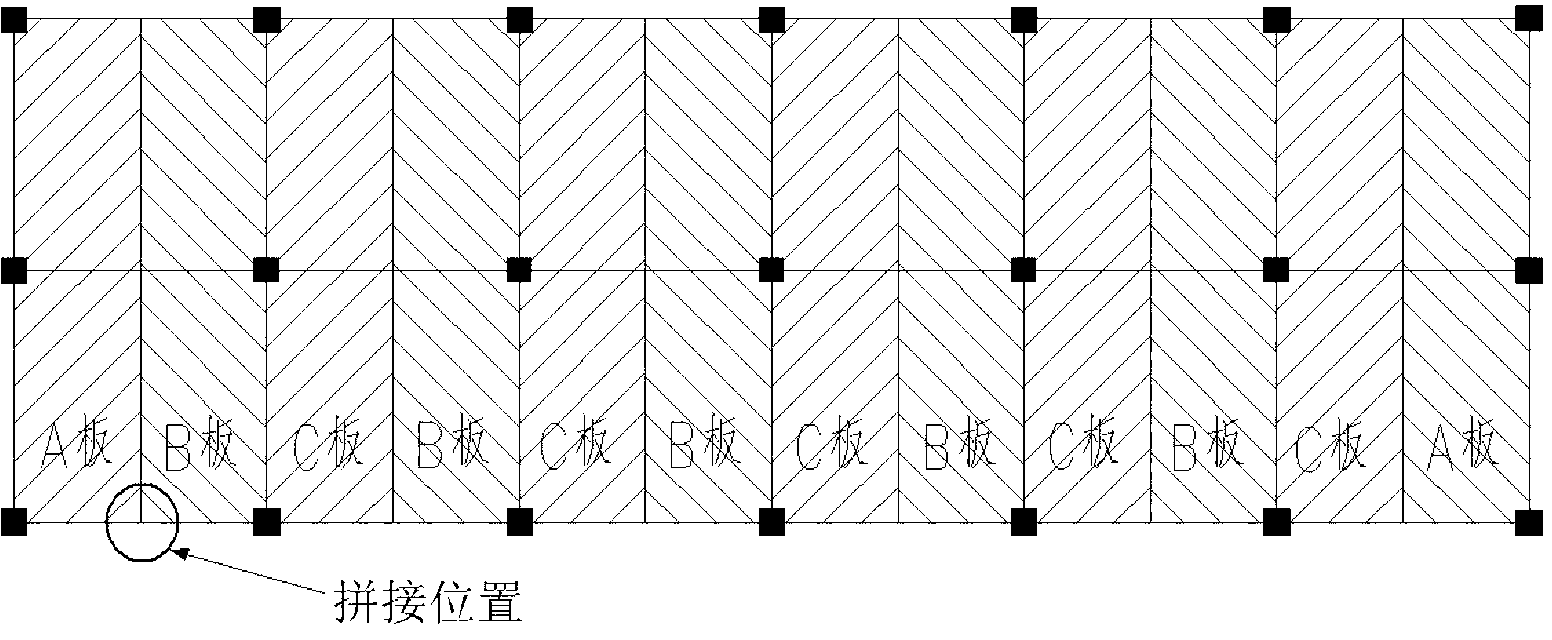

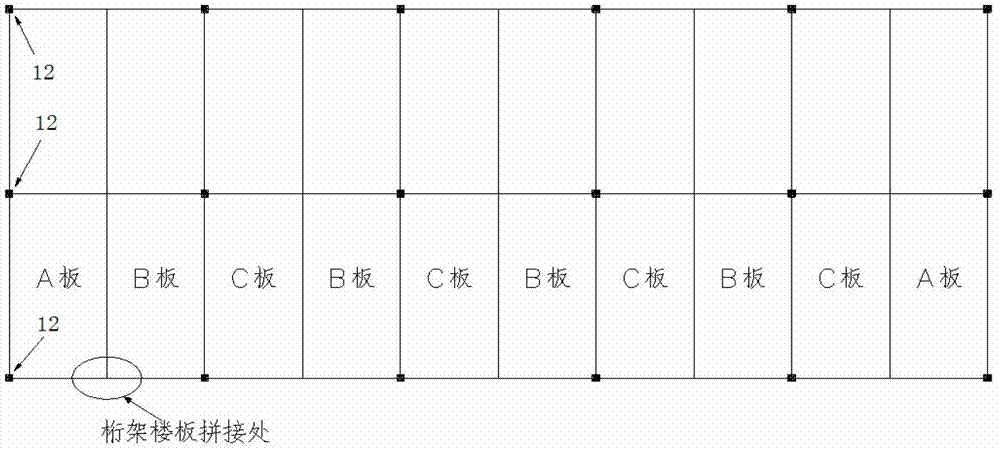

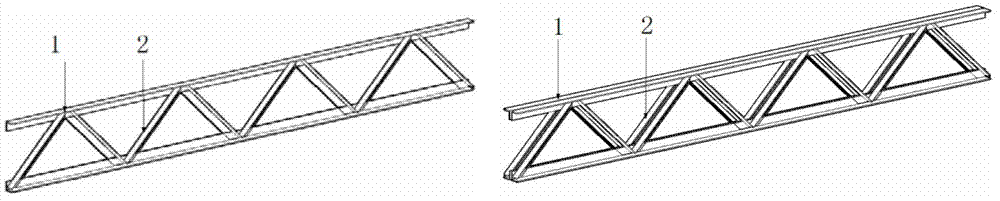

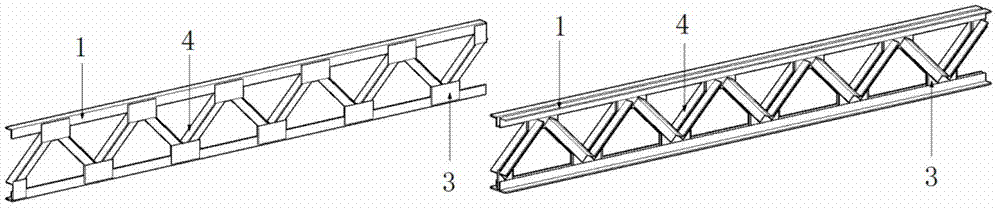

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system comprises assembled truss plates, assembled flange columns and eccentric bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the eccentric bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

Multi-story high-rise assembled steel structure frame - prestressed centrally-braced system

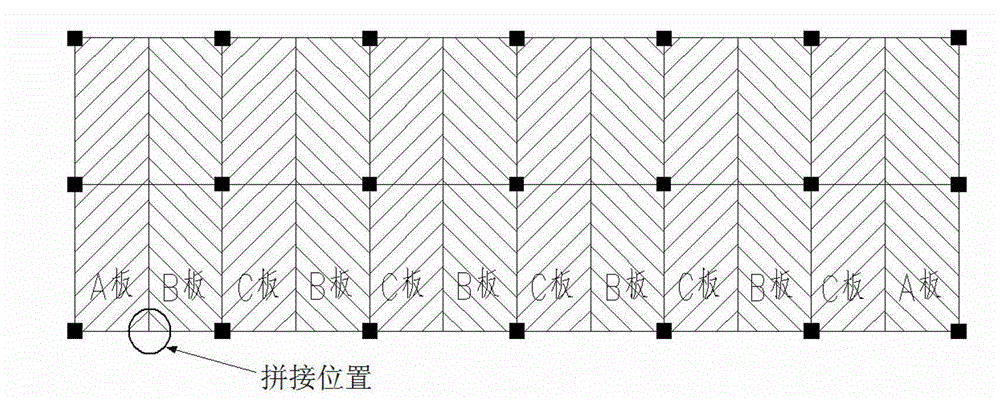

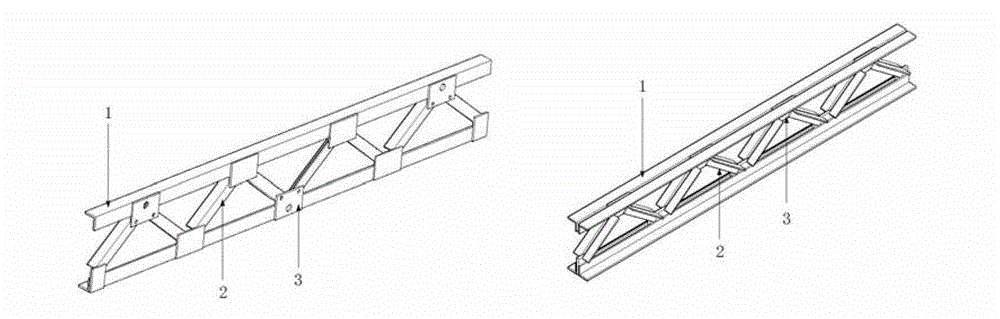

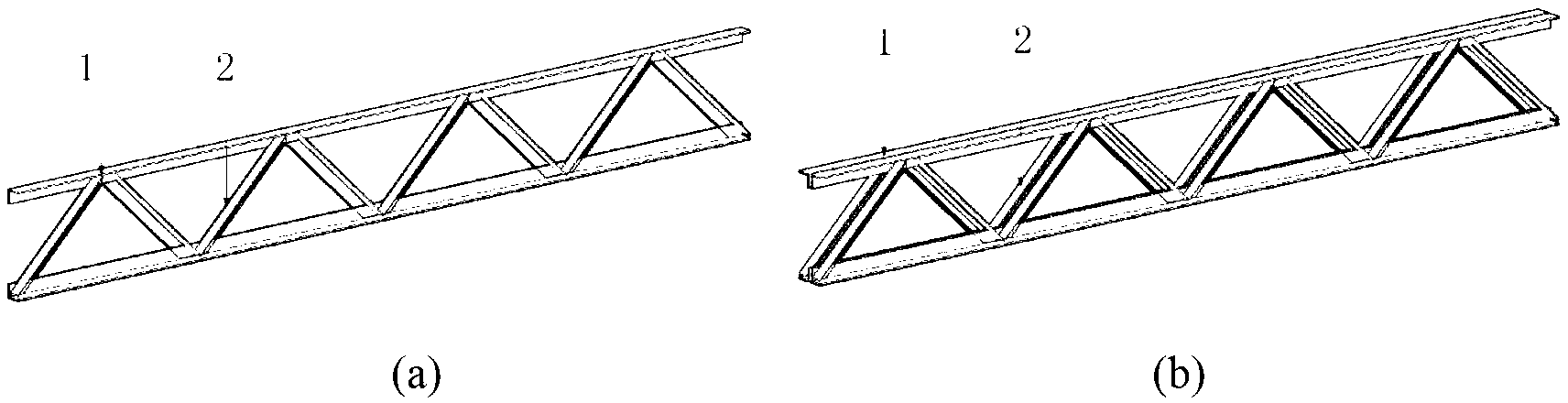

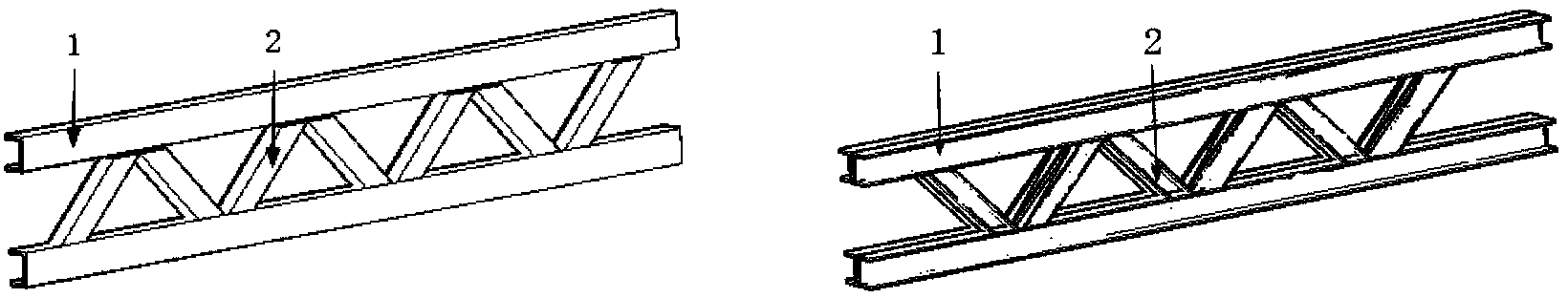

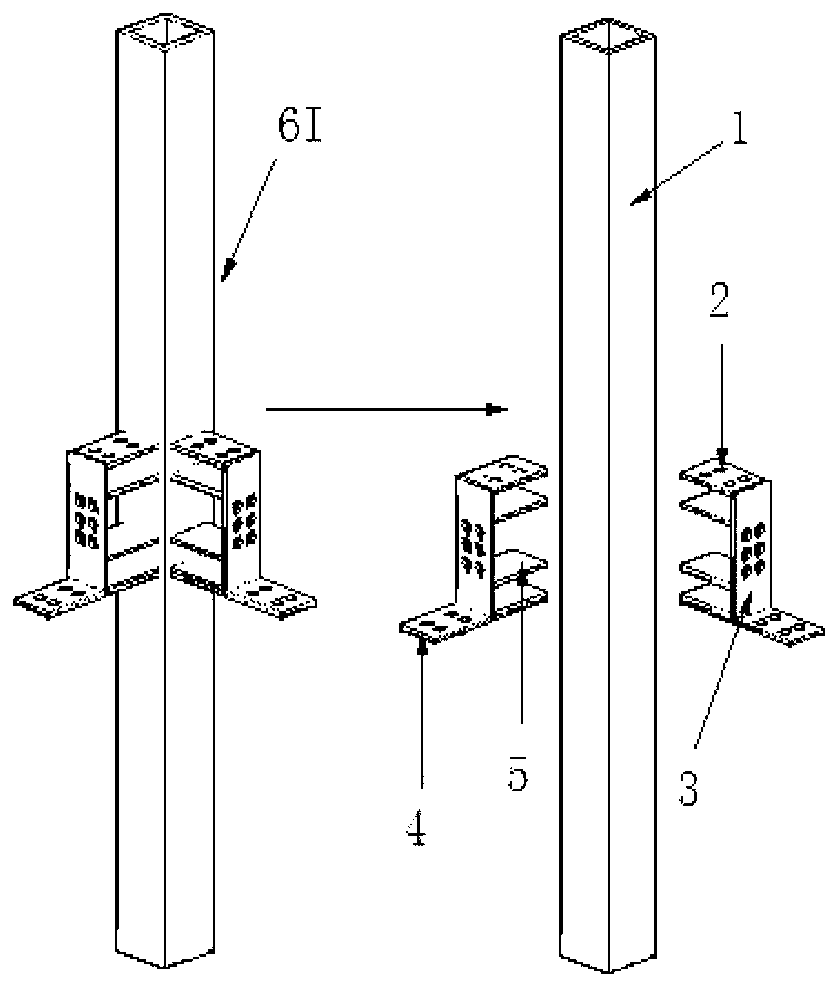

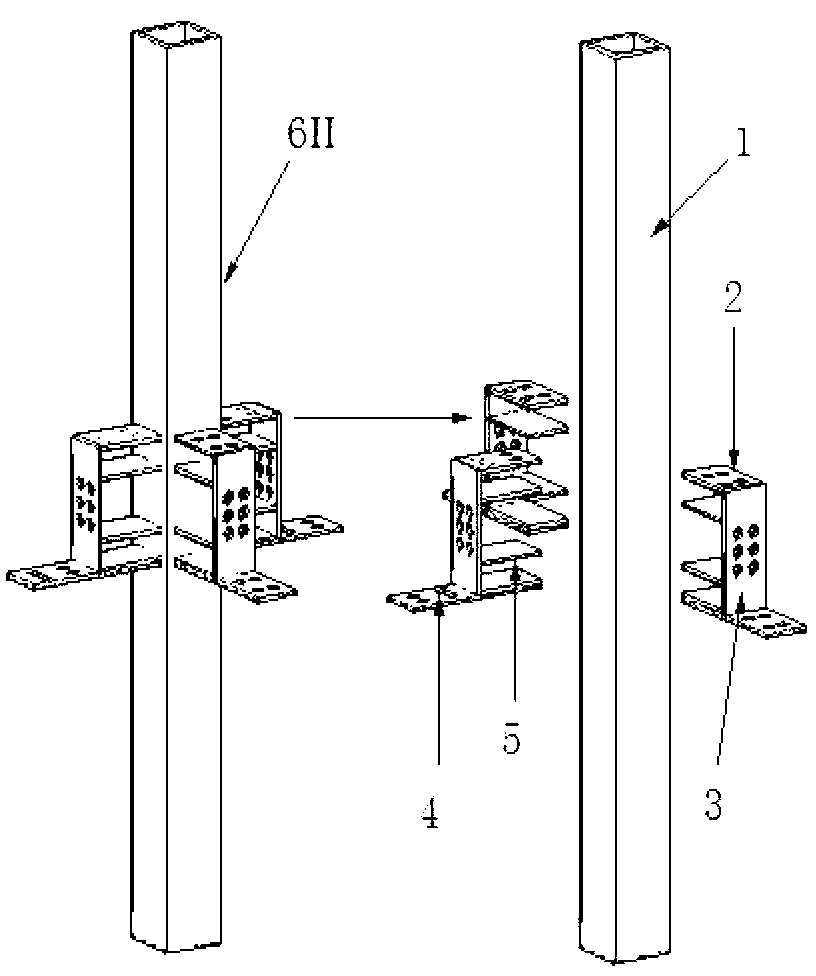

The invention relates to a multi-story high-rise assembled steel structure frame - prestressed centrally-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - prestressed centrally-braced system comprises assembled beams and slabs, assembled stand columns and prestressed sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns consist of box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the prestressed sway braces are arranged on the basis of the steel frame, so as to improve the lateral rigidness of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

Industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system comprises assembled truss plates, assembled flange columns and prestressed eccentric bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the prestressed eccentric bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

Industrialized multi-high-rise assembly type steel structure frame-pre-stressed center support system

ActiveCN102995744AEasy to pass throughIncrease net heightBuilding constructionsPre stressingEngineering

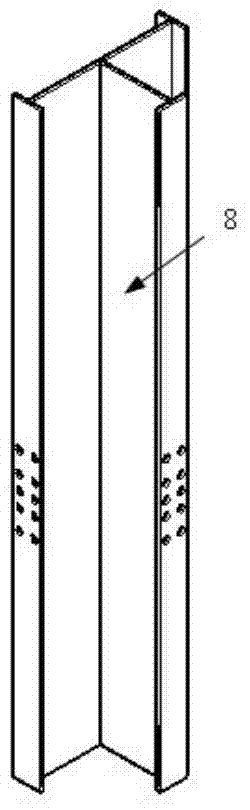

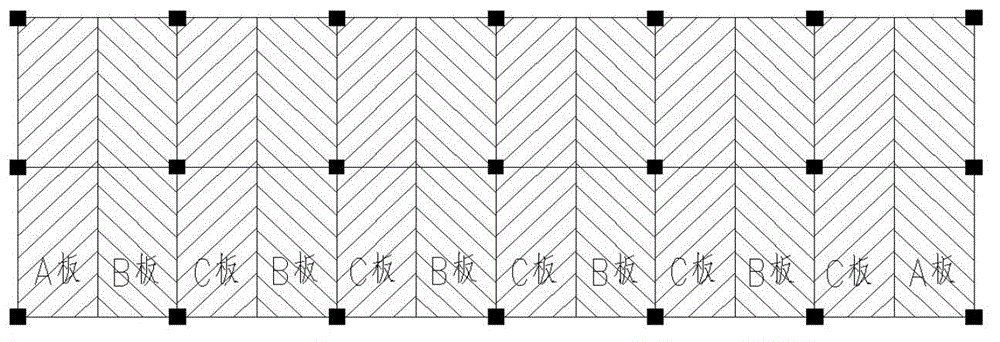

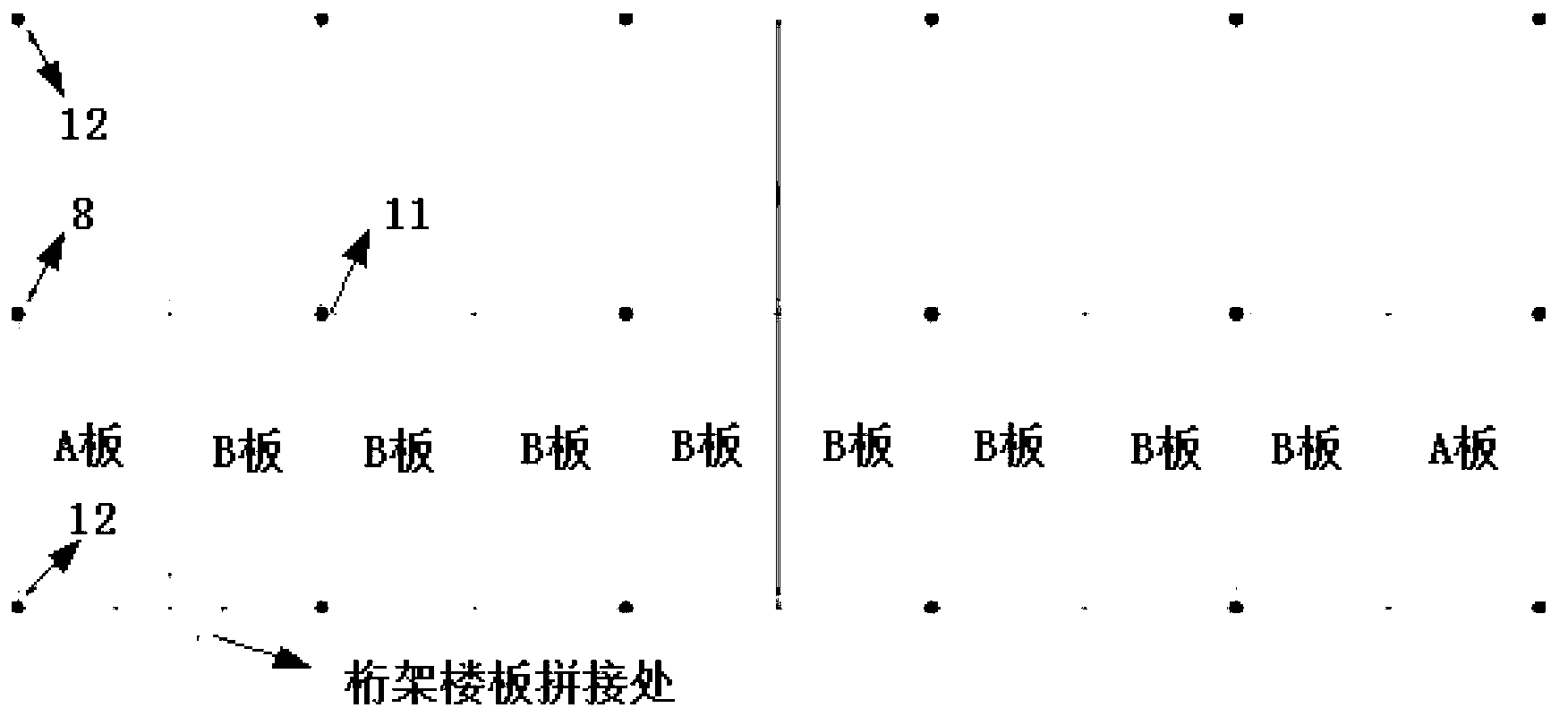

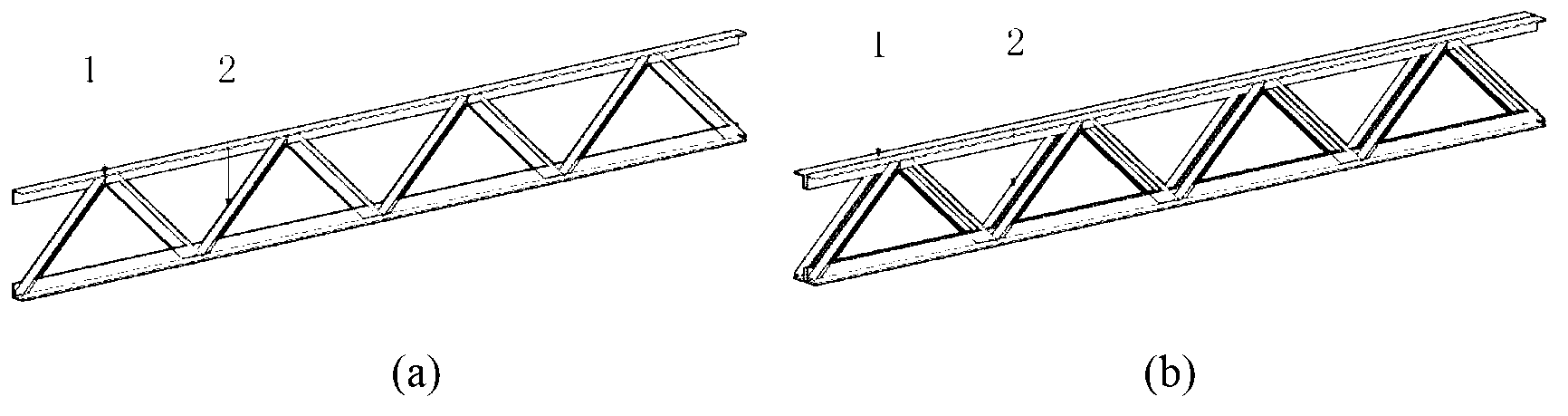

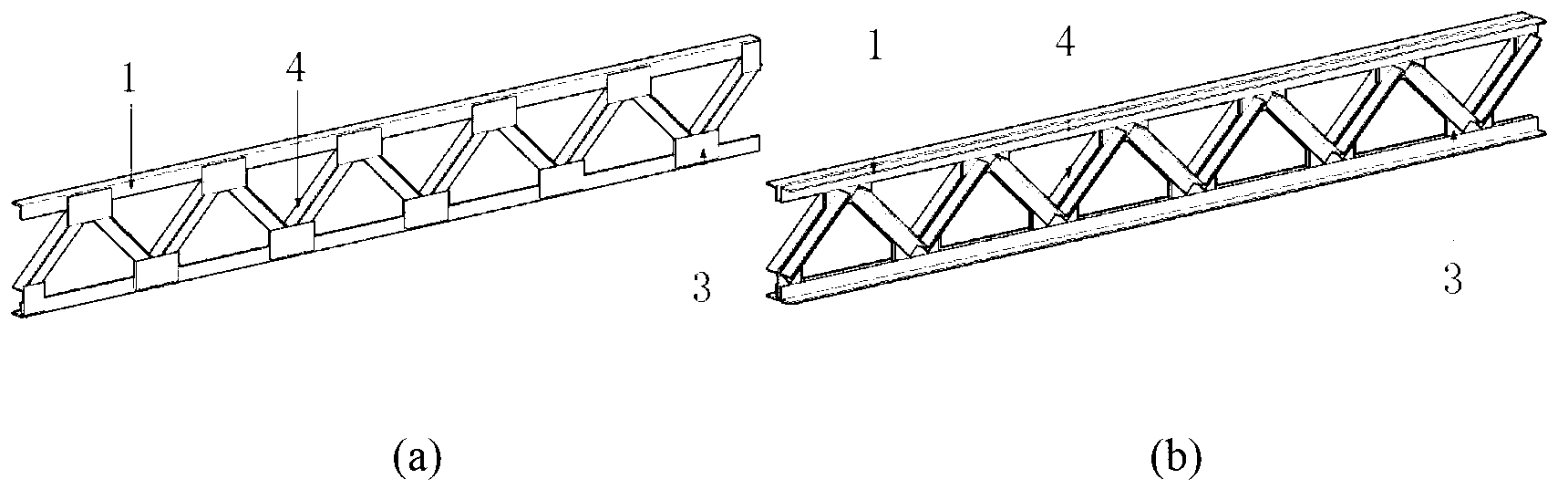

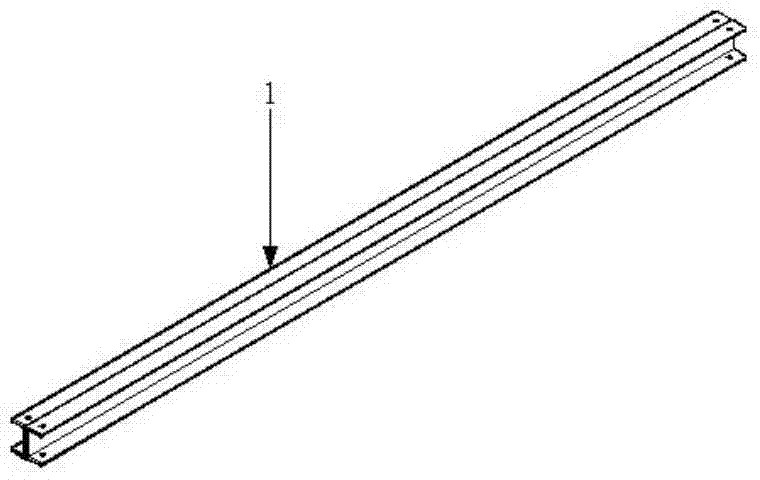

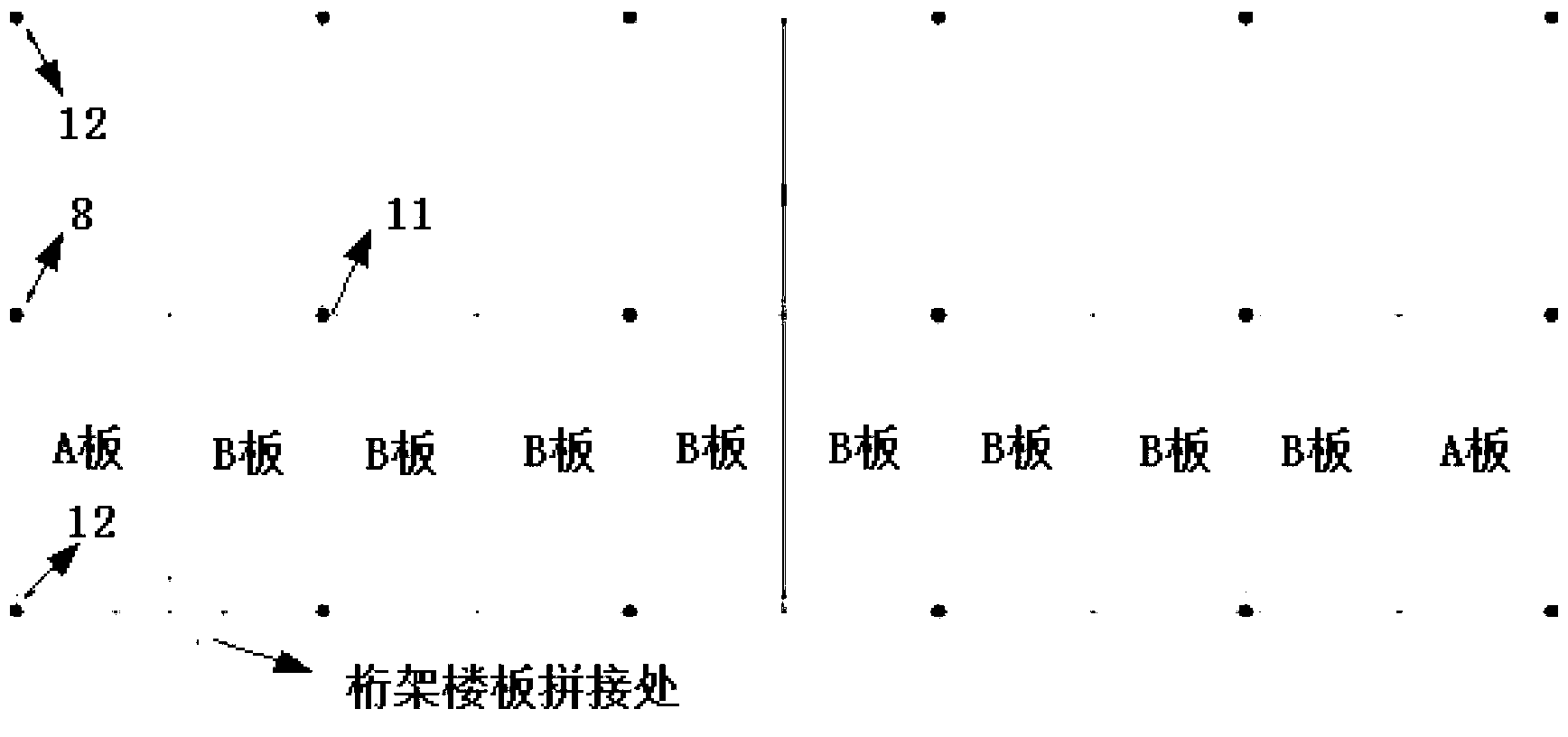

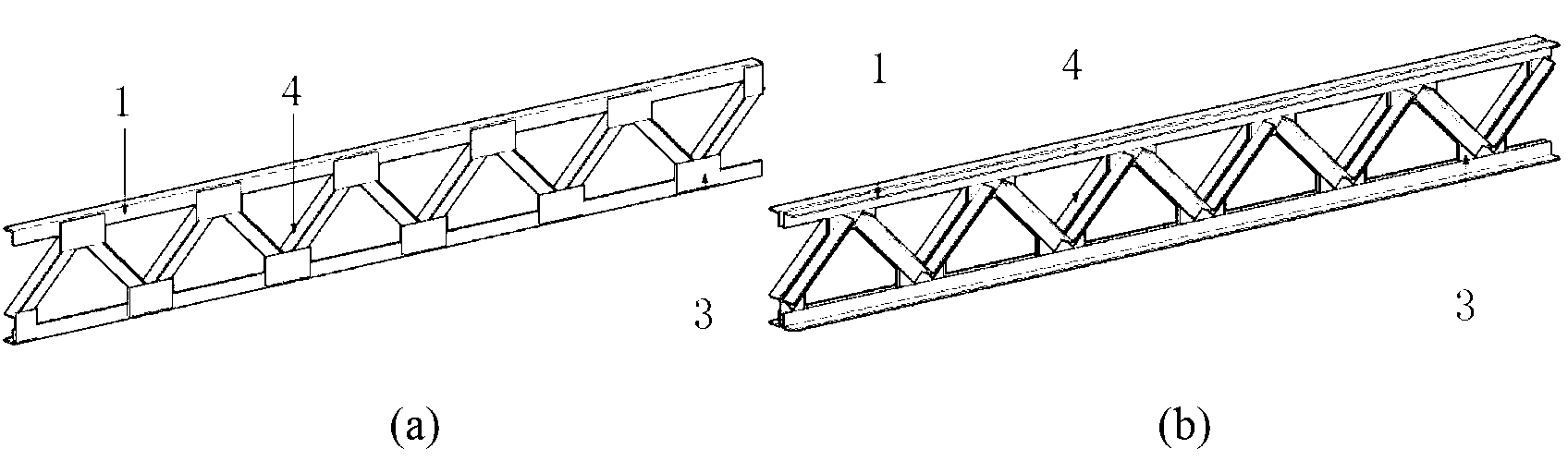

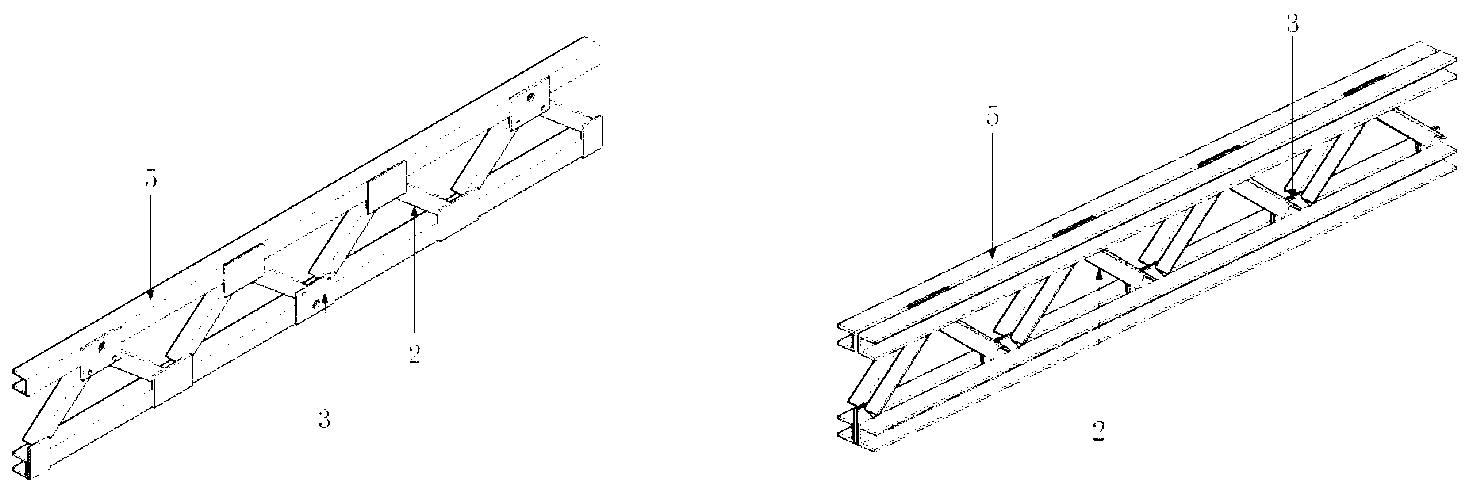

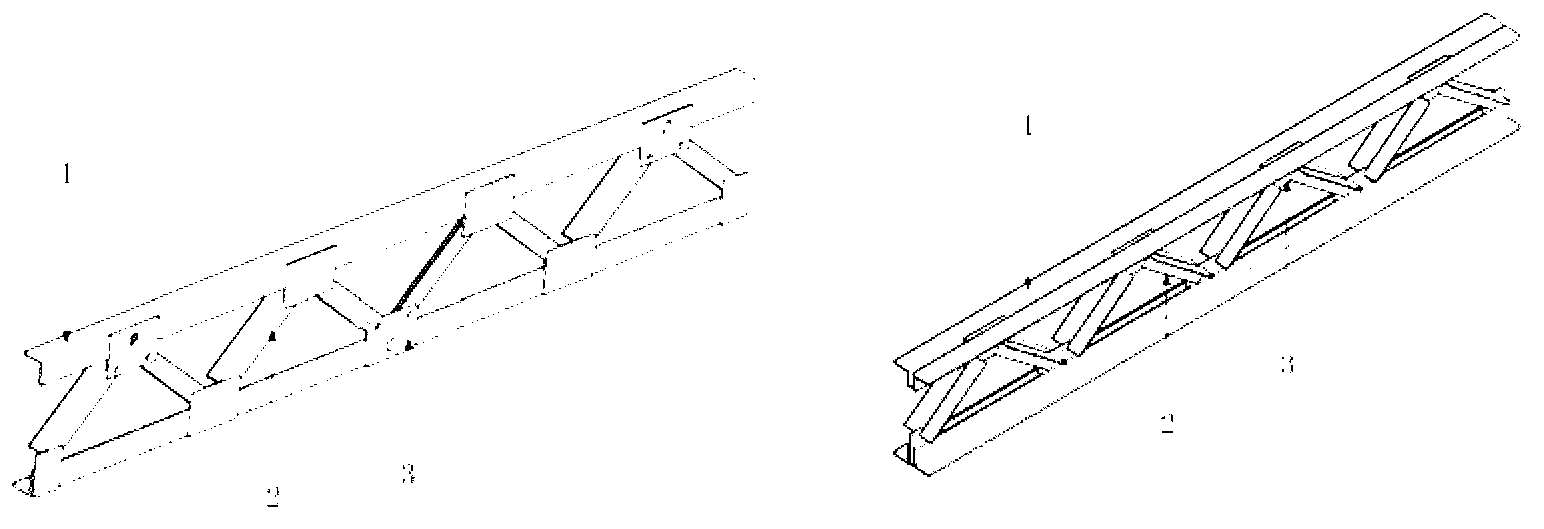

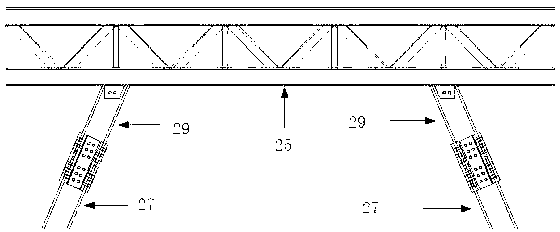

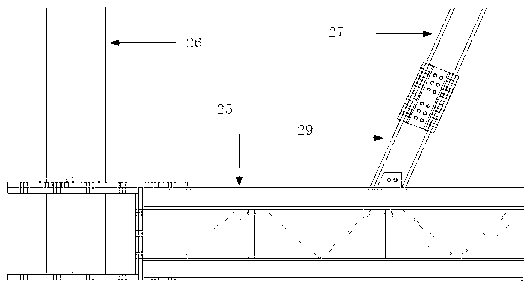

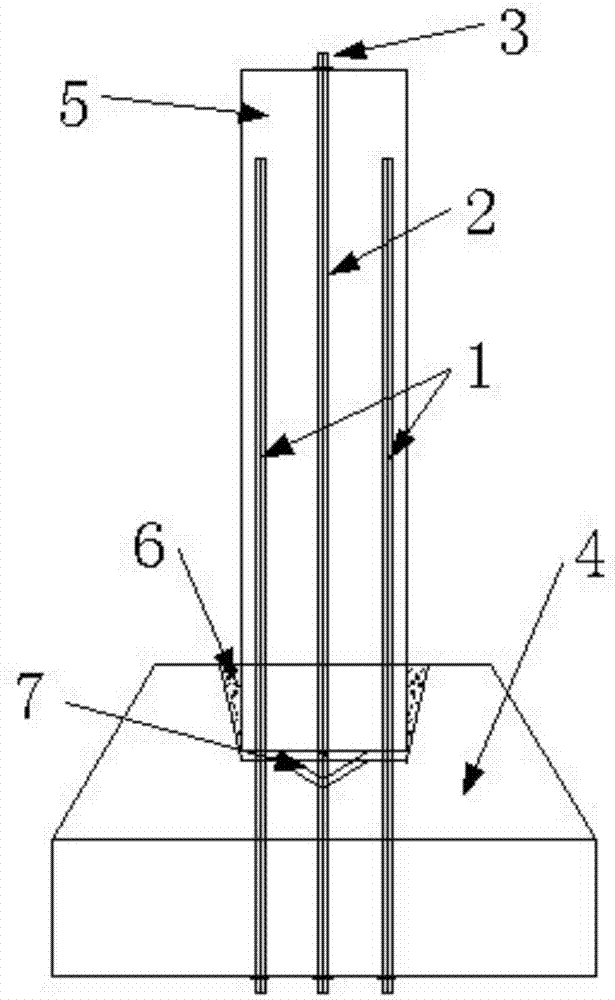

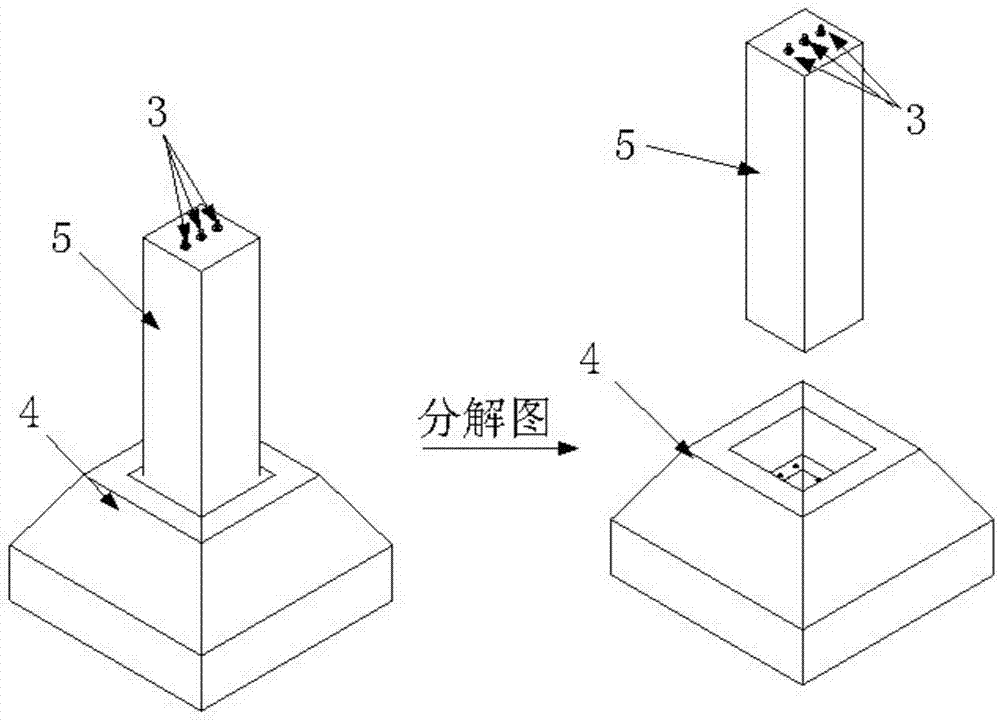

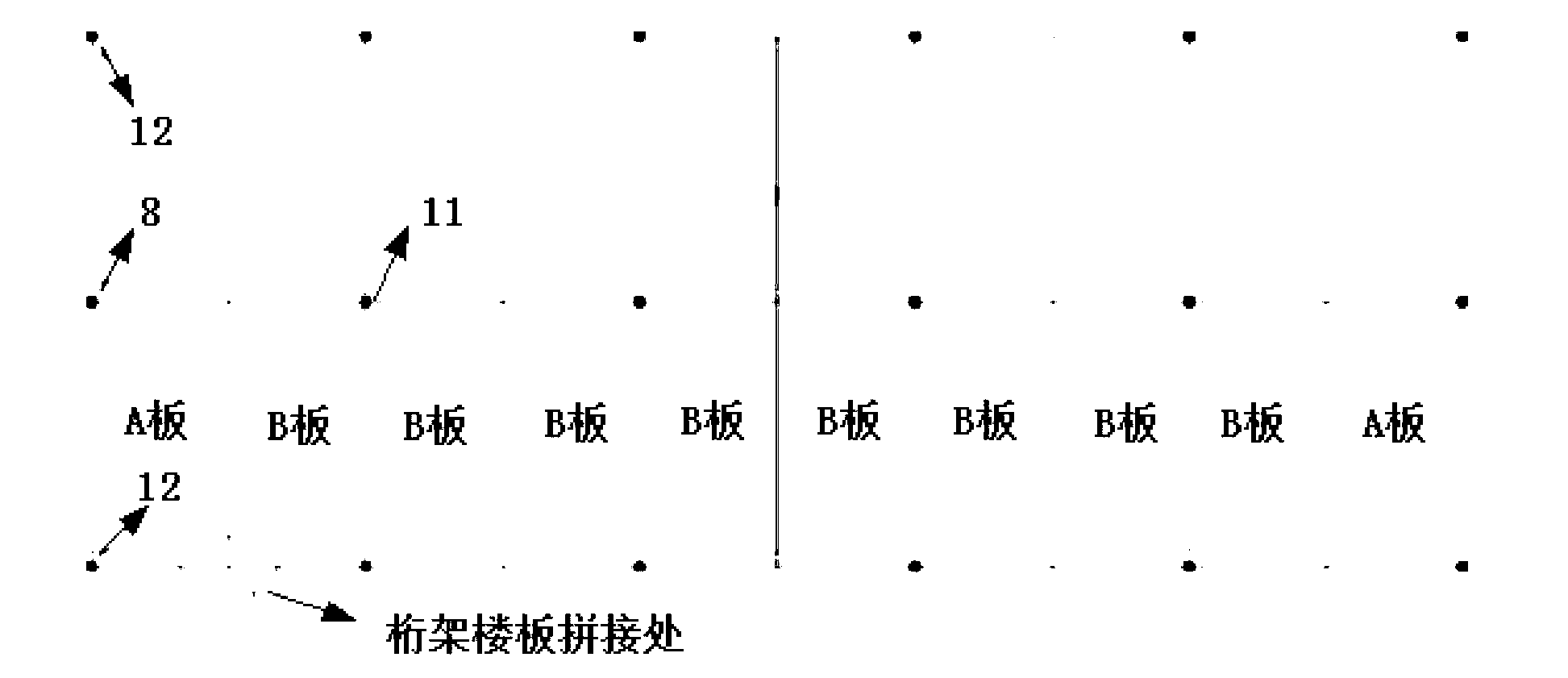

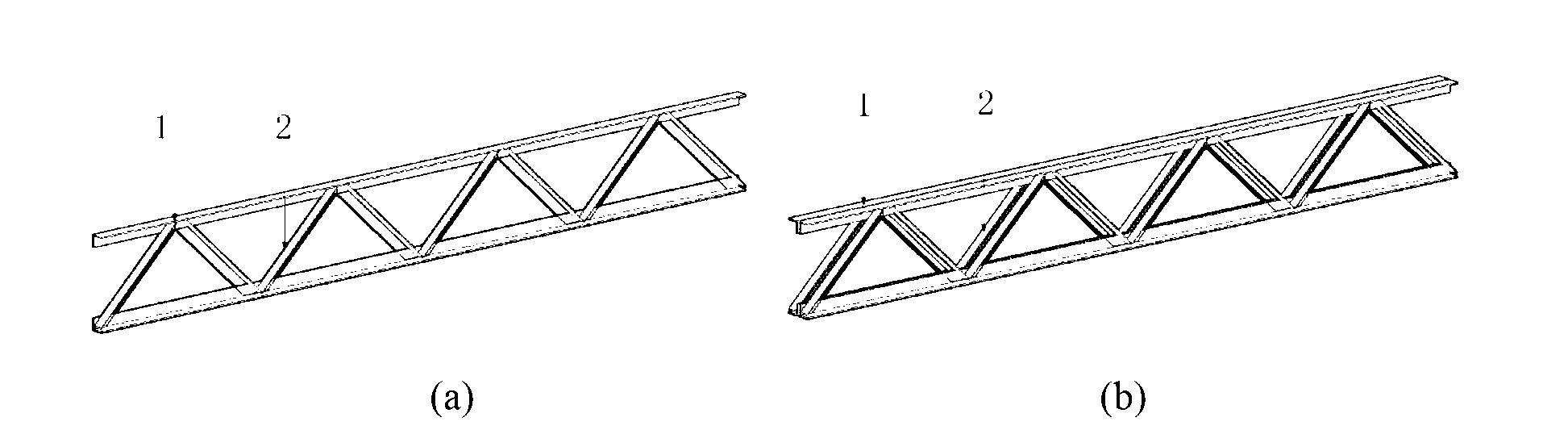

The invention discloses an industrialized multi-high-rise assembly type steel structure frame-pre-stressed center support system, belonging to the technical field of structural engineering, and comprising assembly type truss plates, assembly type flange posts and pre-stressed center support members, wherein the assembly type truss plates are prefabricated in a factory, and are mutually spliced through beam end sealing plates or post base nodes in a construction field to be used as frame structure beam and slab layers, the frame structure beam and slab layers are up and down connected through the assembly type flange posts to form a multi-layer steel frame structure; on the basis of the steel frame structure, the pre-stressed center support members are connected to the bottoms and the tops of posts or the truss beams in the frame structure beam and slab layers to be used as side force-resisting members; and the pre-stressed center support members are pre-fabricated in the factory, and are assembled by using bolts in the construction field. The invention integrates modularization, industrialization, standardization and assembly, realizes industrialized production and rapid field assembly, and has the advantages of increasing the construction speed, reducing the construction period and lowering the engineering cost under the premise of ensuring the construction quality.

Owner:CHINA RAILWAY CONSTR GROUP +1

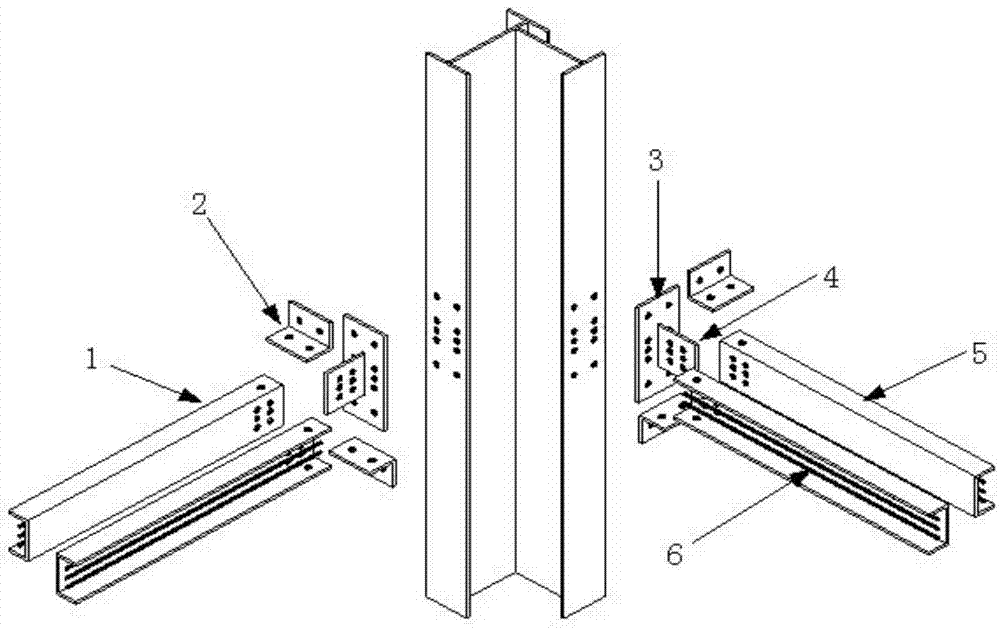

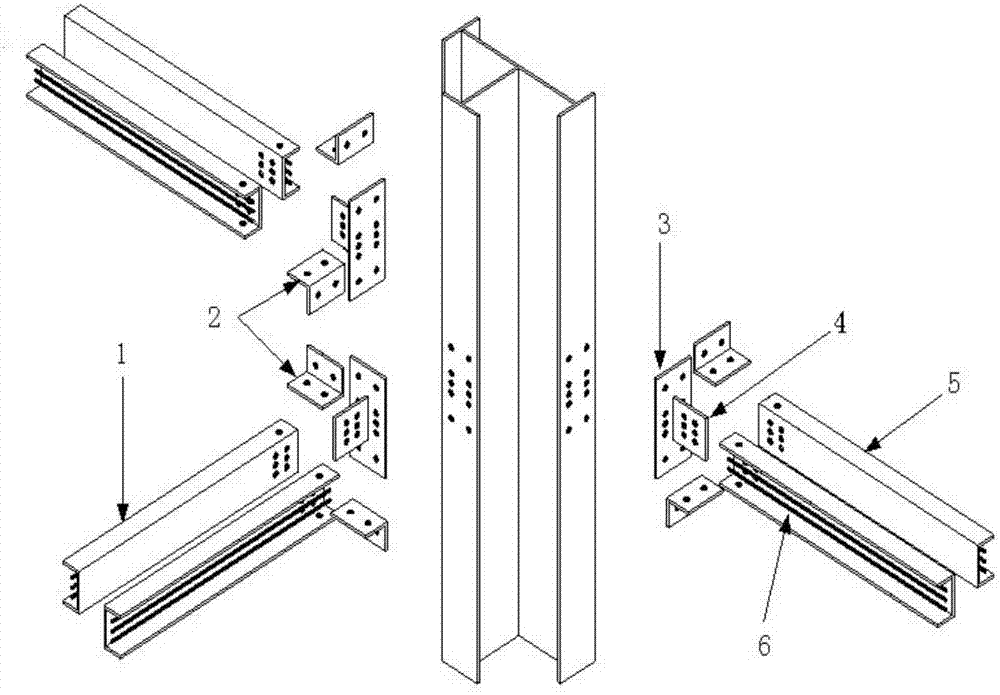

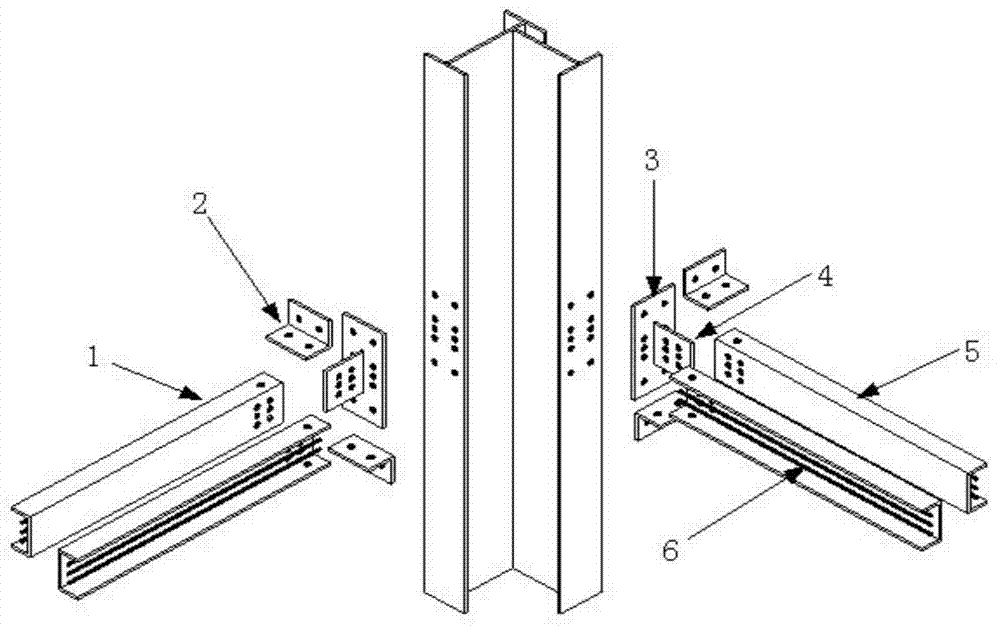

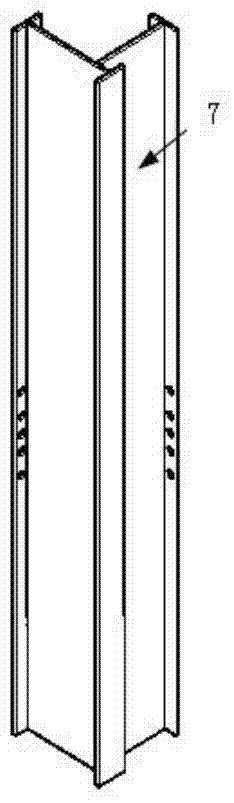

Fabricated multistory and high-rise prestressed steel frame-sway brace system provided with special-shaped columns

InactiveCN103410218AEasy to pass throughIncrease net heightBuilding constructionsFloor slabPre stress

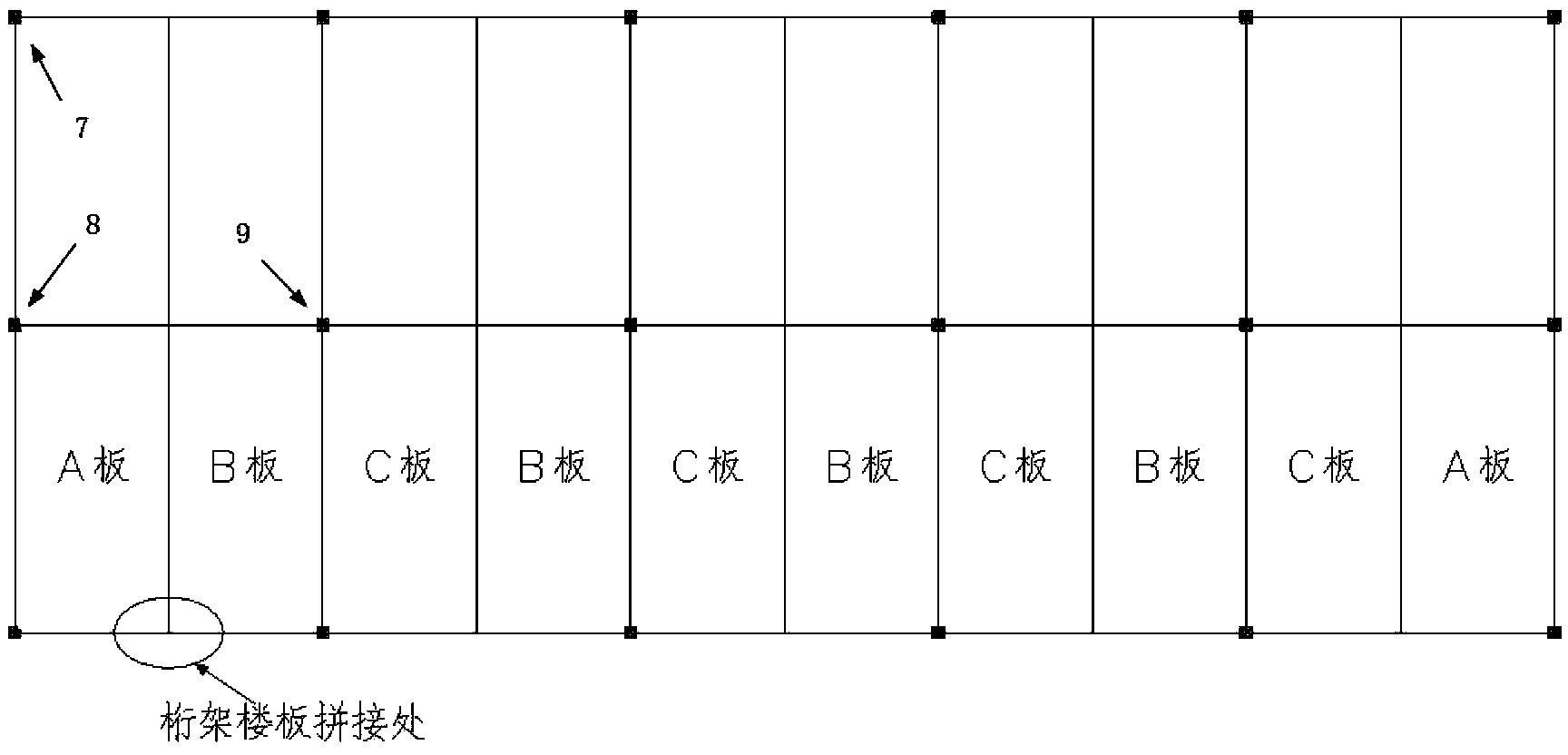

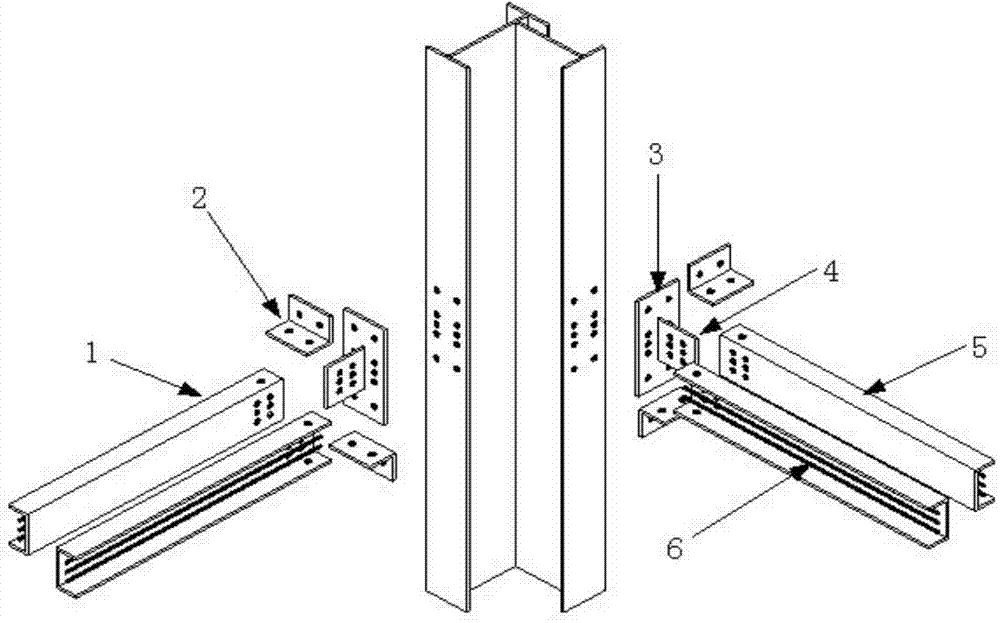

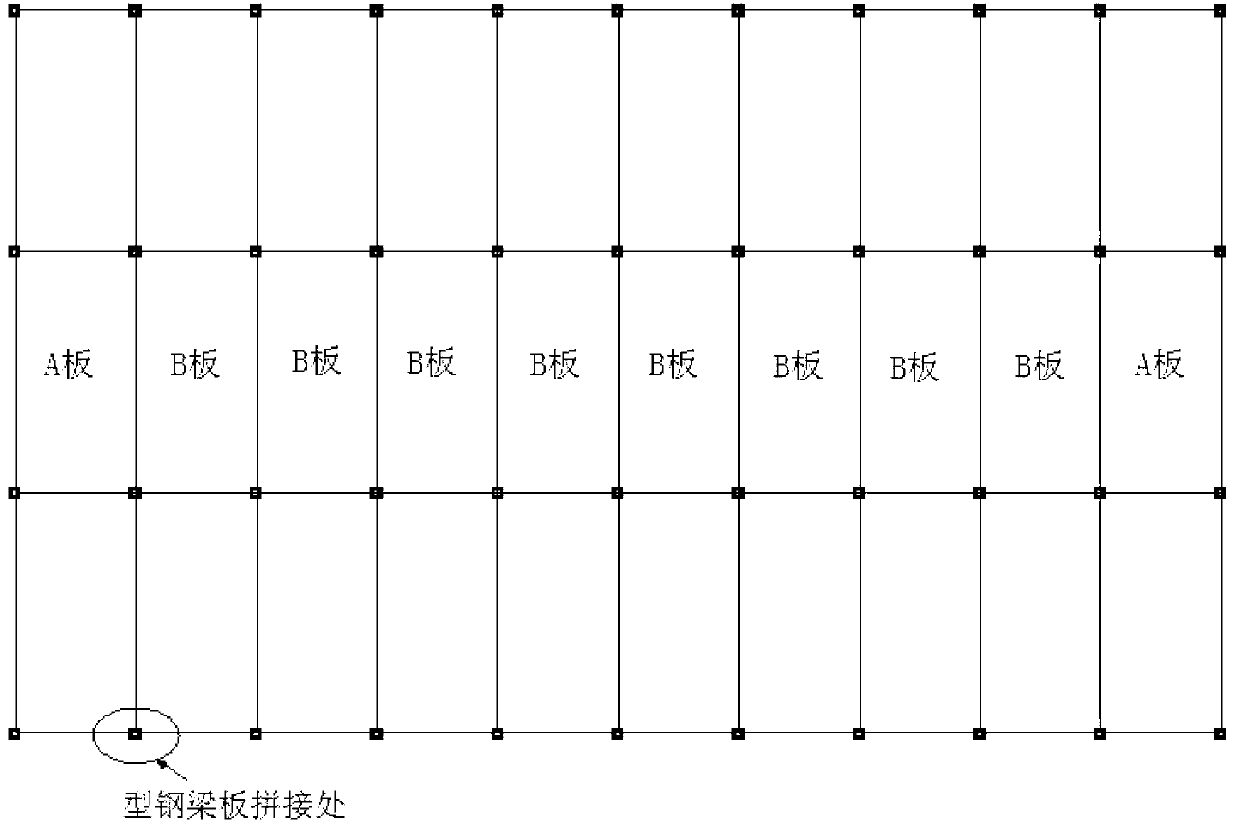

The invention discloses a fabricated multistory and high-rise prestressed steel frame-sway brace system provided with special-shaped columns, and relates to the technical field of structural engineering. The fabricated multistory and high-rise prestressed steel frame-sway brace system comprises fabricated profile steel plates, fabricated special-shaped columns and eccentric supporting members, wherein the fabricated profile steel plates comprise profile steel beams consisting of steel channels and floor slabs; the fabricated profile steel plates are prefabricated in a factory; at the construction site, the fabricated profile steel plates are mutually spliced with flange plates of the fabricated special-shaped columns through beam-end blanking plates of the fabricated profile steel plates, steel angles with equal legs and steel tightwires, and layers of the fabricated special-shaped columns are spliced at the site by bolts, so that a multilayer profile steel plate steel-frame structure is formed; on the basis of the steel-frame structure, the eccentric supporting members are connected to profile steel beams or column bottoms in beam and slab layers of the frame structure and taken as lateral force resisting members; and the fabricated profile steel plates, the fabricated special-shaped columns and the eccentric supporting members are all prefabricated in the factory and assembled at the construction site by bolts.

Owner:BEIJING UNIV OF TECH

Assembled steel structure center support frame system

InactiveCN103290920AEasy to pass throughIncrease net heightBuilding constructionsBraced frameFloor slab

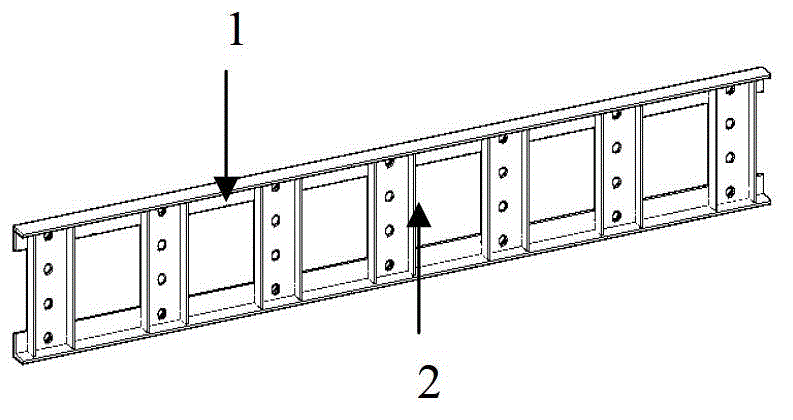

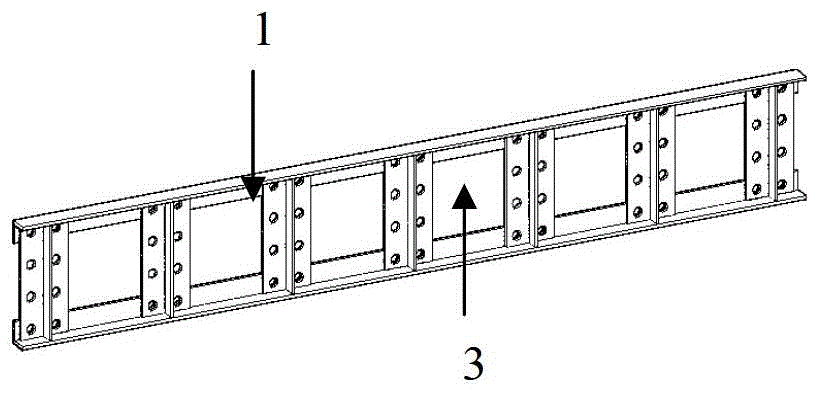

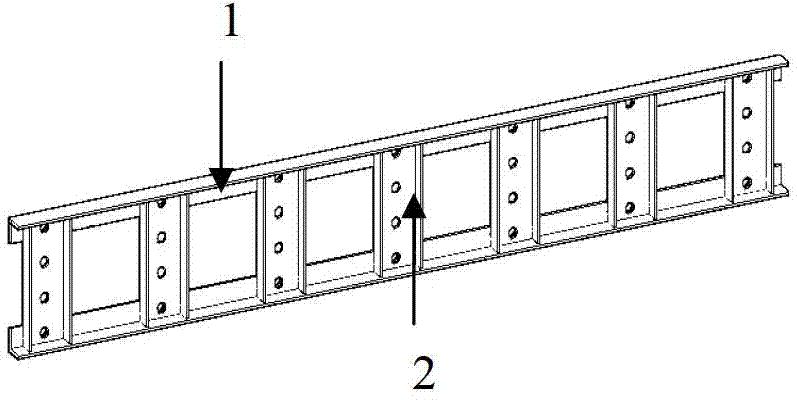

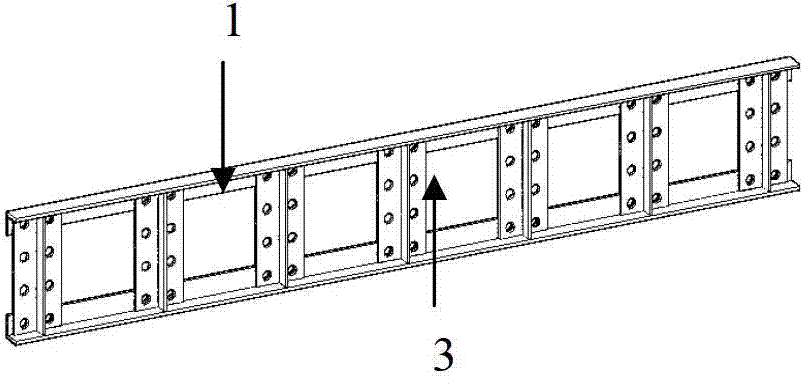

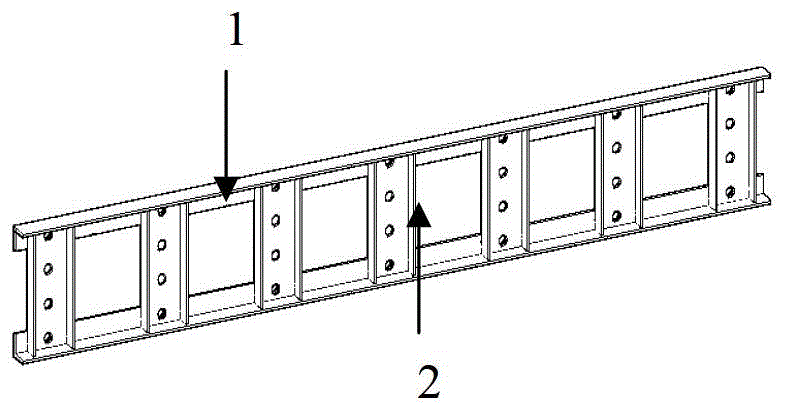

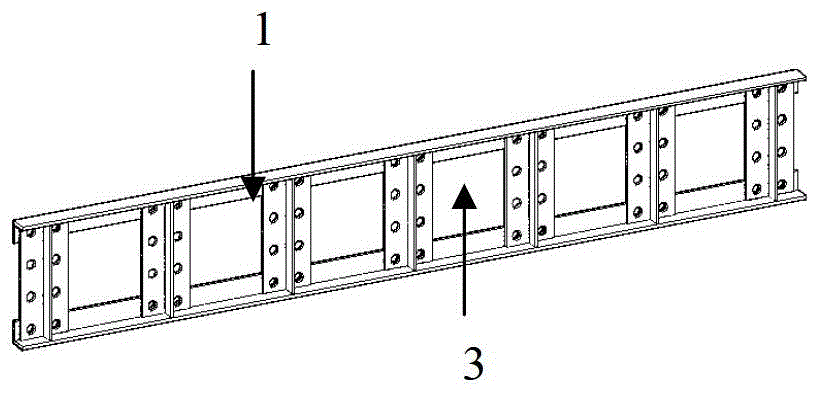

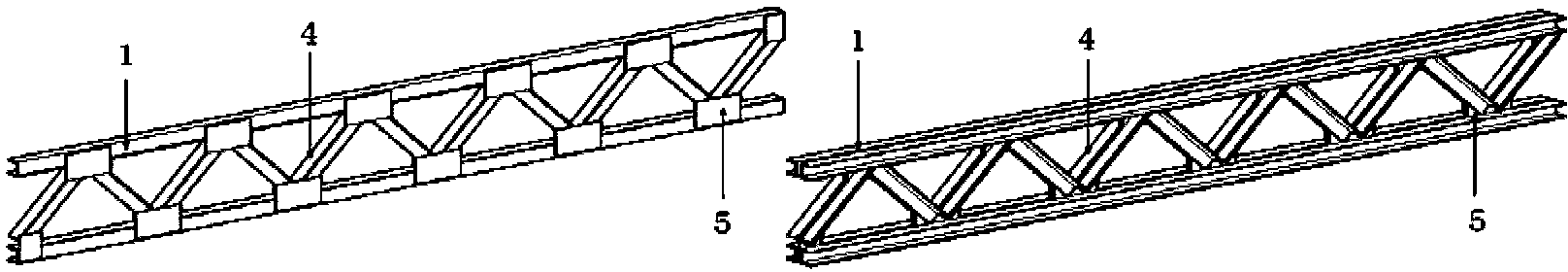

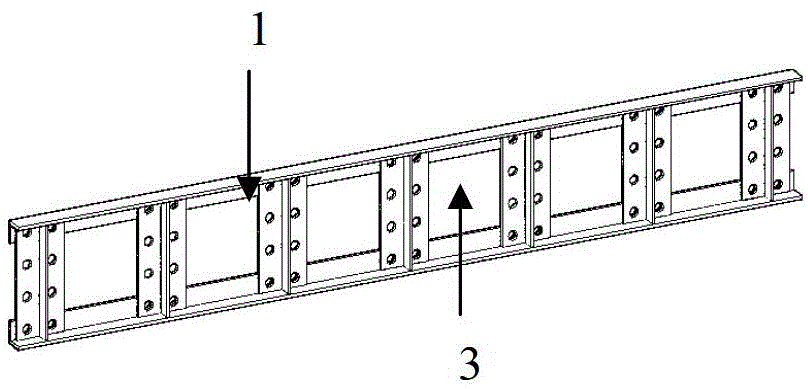

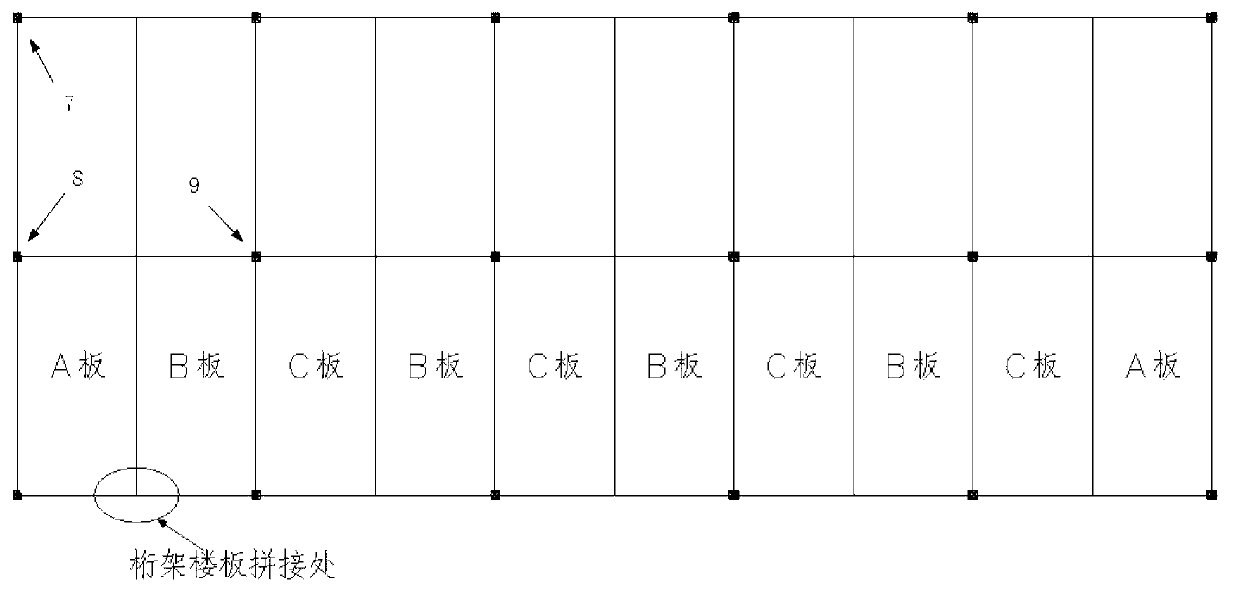

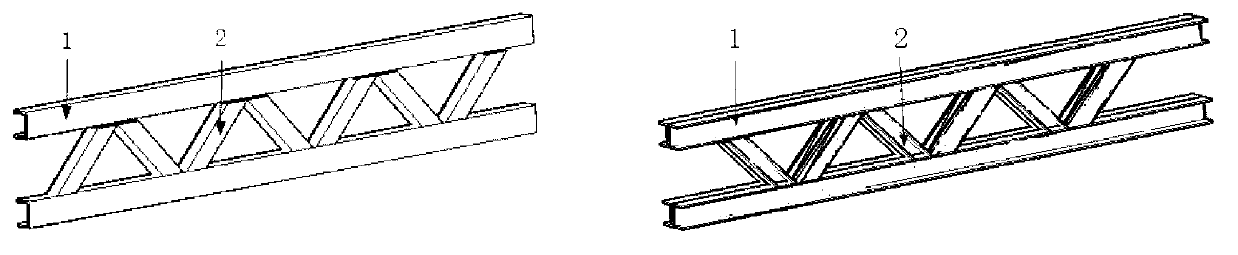

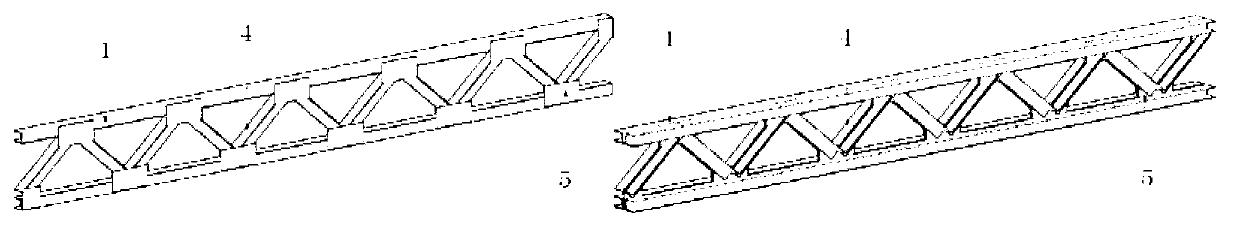

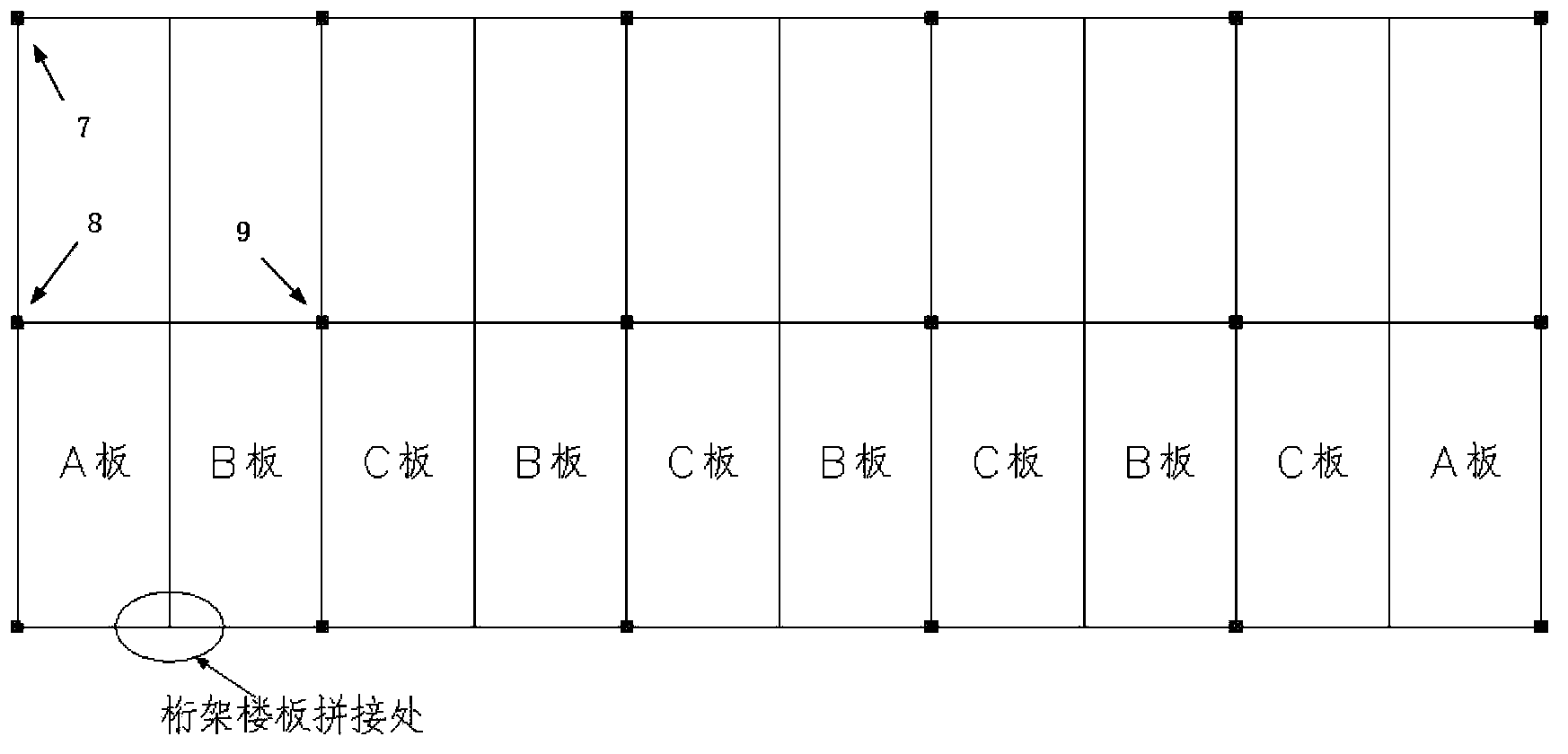

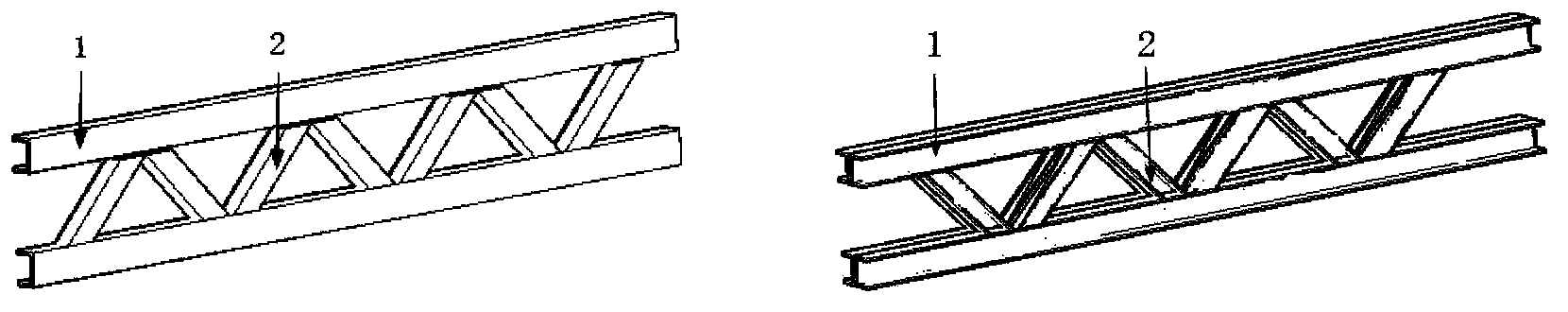

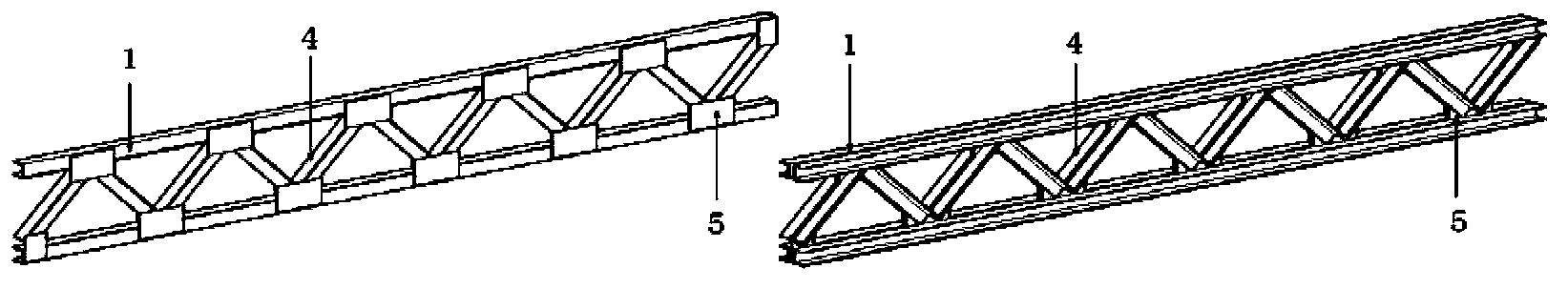

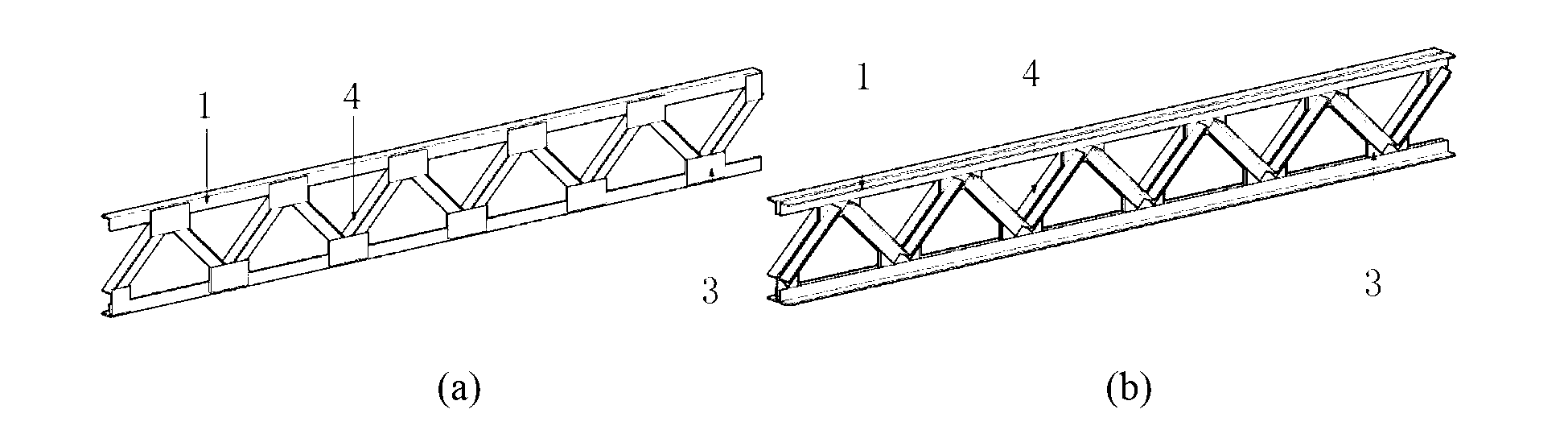

The invention relates to an assembled steel structure center support frame system and belongs to the technical field of structure engineering. The system comprises assembled truss plates, assembled uprights and center support members, wherein the assembled truss plates comprise lattice truss beams with steel angle web members, and floor plate, and are prefabricated in a factory; the assembled truss plates are spliced with beam column nodes of the assembled uprights by beam end sealing plates of the assembled truss plates at a construction site; the assembled uprights are spliced between layers by bolts on site to form a multilayer steel frame structure; based on the steel frame structure, the center support members serve as lateral force resisting members and are connected with the truss beams in the assembled truss plates and the bottoms or tops of the assembled uprights; the assembled truss plates, the assembled uprights and the center support members are prefabricated in the factory and assembled by the bolts at the construction site.

Owner:河南天蚕富煌钢结构有限公司

Industrialized multi-story high-rise assembled steel structure frame - centrally-braced system

ActiveCN102979168AEasy to pass throughIncrease net heightBuilding constructionsModularitySteel frame

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - centrally-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - centrally-braced system comprises assembled truss plates, assembled flange columns and central bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the central bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - centrally-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

Multi-high-layer assembly type steel structure frame-center supporting system

ActiveCN103114648AEasy to pass throughIncrease net heightStrutsFloorsSupporting systemLateral stiffness

The invention provides a multi-high-layer assembly type steel structure frame-center supporting system, and belongs to the technical field of structural engineering. The system comprises assembly type beam-slabs, assembly type upright columns and profile steel inclined supports. Each assembly type beam-slab comprises a floor, a column joint and a hollow steel beam of a matched profile steel web member. The hollow steel beams are connected with the column joints, the floors are supported on the hollow steel beams, and each assembly type upright column is composed of a box-shaped column and a flange plate. During construction, the assembly beam-slabs and the assembly type upright columns are connected to form a frame structure, the profile steel inclined supports are arranged on the basis of the steel frame, and lateral stiffness of the structure is improved. All elements of the system are precast in factories and are rapidly assembled to form the structural system through bolts on construction sites. Concrete pouring and welding work are not needed, the defects that a traditional building is long in construction period, severe in material waste, severe in pollution during the construction process and the like are reduced, and factory integral production of the building can be achieved.

Owner:CHINA RAILWAY CONSTR GROUP +1

Multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system

The invention relates to a multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system comprises assembled beams and slabs, assembled stand columns and prestressed sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns consist of box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the prestressed eccentric sway braces are arranged on the basis of the steel frame to form energy-dissipating beam sections, so as to improve the lateral rigidness and the energy dissipation capacity of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

Special-shaped steel column frame structure joint easy to restore after earthquake

The invention discloses a special-shaped steel column frame structure joint easy to restore after an earthquake. According to the special-shaped steel column frame structure joint easy to restore after the earthquake, a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that the prestress self-reset joint easy to restore after the earthquake is formed. By the adoption of a prestress self-reset joint form, self-reset of the joint after the earthquake is achieved, and restoring cost after the earthquake is greatly reduced; the shock resistance of the joint is improved, and thus the shock resistance of a frame structure system is improved; compared with a traditional steel-structural construction joint, the special-shaped steel column frame structure joint easy to restore after the earthquake has the advantages that the safety performance is high, environmental pollution is light, the number of safety accidents is small, and construction cost is low.

Owner:南通新丰威机械科技有限公司

Novel special-shaped steel column frame-steel plate shear wall easy to restore after earthquake

ActiveCN103669650AImprove securitySmall residual deformation after earthquakeWallsPre stressShock resistance

The invention discloses a novel special-shaped steel column frame-steel plate shear wall easy to restore after an earthquake. According to the novel special-shaped steel column frame-steel plate shear wall easy to restore after the earthquake, a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that a prestress self-reset joint is formed; a self-reset column base and a prestress column base are used for optimizing the axial mechanical performance and the horizontal mechanical performance of the bottom of the column through a reinforcing plate, a bend-preventing steel plate is mainly used for dissipating energy of the earthquake, and a shear plate is used for preventing local deformation, caused by excessive shearing force, of the bottom of the column; the key component of the prestress column base is a prestress pull rod, the pull rod is used for providing precompression for the column so that the column can be tightly connected with the beam, as a result, approximate rigid connection can be achieved when the prestress column base bears small bending moment, and the self-reset capacity of the prestress column base after the earthquake is achieved; better shock resistance of the structure is achieved due to the steel plate shear wall.

Owner:南通新丰威机械科技有限公司

Multi-story high-rise assembled steel structure frame - eccentrically-braced system

ActiveCN102979166AEasy to pass throughIncrease net heightBuilding constructionsFloor slabLateral stiffness

The invention relates to a multi-story high-rise assembled steel structure frame - eccentrically-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - eccentrically-braced system comprises assembled beams and slabs, assembled stand columns and section steel sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns comprise box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the section steel sway braces are arranged on the basis of the steel frame to form energy-dissipating beam sections, so as to improve the lateral stiffness and the plastic energy dissipation capacity of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

Industrialized assembling type special-shaped column steel structure-steel plate shear wall steel structure system

The invention discloses an industrialized assembling type special-shaped column steel structure-steel plate shear wall steel structure system and belongs to the technical field of structure engineering. The industrialized assembling type special-shaped column steel structure-steel plate shear wall steel structure system comprises an assembling type truss plate, assembling type columns and a steel plate shear wall. The assembling type truss plate comprises a lattice truss beam provided with a web member and a floor plate. The assembling type truss plate is prefabricated in a plant and spliced with beam column joints of the assembling type columns through a beam end sealing plate of the assembling type truss plate at the construction site, and the assembling type columns are spliced to form a multiplayer truss plate steel framework structure among layers through bolts at site. On the basis of the steel framework structure, the steel plate shear wall is connected onto the truss beam in a framework structure beam plate layer or the column bottoms or the tops to serves as a lateral load resistance element. The assembling type truss plate, the assembling type special-shaped columns and the steel wall plate shear wall member are all fabricated in the plant and assembled at the construction site through bolts.

Owner:深圳市国富建筑有限公司

Special-shaped steel column-prestress central supporting frame easy to restore after earthquake

The invention discloses a special-shaped steel column-prestress central supporting frame easy to restore after an earthquake. The special-shaped steel column-prestress central supporting frame easy to restore after the earthquake is characterized in that a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that a prestress self-reset joint is formed; a self-reset column base and a prestress column base are used for optimizing the axial mechanical performance and the horizontal mechanical performance of the bottom of the column through a reinforcing plate, a bend-preventing steel plate is mainly used for dissipating energy of the earthquake, and a shear plate is used for preventing local deformation, caused by excessive shearing force, of the bottom of the column; the key component of the prestress column base is a prestress pull rod, the pull rod is used for providing precompression for the column so that the column can be tightly connected with the beam, as a result, approximate rigid connection can be achieved when the prestress column base bears small bending moment, and the self-reset capacity of the prestress column base after the earthquake is achieved; better lateral resistance of the structure is achieved through prestress central supporting.

Owner:南通新丰威机械科技有限公司

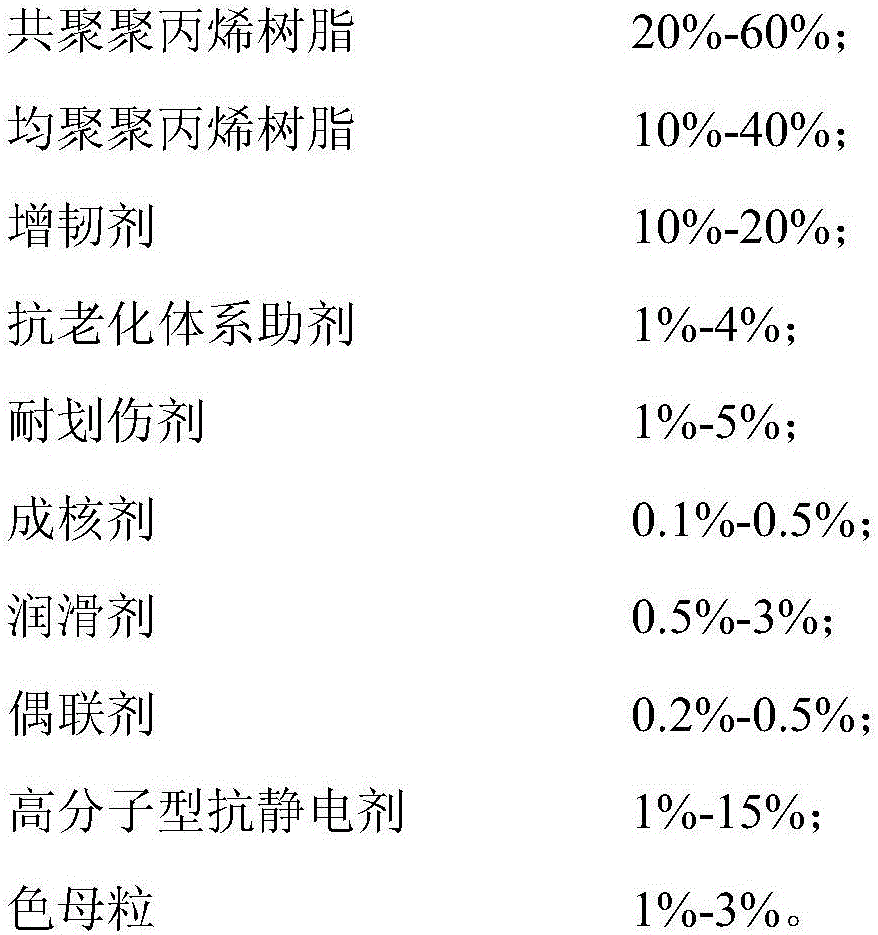

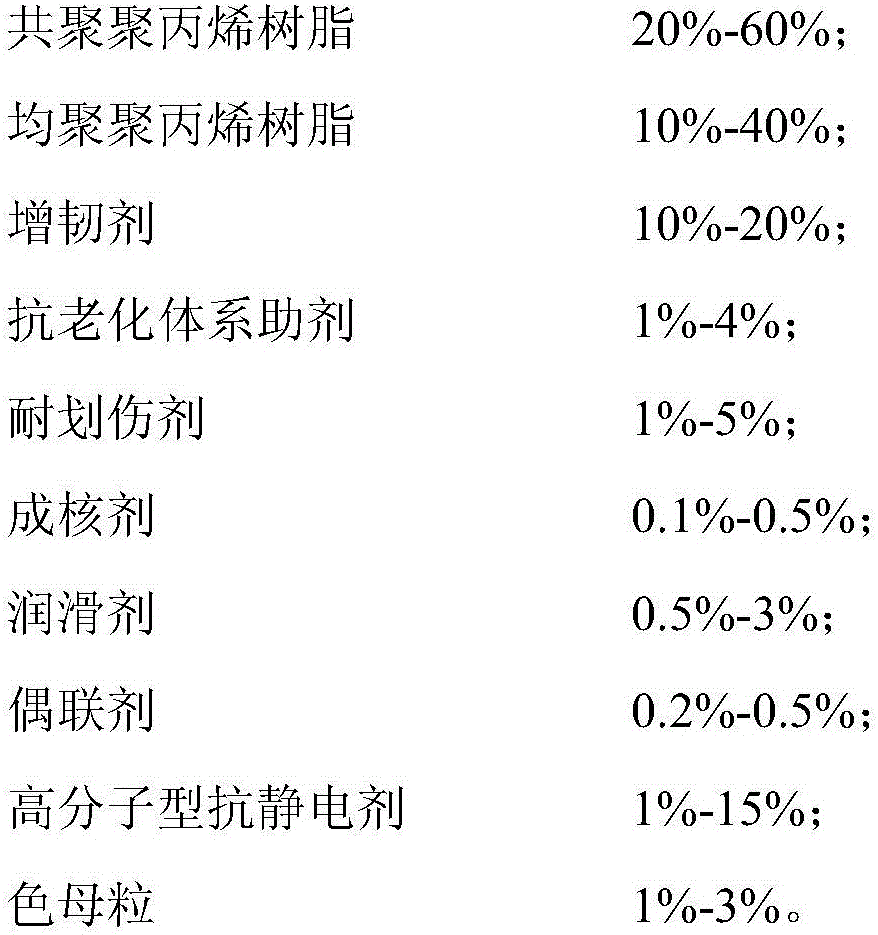

Polypropylene composition for spray-free bumpers and preparation method thereof

InactiveCN106380700AGood anti-aging propertiesInhibition of catalysisPolymer scienceAntistatic agent

The invention discloses a polypropylene composition for spray-free bumpers and a preparation method thereof. The polypropylene composition comprises the following components in percentage by weight: 20-60% of copolymer polypropylene resin, 10-40% of homopolymer polypropylene resin, 10-20% of toughener, 1-4% of antiaging system aid, 1-5% of scratch-resistant agent, 0.1-0.5% of nucleator, 0.5-3% of lubricant, 0.2-0.5% of coupling agent, 1-15% of high-polymer antistatic agent and 1-3% of master batch. The spray-free bumper prepared from the composition has the advantages of favorable washability, favorable permanent antistatic property, favorable long-term aging resistance and low dependence on the environment. The preparation method comprises the following steps: (1) weighing the materials in percentage by weight; (2) stirring and mixing the raw materials to obtain a premix; and (3) carrying out extrusion granulation on the premix to obtain the polypropylene composition. The method has the advantages of simple production technique and low cost.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

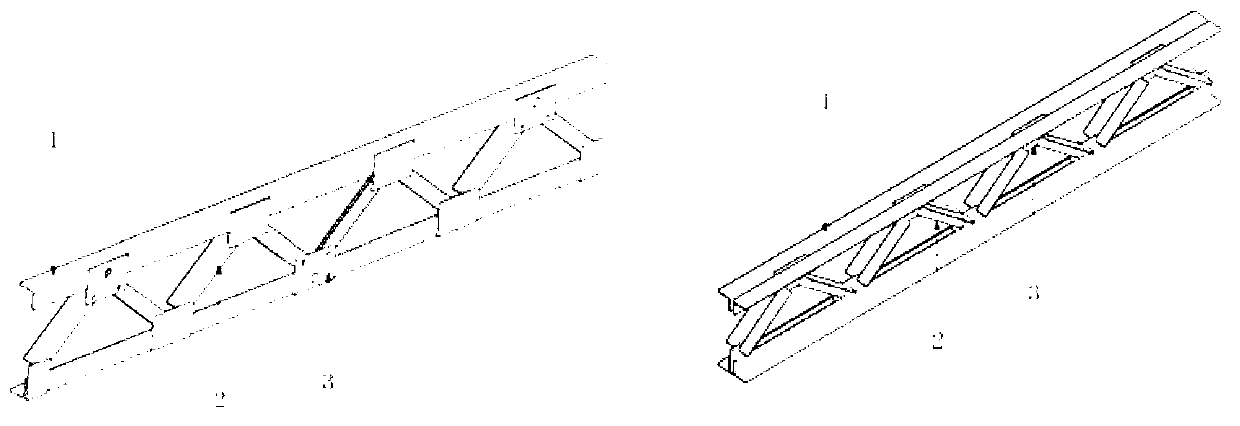

Industrialized assembling type special-shaped column steel structure prestress eccentric supporting system

ActiveCN103276806AIncrease lateral stiffnessGood deformabilityStrutsWallsSupporting systemBraced frame

The invention discloses an industrialized assembling type special-shaped column steel structure prestress eccentric supporting system and belongs to the technical field of structure engineering. The industrialized assembling type special-shaped column steel structure prestress eccentric supporting system comprises an assembling type truss plate, assembling type columns and a prestress eccentric supporting member. The assembling type truss plate comprises a lattice truss beam and a floor plate. The assembling type truss plate is prefabricated in a plant and spliced with beam column joints of the assembling type columns through a beam end sealing plate of the assembling type truss plate at the construction site, and the assembling type columns are spliced to form a multiplayer truss plate steel framework structure among layers through bolts at site. On the basis of the truss plate steel framework structure, the prestress eccentric supporting member serves as a lateral load resistance element to be connected with the bottoms or the tops of the truss beam in the assembling type truss plate and the assembling type columns. The assembling type truss plate, the assembling type columns and the prestress eccentric supporting member are all fabricated in the plant and assembled at the construction site through bolts.

Owner:RIZHAO WEIYE TOOL

Industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system

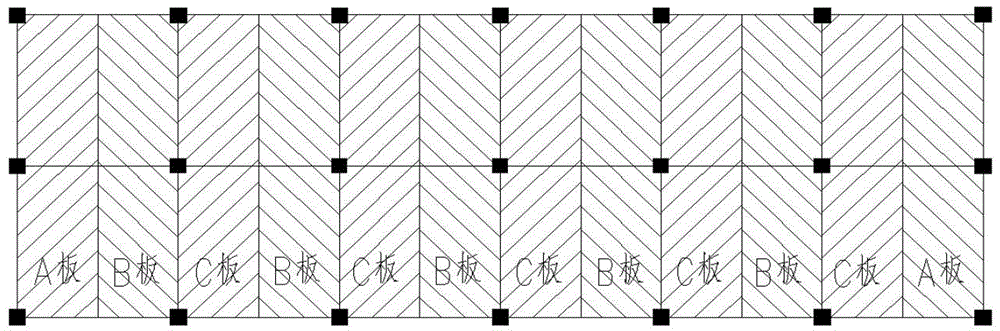

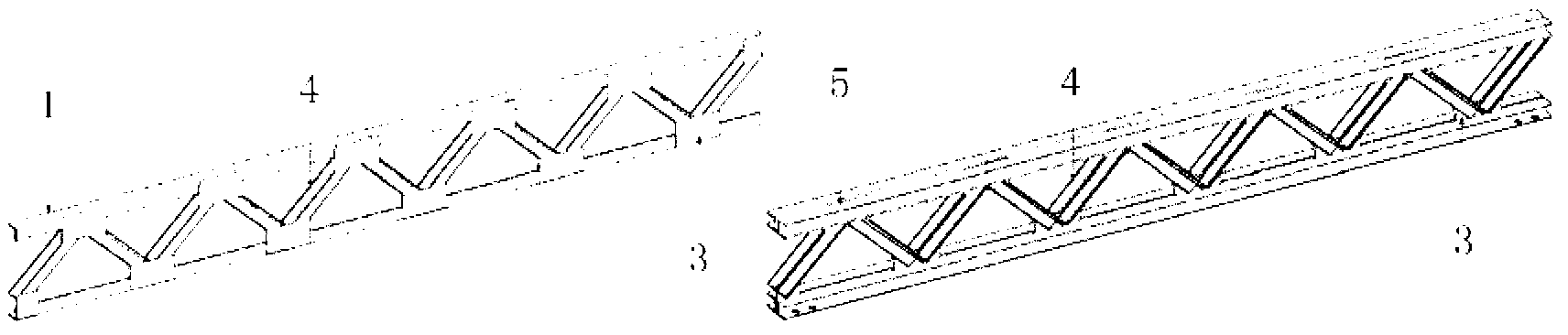

The invention provides an industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system, and relates to the technical field of structural engineering. The industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system comprises assembled truss plates, assembled special-shaped columns and eccentric supporting components, wherein the assembled truss plates comprise structural truss beams and floor slabs, and the structural truss beams are provided with channel steel web members; the assembled truss plates are prefabricated in a factory, the assembled truss plates are mutually spliced with flange plates of the assembled special-shaped columns through beam-end blanking plates of the assembled truss plates at the construction site, and the assembled special-shaped columns are spliced on site through bolts in an interlayer to form a multi-layer truss plate steel frame structure; on the basis of the steel frame structure, the eccentric supporting components are connected to the truss beams in a beam plate layer of the frame structure or the bottoms of the columns to serve as lateral load resistance components; the assembled truss plates, the assembled special-shaped columns and the eccentric supporting components are all fabricated in the factory and assembled through the bolts on the construction site.

Owner:BEIJING UNIV OF TECH

Multi-story high-rise assembled steel structure frame system

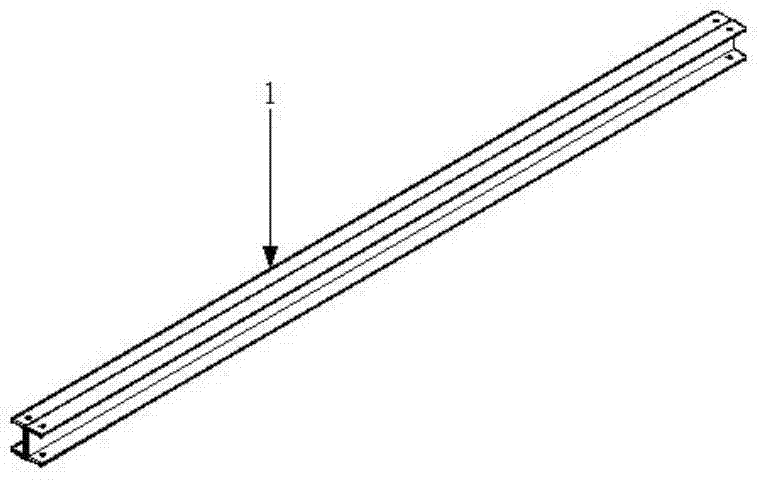

The invention relates to a multi-story high-rise assembled steel structure frame system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame system comprises assembled beams and slabs, and assembled stand columns. The assembled beams and slabs in the system comprise slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns comprise box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:GUANGDONG UNION STEEL MFG

Assembly-type multi-storey steel special-shaped column framework-steel plate shear wall structure system

The invention discloses an assembly-type multi-storey steel special-shaped column framework-steel plate shear wall structure system, and relates to the technical field of structural engineering. The assembly-type multi-storey steel special-shaped column framework-steel plate shear wall structure system comprises an assembly-type truss plate, assembly-type special-shaped columns and a steel plate shear wall component. The assembly-type truss plate comprises a lattice truss girder provided with a steel channel web member, and a floor slab. The assembly-type truss plate is prefabricated in a plant. On a construction site, the assembly-type truss plate is spliced with a flange plate of the assembly-type special-shaped columns through a beam-end blanking plate of the assembly-type truss plate. The assembly-type special-shaped columns are spliced on site through bolts between storeys to form a multi-storey truss plate steel framework structure. One the basis of the steel framework structure, a steel plate shear wall is connected to the truss girder in a beam and slab layer of the steel framework structure or the bottom or the top of each column and used as a lateral load resistance component. The assembly-type truss plate, the assembly-type special-shaped columns and the steel plate shear wall component are all prefabricated in the plant and assembled through bolts on the construction site.

Owner:BEIJING UNIV OF TECH

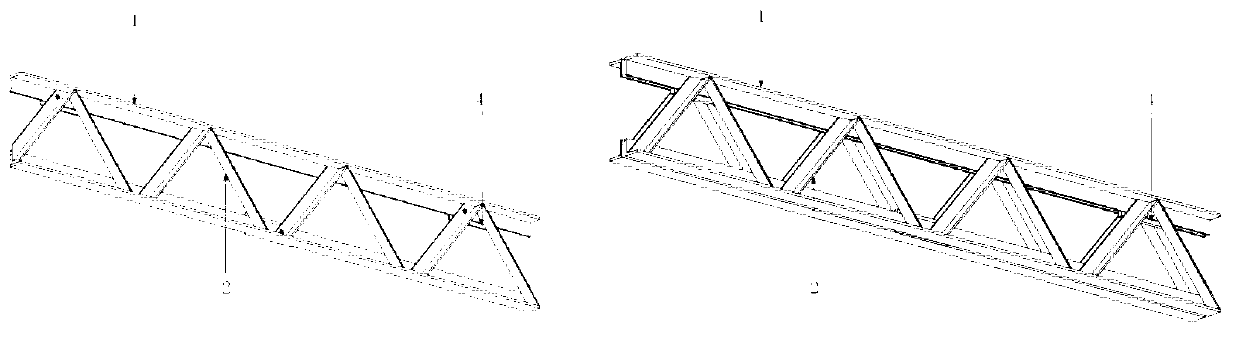

Hollow irregular column multi-layer high-rise assembling steel frame-central support system

A hollow irregular column multi-layer high-rise assembling steel frame-central support system relates to the technical field of structural engineering. The hollow irregular column multi-layer high-rise assembling steel frame-central support system comprises assembling truss plates, assembling flange columns and central support members. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. On the basis of the steel frame structure, the central support members are connected with the bottoms and tops of the truss beams or the columns in the frame structure beam plate layers to be used as lateral load resistance members. The assembling truss plates, the assembling flange columns and the central support members are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:BEIJING UNIV OF TECH

Hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system

The invention relates to a hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system and belongs to the technical field of structural engineering. The hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system comprises assembling truss plates, assembling flange columns and steel plate shear walls. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. On the basis of the steel frame structure, steel plate shear wall members are connected with the truss beams or the columns in the frame structure beam plate layers to be used as lateral load resistance members. The assembling truss plates, the assembling flange columns and steel plate shear wall members are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:BEIJING UNIV OF TECH

Novel post-earthquake easy-to-repair steel irregular column framework

InactiveCN103696503AImprove securitySmall residual deformation after earthquakeShock proofingHorizontal stressPre stress

Provided is a novel post-earthquake easy-to-repair steel irregular column framework. Double-channel steel beams of the framework are connected with irregular columns through beam end sealing plates to form a welding-gap-free full-bolt connection mode. Prestress steel cables are applied to welding-gap-free full-bolt nodes to form prestress self-resetting nodes. Axial and horizontal stress performance of the bottoms of the columns are optimized through reinforcing plates by self-resetting column legs and prestress column legs, bending-proof steel plates are mainly used for dissipating earthquake energy, and shearing plates are used for preventing shearing force from being too large and leading to local bending of the bottoms of the columns. Key members of the prestress column legs are prestress pull rods which are used for providing prestress for the columns to enable the columns to be closely connected with the beams, the column legs can be in rigid connection similarly when the torque borne by the column legs is small, and a post-earthquake self-resetting capability is achieved.

Owner:BEIJING UNIV OF TECH

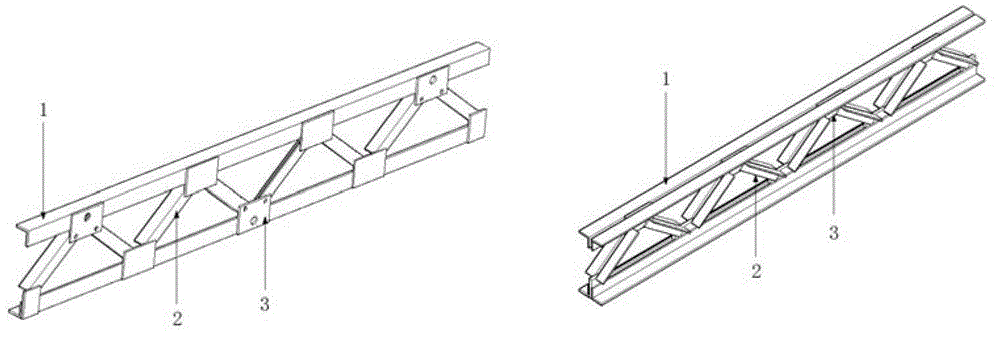

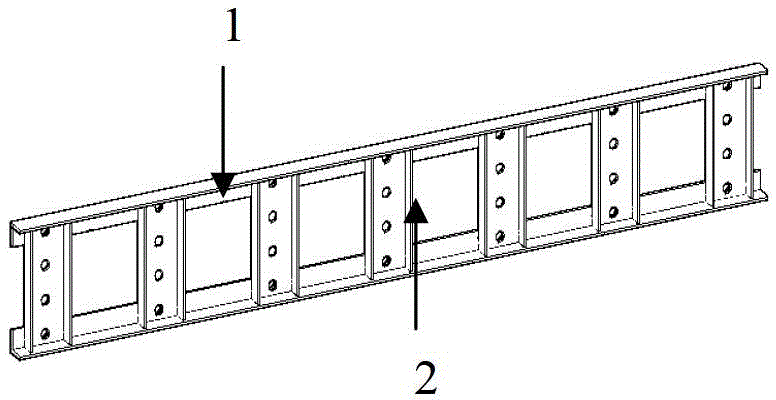

Industrialized assembly type pillar-running-through beam solid-web steel structure frame eccentric support system

ActiveCN103276799AIncrease lateral stiffnessGood deformabilityBuilding constructionsSupporting systemFloor slab

The invention relates to an industrialized assembly type pillar-running-through beam solid-web steel structure frame eccentric support system, and belongs to the technical field of structural engineering. The structural system is formed by assembly type floor slabs, assembly type stand columns and eccentric supporting members in an assembled mode through bolts. Each assembly type floor slab comprises a section steel beam and a slab, each section steel beam is connected with other section steel beams or other stand columns through a beam end close plate and a cover plate on the beam to form a beam slab steel frame structure, and then each slab is placed on one beam slab steel frame structure and connected with the beam slab steel frame structure to form an assembly type beam slab. The assembly type beam slabs are prefabricated in a factory, at the construction field, the assembly type beam slabs are mutually connected with beam column nodal points in a splicing mode through the beam end close plates and the cover plates on the beams of the assembly type beam slabs, the assembly type stand columns run through the beam column nodal points, and on the basis of multiple layers of beam slab steel frame structures, the eccentric supporting members are connected to the bottoms or the tops of the section steel beams in a frame structure beam slab layer to serve as lateral load resisting members. Field assembly is carried out by complete adoption of the bolts, and a traditional field welding mode and a traditional concrete pouring mode are canceled.

Owner:RIZHAO WEIYE TOOL

Industrial prefabricated steel structural frame system with penetrating columns

InactiveCN103290921AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

The invention discloses an industrial prefabricated steel structural frame system with penetrating columns, and belongs to the technical field of structural engineering. The industrial prefabricated steel structural frame system comprises prefabricated truss plates and prefabricated upright columns, and the prefabricated truss plates comprise floors and latticed truss beams with angle steel web members; the prefabricated truss plates are prefabricated in a factory, and are spliced with beam-column joints of the prefabricated upright columns by beam-end sealing plates and on-beam cover plates of the prefabricated truss plates in a construction site; portions, the prefabricated upright columns penetrate the beam-column joints, each upright column with the certain length can penetrate 4-5 stories, and the upright columns are spliced at inflection points, which have low stress, of middle columns of the stories by bolts in the site, so that a multilayer truss plate and steel frame structure is formed; various members of the prefabricated truss plates and the prefabricated upright columns are prefabricated in the factory and are assembled by bolts in the construction site.

Owner:BEIJING UNIV OF TECH

Assembly type multi-high-rise steel specially-shaped column frame and prestress eccentric supporting system

ActiveCN103410217AEasy to pass throughIncrease net heightBuilding constructionsSupporting systemFloor slab

The invention discloses an assembly type multi-high-rise steel specially-shaped column frame and prestress eccentric supporting system, and belongs to the technical field of structural engineering. The assembly type multi-high-rise steel specially-shaped column frame and prestress eccentric supporting system comprises assembly type truss plates, assembly type specially-shaped columns and prestress eccentric supporting components. Each assembly type truss plate comprises lattice type truss beams with steel channel web members, and a floor slab. The assembly type truss plates are prefabricated in factories, and are mutually spliced with flanges of the assembly type specially-shaped columns through beam end blanking plates of the assembly type truss plates on the construction site, and bolts are used for splicing the assembly type specially-shaped columns between layers to form a multi-layer truss plate steel-frame structure on the site. On the basis of the truss plate steel-frame structure, the presstress eccentric supporting components serve as lateral-load resistant components, and are connected with the truss beams of the assembly type truss plates and the column bottoms or the tops of assembly type stand columns. The assembly type truss plates, the assembly type specially-shaped columns and the presstress eccentric supporting components are prefabricated in the factories, and are assembled through bolts on the construction site.

Owner:广西新峰钢构有限公司

Hollow irregular column multi-layer high-rise assembling steel frame-eccentric support system

The invention relates to a hollow irregular column multi-layer high-rise assembling steel frame-eccentric support system and belongs to the technical field of structural engineering. The hollow irregular column multi-layer high-rise assembling steel frame-eccentric support system comprises assembling truss plates, assembling flange columns and eccentric support members. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. On the basis of the steel frame structure, the eccentric support members are connected with the bottoms of the truss beams or the columns in the frame structure beam plate layers to be used as lateral load resistance members. The assembling truss plates, the assembling flange columns and the eccentric support members are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:江苏瑞成建筑科技有限公司

Assembly prestress center support system for steel structure

The invention discloses an assembly prestress center support system for a steel structure and belongs to the technical field of structural engineering. The assembly prestress center support system comprises assembly truss plates, assembly columns and prestress center support members. The assembly truss plates comprise lattice truss girders and floor plates, and the lattice truss girders are equipped with angle steel web members. The assembly truss plates are prefabricated in factories and spliced with girder column nodes of the assembly columns through beam-end sealing plates at construction sites. The prestress center support members serve as lateral load resistant members to be connected with truss girders of the assembly truss plates and the bottoms or tops of the assembly columns. The assembly truss plates, the assembly columns and the prestress center support members are prefabricated in factories and assembled at construction sites through bolts.

Owner:BEIJING UNIV OF TECH

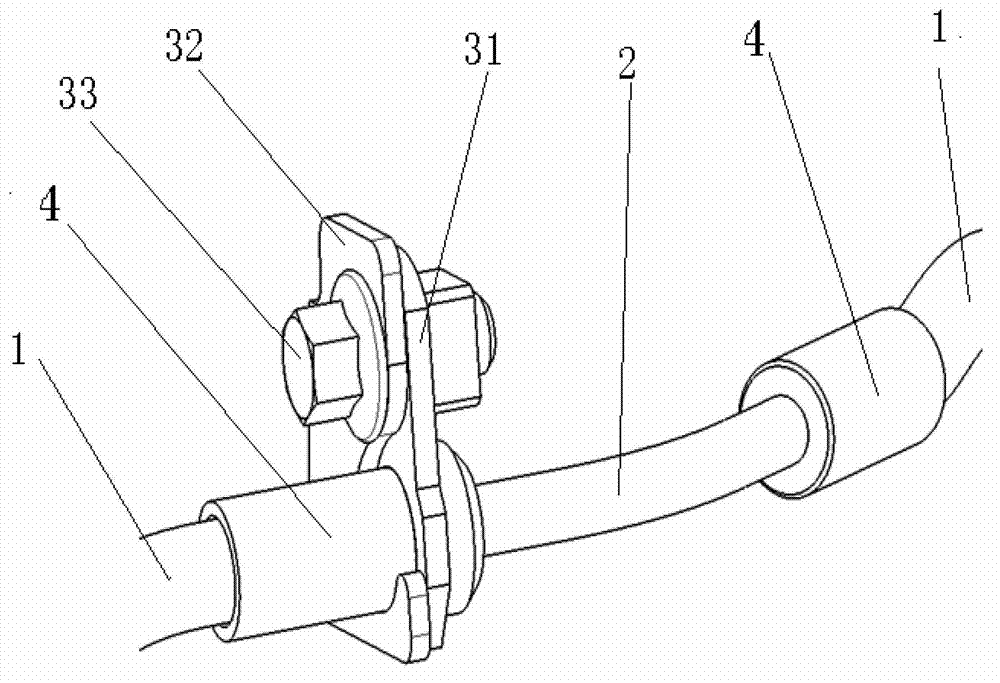

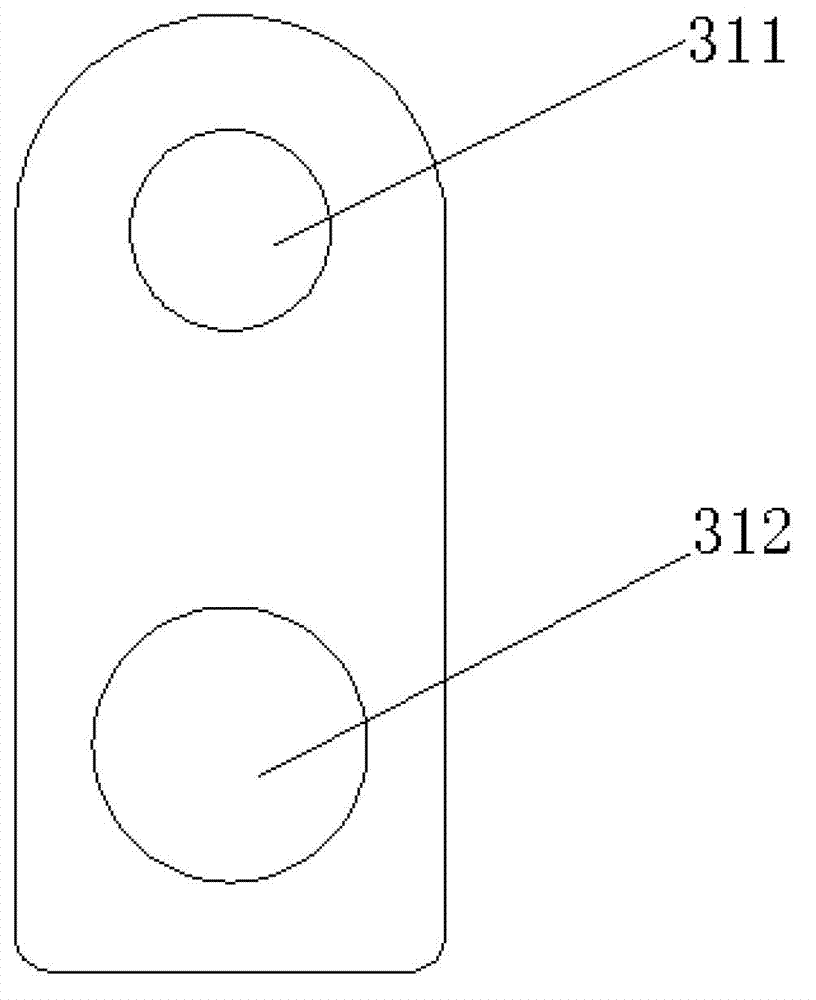

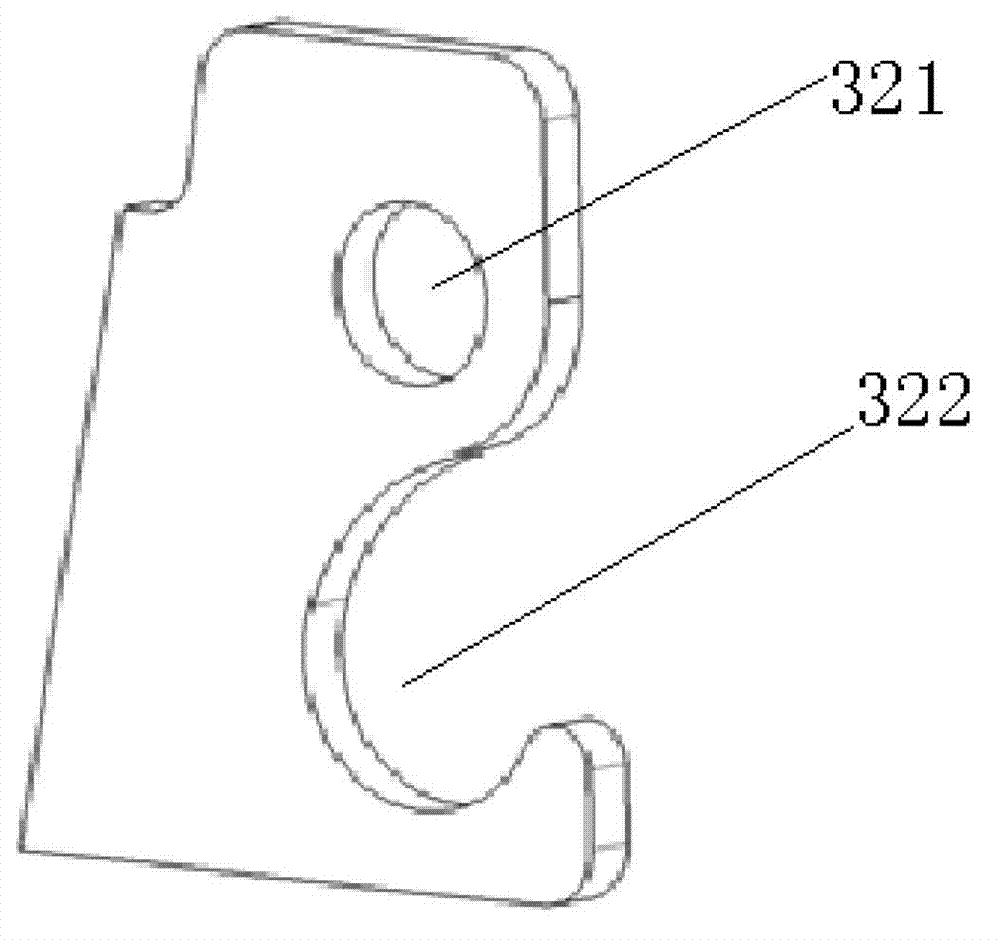

Flexible pipe connecting device

InactiveCN102900905AAvoid damageReducing Hazardous AccidentsHose connectionsEngineeringMechanical engineering

The invention relates to a flexible pipe connecting device used for connecting two flexible pipes. The flexible pipe connecting device comprises a rigid pipe and a bracket component, wherein the rigid pipe is arranged between two flexible pipes, both ends of the rigid pipes are respectively connected with connecting ends of the two flexible pipes, and the rigid pipe has flexibility; and the bracket component is sleeved at a connecting part of any one of the two flexible pipes and the rigid pipe and used for fixing the rigid pipe. According to the flexible pipe connecting device, the rigid pipe is arranged between the two brake flexible pipes and used for replacing the brake flexible pipes to be arranged in a position with smaller space, which is needed to be passed through, and because the rigid pipe is a rigid piece, the rigid pipe can be consistently moved along with a fixing bracket; and the rigid pipe can be provided with the flexibility according to actual conditions to ensure that the rigid pipe can smoothly pass through the position with the smaller space, and meanwhile, the directions of the brake flexible pipes can be better controlled so as to prevent the brake flexible pipes from having friction interference with peripheral parts and causing damages and reduce accidents having damages to drivers; and in addition, the flexible pipe connecting device has the advantages of convenience in mounting, simple structure and reliable fixing.

Owner:CHERY AUTOMOBILE CO LTD

Novel post-earthquake self-reset concrete framework-eccentric supporting structural system

ActiveCN103790258ASolve the problem of difficult assemblyAvoid pollutionShock proofingPre stressSteel bar

The invention relates to a novel post-earthquake self-reset concrete framework-eccentric supporting structural system, and belongs to the technical field of earthquake prevention and disaster reduction. The initial rigidity of an embedded type cup-shaped foundation is basically the same as the rigidity of a cast-in-place concrete structure, under the condition of a small interlayer displacement angle, prestressed steel keeps elasticity, energy consummation steel bars enter the plastic state to dissipate energy, and the embedded type cup-shaped foundation can reset to the initial position after the earthquake action. Compared with the prior art, the novel post-earthquake self-reset concrete framework-eccentric supporting structural system overturns a traditional concrete structural building foundation, and basically solves the difficult problems that concrete structures are not easy to assemble and poor in ductility. Compared with the traditional concrete structural foundation, the novel post-earthquake self-reset concrete framework-eccentric supporting structural system has the advantages of being high in safety performance, small in environmental pollution, few in accident, low in manufacturing cost of projects and the like.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Industrialized assembly type special-shaped column steel structure frame-eccentric support system

InactiveCN103276796AIncrease net heightGuarantee the construction qualityBuilding constructionsAbnormal shapedFloor slab

The invention provides an industrialized assembly type special-shaped column steel structure frame-eccentric support system and belongs to the technical field of structural engineering. The industrialized assembly type special-shaped column steel structure frame-eccentric support system comprises assembly type truss plates, assembly type columns and eccentric support members. Each assembly type truss plate comprises lattice truss beams and floor slabs and is prefabricated in a factory, and the assembly type truss plates and beam-column joints of the assembly type columns are spliced through beam-end seal plates in a construction site, and the assembly type columns are spliced among layers in the site through bolts to form a multiple-layer truss plate steel frame structure. Based on the truss plate steel frame structure, the eccentric support members serve as lateral force resisting members and are connected with the truss beams in the assembly type truss plates and the bottoms or the tops of the assembly type columns. The assembly type truss plates, the assembly type columns and the eccentric support members are prefabricated in the factory and are assembled in the construction site through bolts.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com