Industrial prefabricated steel structural frame system with penetrating columns

A steel structure frame and industrialized assembly technology, which is applied in the direction of building construction and construction, can solve the problems of affecting the safety performance of buildings, the quality of welding seams is not suitable for control, and the construction speed is slow, so as to reduce construction waste, reduce fires, increase net height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

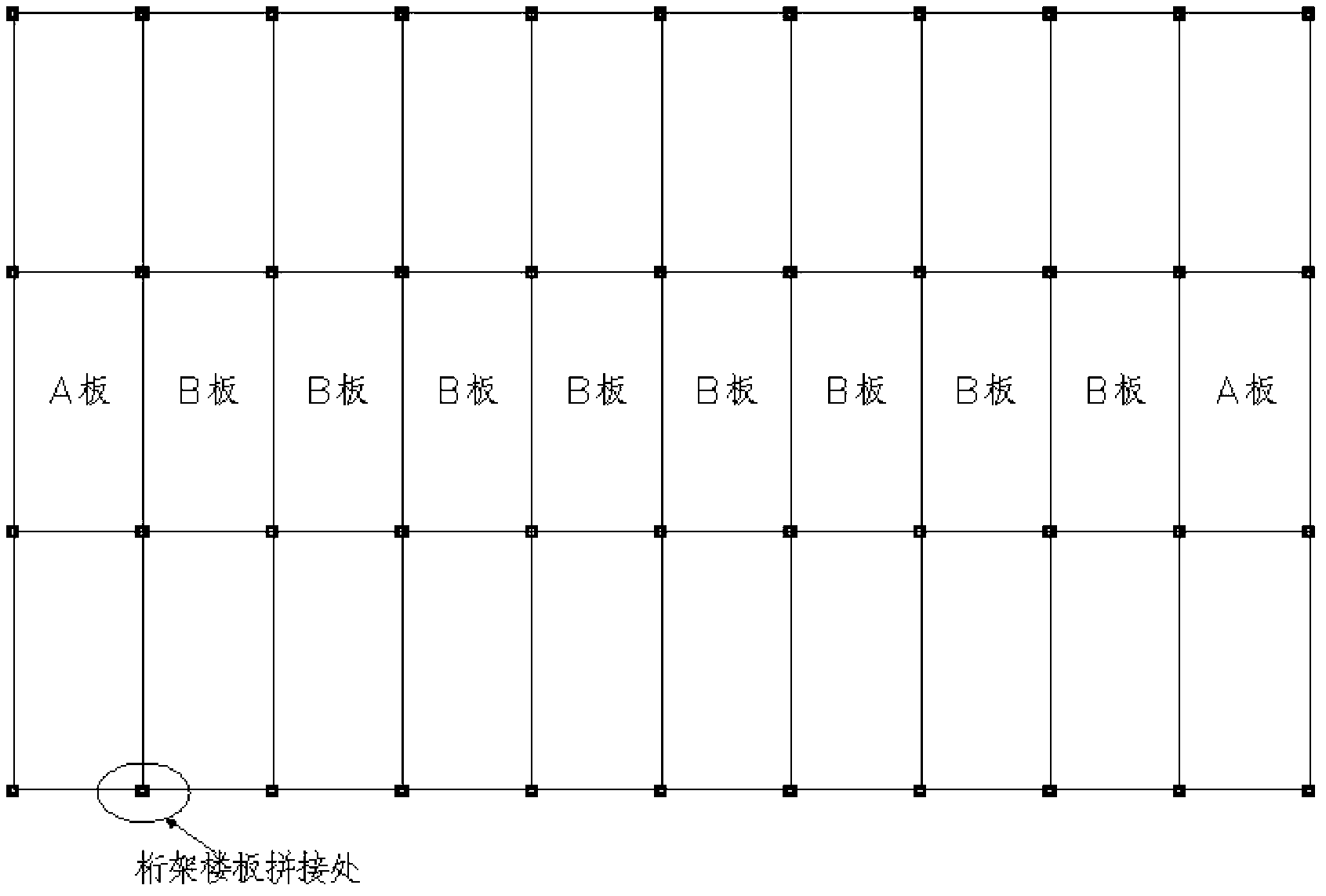

[0044] as attached figure 1 As shown, the prefabricated truss plate of the present invention is spliced with the prefabricated column in the manner of ABB···BBA (both sides are A plates, and the middle is several B plates).

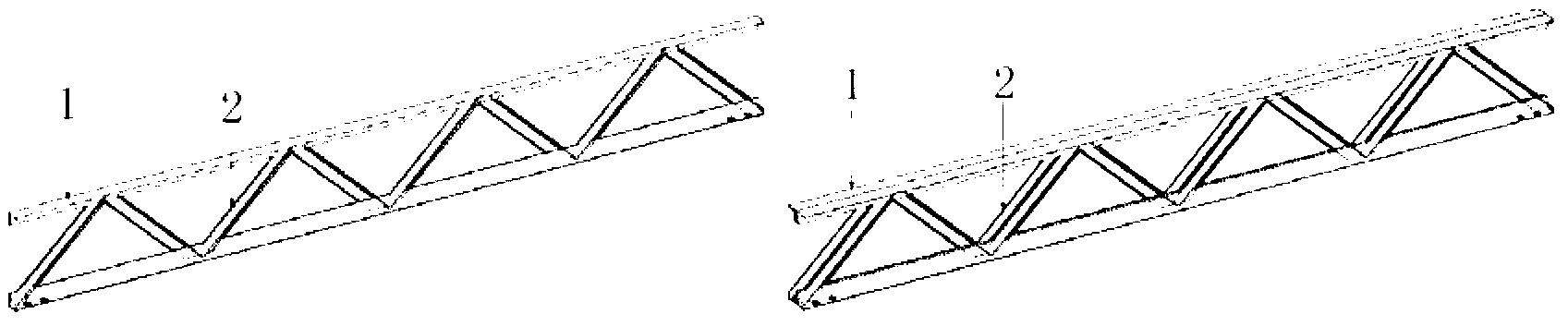

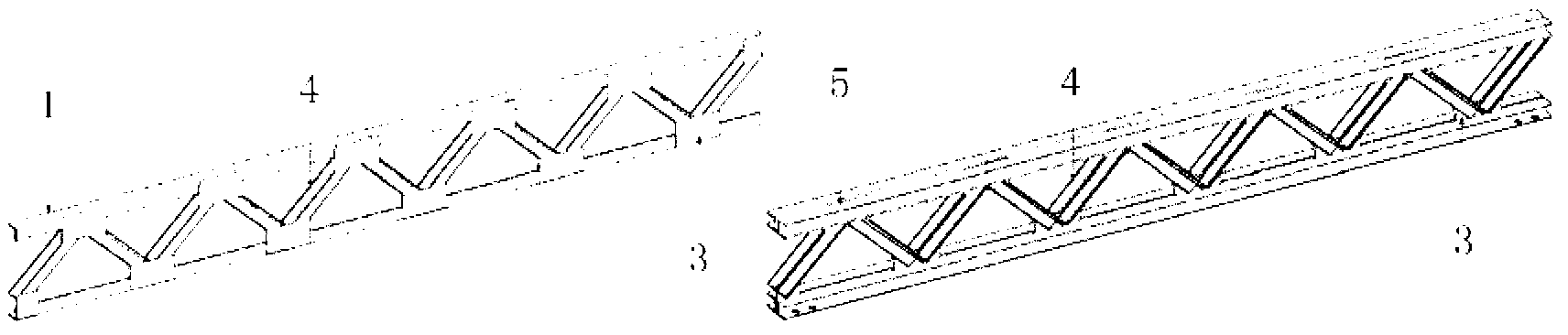

[0045] as attached figure 2 As shown, in the industrialized assembled column through-type steel structure frame system of the present invention, the involved beams are truss beams composed of angle steel splicing, including upper and lower chords I1 and webs I2, wherein the upper and lower chords I1 and webs I2 uses angle steel, and is divided into single-angle steel beams and double-angle steel beams. The single-angle steel beams are provided with connecting holes at a fixed distance, which is convenient for splicing two single-angle steel beams into double-angle steel beams with bolts when splicing panels. For steel beams, for double-angle steel be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com