Patents

Literature

37results about How to "Reduce hazards such as fire accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system

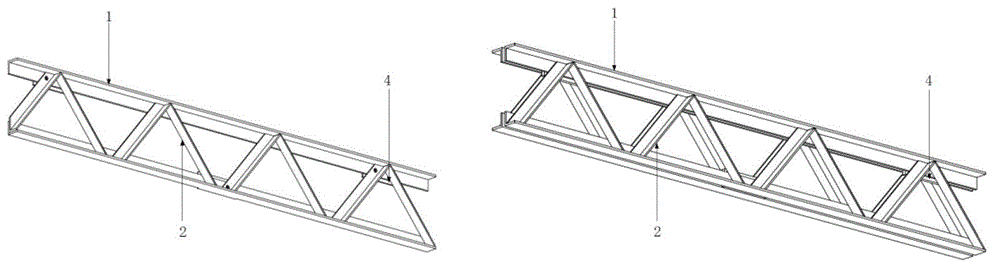

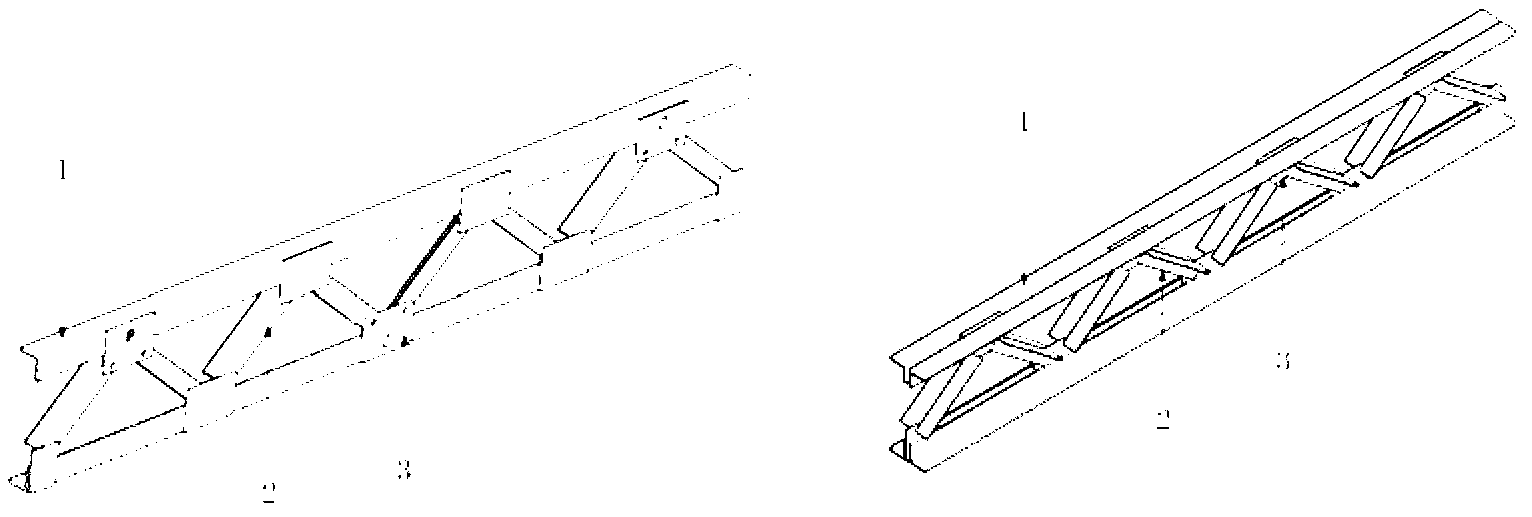

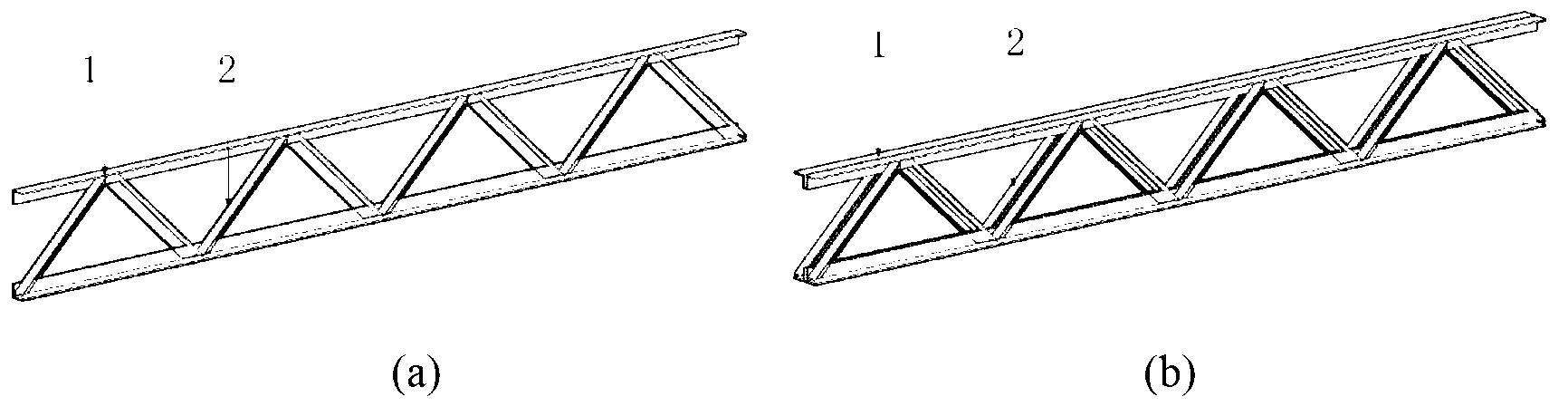

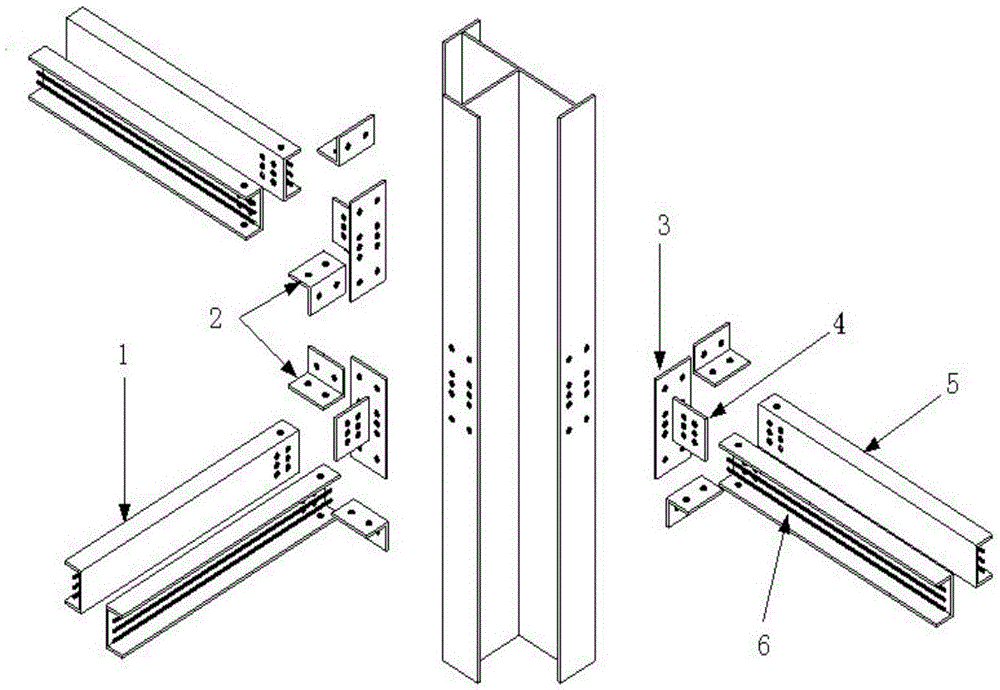

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system comprises assembled truss plates, assembled flange columns and eccentric bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the eccentric bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

Assembled steel structure center support frame system

InactiveCN103290920AEasy to pass throughIncrease net heightBuilding constructionsBraced frameFloor slab

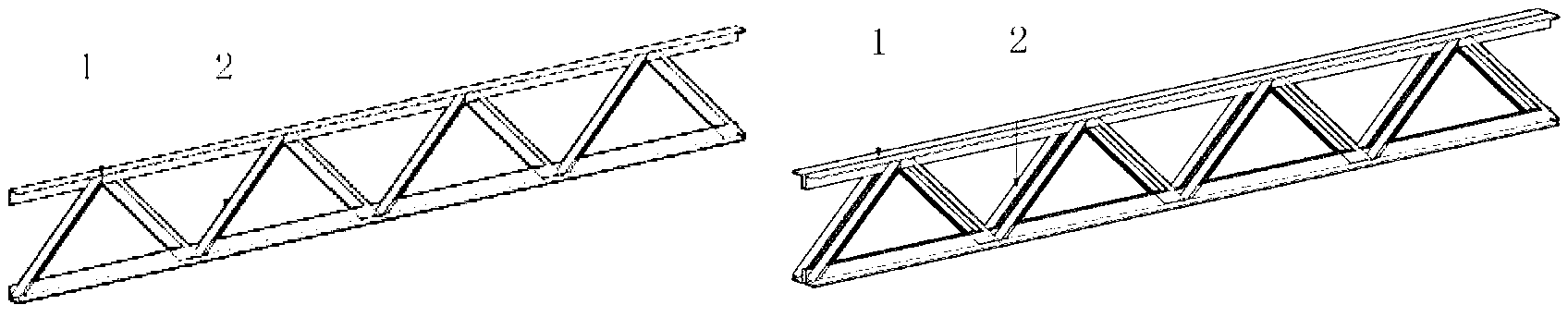

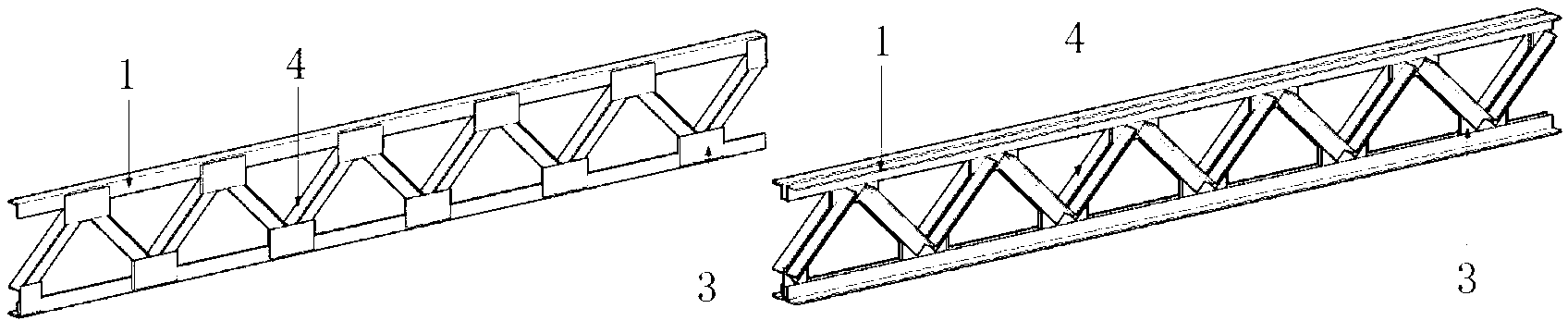

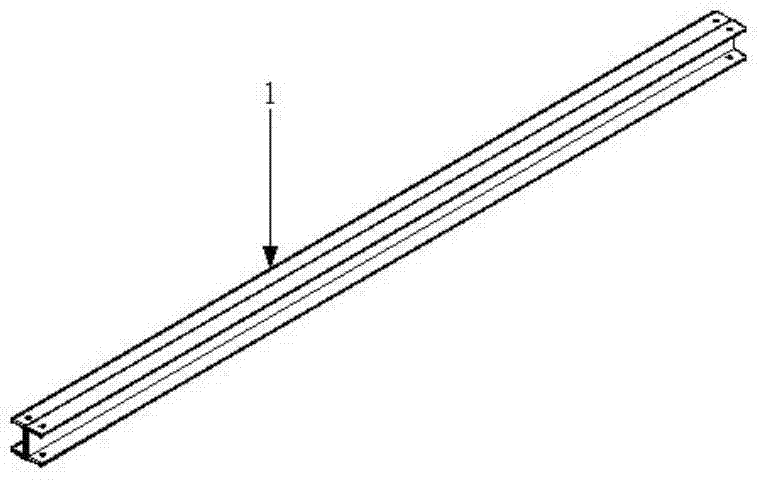

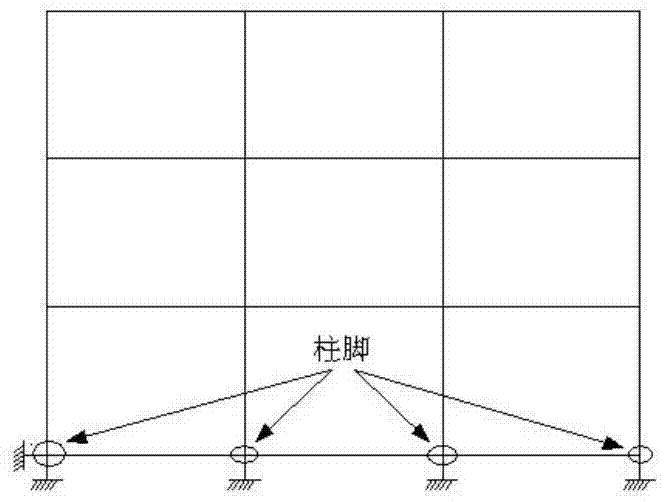

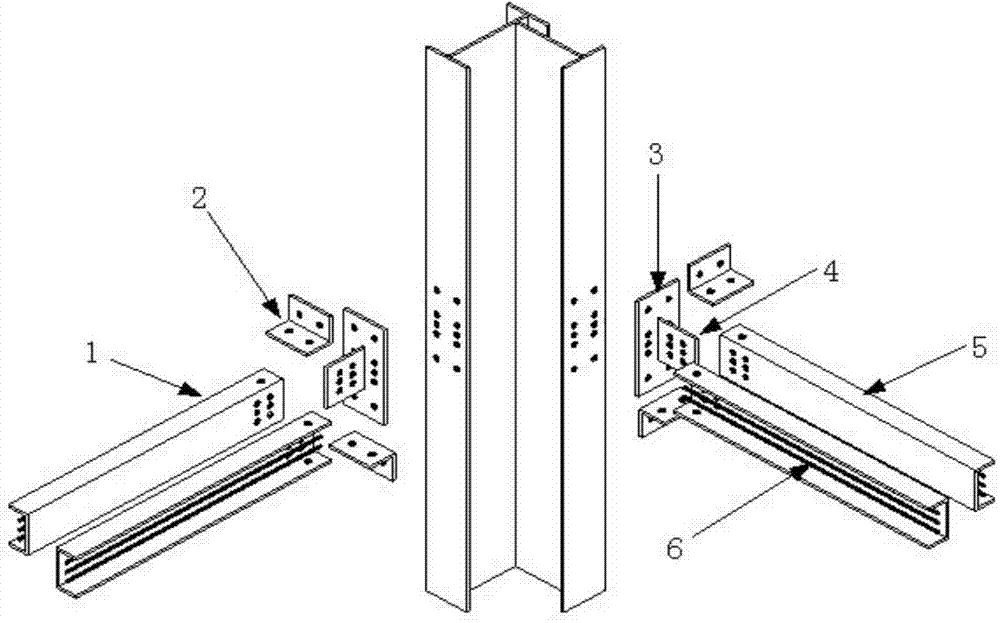

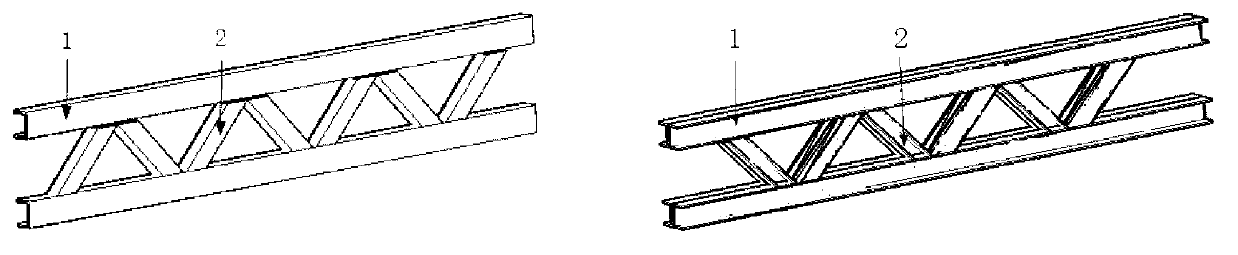

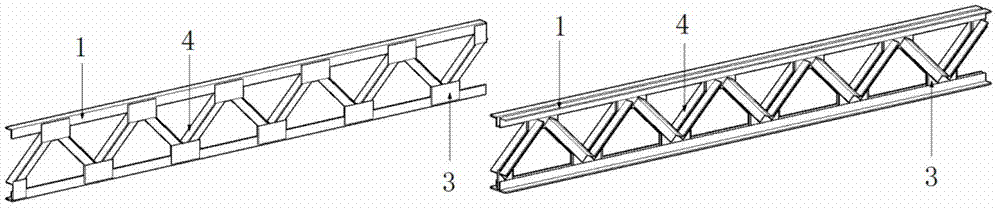

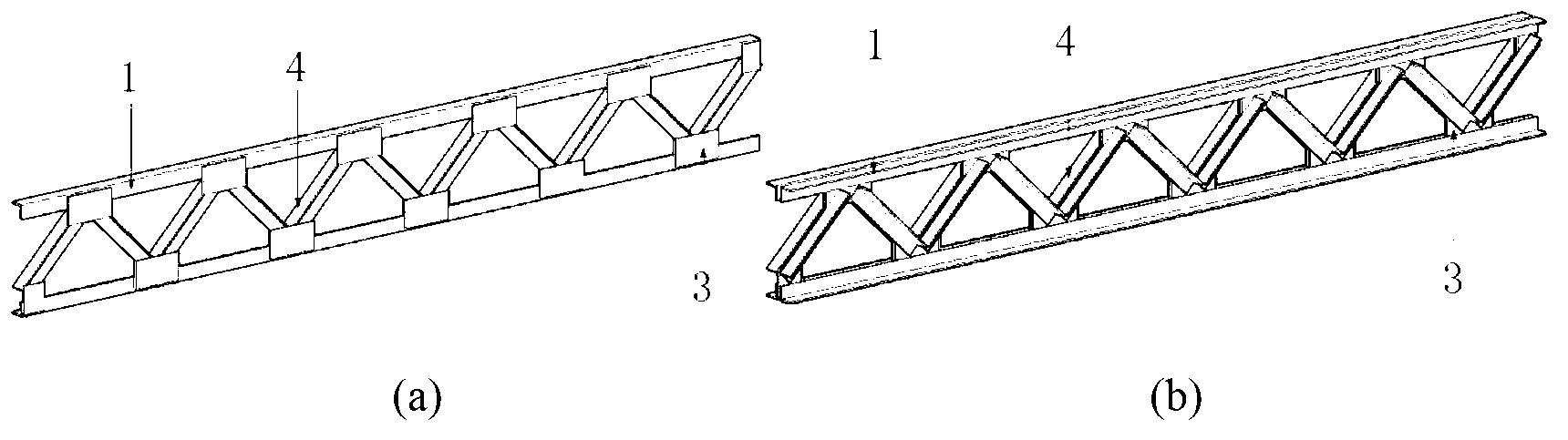

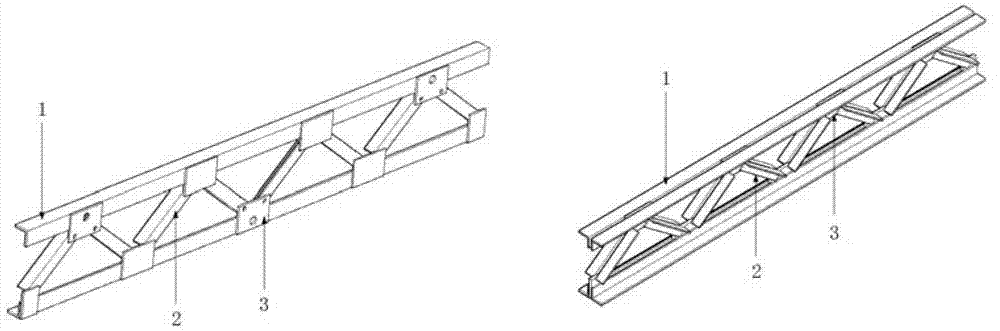

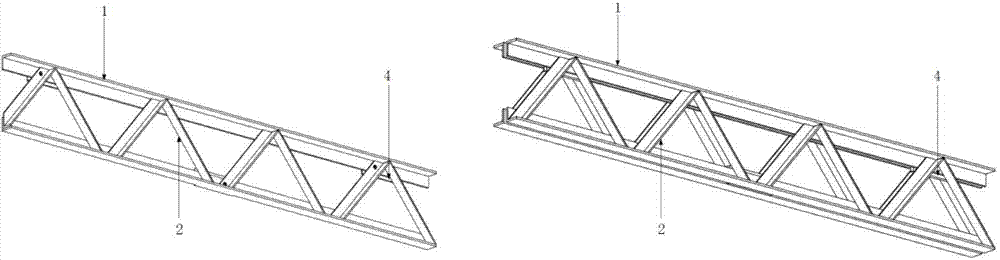

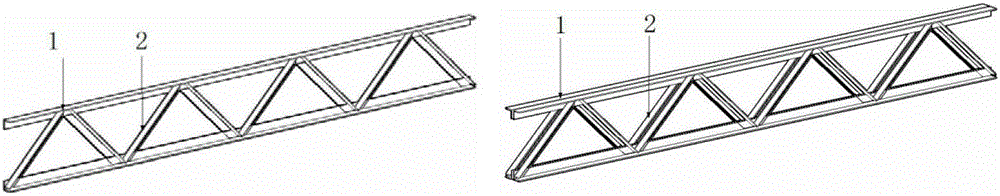

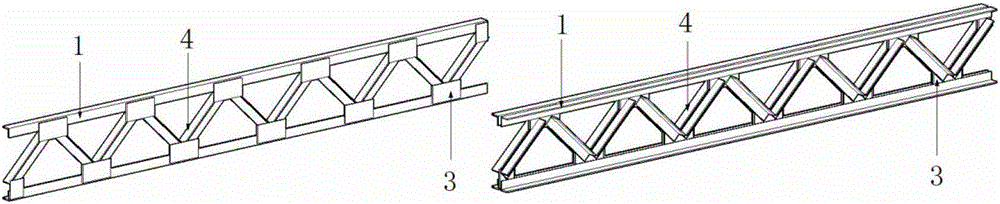

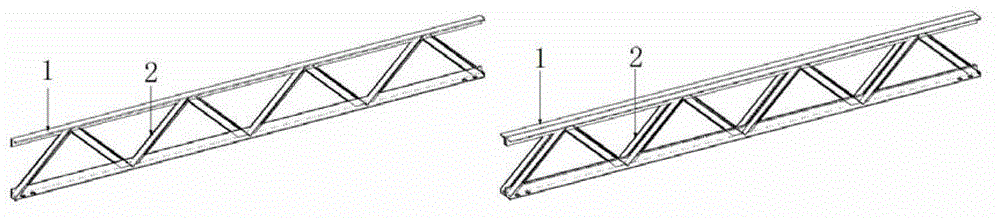

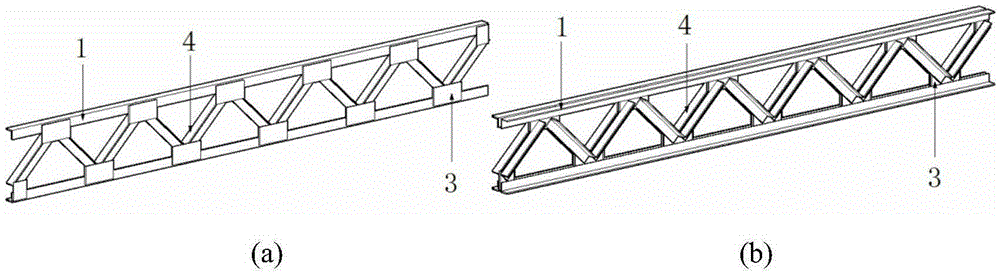

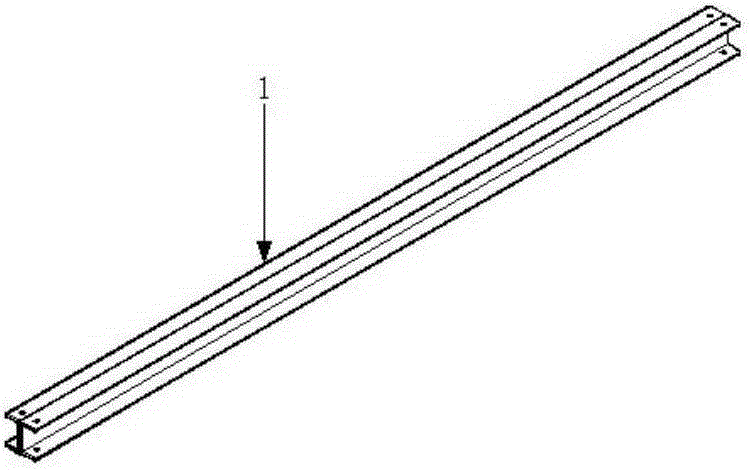

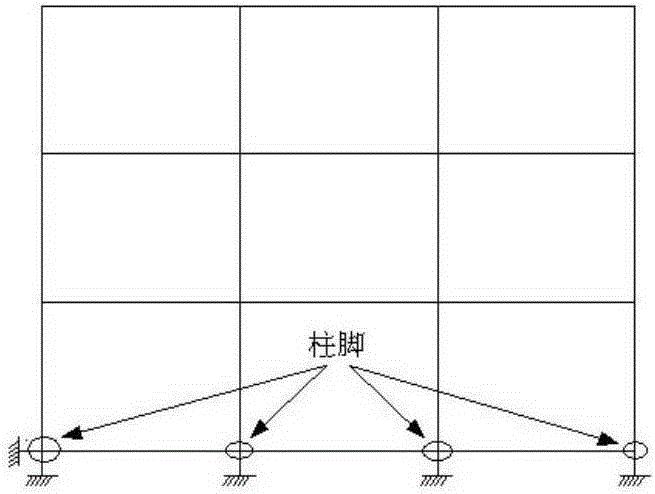

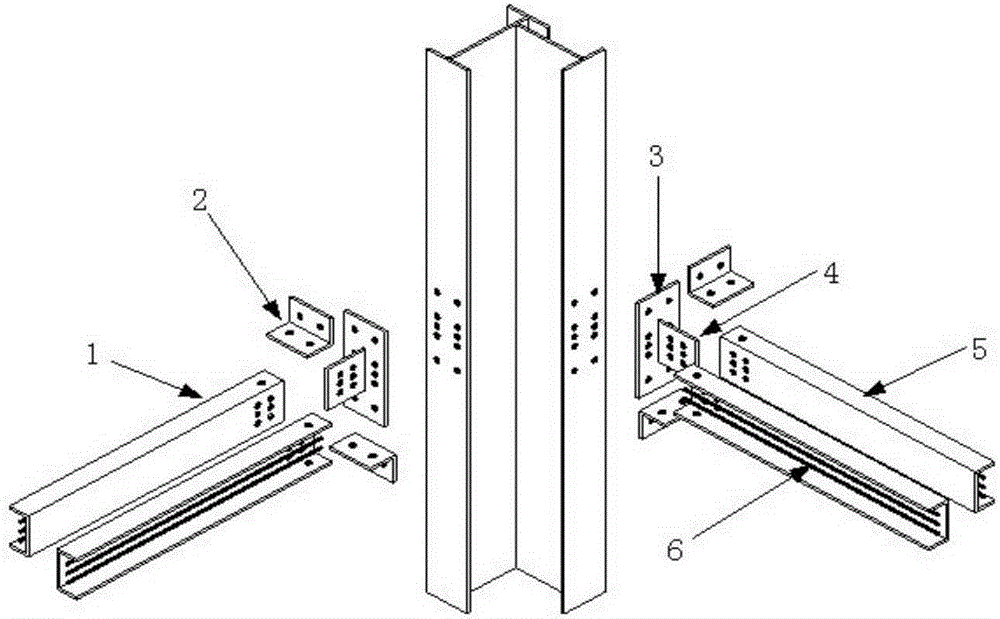

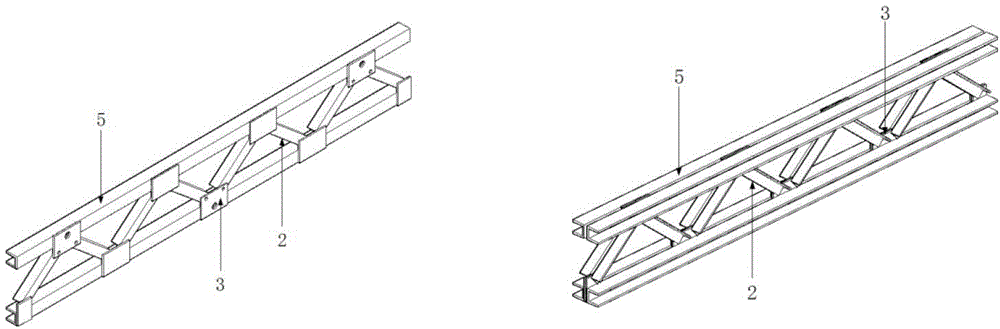

The invention relates to an assembled steel structure center support frame system and belongs to the technical field of structure engineering. The system comprises assembled truss plates, assembled uprights and center support members, wherein the assembled truss plates comprise lattice truss beams with steel angle web members, and floor plate, and are prefabricated in a factory; the assembled truss plates are spliced with beam column nodes of the assembled uprights by beam end sealing plates of the assembled truss plates at a construction site; the assembled uprights are spliced between layers by bolts on site to form a multilayer steel frame structure; based on the steel frame structure, the center support members serve as lateral force resisting members and are connected with the truss beams in the assembled truss plates and the bottoms or tops of the assembled uprights; the assembled truss plates, the assembled uprights and the center support members are prefabricated in the factory and assembled by the bolts at the construction site.

Owner:河南天蚕富煌钢结构有限公司

Industrialized multi-story high-rise assembled steel structure frame - centrally-braced system

ActiveCN102979168AEasy to pass throughIncrease net heightBuilding constructionsModularitySteel frame

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - centrally-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - centrally-braced system comprises assembled truss plates, assembled flange columns and central bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the central bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - centrally-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

Modular low-layer assembling type house system of special-shaped column steel structure

InactiveCN105863067AEasy to disassemble and transportAvoid pollutionBuilding constructionsComputer moduleEngineering

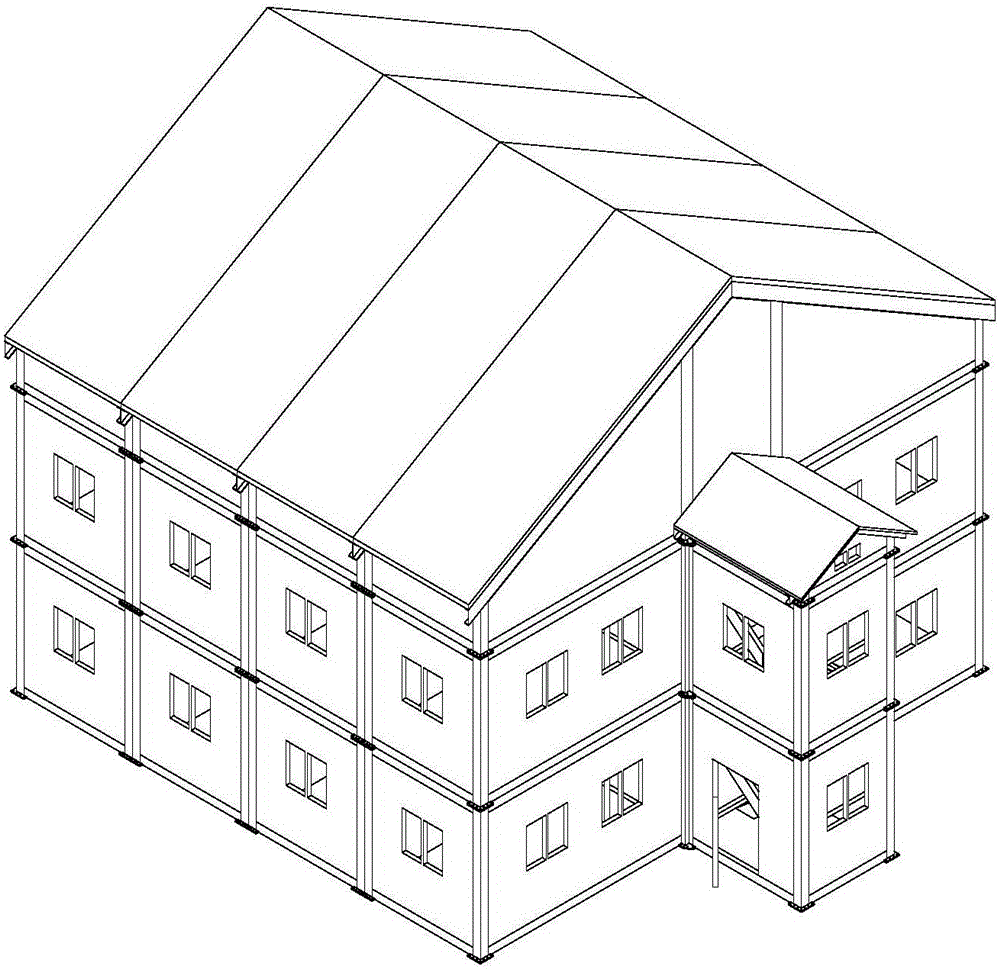

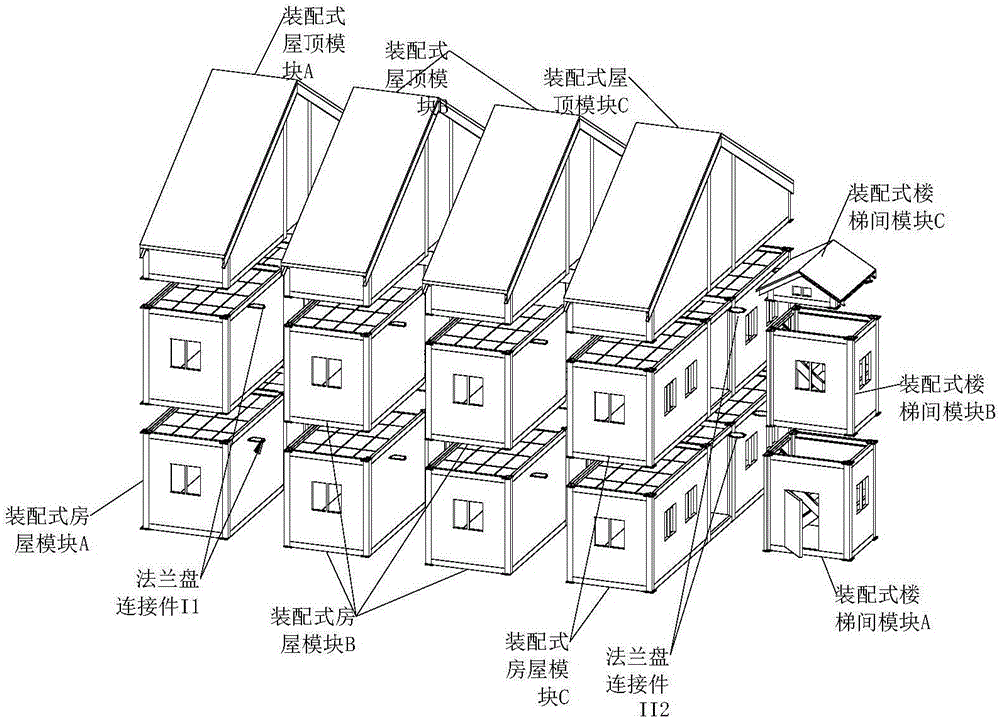

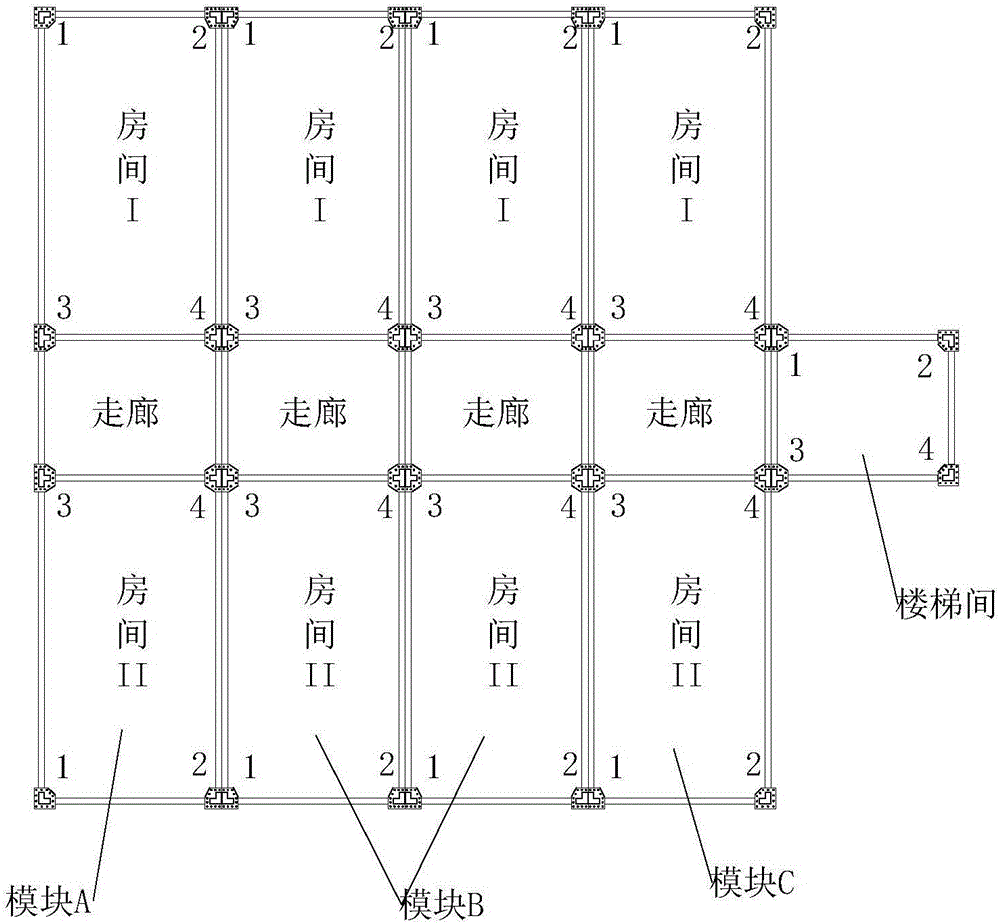

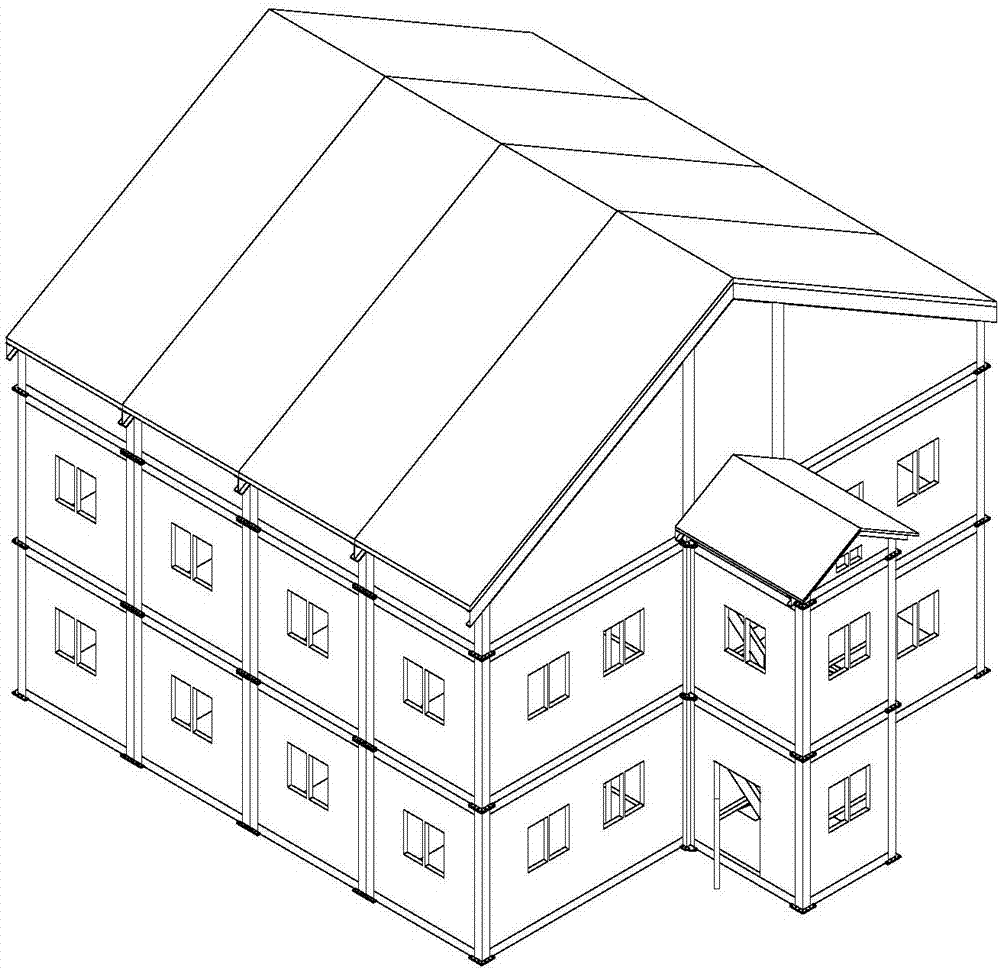

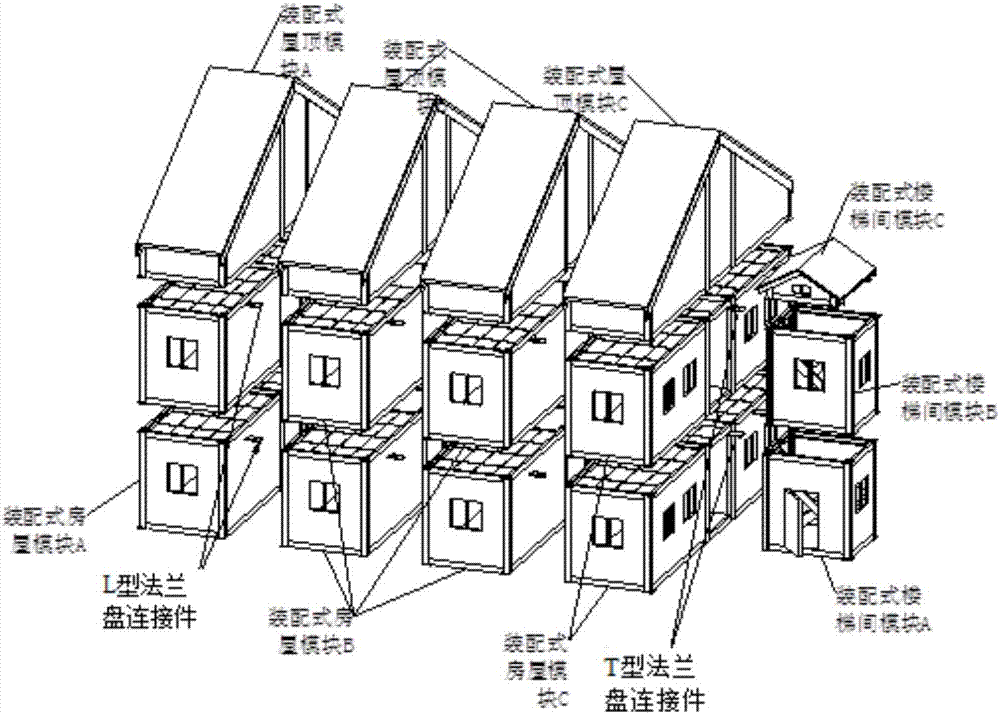

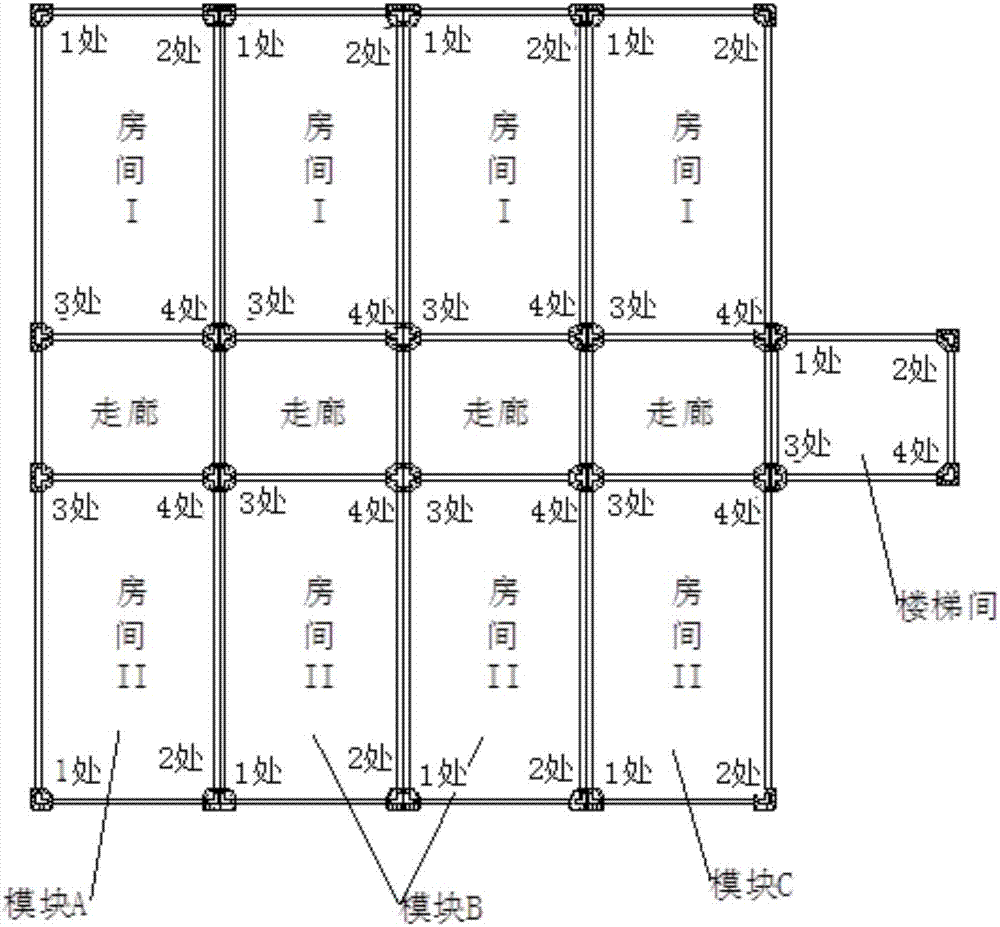

The invention discloses a modular low-layer assembling type house system of a special-shaped column steel structure, and belongs to the technical field of structural engineering. The modular low-layer assembling type house system of the special-shaped column steel structure comprises assembling type house modules, assembling type roof modules, assembling type staircase modules and flange plate connectors among the modules. The assembling type house modules, the assembling type roof modules and the assembling type staircase modules are processed and manufactured in a factory. On the construction site, the modules are connected through the flange plate connectors via high-strength bolts in a bolting mode, and then pipelines among the modules are mutually connected, so that construction is finished. The modules are easy to detach and convey, and can be reused. The modular low-layer assembling type house system of the special-shaped column steel structure integrates modularization, industrialization, standardization and assembling performance, realizes industrialized production, can be rapidly assembled on site and can be reused. On the premise of guaranteeing construction quality, the construction speed is improved, the construction period is shortened, and engineering construction cost is reduced.

Owner:BEIJING UNIV OF TECH

Special-shaped steel column frame structure joint easy to restore after earthquake

The invention discloses a special-shaped steel column frame structure joint easy to restore after an earthquake. According to the special-shaped steel column frame structure joint easy to restore after the earthquake, a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that the prestress self-reset joint easy to restore after the earthquake is formed. By the adoption of a prestress self-reset joint form, self-reset of the joint after the earthquake is achieved, and restoring cost after the earthquake is greatly reduced; the shock resistance of the joint is improved, and thus the shock resistance of a frame structure system is improved; compared with a traditional steel-structural construction joint, the special-shaped steel column frame structure joint easy to restore after the earthquake has the advantages that the safety performance is high, environmental pollution is light, the number of safety accidents is small, and construction cost is low.

Owner:南通新丰威机械科技有限公司

Novel special-shaped steel column frame-steel plate shear wall easy to restore after earthquake

ActiveCN103669650AImprove securitySmall residual deformation after earthquakeWallsPre stressShock resistance

The invention discloses a novel special-shaped steel column frame-steel plate shear wall easy to restore after an earthquake. According to the novel special-shaped steel column frame-steel plate shear wall easy to restore after the earthquake, a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that a prestress self-reset joint is formed; a self-reset column base and a prestress column base are used for optimizing the axial mechanical performance and the horizontal mechanical performance of the bottom of the column through a reinforcing plate, a bend-preventing steel plate is mainly used for dissipating energy of the earthquake, and a shear plate is used for preventing local deformation, caused by excessive shearing force, of the bottom of the column; the key component of the prestress column base is a prestress pull rod, the pull rod is used for providing precompression for the column so that the column can be tightly connected with the beam, as a result, approximate rigid connection can be achieved when the prestress column base bears small bending moment, and the self-reset capacity of the prestress column base after the earthquake is achieved; better shock resistance of the structure is achieved due to the steel plate shear wall.

Owner:南通新丰威机械科技有限公司

Hollow irregular column multi-layer high-rise assembling steel structure system

ActiveCN103276803AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

A hollow irregular column multi-layer high-rise assembling steel structure system relates to the technical field of engineering and comprises assembling truss plates and assembling flange columns. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. The assembling truss plates and the assembling flange columns are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:镇江电力设计院有限公司

Novel post-earthquake easy-to-repair steel irregular column framework

InactiveCN103696503AImprove securitySmall residual deformation after earthquakeShock proofingHorizontal stressPre stress

Provided is a novel post-earthquake easy-to-repair steel irregular column framework. Double-channel steel beams of the framework are connected with irregular columns through beam end sealing plates to form a welding-gap-free full-bolt connection mode. Prestress steel cables are applied to welding-gap-free full-bolt nodes to form prestress self-resetting nodes. Axial and horizontal stress performance of the bottoms of the columns are optimized through reinforcing plates by self-resetting column legs and prestress column legs, bending-proof steel plates are mainly used for dissipating earthquake energy, and shearing plates are used for preventing shearing force from being too large and leading to local bending of the bottoms of the columns. Key members of the prestress column legs are prestress pull rods which are used for providing prestress for the columns to enable the columns to be closely connected with the beams, the column legs can be in rigid connection similarly when the torque borne by the column legs is small, and a post-earthquake self-resetting capability is achieved.

Owner:BEIJING UNIV OF TECH

Industrialized assembly type pillar-running-through beam solid-web steel structure frame eccentric support system

ActiveCN103276799AIncrease lateral stiffnessGood deformabilityBuilding constructionsSupporting systemFloor slab

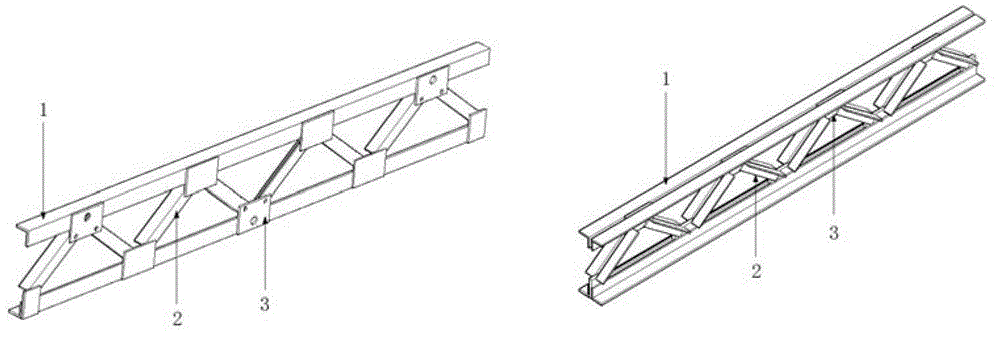

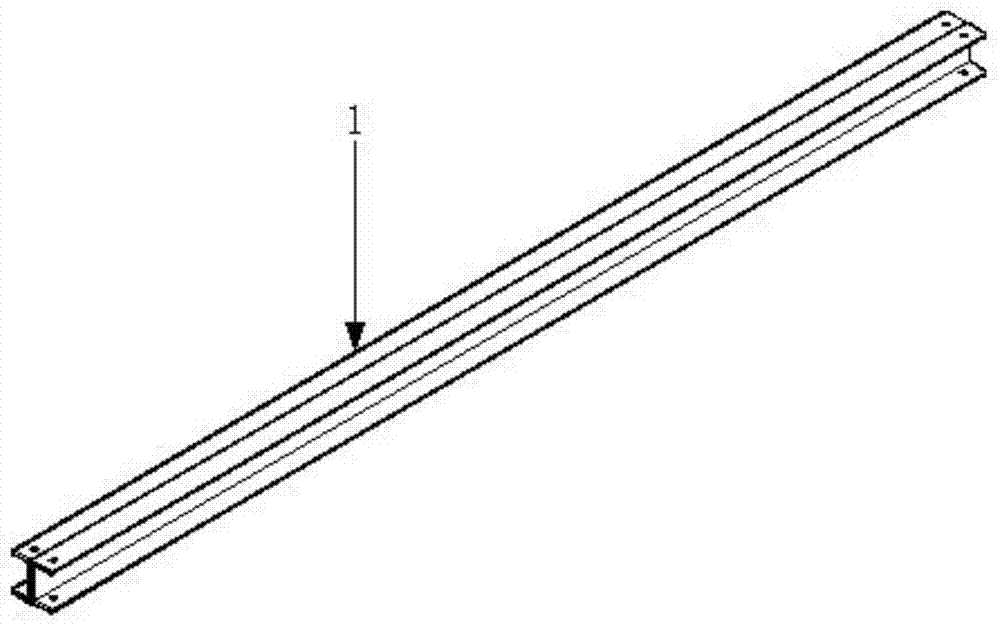

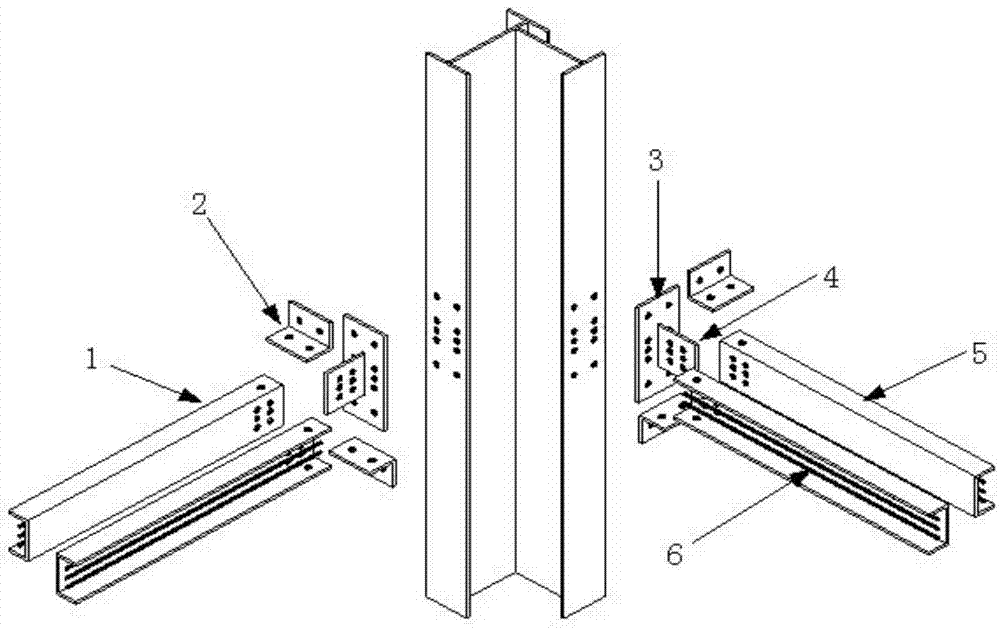

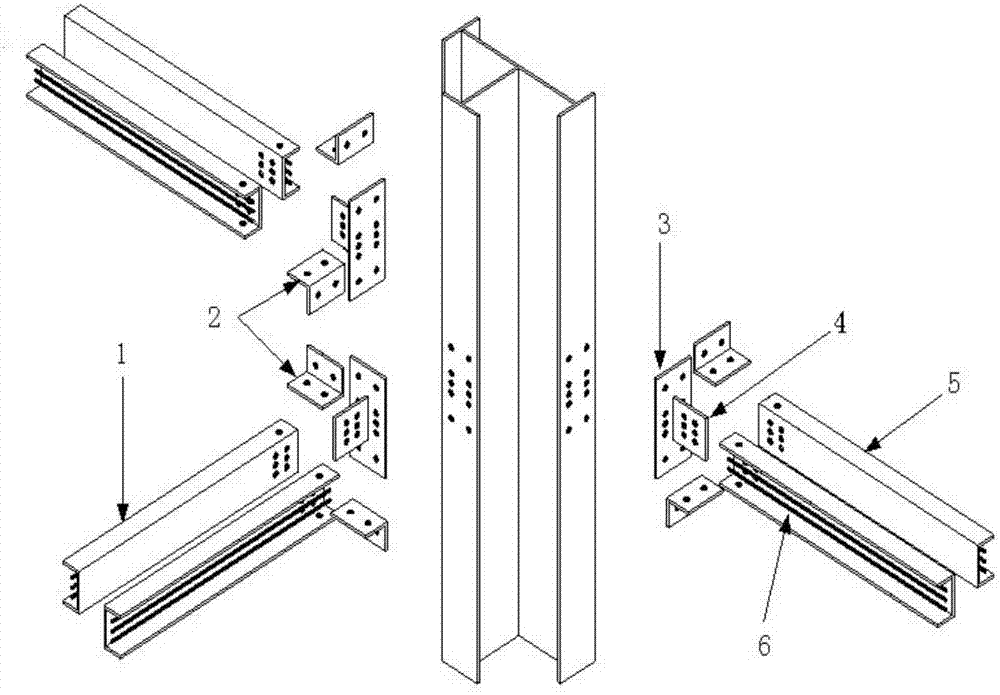

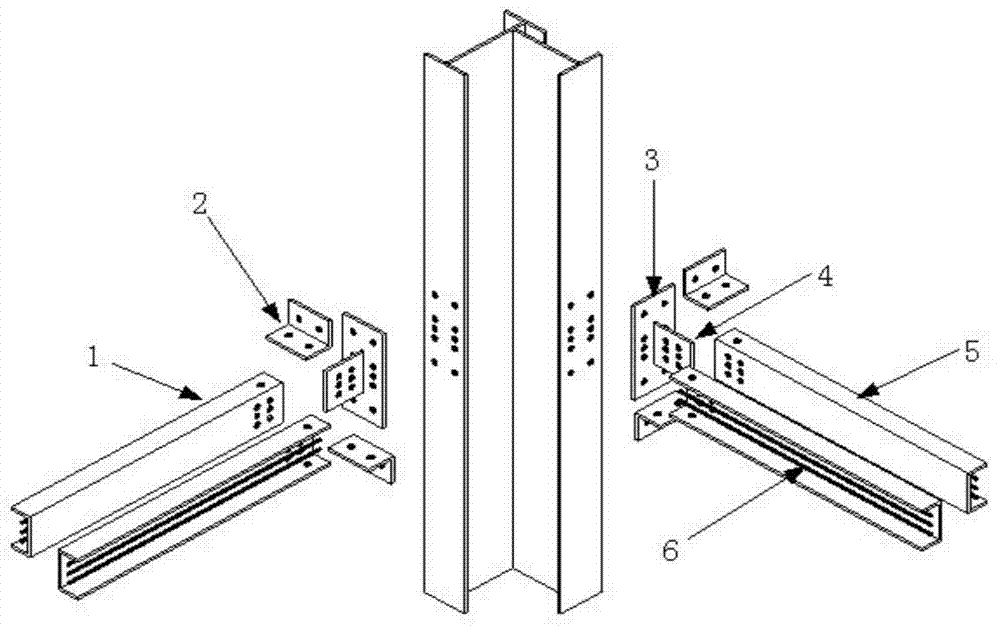

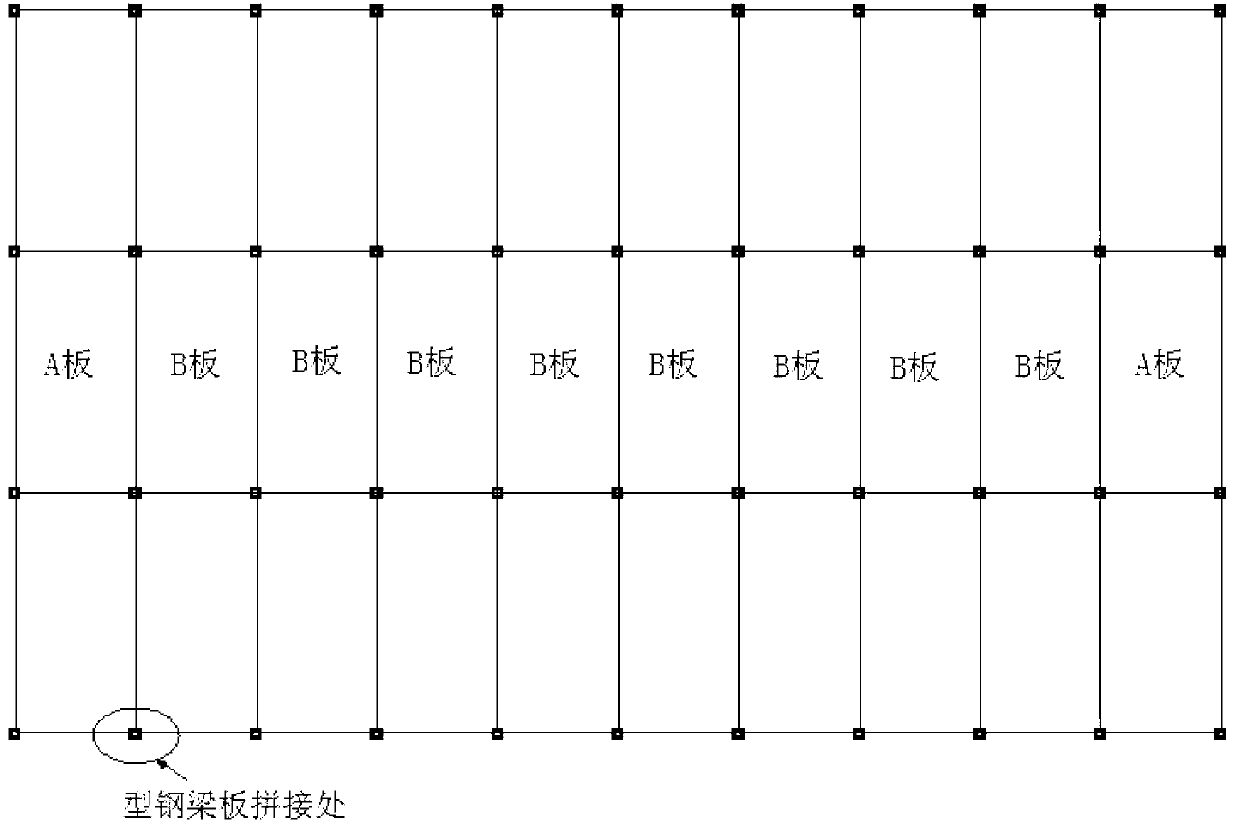

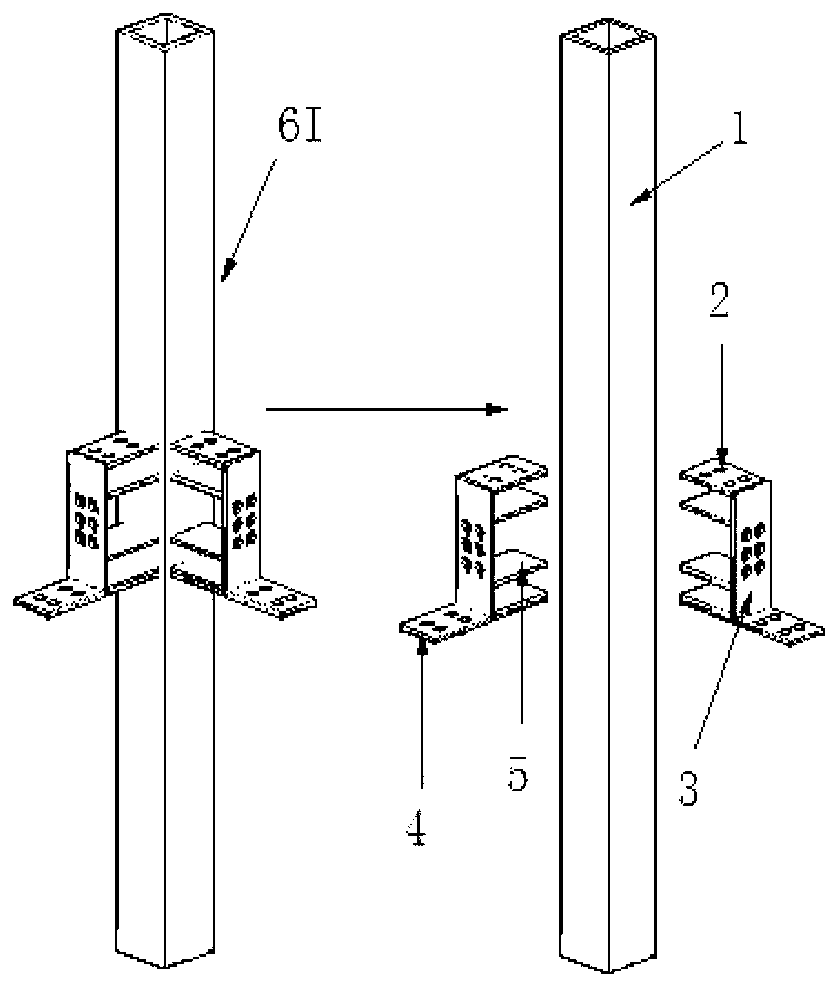

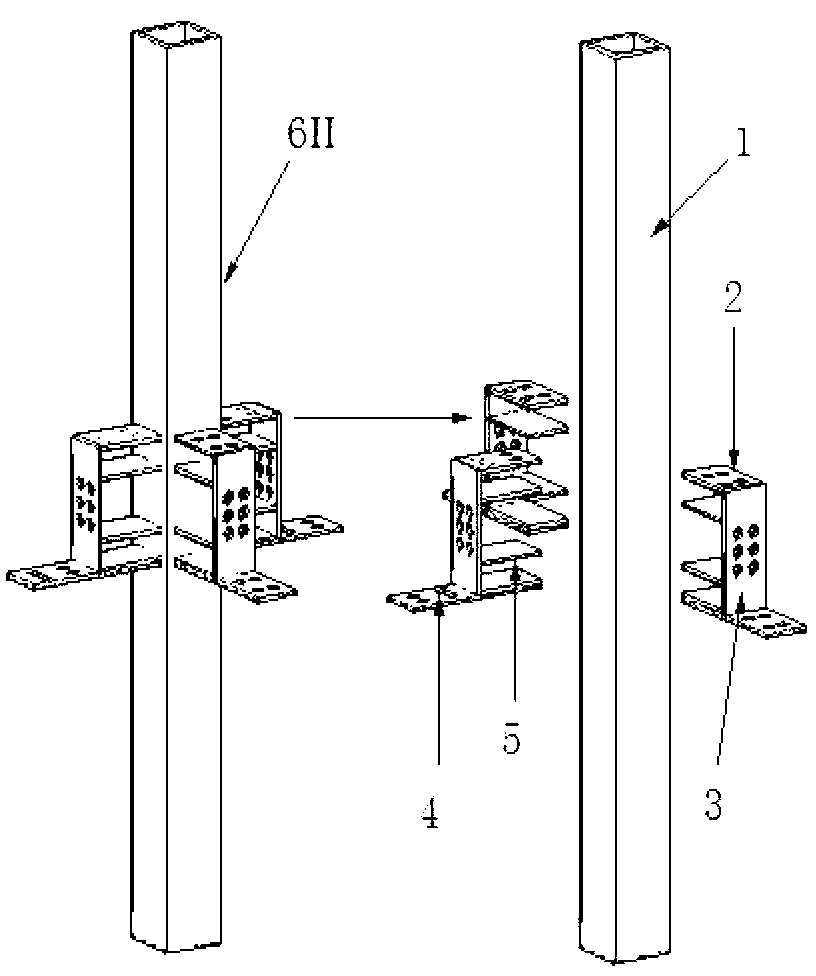

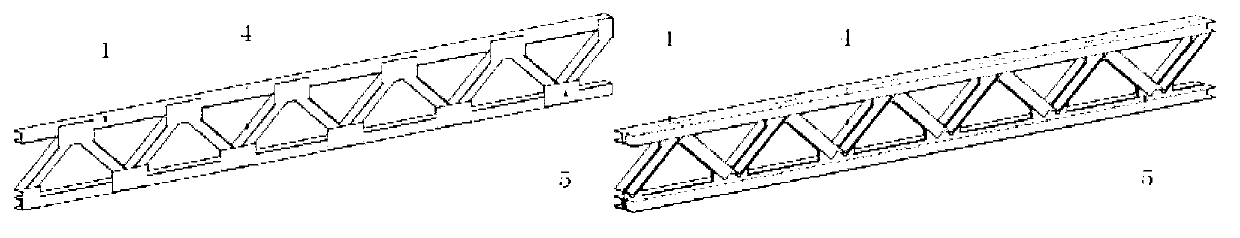

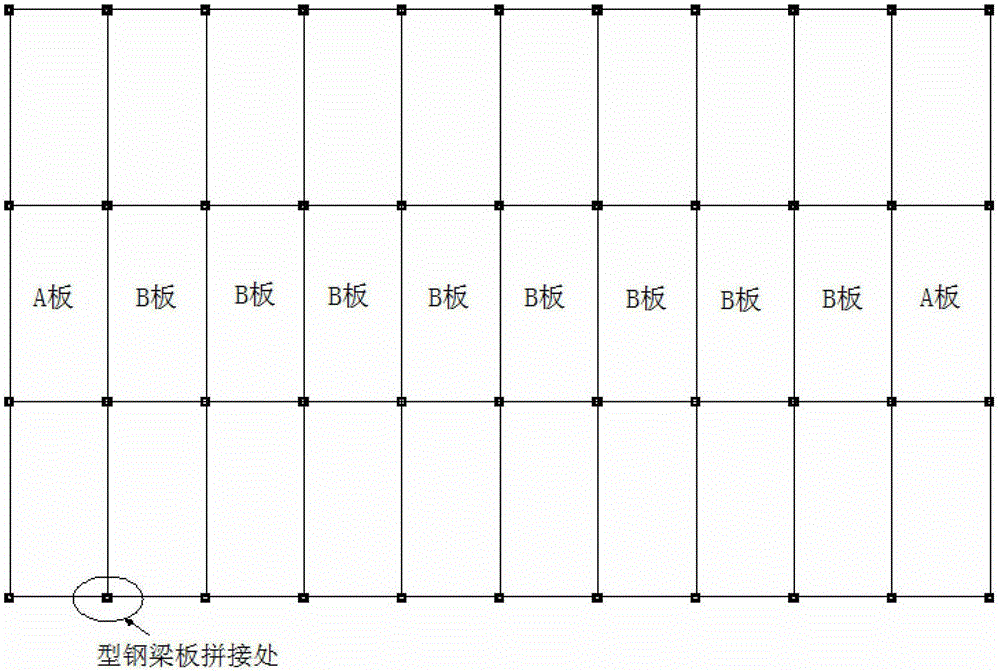

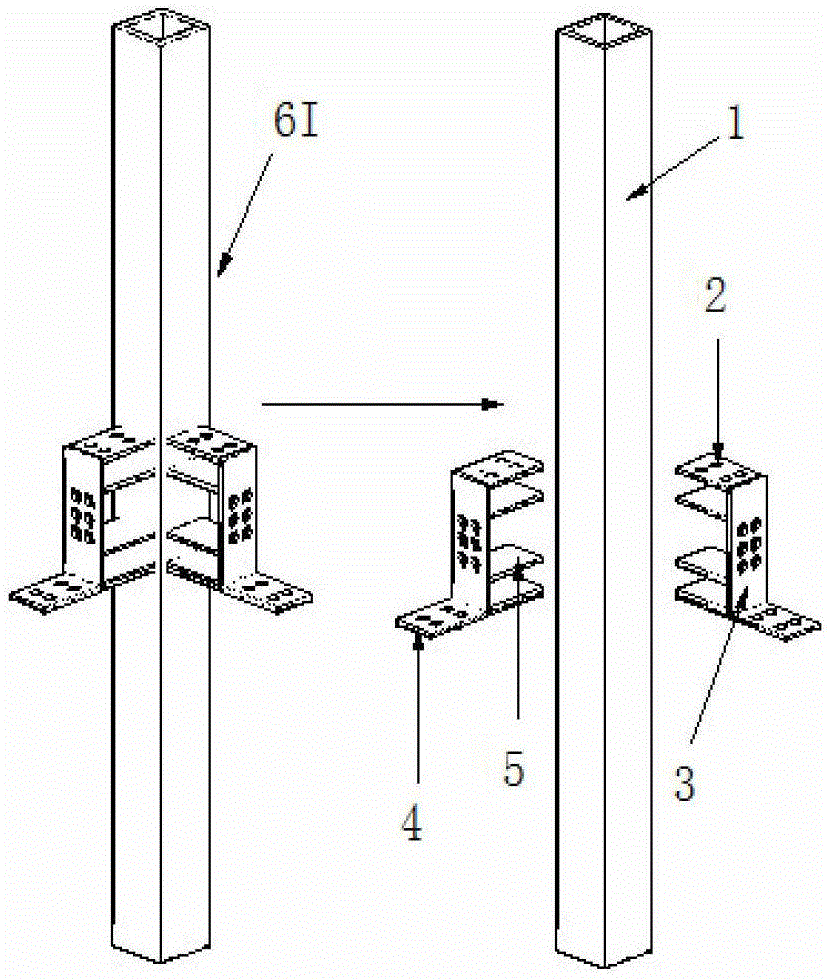

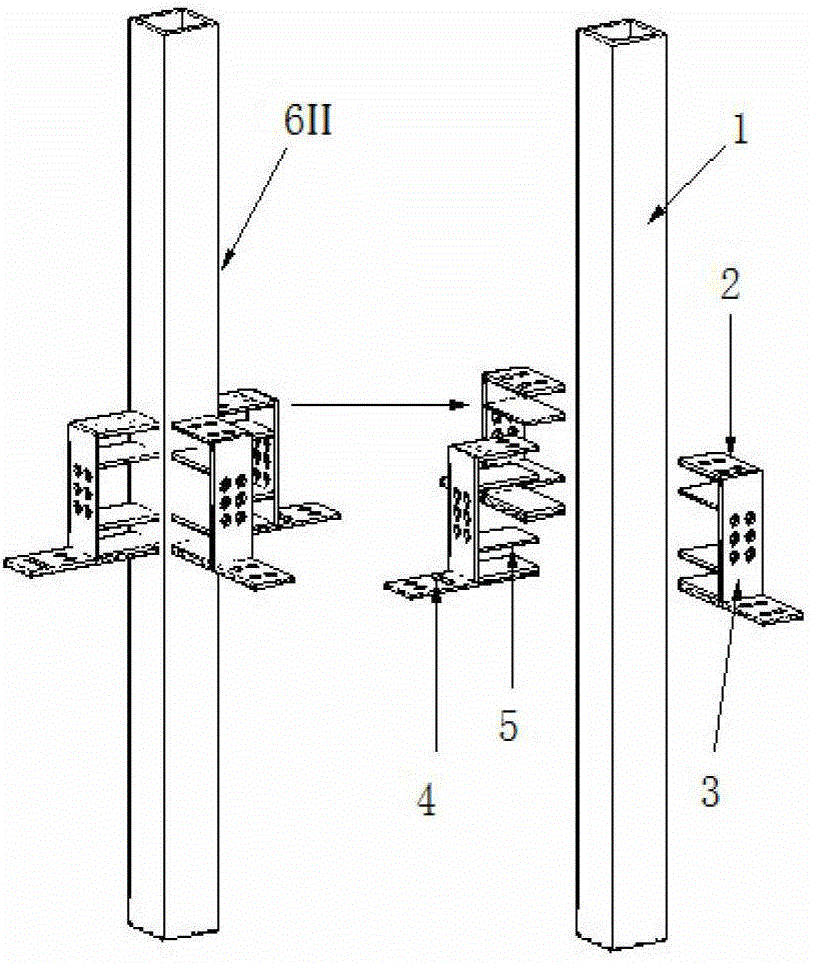

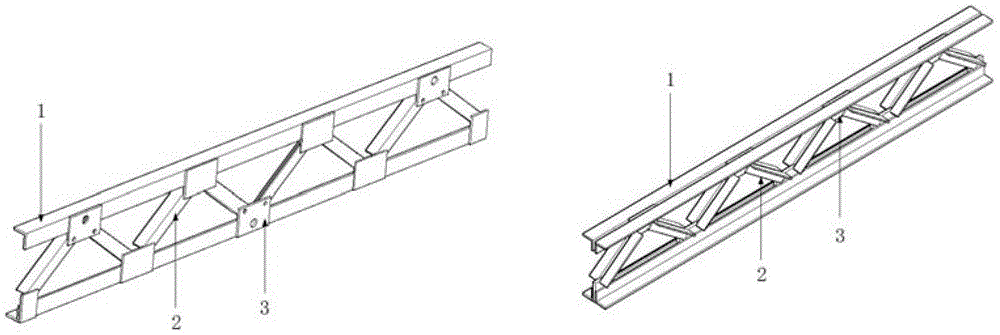

The invention relates to an industrialized assembly type pillar-running-through beam solid-web steel structure frame eccentric support system, and belongs to the technical field of structural engineering. The structural system is formed by assembly type floor slabs, assembly type stand columns and eccentric supporting members in an assembled mode through bolts. Each assembly type floor slab comprises a section steel beam and a slab, each section steel beam is connected with other section steel beams or other stand columns through a beam end close plate and a cover plate on the beam to form a beam slab steel frame structure, and then each slab is placed on one beam slab steel frame structure and connected with the beam slab steel frame structure to form an assembly type beam slab. The assembly type beam slabs are prefabricated in a factory, at the construction field, the assembly type beam slabs are mutually connected with beam column nodal points in a splicing mode through the beam end close plates and the cover plates on the beams of the assembly type beam slabs, the assembly type stand columns run through the beam column nodal points, and on the basis of multiple layers of beam slab steel frame structures, the eccentric supporting members are connected to the bottoms or the tops of the section steel beams in a frame structure beam slab layer to serve as lateral load resisting members. Field assembly is carried out by complete adoption of the bolts, and a traditional field welding mode and a traditional concrete pouring mode are canceled.

Owner:RIZHAO WEIYE TOOL

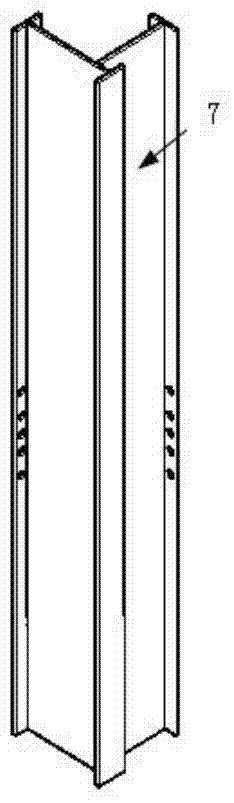

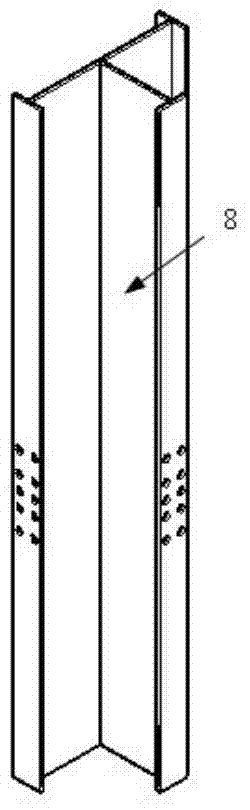

Industrialized assembly type multi-high-rise steel specially shaped column frame structure system

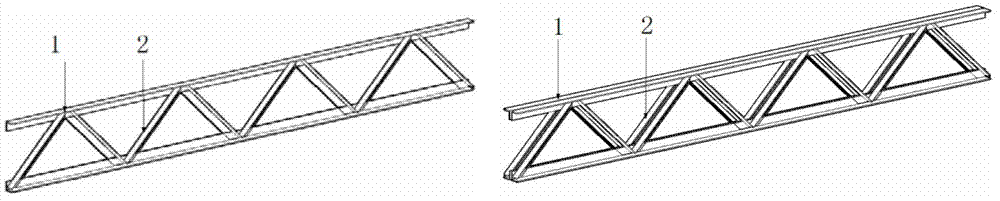

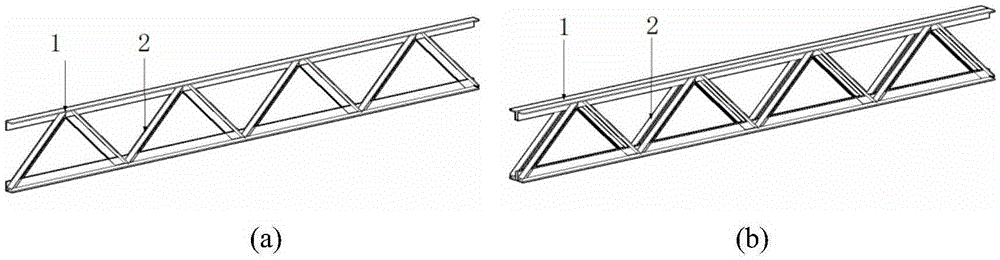

InactiveCN103276802AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

The invention provides an industrialized assembly type multi-high-rise steel specially shaped column frame structure system and relates to the technical field of structure engineering. The industrialized assembly type multi-high-rise steel specially shaped column frame structure system comprises assembly type truss plates and assembly type specially shaped columns. Each assembly type truss plate comprises a lattice type truss girder provided with a channel steel web member and a floor plate. Each assembly type truss plate is prefabricated in a factory and is mutually spliced with a flange plate of one assembly type specially shaped column through a girder end sealing plate of the assembly type truss plate at a construction site. The assembly type specially shaped columns are spliced among floors in site through bolts so that a multi-layer truss plate steel frame structure can be formed. The assembly type truss plates and the assembly type specially shaped columns are all prefabricated in the factory and assembled through bolts at the construction site.

Owner:BEIJING UNIV OF TECH

Assembly prestress center support system for steel structure

The invention discloses an assembly prestress center support system for a steel structure and belongs to the technical field of structural engineering. The assembly prestress center support system comprises assembly truss plates, assembly columns and prestress center support members. The assembly truss plates comprise lattice truss girders and floor plates, and the lattice truss girders are equipped with angle steel web members. The assembly truss plates are prefabricated in factories and spliced with girder column nodes of the assembly columns through beam-end sealing plates at construction sites. The prestress center support members serve as lateral load resistant members to be connected with truss girders of the assembly truss plates and the bottoms or tops of the assembly columns. The assembly truss plates, the assembly columns and the prestress center support members are prefabricated in factories and assembled at construction sites through bolts.

Owner:BEIJING UNIV OF TECH

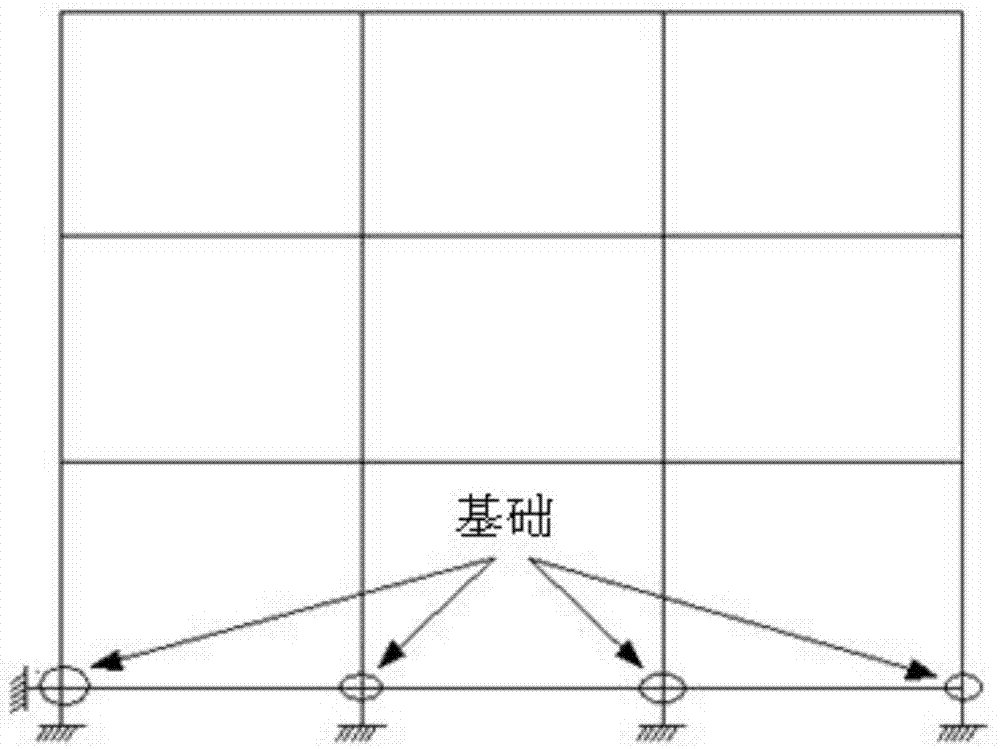

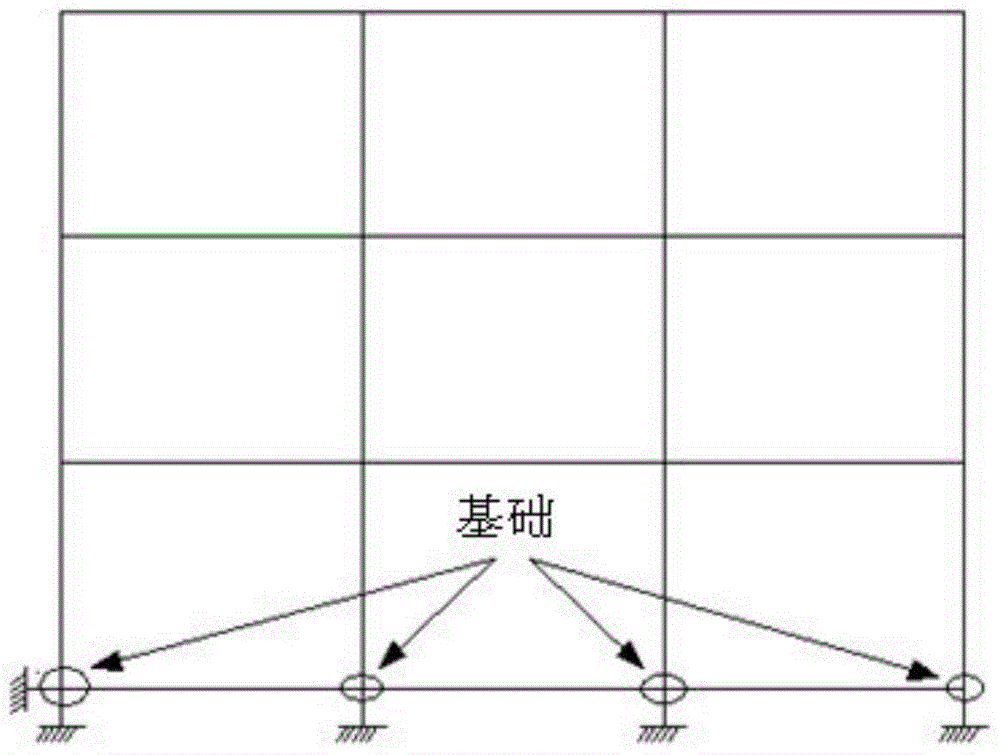

Novel post-earthquake self-reset concrete framework-eccentric supporting structural system

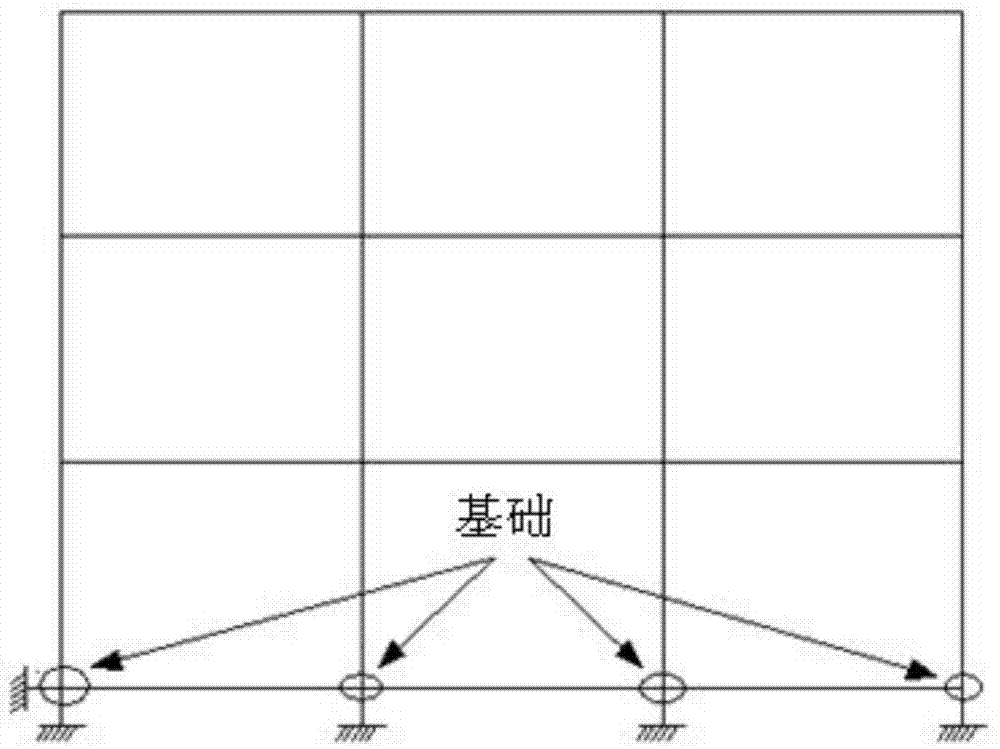

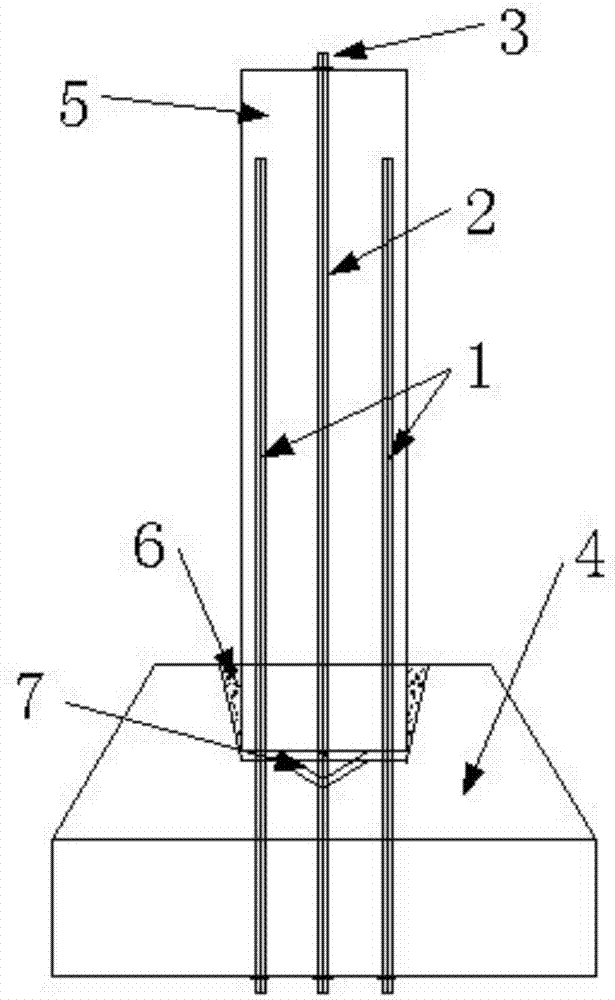

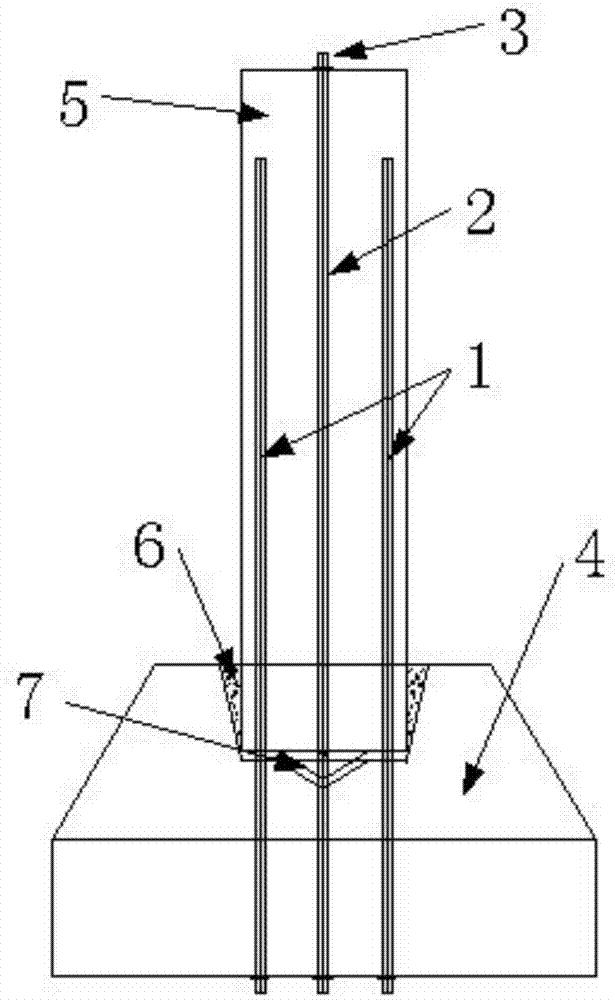

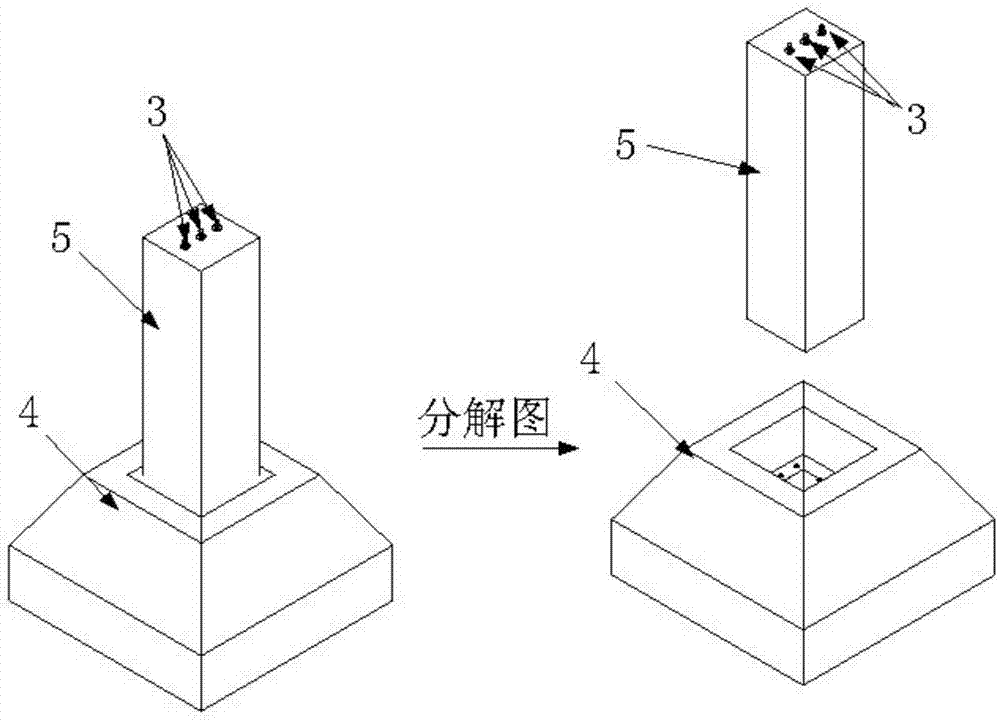

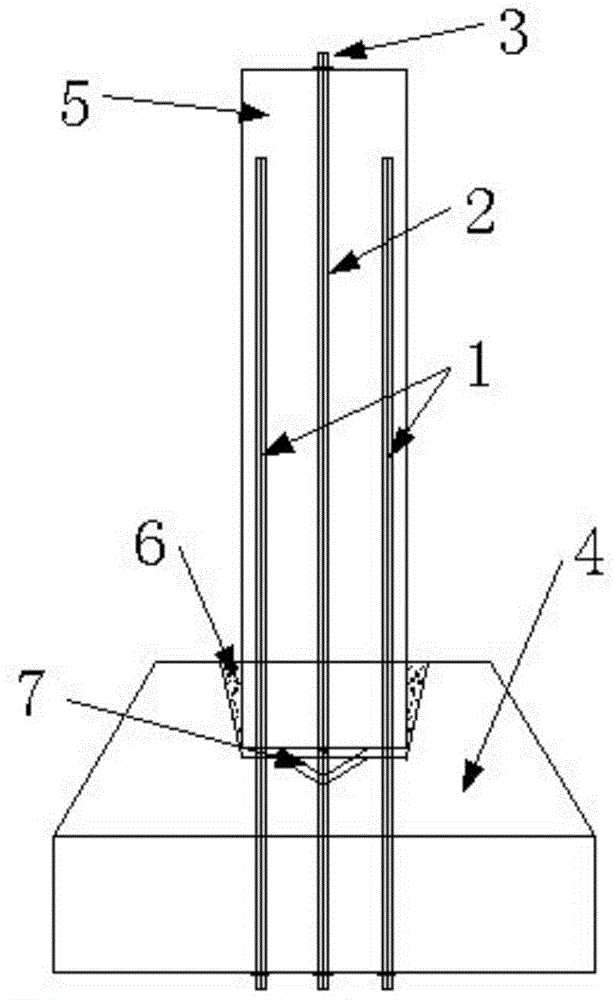

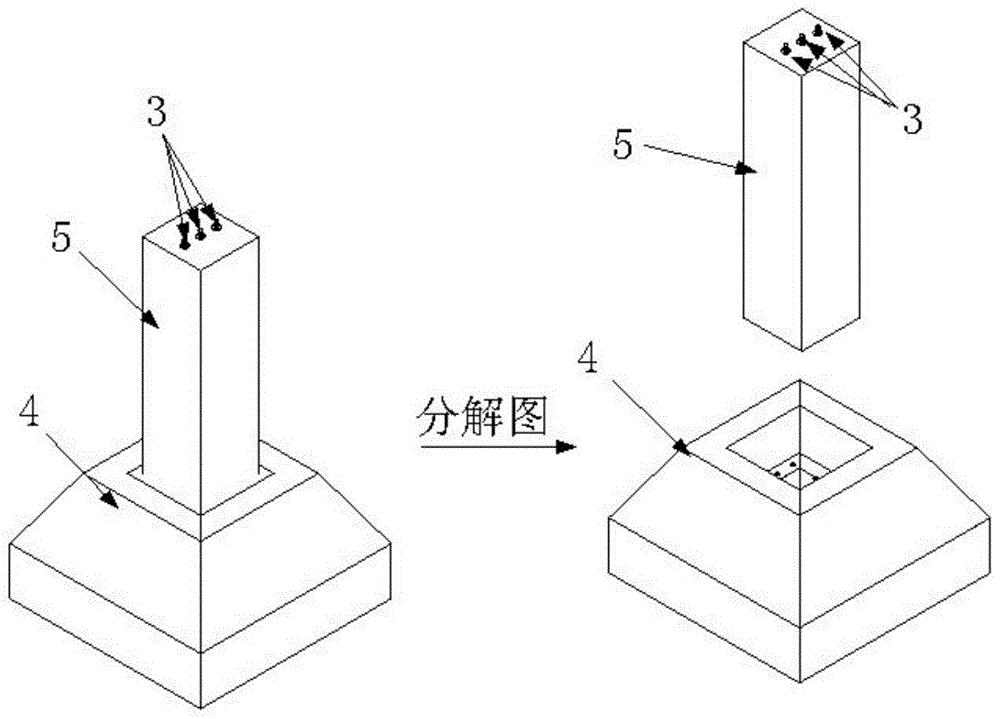

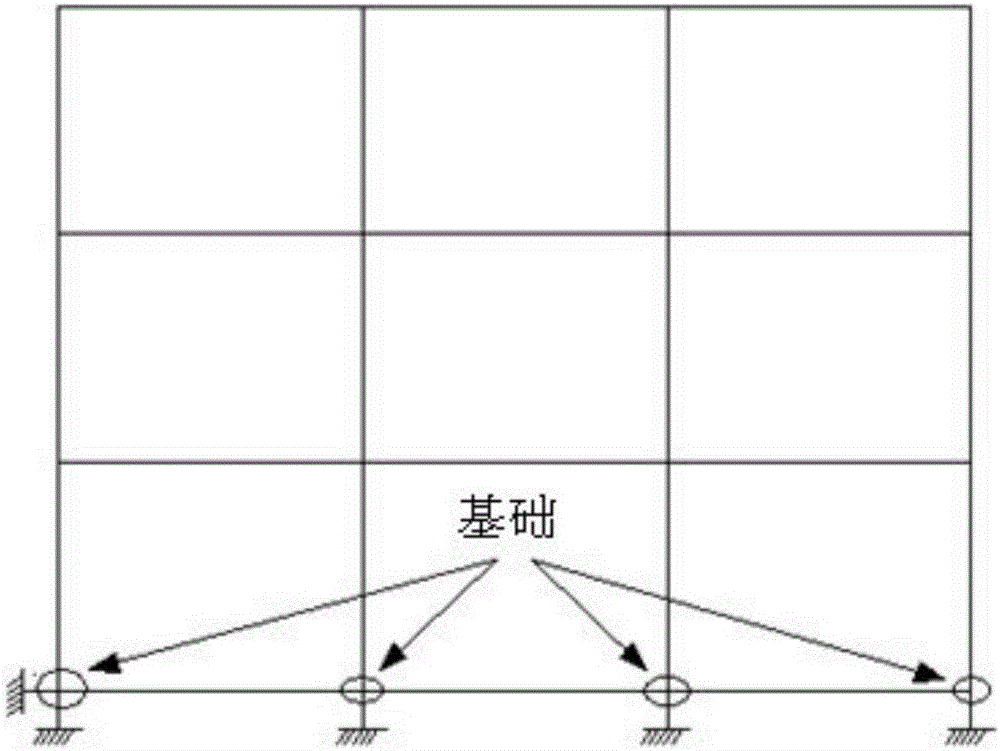

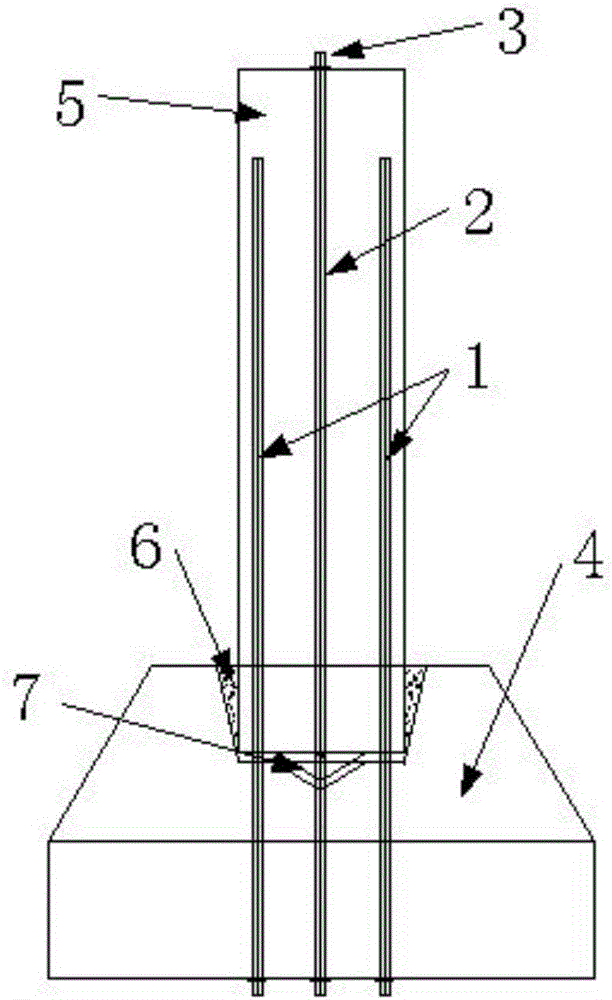

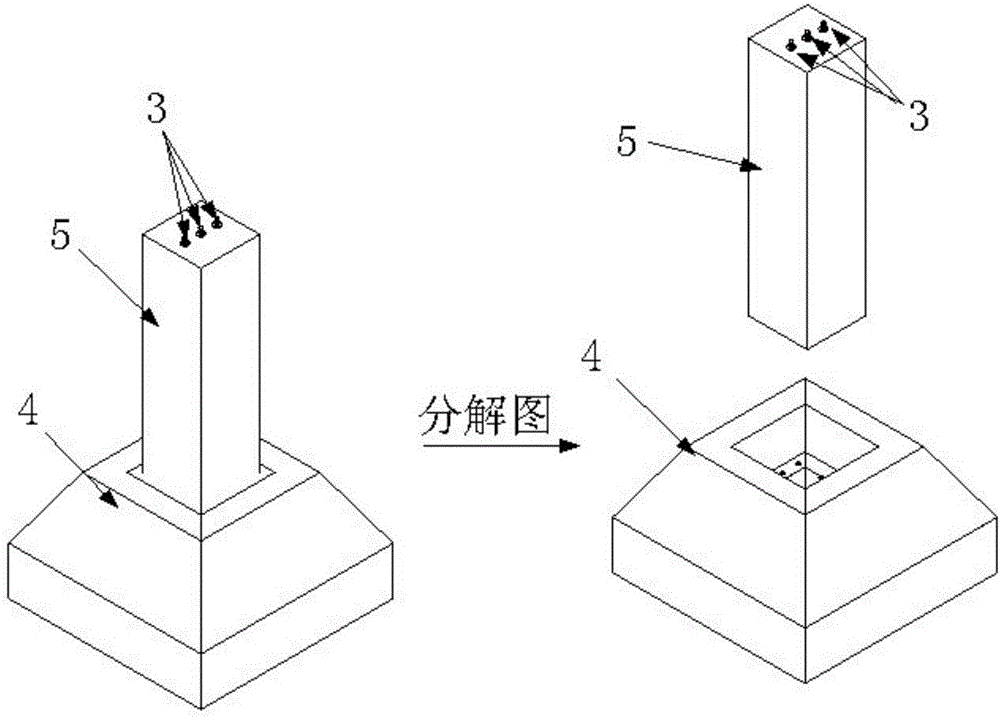

ActiveCN103790258ASolve the problem of difficult assemblyAvoid pollutionShock proofingPre stressSteel bar

The invention relates to a novel post-earthquake self-reset concrete framework-eccentric supporting structural system, and belongs to the technical field of earthquake prevention and disaster reduction. The initial rigidity of an embedded type cup-shaped foundation is basically the same as the rigidity of a cast-in-place concrete structure, under the condition of a small interlayer displacement angle, prestressed steel keeps elasticity, energy consummation steel bars enter the plastic state to dissipate energy, and the embedded type cup-shaped foundation can reset to the initial position after the earthquake action. Compared with the prior art, the novel post-earthquake self-reset concrete framework-eccentric supporting structural system overturns a traditional concrete structural building foundation, and basically solves the difficult problems that concrete structures are not easy to assemble and poor in ductility. Compared with the traditional concrete structural foundation, the novel post-earthquake self-reset concrete framework-eccentric supporting structural system has the advantages of being high in safety performance, small in environmental pollution, few in accident, low in manufacturing cost of projects and the like.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Industrialized assembly type special-shaped column steel structure frame-eccentric support system

InactiveCN103276796AIncrease net heightGuarantee the construction qualityBuilding constructionsAbnormal shapedFloor slab

The invention provides an industrialized assembly type special-shaped column steel structure frame-eccentric support system and belongs to the technical field of structural engineering. The industrialized assembly type special-shaped column steel structure frame-eccentric support system comprises assembly type truss plates, assembly type columns and eccentric support members. Each assembly type truss plate comprises lattice truss beams and floor slabs and is prefabricated in a factory, and the assembly type truss plates and beam-column joints of the assembly type columns are spliced through beam-end seal plates in a construction site, and the assembly type columns are spliced among layers in the site through bolts to form a multiple-layer truss plate steel frame structure. Based on the truss plate steel frame structure, the eccentric support members serve as lateral force resisting members and are connected with the truss beams in the assembly type truss plates and the bottoms or the tops of the assembly type columns. The assembly type truss plates, the assembly type columns and the eccentric support members are prefabricated in the factory and are assembled in the construction site through bolts.

Owner:BEIJING UNIV OF TECH

Novel post-earthquake self-reset concrete framework-center supporting structural system

ActiveCN103790259AImprove securitySmall residual deformation after earthquakeShock proofingPre stressEngineering

The invention relates to a novel post-earthquake self-reset concrete framework-center supporting structural system, and belongs to the technical field of earthquake prevention and disaster reduction. The initial rigidity of an embedded type cup-shaped foundation is basically the same as the rigidity of a cast-in-place concrete structure, under the condition of a small interlayer displacement angle, prestressed steel keeps elasticity, energy consummation steel bars enter the plastic state to dissipate energy, and the embedded type cup-shaped foundation can reset to the initial position after the earthquake action. Compared with the prior art, the novel post-earthquake self-reset concrete framework-center supporting structural system overturns a traditional concrete structural building foundation, and basically solves the difficult problems that concrete structures are not easy to assemble and poor in ductility. Compared with the traditional concrete structural foundation, the novel post-earthquake self-reset concrete framework-center supporting structural system has the advantages of being high in safety performance, small in environmental pollution, few in accident, low in manufacturing cost of projects and the like.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Industrialized assembly type special-shaped column steel structure frame-eccentric support system

The invention provides an industrialized assembly type special-shaped column steel structure frame-eccentric support system and belongs to the technical field of structural engineering. The industrialized assembly type special-shaped column steel structure frame-eccentric support system comprises assembly type truss plates, assembly type columns and central support members. Each assembly type truss plate comprises lattice truss beams and floor slabs and is prefabricated in a factory, and the assembly type truss plates and beam-column joints of the assembly type columns are spliced through beam-end seal plates in a construction site, and the assembly type columns are spliced among layers in the site through bolts to form a multiple-layer truss plate steel frame structure. Based on the truss plate steel frame structure, the central support members serve as lateral force resisting members and are connected with the truss beams in the assembly type truss plates and the bottoms or the tops of the assembly type columns. The assembly type truss plates, the assembly type columns and the central support members are prefabricated in the factory and are assembled in the construction site through bolts.

Owner:BEIJING UNIV OF TECH

A modular low-rise assembled special-shaped column steel structure building system

InactiveCN105863067BEasy to disassemble and transportAvoid pollutionBuilding constructionsLine tubingArchitectural engineering

The invention discloses a modular low-layer assembling type house system of a special-shaped column steel structure, and belongs to the technical field of structural engineering. The modular low-layer assembling type house system of the special-shaped column steel structure comprises assembling type house modules, assembling type roof modules, assembling type staircase modules and flange plate connectors among the modules. The assembling type house modules, the assembling type roof modules and the assembling type staircase modules are processed and manufactured in a factory. On the construction site, the modules are connected through the flange plate connectors via high-strength bolts in a bolting mode, and then pipelines among the modules are mutually connected, so that construction is finished. The modules are easy to detach and convey, and can be reused. The modular low-layer assembling type house system of the special-shaped column steel structure integrates modularization, industrialization, standardization and assembling performance, realizes industrialized production, can be rapidly assembled on site and can be reused. On the premise of guaranteeing construction quality, the construction speed is improved, the construction period is shortened, and engineering construction cost is reduced.

Owner:BEIJING UNIV OF TECH

Industrialized assembly type special-shaped column steel structure frame-eccentric support system

InactiveCN103276796BIncrease lateral stiffnessGood deformabilityBuilding constructionsSupporting systemFloor slab

The invention provides an industrialized assembly type special-shaped column steel structure frame-eccentric support system and belongs to the technical field of structural engineering. The industrialized assembly type special-shaped column steel structure frame-eccentric support system comprises assembly type truss plates, assembly type columns and eccentric support members. Each assembly type truss plate comprises lattice truss beams and floor slabs and is prefabricated in a factory, and the assembly type truss plates and beam-column joints of the assembly type columns are spliced through beam-end seal plates in a construction site, and the assembly type columns are spliced among layers in the site through bolts to form a multiple-layer truss plate steel frame structure. Based on the truss plate steel frame structure, the eccentric support members serve as lateral force resisting members and are connected with the truss beams in the assembly type truss plates and the bottoms or the tops of the assembly type columns. The assembly type truss plates, the assembly type columns and the eccentric support members are prefabricated in the factory and are assembled in the construction site through bolts.

Owner:BEIJING UNIV OF TECH

A post-earthquake self-resetting concrete frame-eccentric support structure system

ActiveCN103790258BSolve the problem of difficult assemblyAvoid pollutionShock proofingPre stressRebar

The invention relates to a novel post-earthquake self-reset concrete framework-eccentric supporting structural system, and belongs to the technical field of earthquake prevention and disaster reduction. The initial rigidity of an embedded type cup-shaped foundation is basically the same as the rigidity of a cast-in-place concrete structure, under the condition of a small interlayer displacement angle, prestressed steel keeps elasticity, energy consummation steel bars enter the plastic state to dissipate energy, and the embedded type cup-shaped foundation can reset to the initial position after the earthquake action. Compared with the prior art, the novel post-earthquake self-reset concrete framework-eccentric supporting structural system overturns a traditional concrete structural building foundation, and basically solves the difficult problems that concrete structures are not easy to assemble and poor in ductility. Compared with the traditional concrete structural foundation, the novel post-earthquake self-reset concrete framework-eccentric supporting structural system has the advantages of being high in safety performance, small in environmental pollution, few in accident, low in manufacturing cost of projects and the like.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Industrialized multi-story high-rise assembled steel structure system

The invention relates to an industrialized multi-story high-rise assembled steel structure system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure system comprises assembled truss plates and assembled flange columns. The assembled truss plates comprise latticed truss beams with angle steel web members, column base joints and slabs. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or the column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure, and the assembled flange columns are arranged on the column base joints on the assembled truss plates; and the assembled truss plates and the assembled flange columns are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

A prefabricated steel structure central support frame system

InactiveCN103290920BEasy to pass throughIncrease net heightBuilding constructionsSteel frameBeam column

The invention relates to an assembled steel structure center support frame system and belongs to the technical field of structure engineering. The system comprises assembled truss plates, assembled uprights and center support members, wherein the assembled truss plates comprise lattice truss beams with steel angle web members, and floor plate, and are prefabricated in a factory; the assembled truss plates are spliced with beam column nodes of the assembled uprights by beam end sealing plates of the assembled truss plates at a construction site; the assembled uprights are spliced between layers by bolts on site to form a multilayer steel frame structure; based on the steel frame structure, the center support members serve as lateral force resisting members and are connected with the truss beams in the assembled truss plates and the bottoms or tops of the assembled uprights; the assembled truss plates, the assembled uprights and the center support members are prefabricated in the factory and assembled by the bolts at the construction site.

Owner:河南天蚕富煌钢结构有限公司

Industrialized multi-story high-rise assembled steel structure frame - centrally-braced system

ActiveCN102979168BEasy to pass throughIncrease net heightBuilding constructionsSteel frameEngineering

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - centrally-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - centrally-braced system comprises assembled truss plates, assembled flange columns and central bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the central bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - centrally-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

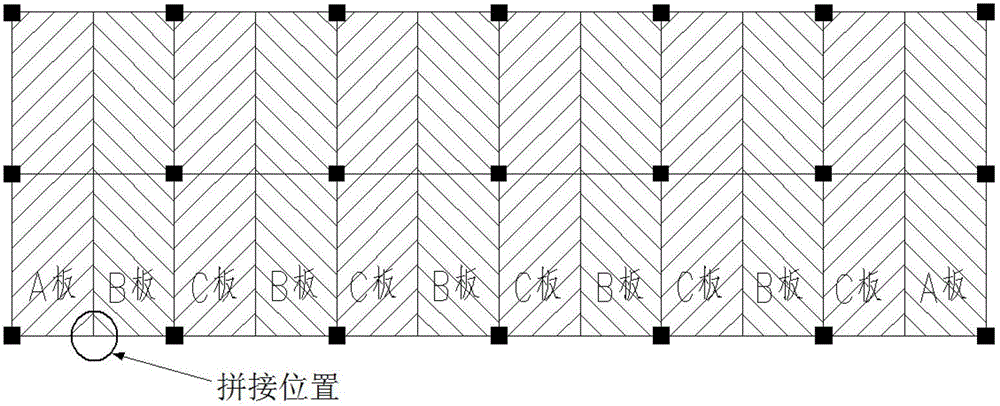

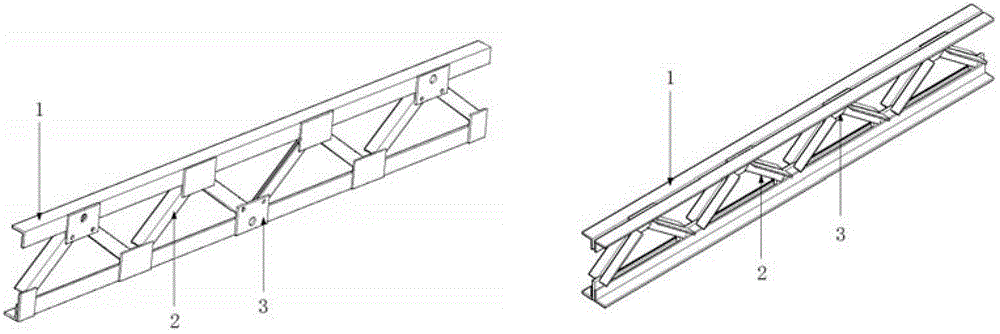

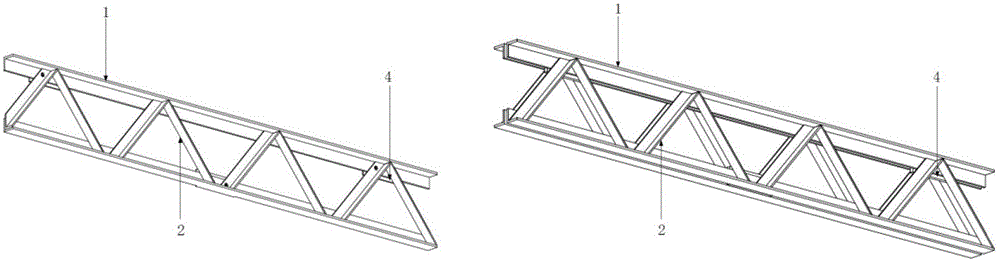

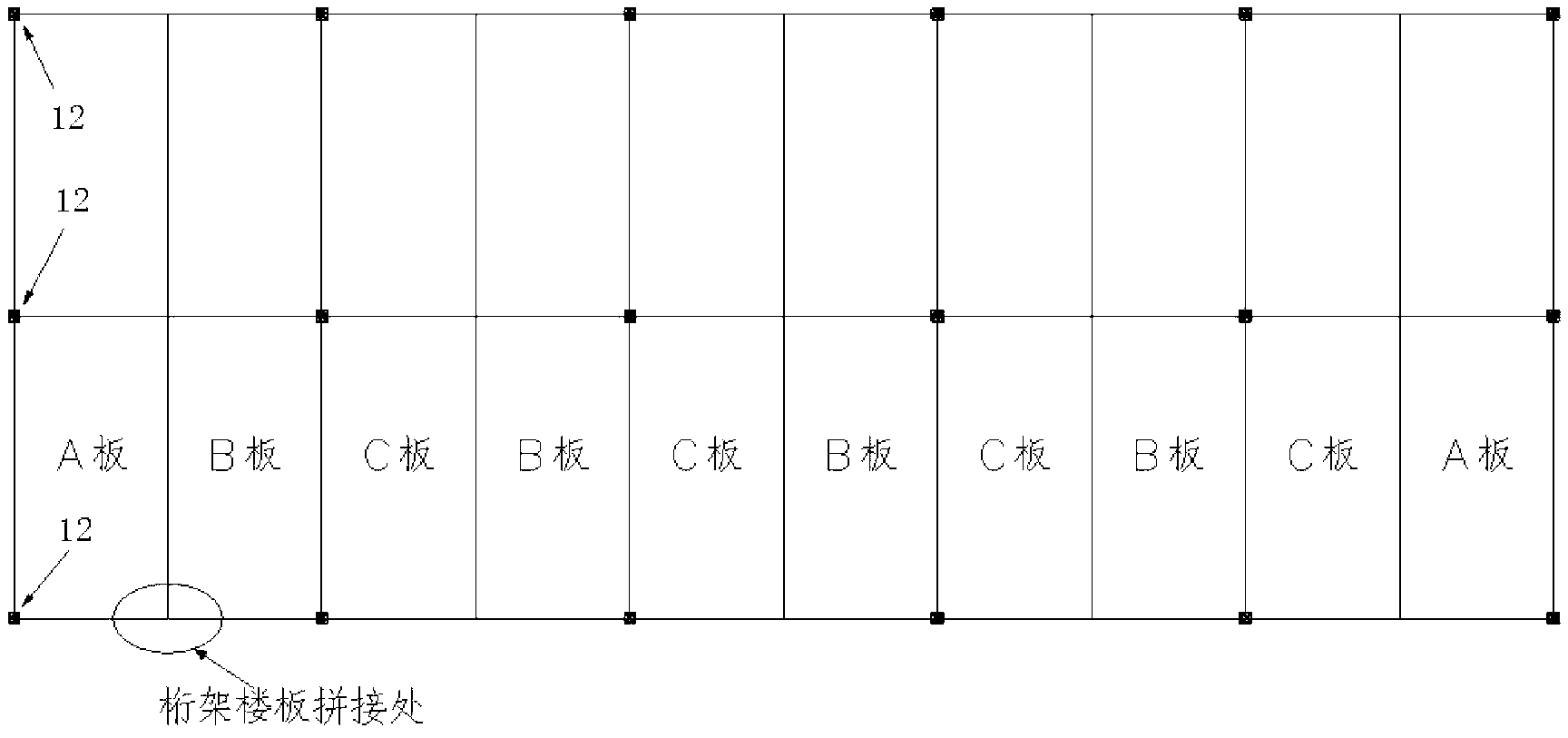

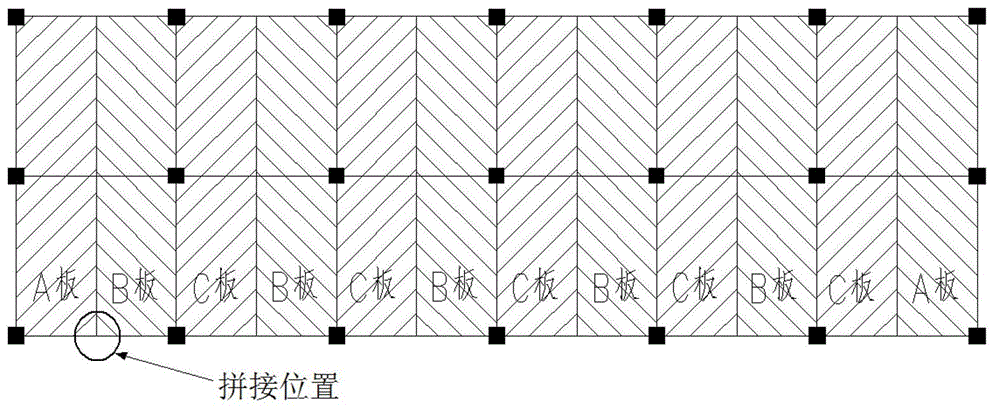

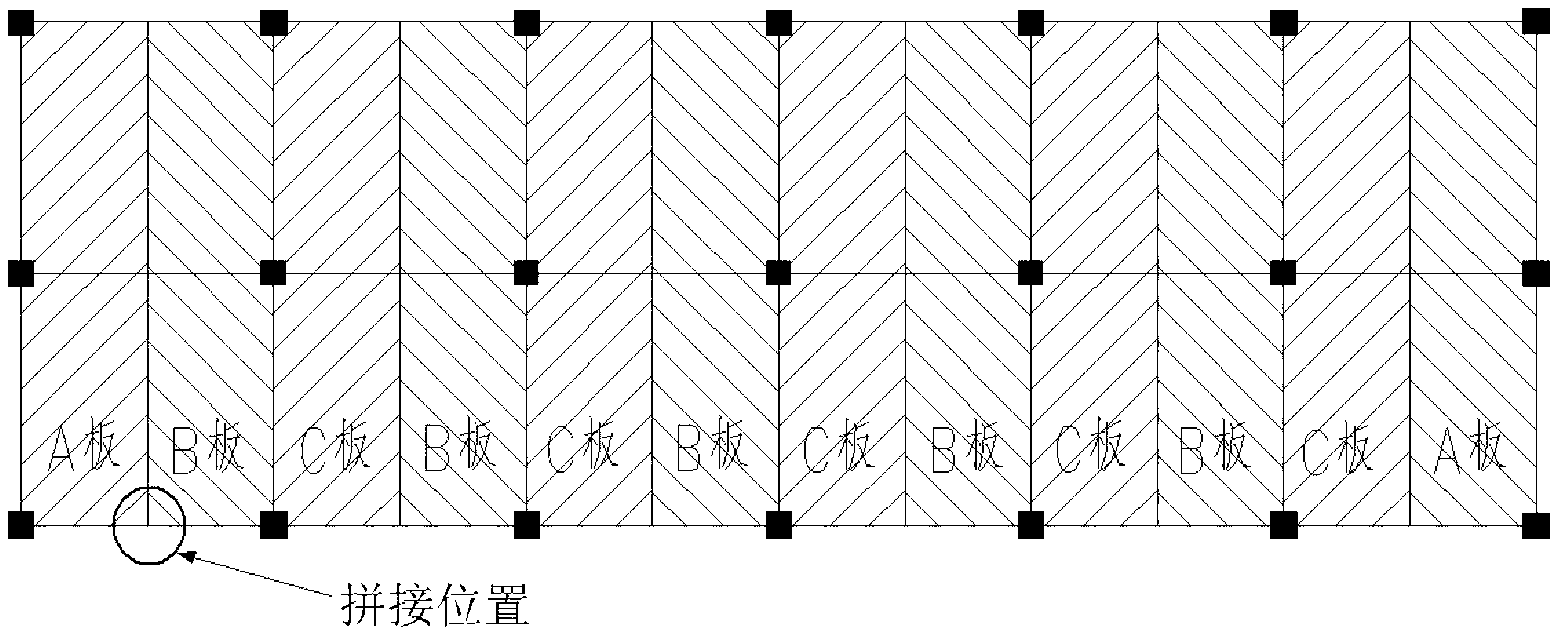

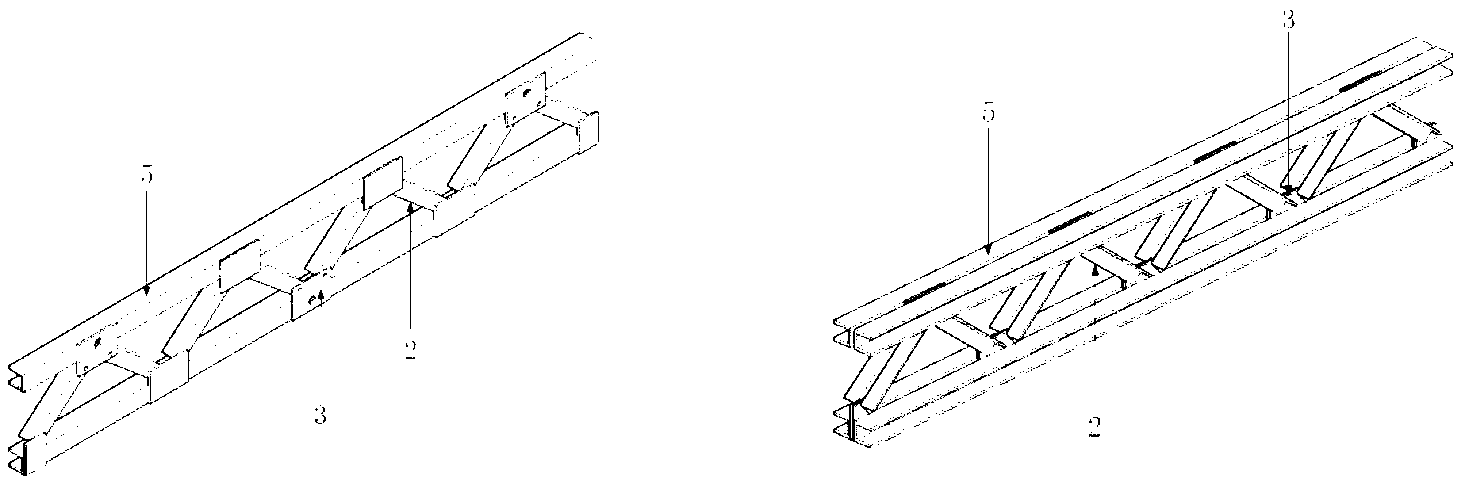

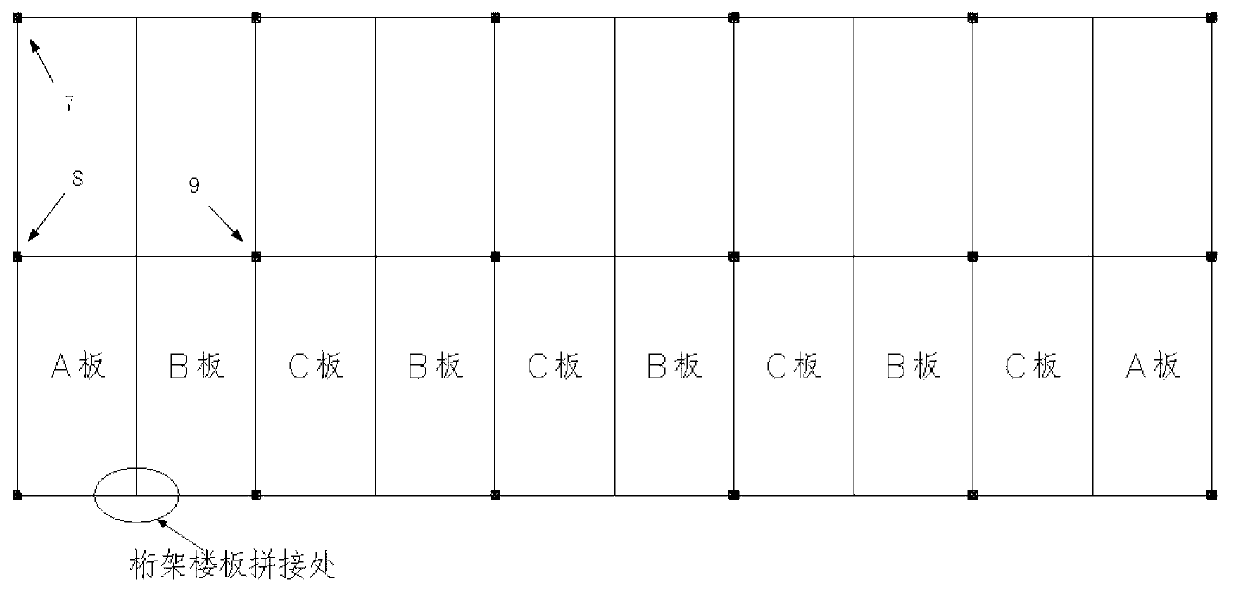

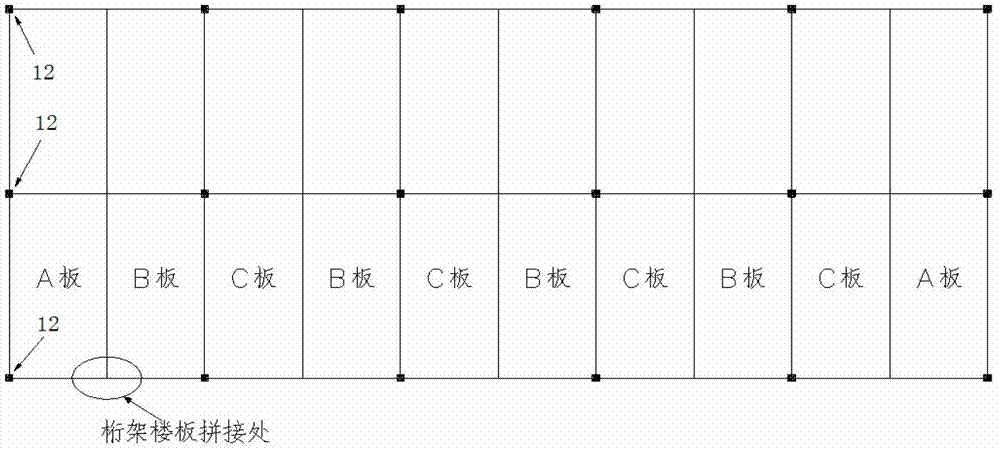

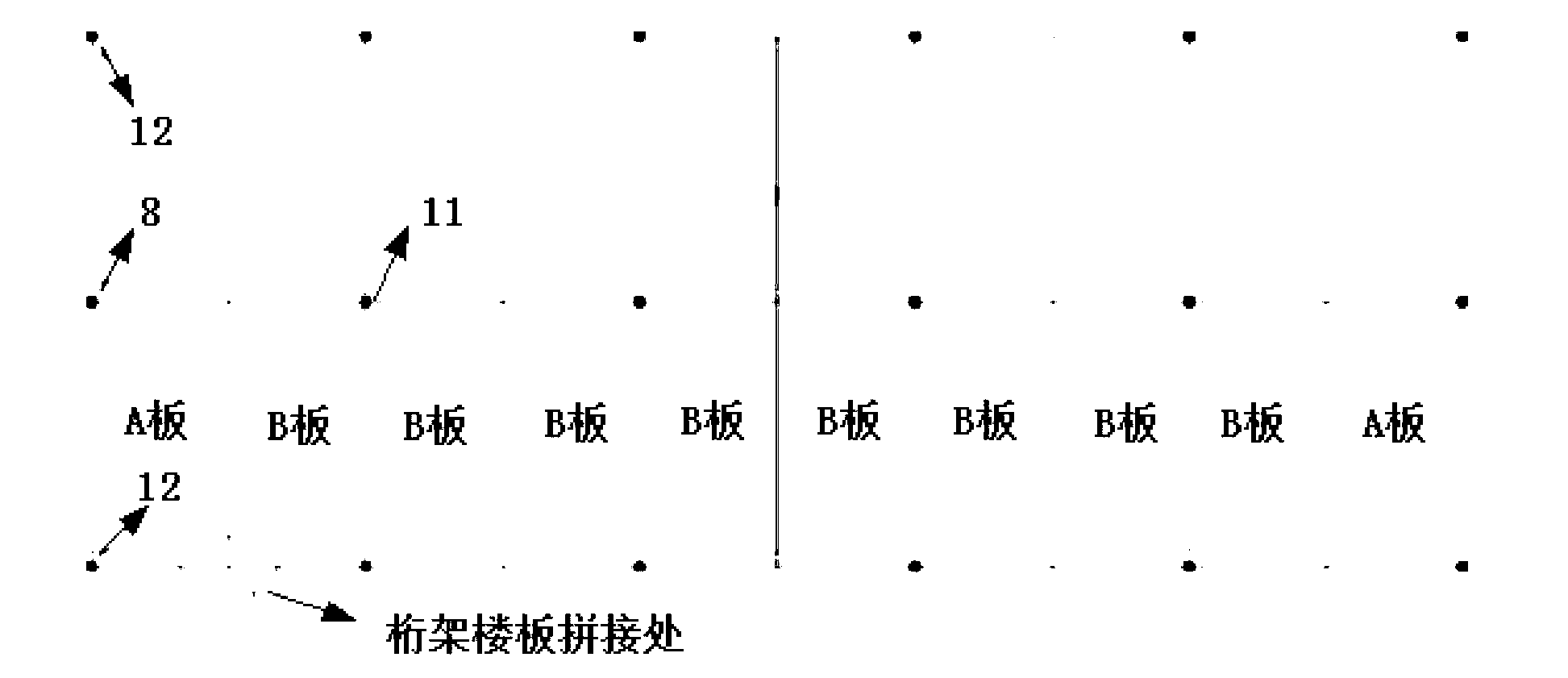

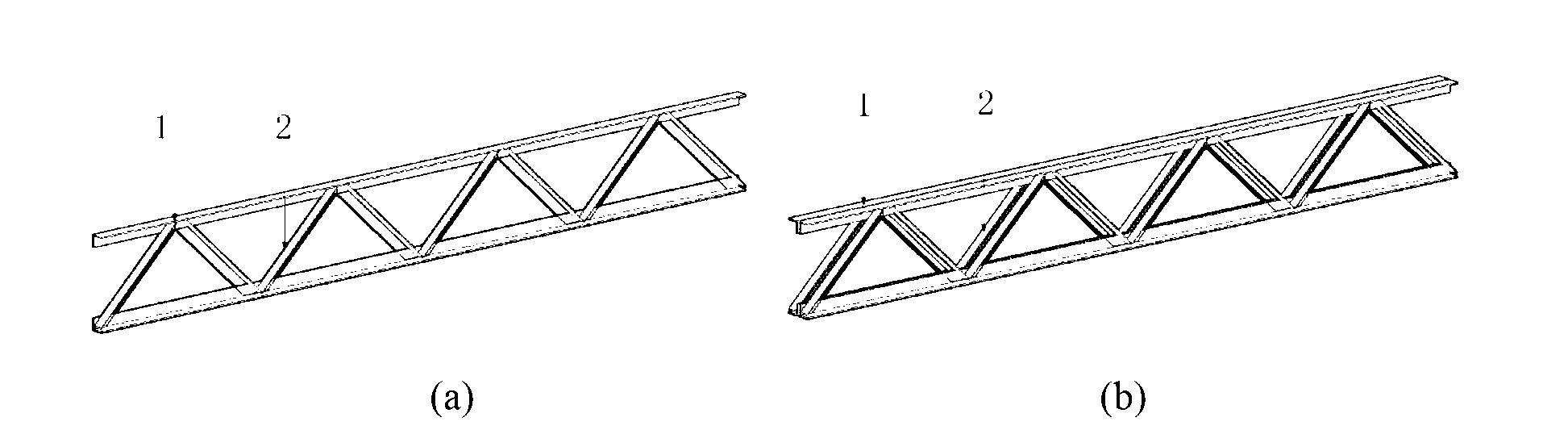

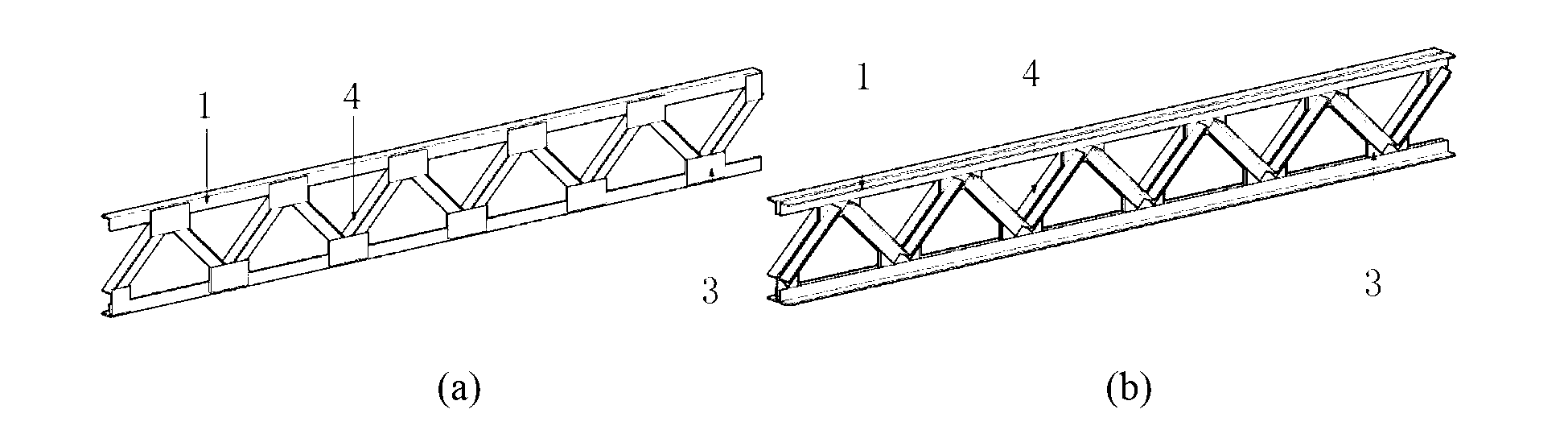

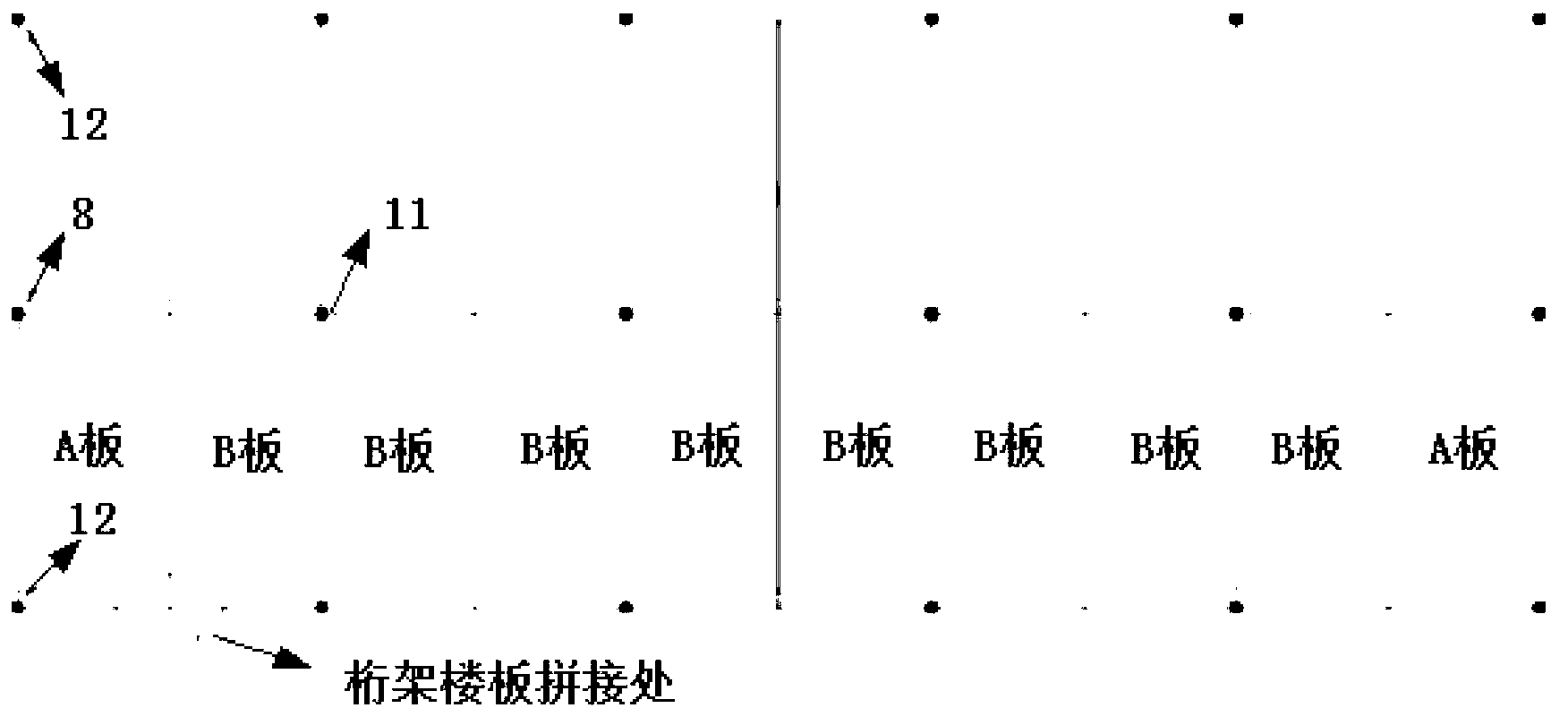

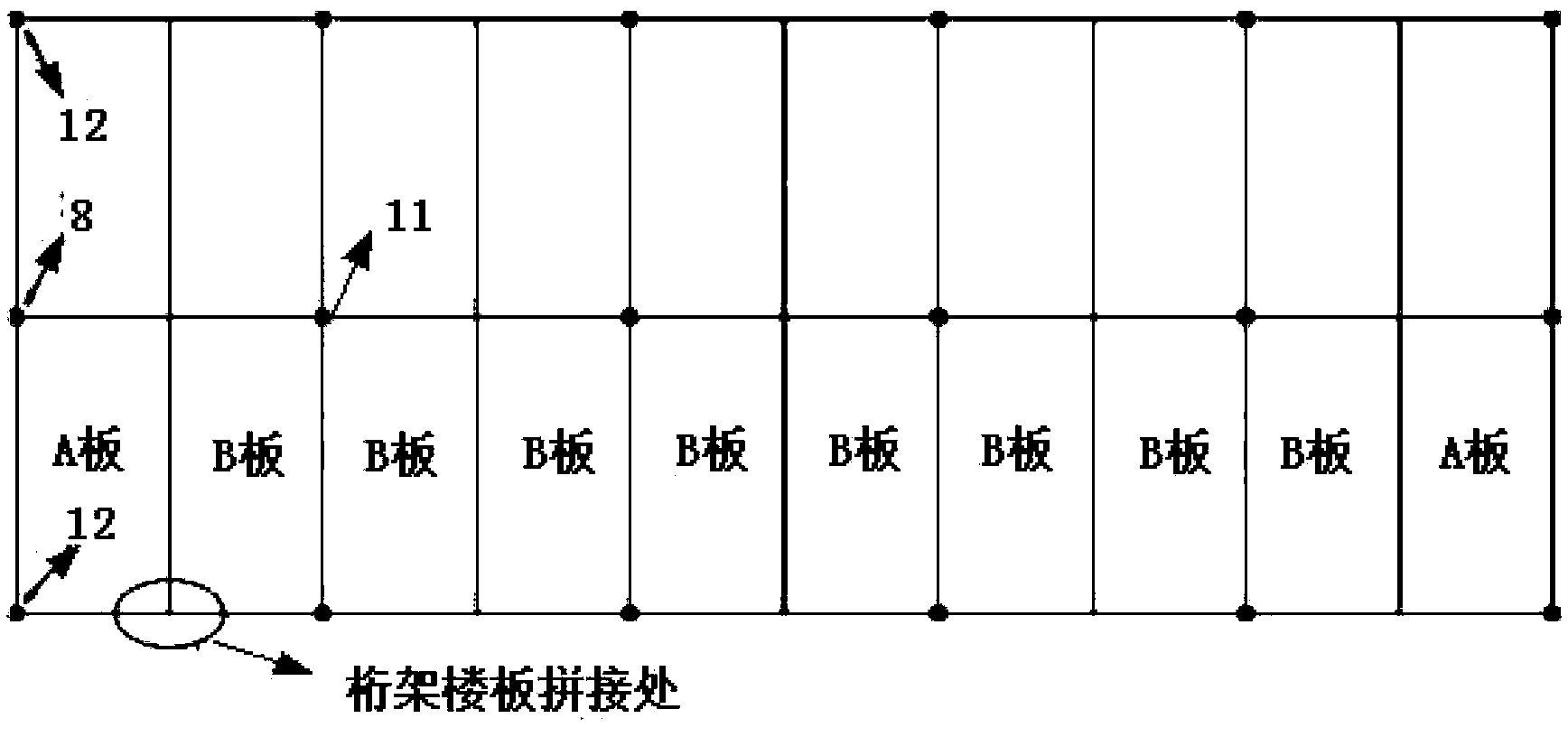

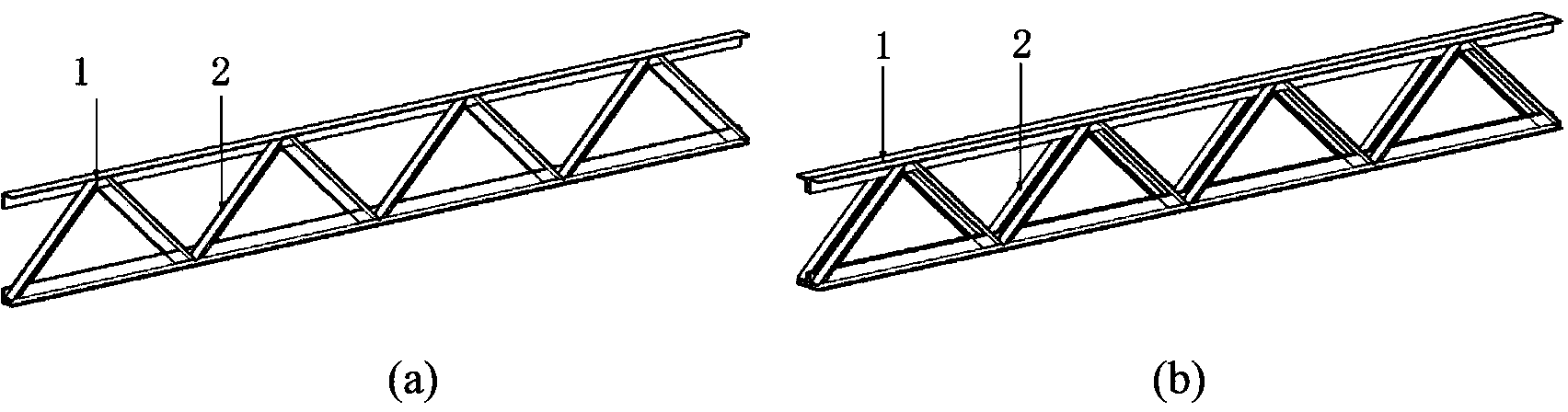

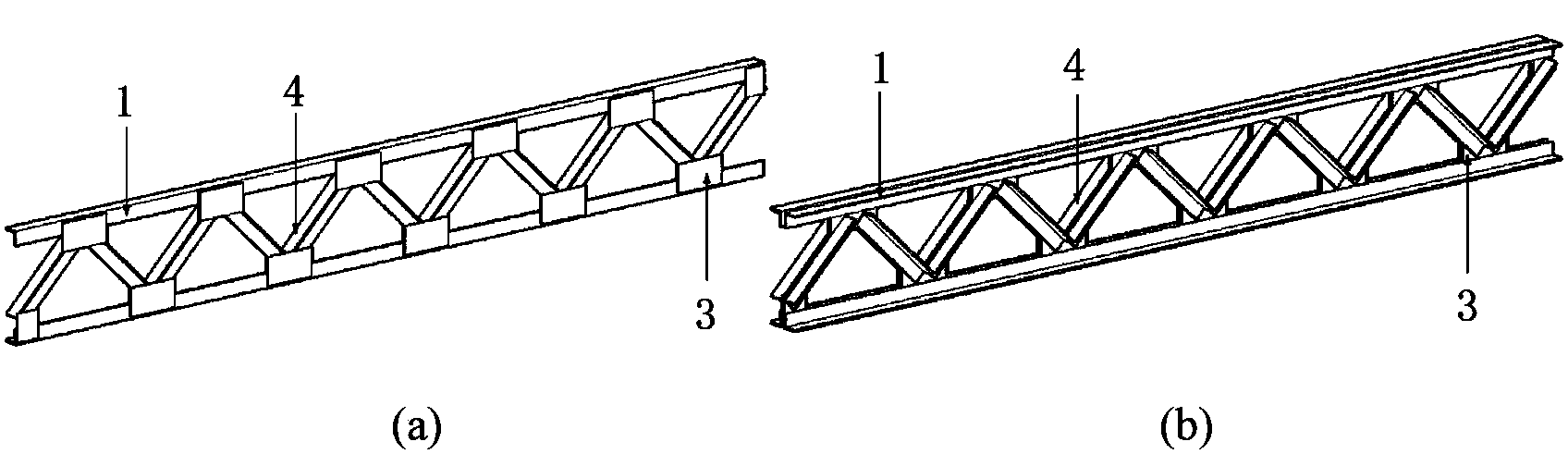

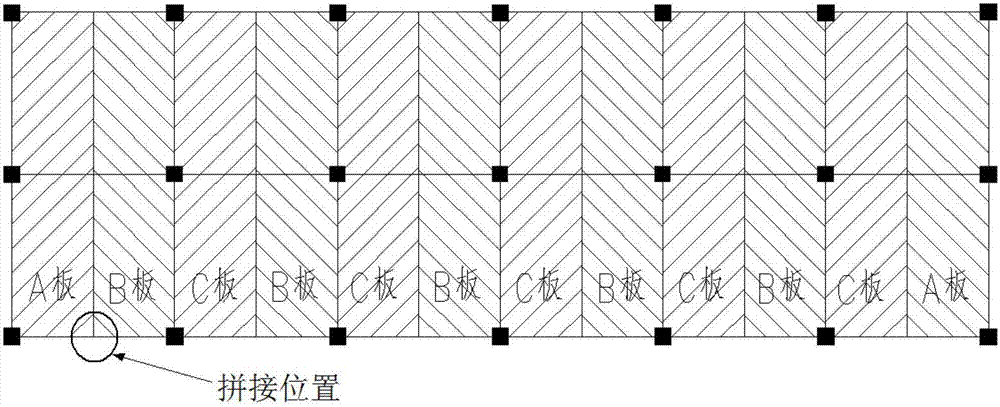

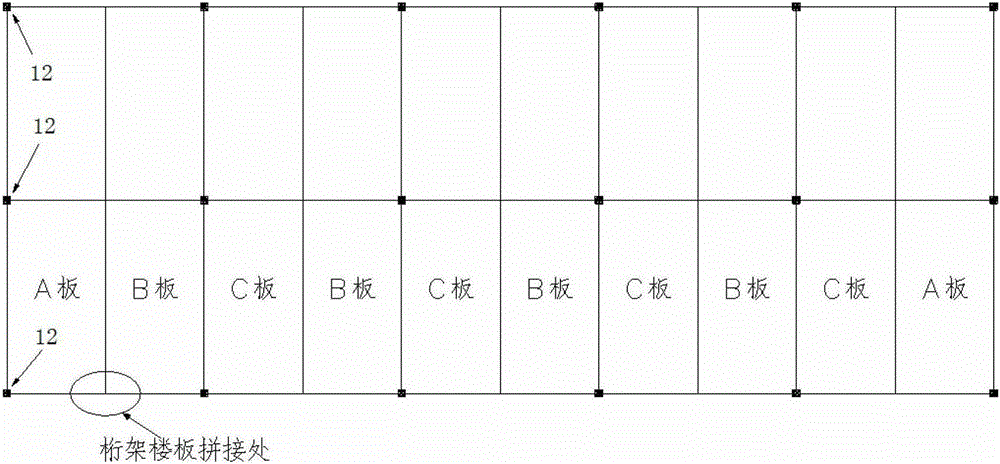

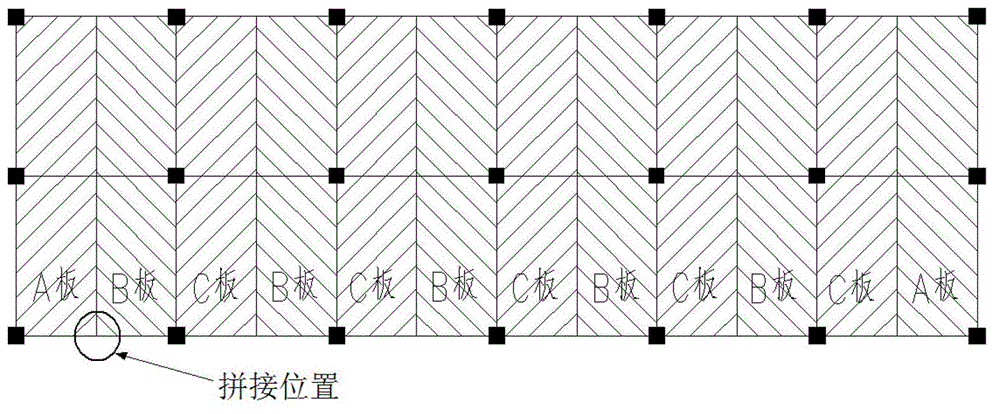

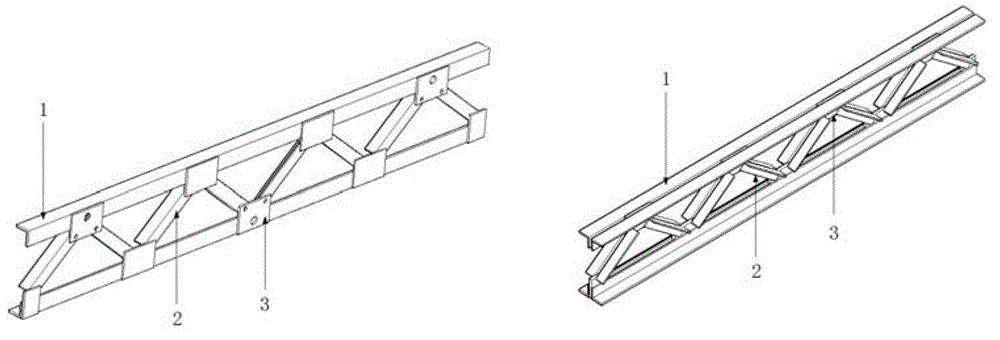

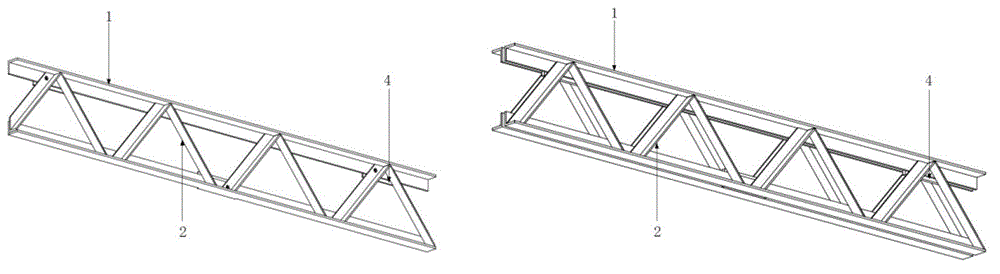

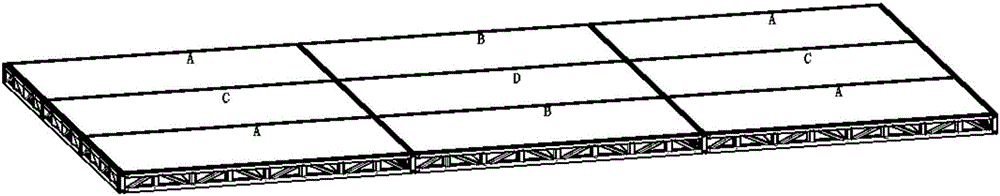

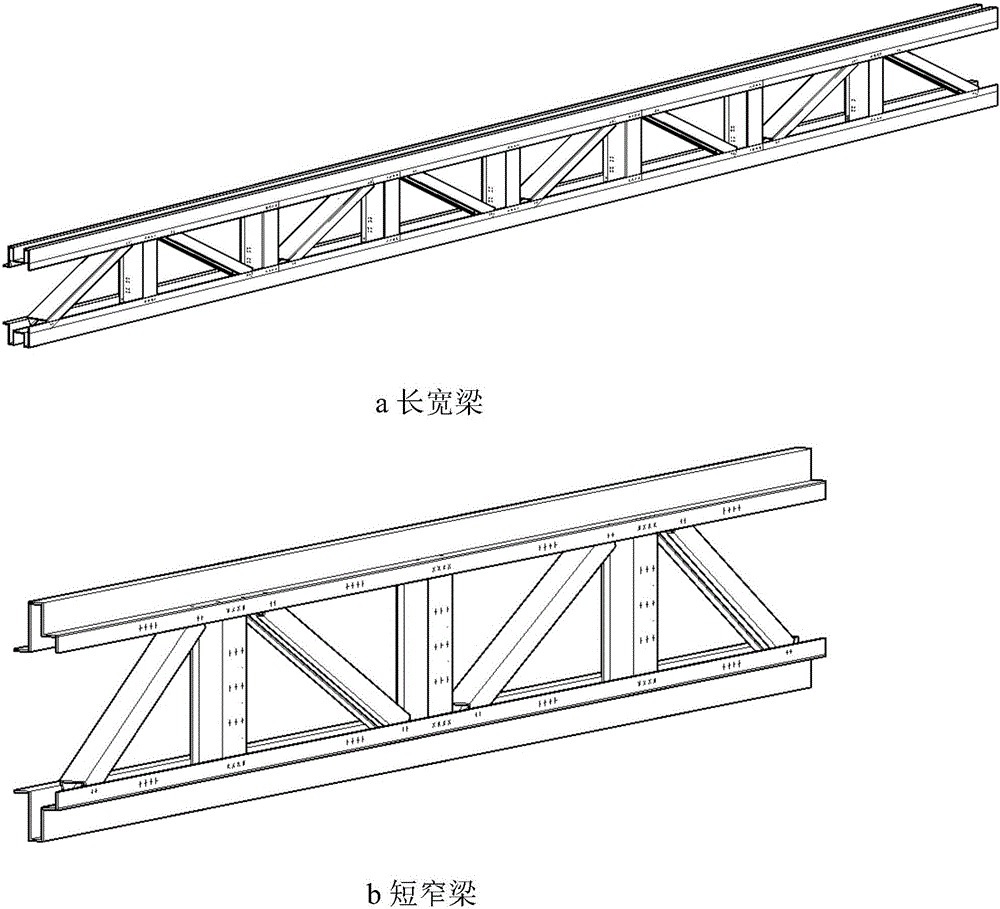

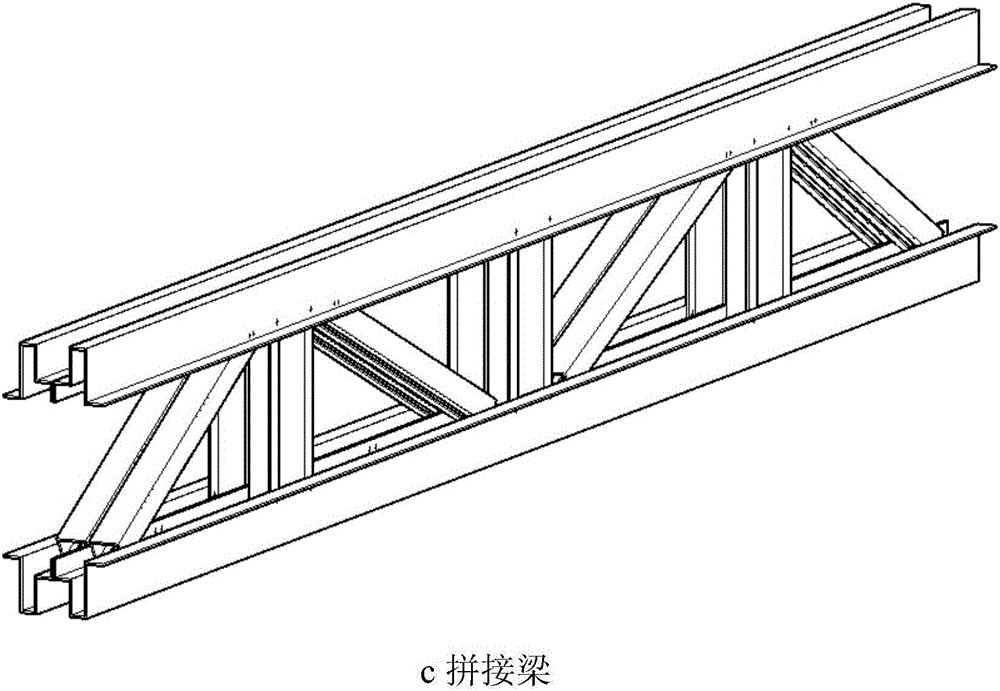

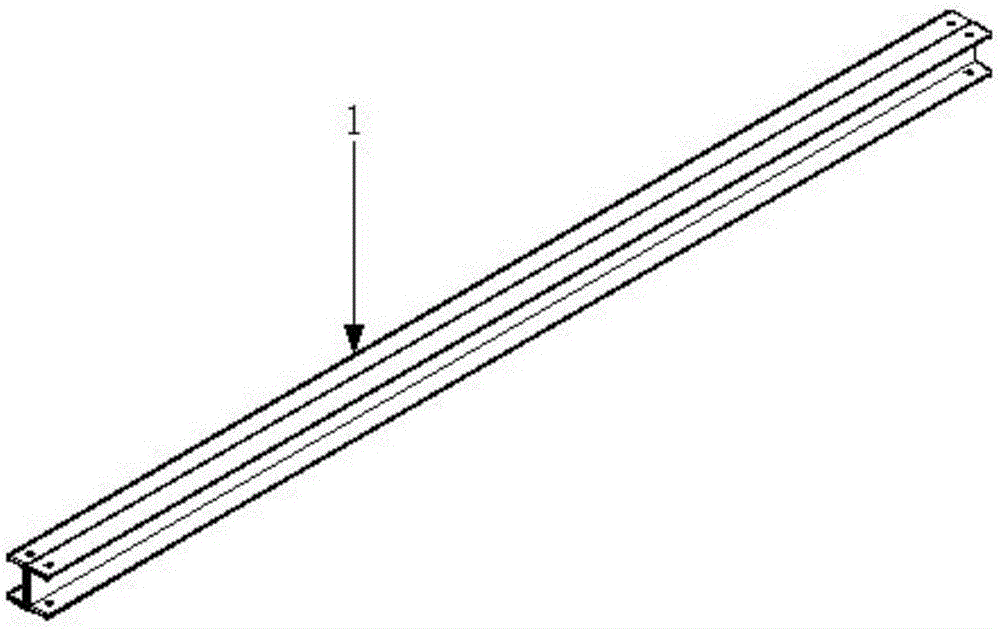

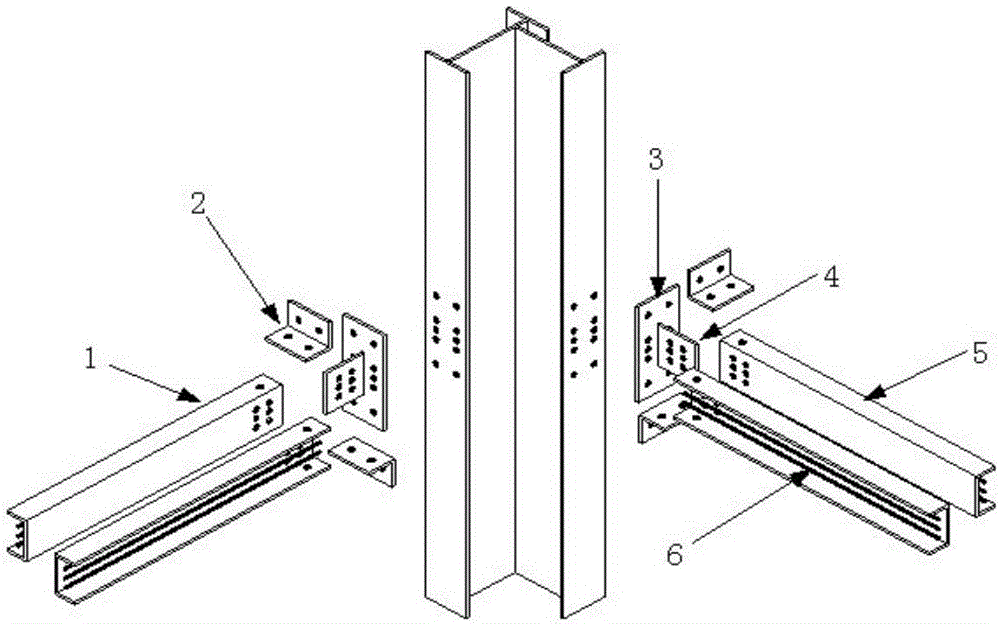

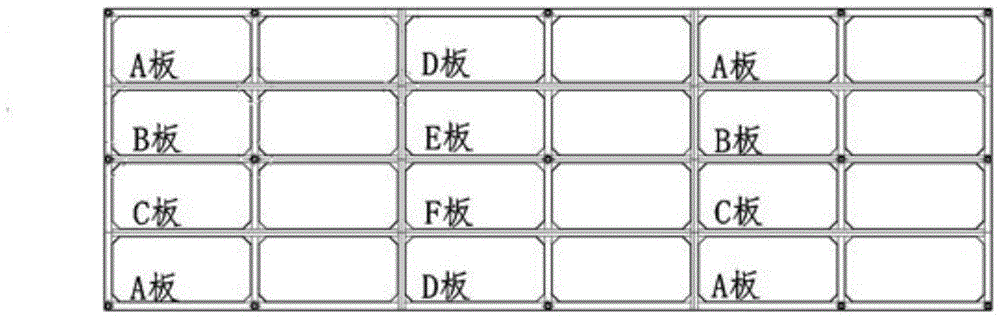

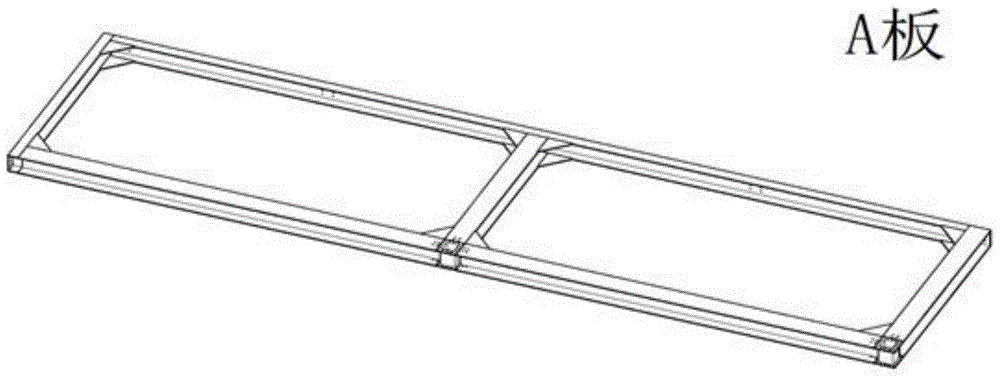

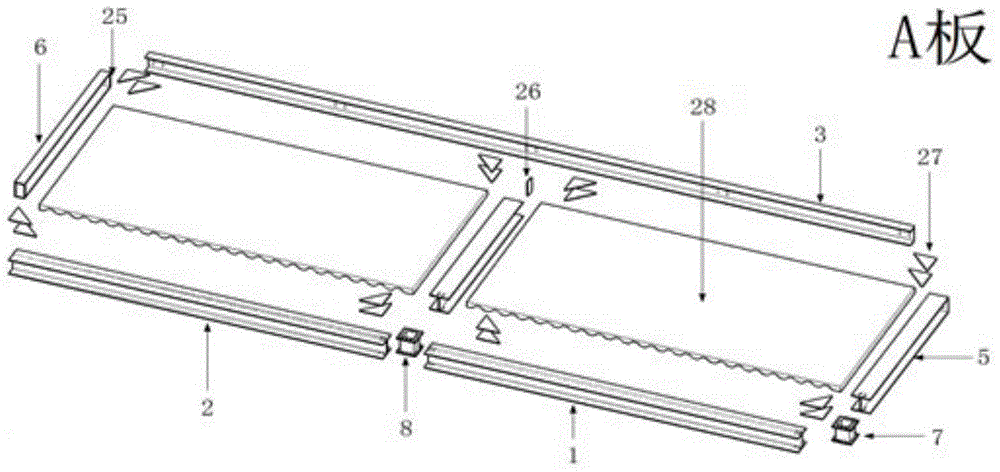

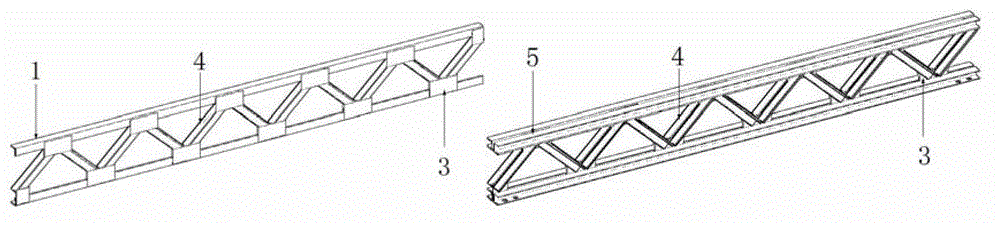

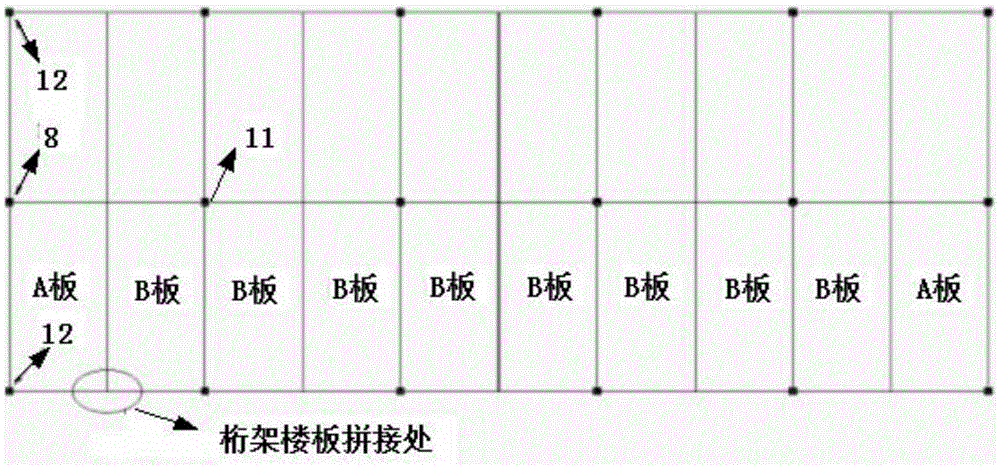

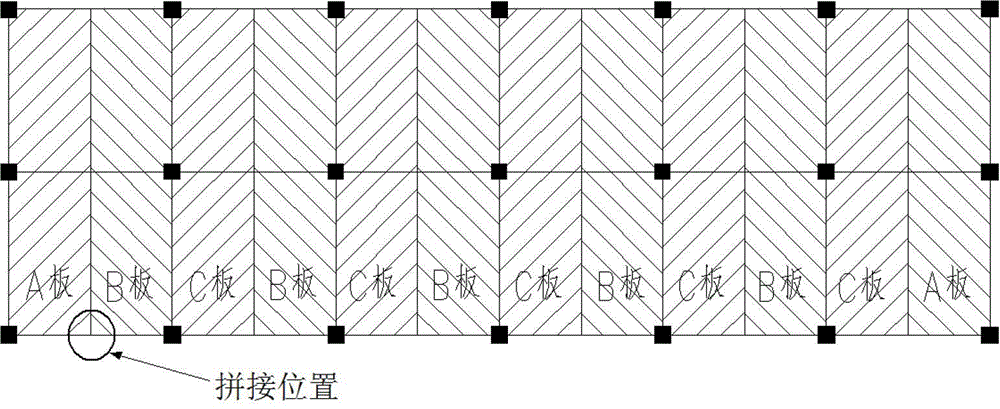

A modular assembly low-rise cold-formed thin-walled steel floor module

Provided is a novel modular assembled lower-layer thin-walled cold-formed steel floor module. The floor module is formed by connecting A, B, C, and D four kinds of sub-units. The four kinds of sub-modules use a truss girder and profiled steel sheet and foam cement composite floor system. A concave (called a wide beam) thin-walled cold-formed steel section or a thin-walled cold-formed steel section which can be spliced into a concave shape (called a narrow beam) in a pairwise manner are used in the upper boom and the lower boom of the truss girder. A C-shaped section is used in the web plate of the truss girder. A surface plate comprises foam cement, a reinforcing mesh, and a cold-bending steel plate from top to bottom in sequence. The wide beam, the narrow beam, and the surface plate are assembled together, so as to form A, B, C, and D four kinds of floor sub-units. Through expanding, combining, and splicing the four kinds of floor sub-units, modular assembling of floor systems in different dimensions is realized. The floor module system combines modulization, factorization, and assemblage, and realizes factory-like production and fast assembling on site. The floor module is a green and environmentally-friendly structural system.

Owner:BEIJING UNIV OF TECH

An easy-to-repair steel special-shaped column frame structure joint after earthquake

Owner:南通新丰威机械科技有限公司

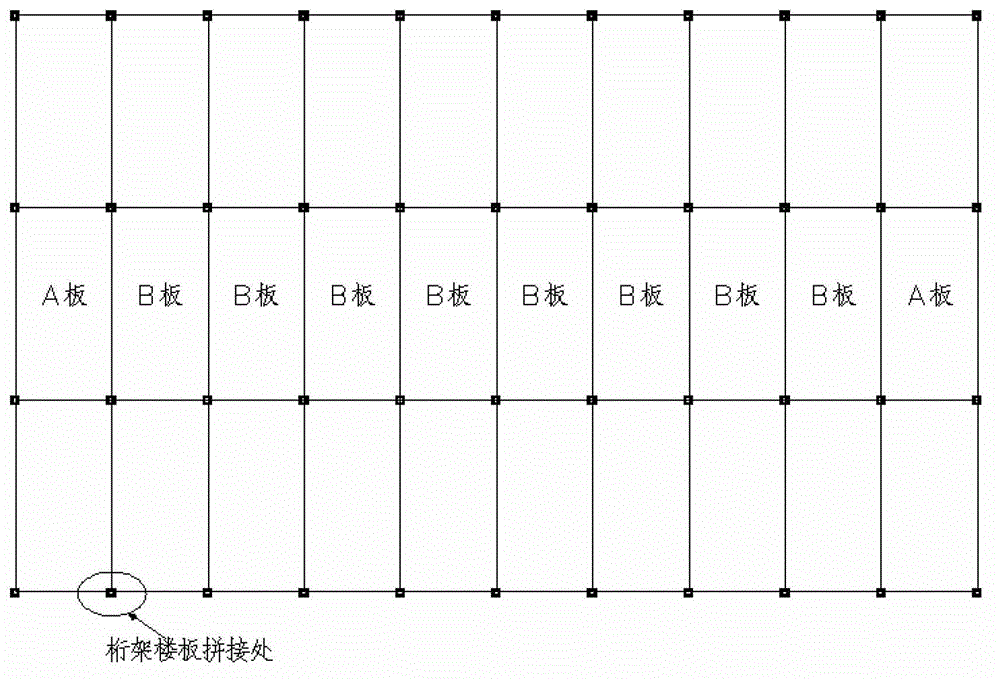

A modular multi-story fabricated steel structure system

The invention relates to a modular multi-high-rise assembled steel structure system belonging to the technical field of structural engineering. The structural system is assembled by bolts on the assembled floor and the assembled flange column; the assembled floor can be spliced to a required scale, and bolts are used to splice the assembled floors to form the entire floor of the building; The steel structure system of the present invention realizes factory production and rapid on-site assembly. At the same time, the present invention completely uses high-strength bolts for on-site assembly, which avoids environmental pollution caused by concrete pouring and steel welding. When the structural components are removed, they can be recycled efficiently. It is a green structural system that truly realizes the concept of green environmental protection.

Owner:江苏元润建设有限公司

An industrially assembled column-through-beam solid-web steel frame system

ActiveCN103290922BAvoid pollutionGuarantee the construction qualityBuilding constructionsFloor slabSteel frame

The invention discloses an industrial prefabricated solid-web steel structural frame system with columns penetrating beams, and belongs to the technical field of structural engineering. The structural frame system comprises prefabricated beam plates and the prefabricated upright columns which are assembled by bolts to form the structural frame system; prefabricated floors comprise section steel beams and floors, the section steel beams are connected with other section steel beams or upright columns by beam-end sealing plates and on-beam cover plates to form beam plate and steel frame structures, and the floors are placed on the beam plate and steel frame structures and are connected with the beam plate and steel frame structures, so that the prefabricated beam plates are formed; the prefabricated beam plates are spliced with beam-column joints of the prefabricated upright columns by beam-end sealing plates and on-beam cover plates of the prefabricated beam plates; the prefabricated upright columns penetrate the beam-column joints, each upright column with the certain length can penetrate 4-5 stories, and the upright columns are spliced at inflection points, which have low stress, of middle columns of the stories by bolts in a site, so that a multilayer beam plate and steel frame structure is formed; various members of the prefabricated beam plates and the prefabricated upright columns are prefabricated in a factory and are assembled by bolts in the construction site.

Owner:北京国电恒嘉科技产业集团有限公司

An industrially assembled column-through-type steel structure frame eccentric support system

ActiveCN103290925BIncrease lateral stiffnessGood deformabilityBuilding constructionsSupporting systemFloor slab

The invention discloses an industrial prefabricated eccentric bracing system with penetrating columns for a steel structural frame, and belongs to the technical field of structural engineering. The industrial prefabricated eccentric bracing system comprises prefabricated truss plates, prefabricated upright columns and eccentric bracing members; the prefabricated truss plates comprise floors and latticed truss beams with angle steel web members; the prefabricated truss plates are prefabricated in a factory and are spliced with beam-column joints of the prefabricated upright columns by beam-end sealing plates and on-beam cover plates of the prefabricated truss plates in a construction site; the prefabricated upright columns penetrate the beam-column joints, each upright column with the certain length can penetrate 4-5 stories, and the upright columns are spliced at inflection points, which have low stress, of middle columns of the stories by bolts in the site, so that a multilayer truss plate and steel frame structure is formed; the eccentric bracing members are connected to the bottoms or the tops of the truss beams of the prefabricated truss plates to be used as lateral-resistant members on the basis of the truss plate and steel frame structure; the prefabricated truss plates, the prefabricated upright columns and the eccentric bracing members are prefabricated in the factory and are assembled by bolts in the construction site.

Owner:RIZHAO WEIYE TOOL

An industrialized assembled special-shaped column steel structure frame-central support system

InactiveCN103276805BIncrease lateral stiffnessGood deformabilityStrutsWallsSupporting systemFloor slab

The invention provides an industrialized assembly type special-shaped column steel structure frame-eccentric support system and belongs to the technical field of structural engineering. The industrialized assembly type special-shaped column steel structure frame-eccentric support system comprises assembly type truss plates, assembly type columns and central support members. Each assembly type truss plate comprises lattice truss beams and floor slabs and is prefabricated in a factory, and the assembly type truss plates and beam-column joints of the assembly type columns are spliced through beam-end seal plates in a construction site, and the assembly type columns are spliced among layers in the site through bolts to form a multiple-layer truss plate steel frame structure. Based on the truss plate steel frame structure, the central support members serve as lateral force resisting members and are connected with the truss beams in the assembly type truss plates and the bottoms or the tops of the assembly type columns. The assembly type truss plates, the assembly type columns and the central support members are prefabricated in the factory and are assembled in the construction site through bolts.

Owner:BEIJING UNIV OF TECH

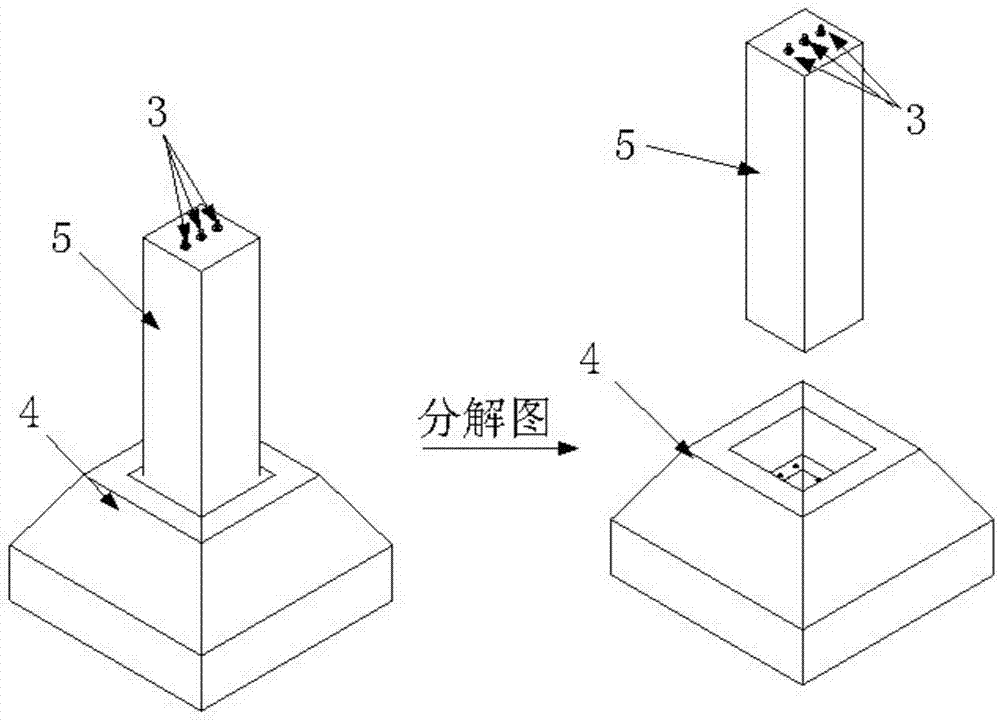

Self-resetting concrete frame structure cup foundation after earthquake

InactiveCN103790172BSolve the problem of difficult assemblyAvoid pollutionFoundation engineeringDrift angleRebar

The invention relates to a novel post-earthquake self-returning concrete frame structure cup-shaped foundation, and belongs to the technical field of earthquake prevention and disaster reduction. The initial rigidity of the embedded cup-shaped foundation is identical to the rigidity of a cast-in-place concrete structure; under the situation that a story drift angle is small, prestressed steel bars still keep elasticity, energy-dissipation steel bars enter a plastic state so as to dissipate energy, and the embedded cup-shaped foundation can return to the initial position after an earthquake. Compared with the prior art, the novel post-earthquake self-returning concrete frame structure cup-shaped foundation is a breakthrough for traditional concrete structure building foundations, and fundamentally solves the problems that concrete structures are difficult to assemble and poor in ductility; compared with traditional concrete structure foundations, the novel post-earthquake self-returning concrete frame structure cup-shaped foundation has the advantages of having high safety, low pollution to the environment, few safety accidents, low engineering cost and the like.

Owner:BEIJING UNIV OF TECH

A new type of post-earthquake easy-to-repair steel special-shaped column-prestressed central support frame

The invention discloses a special-shaped steel column-prestress central supporting frame easy to restore after an earthquake. The special-shaped steel column-prestress central supporting frame easy to restore after the earthquake is characterized in that a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that a prestress self-reset joint is formed; a self-reset column base and a prestress column base are used for optimizing the axial mechanical performance and the horizontal mechanical performance of the bottom of the column through a reinforcing plate, a bend-preventing steel plate is mainly used for dissipating energy of the earthquake, and a shear plate is used for preventing local deformation, caused by excessive shearing force, of the bottom of the column; the key component of the prestress column base is a prestress pull rod, the pull rod is used for providing precompression for the column so that the column can be tightly connected with the beam, as a result, approximate rigid connection can be achieved when the prestress column base bears small bending moment, and the self-reset capacity of the prestress column base after the earthquake is achieved; better lateral resistance of the structure is achieved through prestress central supporting.

Owner:南通新丰威机械科技有限公司

A multi-story fabricated steel structure system with hollow special-shaped columns

ActiveCN103276803BEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

A hollow irregular column multi-layer high-rise assembling steel structure system relates to the technical field of engineering and comprises assembling truss plates and assembling flange columns. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. The assembling truss plates and the assembling flange columns are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:镇江电力设计院有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com