A modular assembly low-rise cold-formed thin-walled steel floor module

A technology of cold-formed thin-walled steel and floor coverings, applied in floors, building components, buildings, etc., can solve the problems of high cost, complex structure, and low degree of assembly, so as to reduce project cost, avoid environmental pollution, and improve construction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The implementation of the structural system will be described in detail below in conjunction with the accompanying drawings.

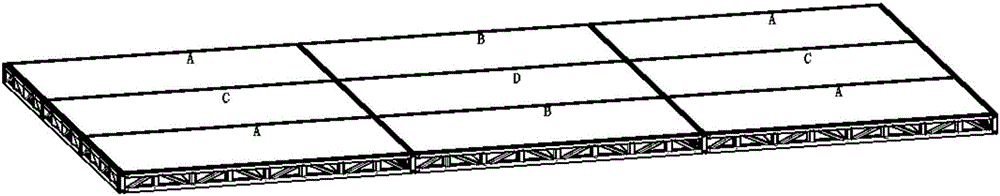

[0042] as attached figure 1 As shown, the basic constituent units of the modular assembly type low-rise cold-formed thin-walled steel floor module include four sub-units A, B, C, and D; the four corners of the modular assembly type floor module The end is unit A, unit B is spliced horizontally with unit A, unit C is spliced longitudinally with unit A, and unit D is connected with unit B and unit C on the other side; the modularization of the prefabricated floor module Expansion is to splice unit B horizontally, unit C vertically, and several D units in the middle.

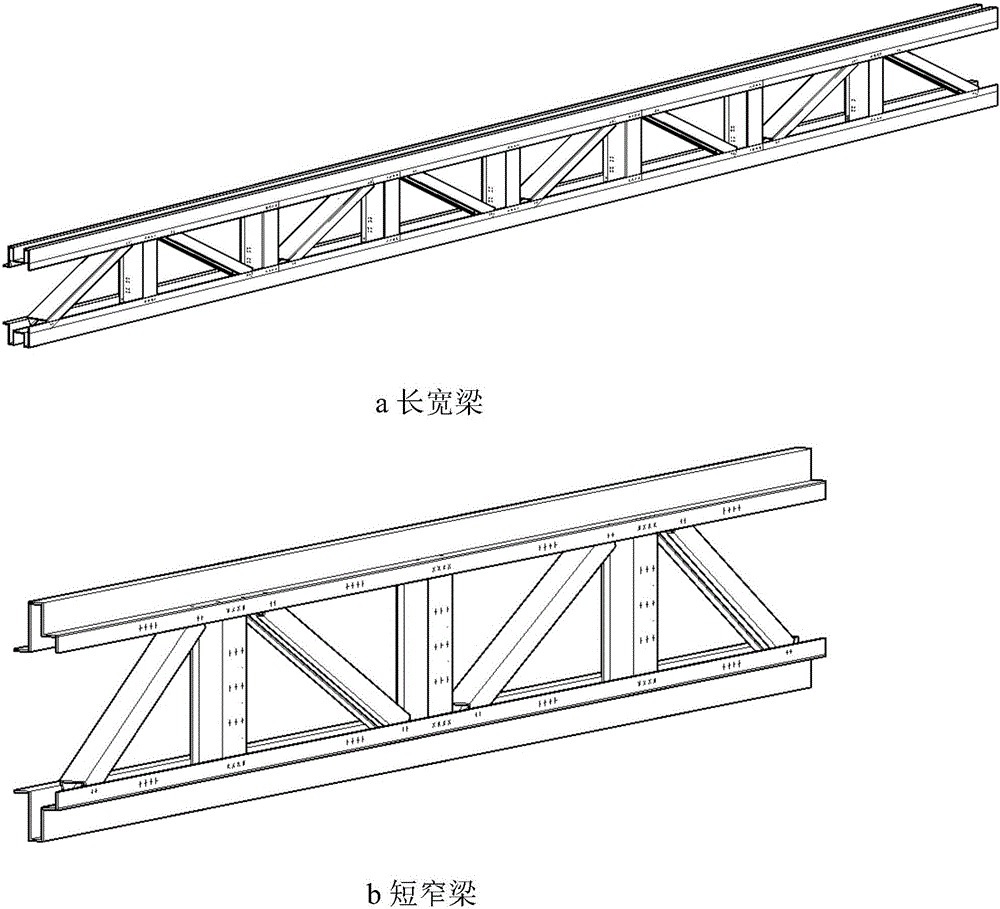

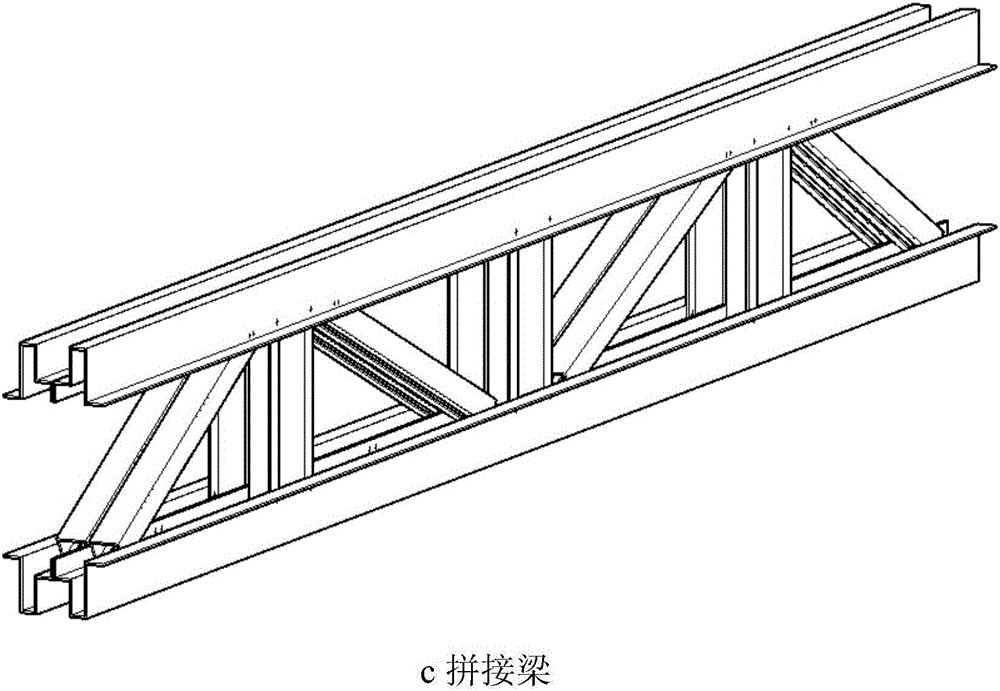

[0043] as attached figure 2 and 3 As shown, the structures of the beams involved in the four sub-units A, B, C, and D are the same, and they are all truss beams; wherein the upper and lower chords of the truss beams are concave (called wide beams such as figure 2 -a) or can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com