A modular multi-story fabricated steel structure system

A prefabricated and modularized technology, which is applied to building components, building structures, floors, etc., can solve the problems that the quality of welds is not suitable for control, affects the safety performance of buildings, and is in its infancy, so as to reduce construction waste and reduce Fire protection, effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

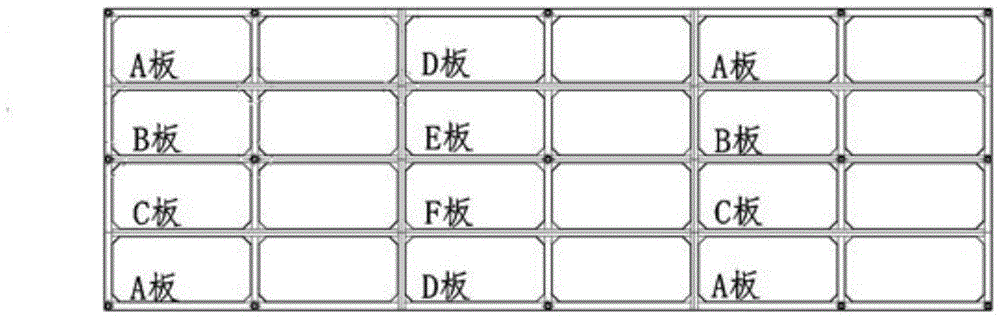

[0036] as attached figure 1 As shown, in the modularized multi-high-rise assembled steel structure system proposed by the present invention, the modularized multi-high-rise assembled steel structure system is assembled by the assembled floor slab and the assembled flange column with bolts; the assembled floor slab It is spliced by 6 prefabricated floor slabs of A board, B board, C board, D board, E board and F board.

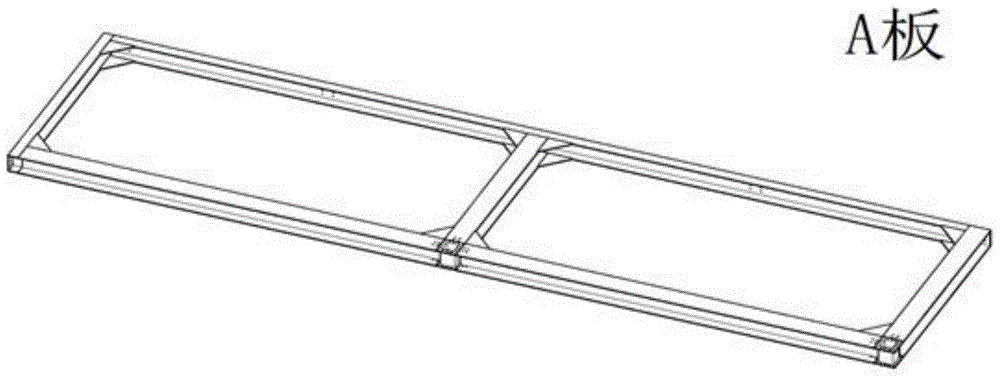

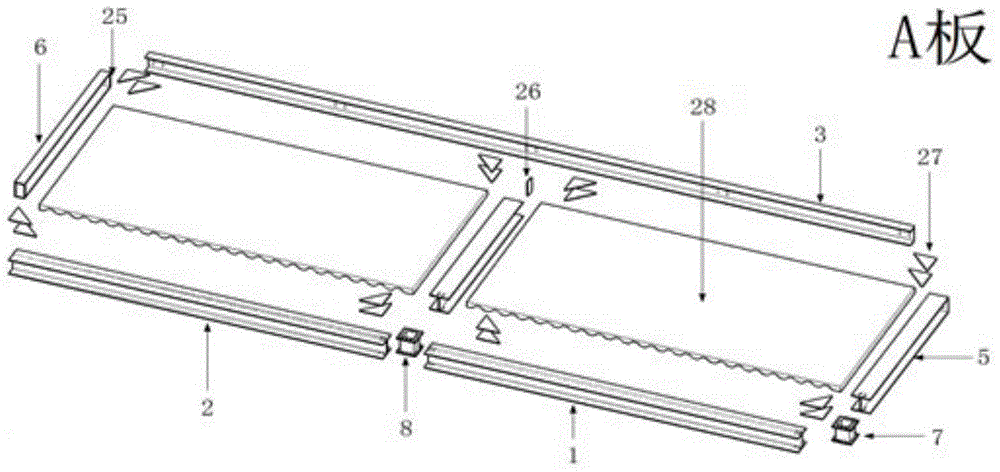

[0037] as attached figure 2 And attached image 3As shown, the A plate includes short main beam I1, short main beam II2, long main beam I3, secondary beam I5, secondary beam II6, column base I7, column base II8, connection plate III25, connection plate IV26, connection plate V27 and the floor slab 28; all the components of the A-slab are processed and manufactured in the factory, and then each component is assembled into the prefabricated floor A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com