Patents

Literature

83results about How to "Less recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

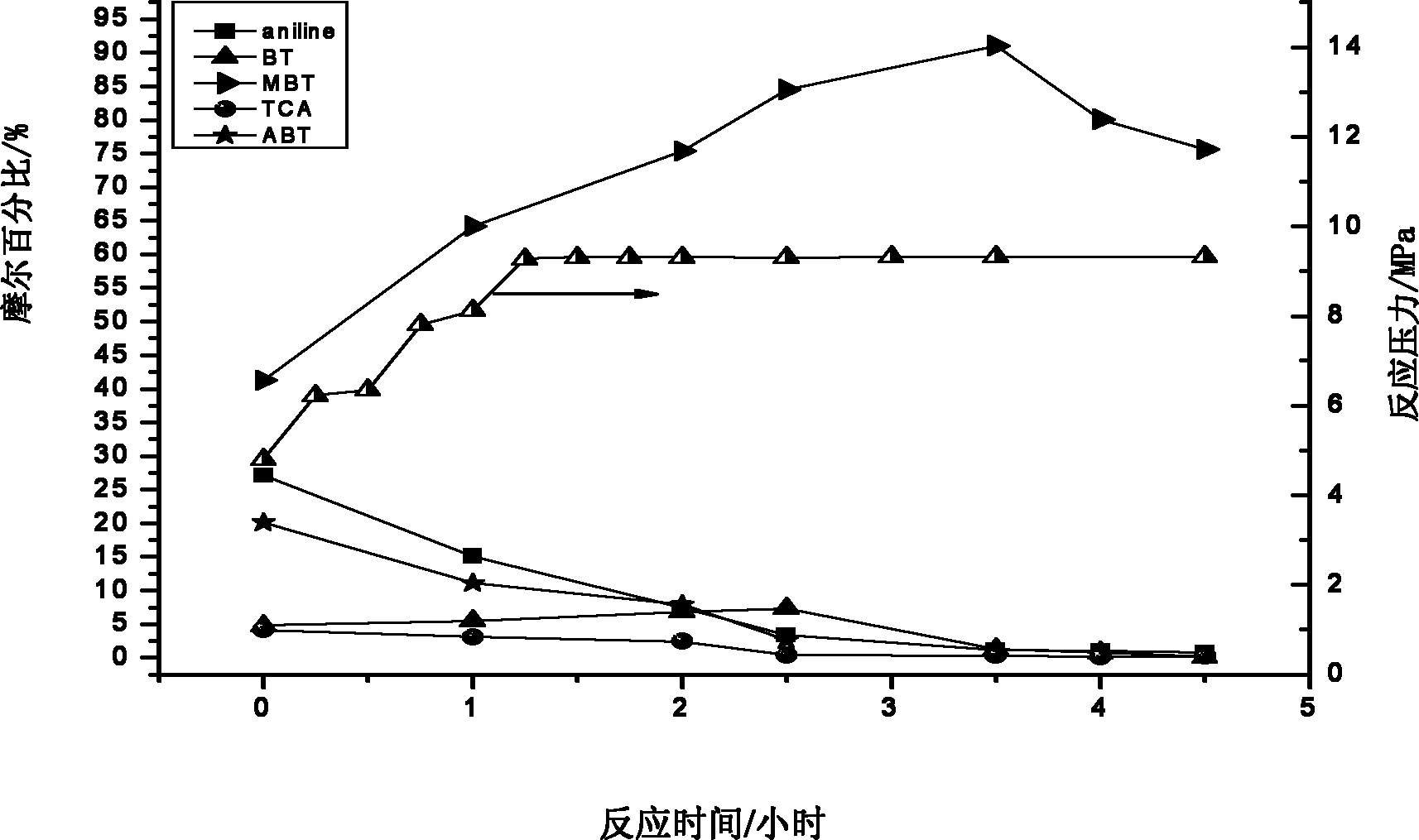

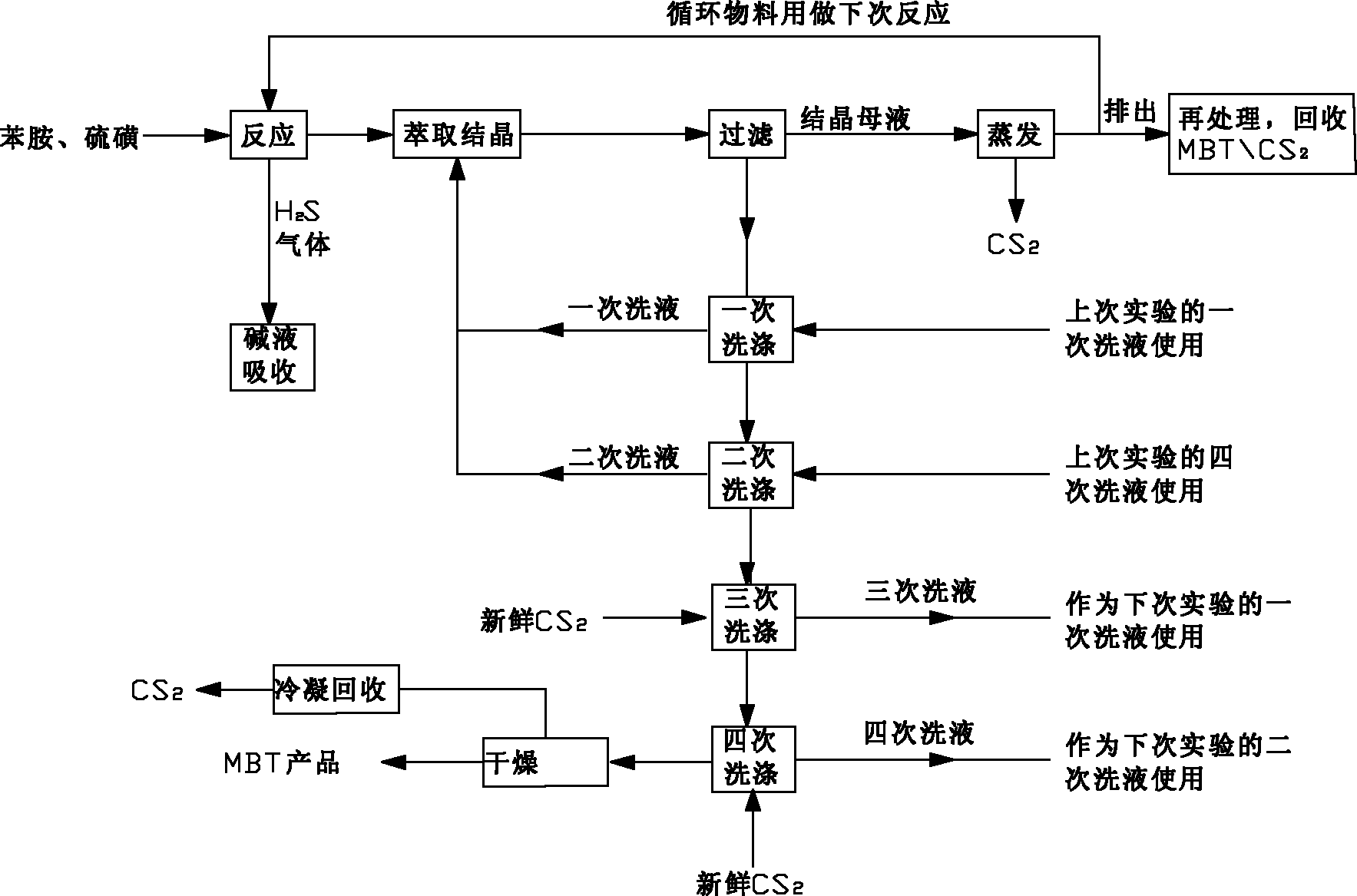

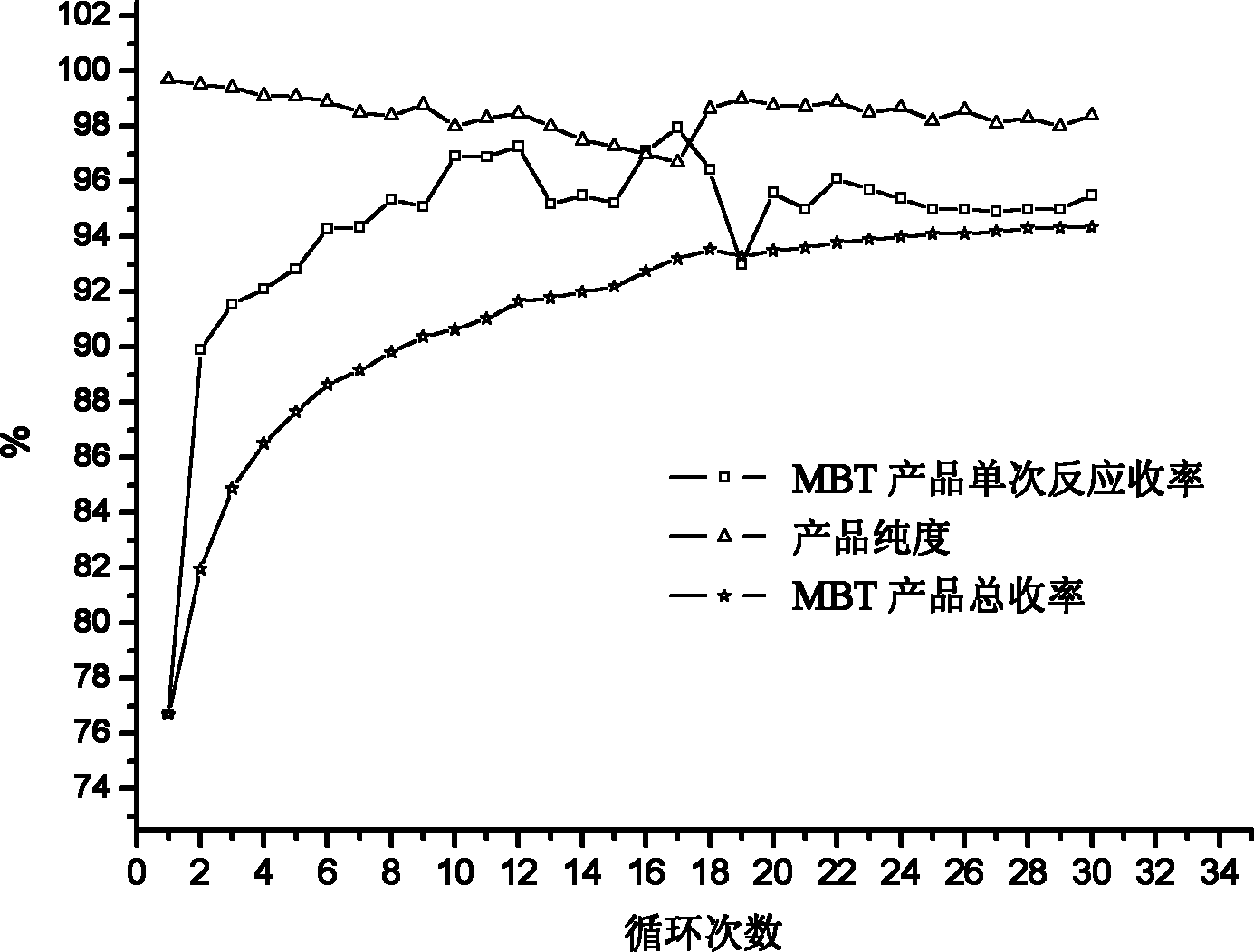

Method for preparing 2-mercaptobenzothiazole

The invention discloses a method for preparing 2-mercaptobenzothiazole, which comprises the steps of: adding carbon disulfide, aniline and sulfur into a reaction kettle; and heating the mixture, finishing a reaction under the reaction pressure of 6.8 to 9.5MPa to obtain a crude product, namely a melt, pressing the melt into a crystallizer loaded with carbon disulfide, controlling the initial temperature of the crystallization, reducing the temperature, beginning to discharge hydrogen sulfide when the material temperature in the crystallizer is reduced to be between 70 and 100 DEG C, controlling the discharge time of hydrogen sulfide to be between 20 and 60min, cooling the obtained product to be between 15 and 20 DEG C, filtering the obtained product to obtain a filter cake and carbon disulfide mother liquor, washing the filter cake for 2 to 5 times by using carbon disulfide in an amount which is 1 to 3 times mass of the filter cake, and drying the scrubbed filter cake to obtain the 2-mercaptobenzothiazole at the mass percentage concentration of over 98 percent. By the method, no 'waste water' and 'waste gas' are discharged, and asphalt-like wastes are greatly reduced. The circulation of crystallization mother liquor realizes the recycling of intermediate products, and the total yield of the process is improved to be over 94 percent.

Owner:TIANJIN UNIV +1

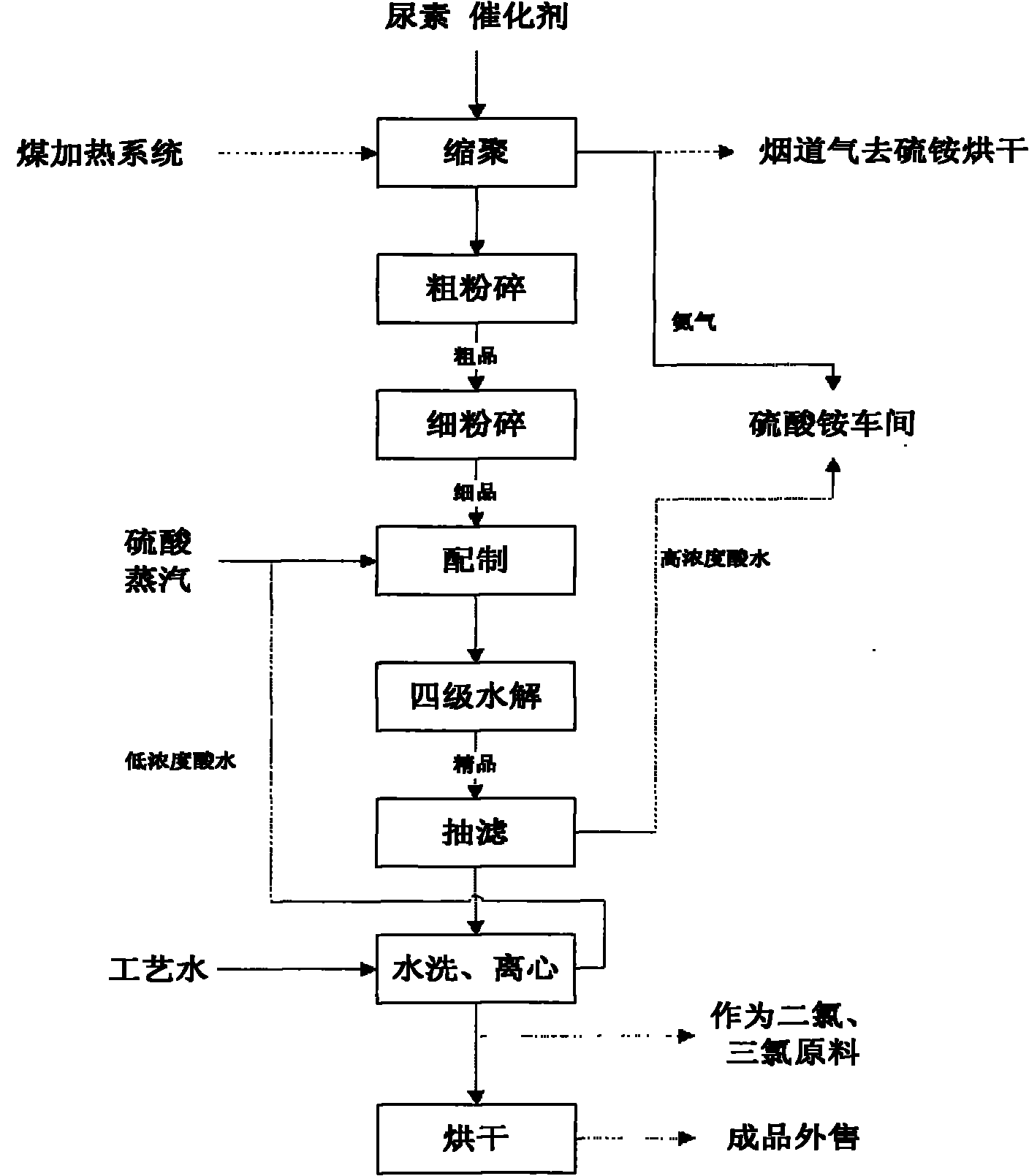

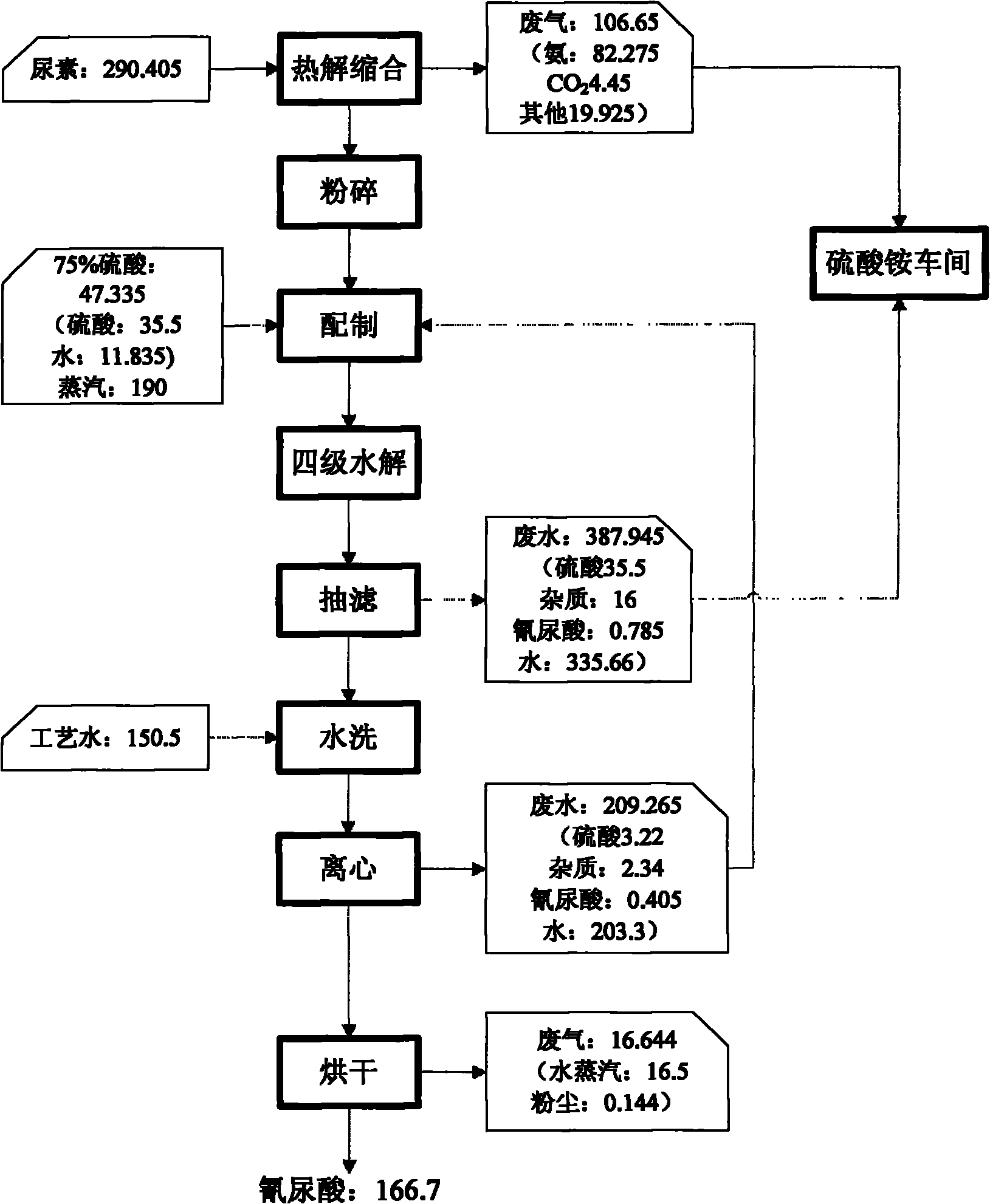

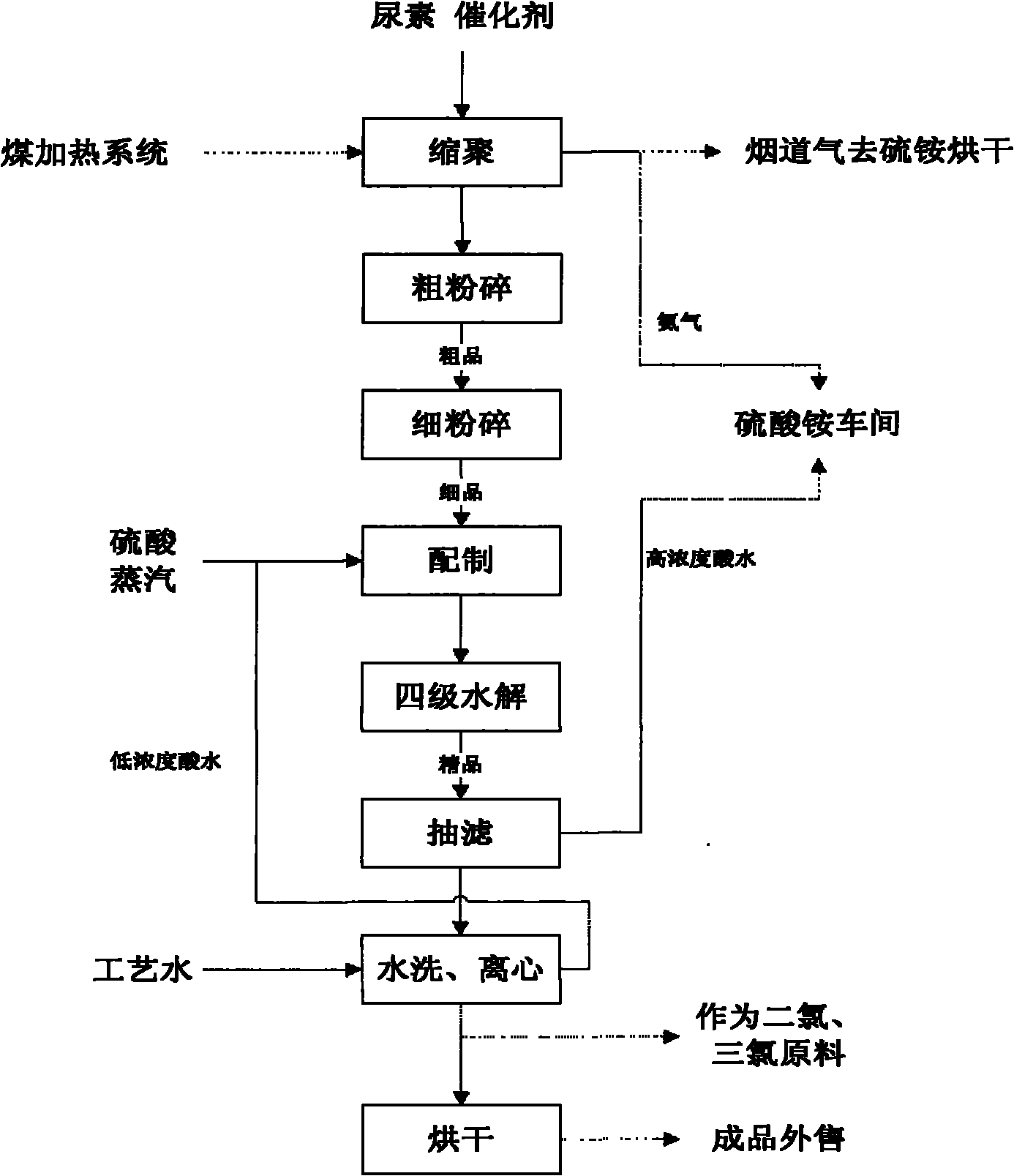

Production method of isocyanuric acid

The invention discloses a production method of isocyanuric acid, in particular relates to a method for producing isocyanuric acid by adopting fully-enclosed continuous four-stage vapour pressure differential reaction. The production method of the isocyanuric acid is characterized in that after isocyanuric acid fine material and sulfuric acid the weight percent of which is 25 percent are evenly mixed, the hydrolysis reaction is generated in sequence by a closed four-stage pressurizing reaction kettle under the action of vapour heating, and feed liquid enters a cooling reaction kettle for being cooled after the reaction is ended, therefore, the production method of the isocyanuric acid has the advantages of not only effectively utilizing energy sources and saving cost but also greatly reducing the smoke discharge amount, saving coal and electricity and greatly improving the production efficiency.

Owner:HEZE WOLAN CHEM

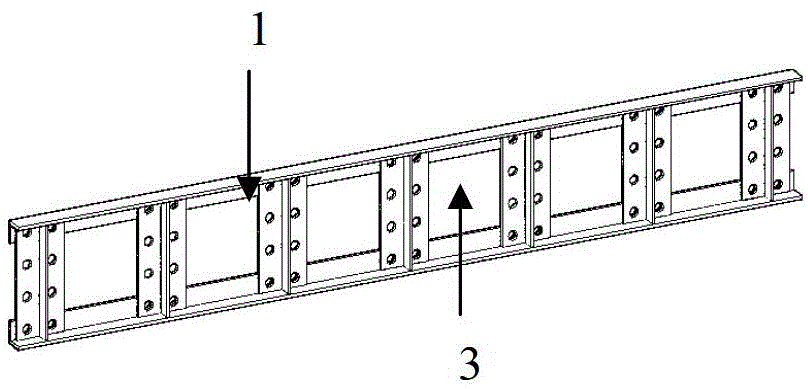

Multi-story high-rise assembled steel structure frame system

The invention relates to a multi-story high-rise assembled steel structure frame system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame system comprises assembled beams and slabs, and assembled stand columns. The assembled beams and slabs in the system comprise slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns comprise box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:GUANGDONG UNION STEEL MFG

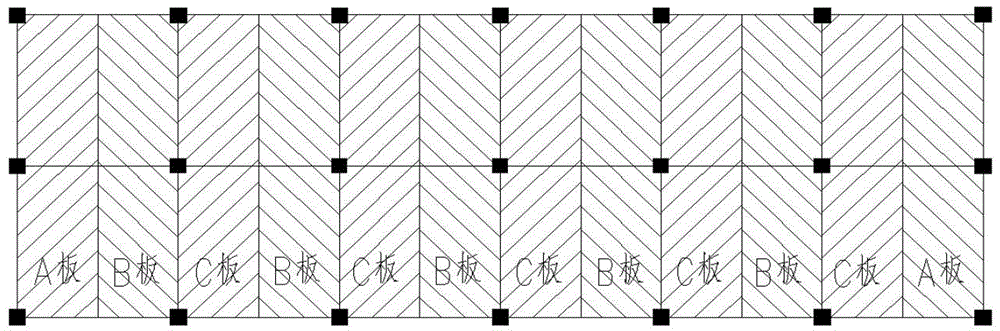

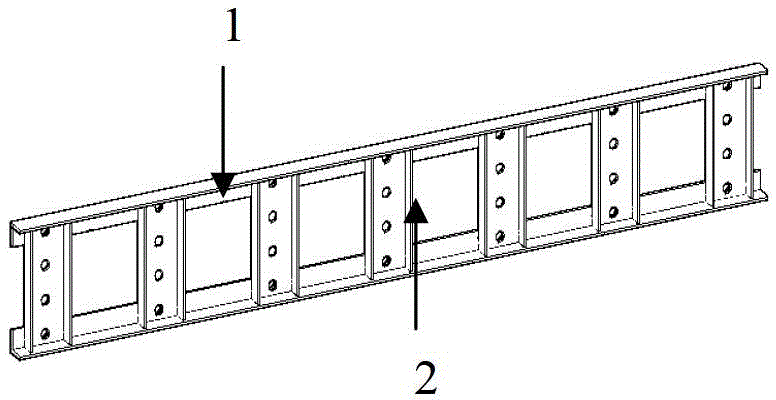

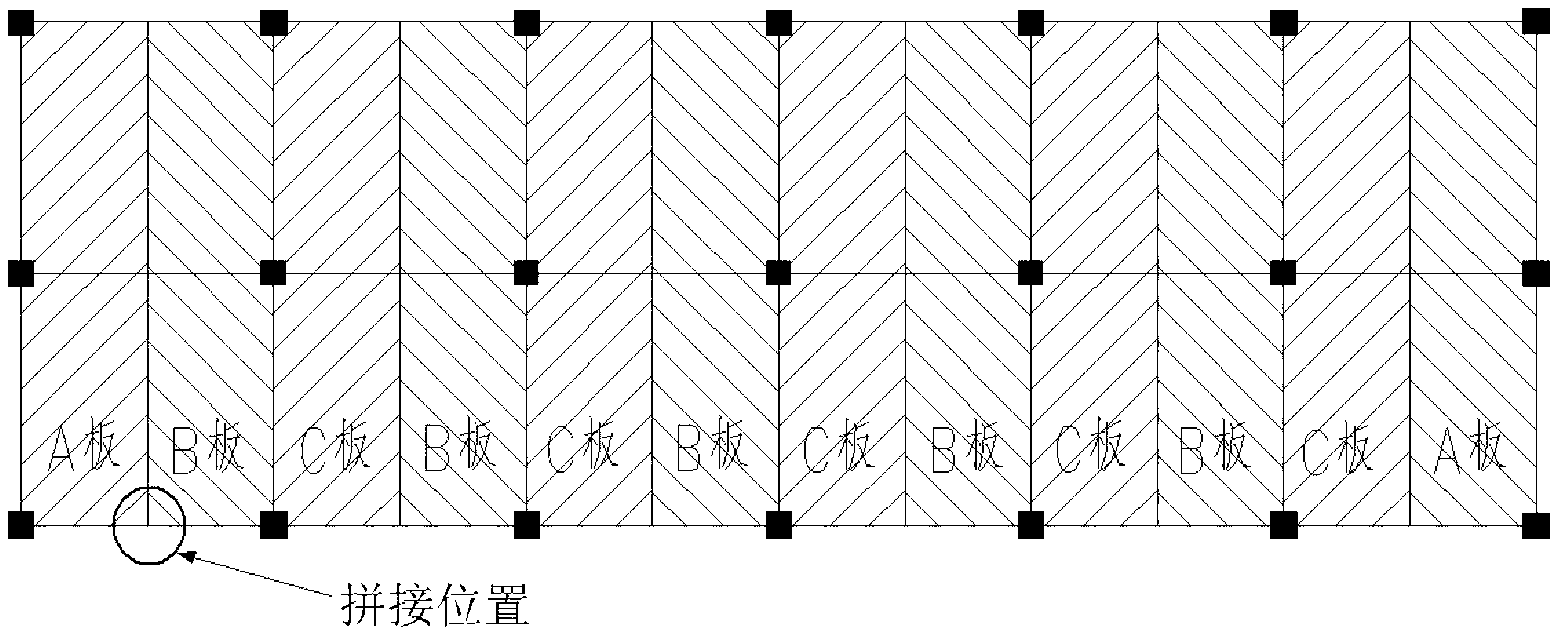

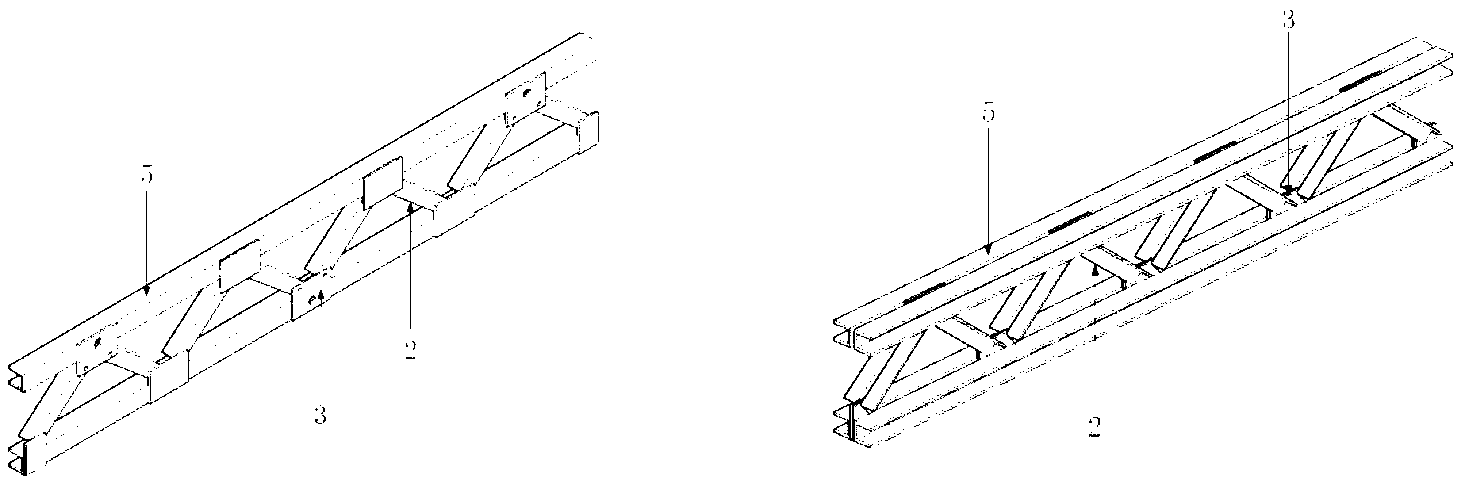

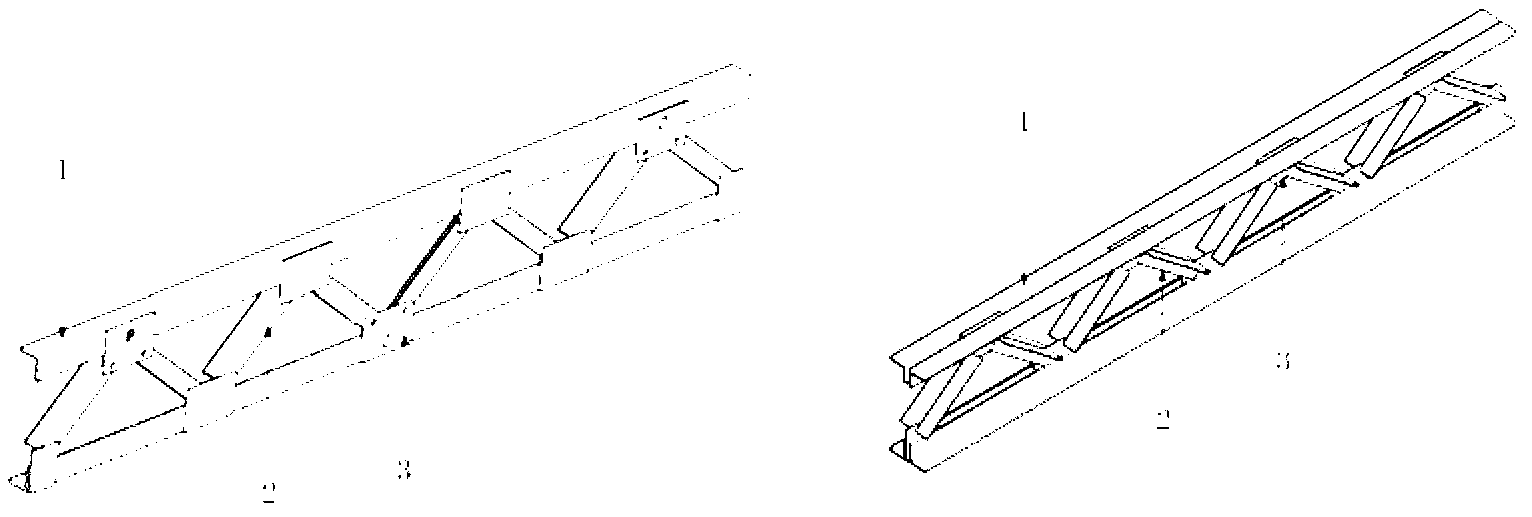

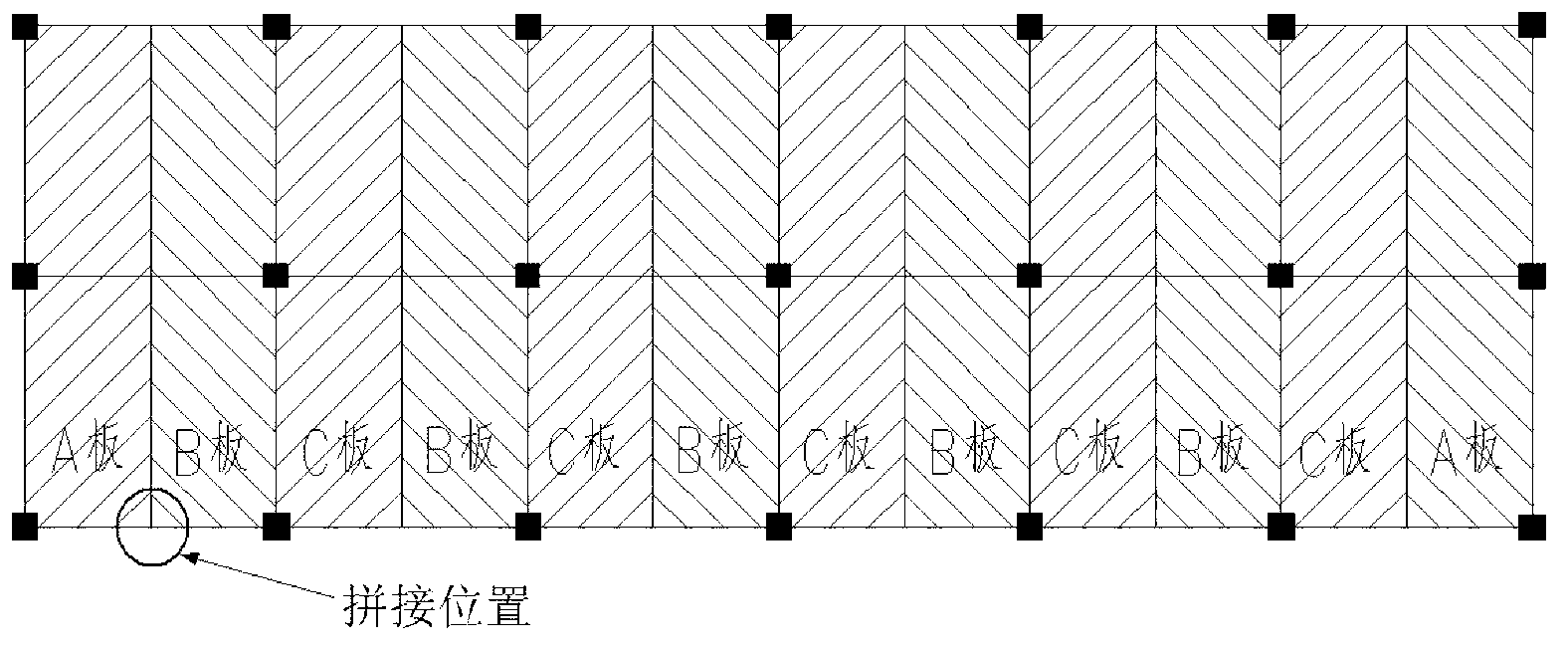

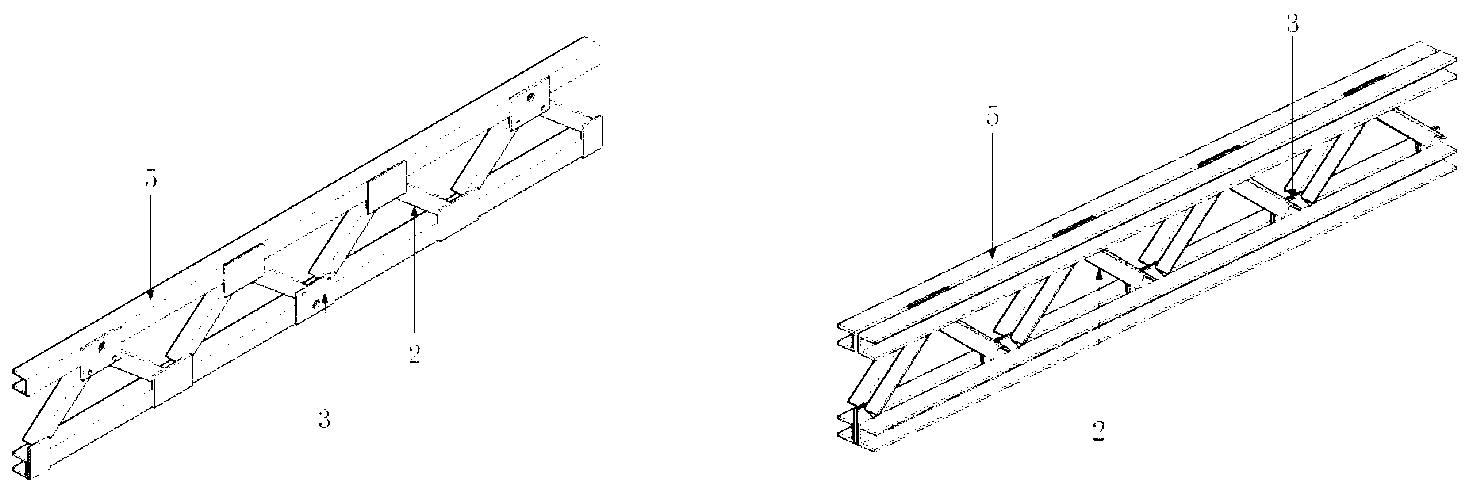

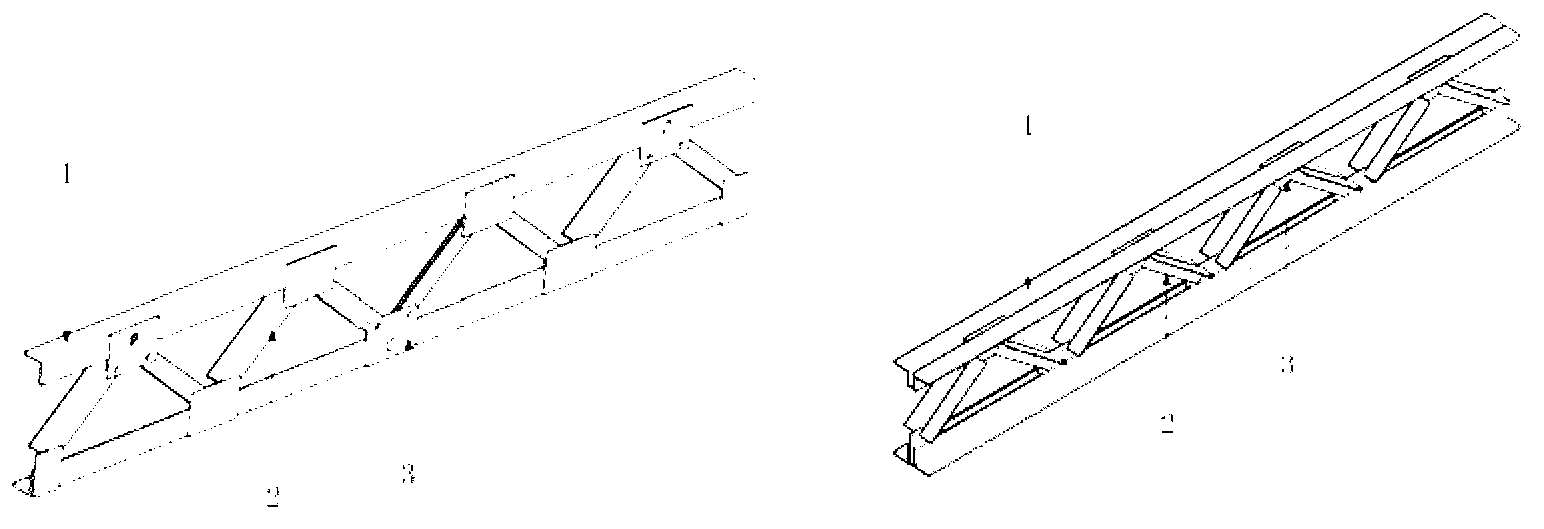

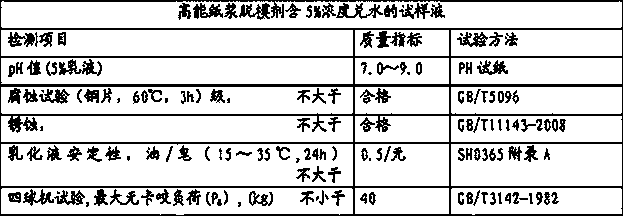

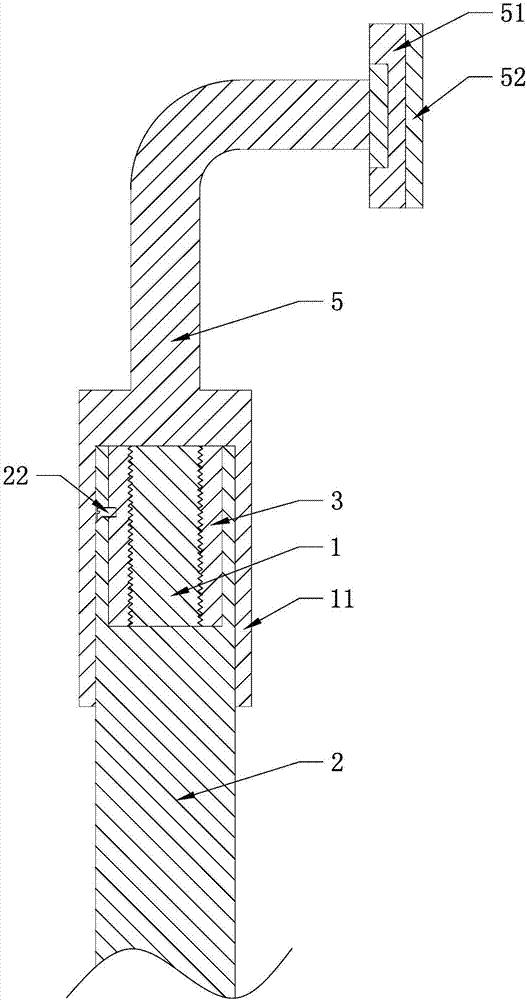

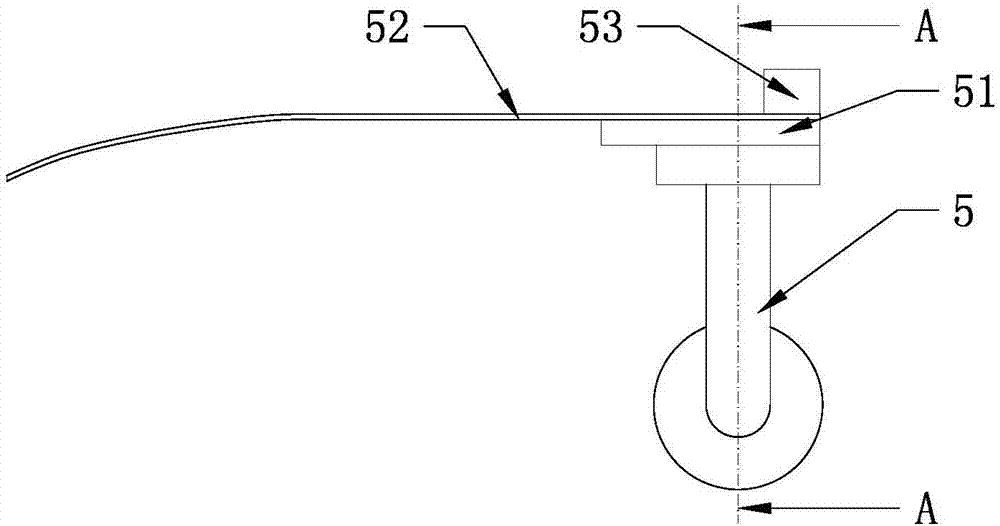

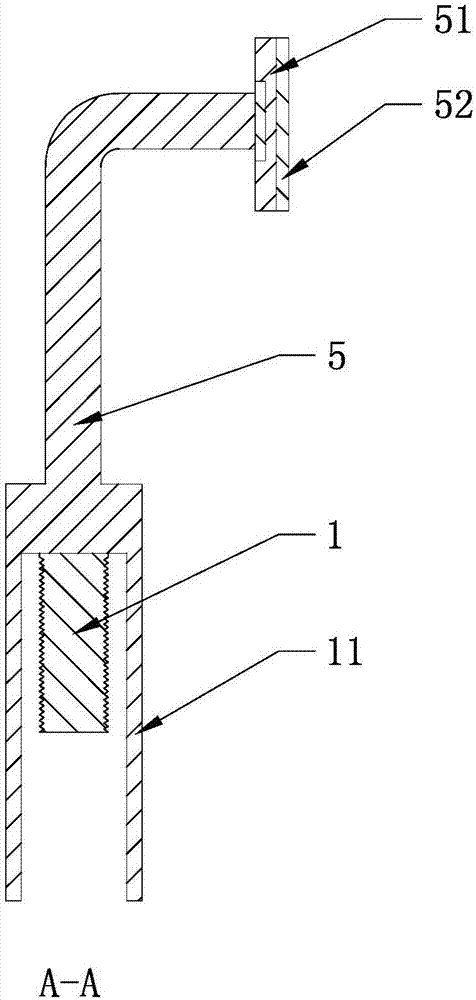

Hollow irregular column multi-layer high-rise assembling steel structure system

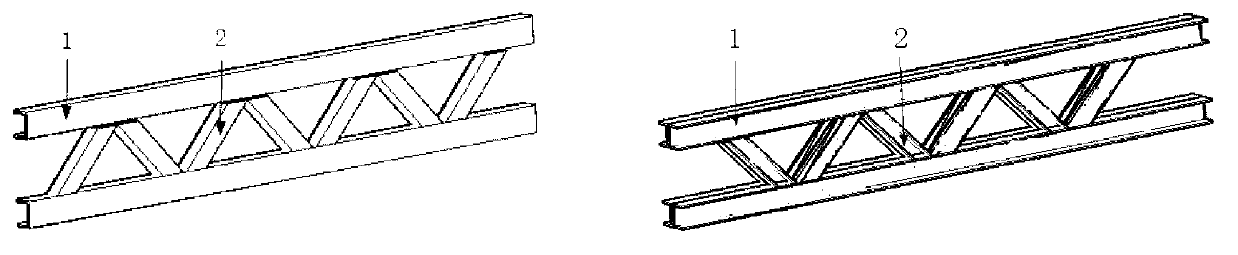

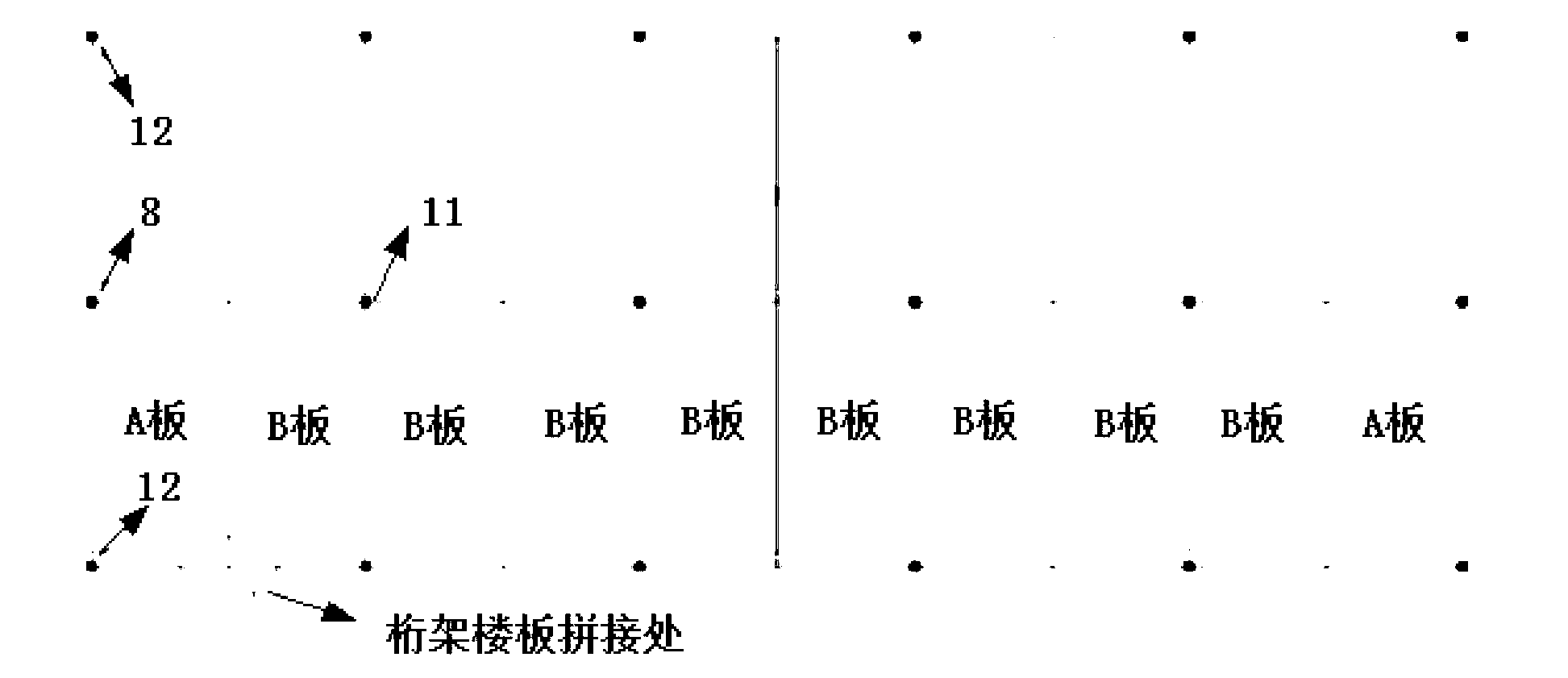

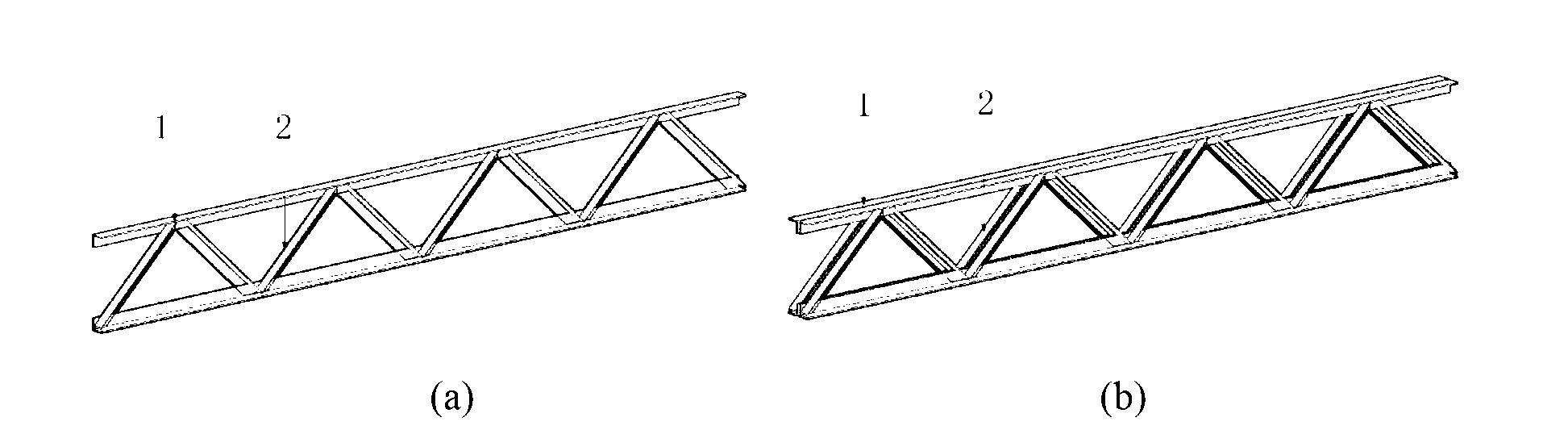

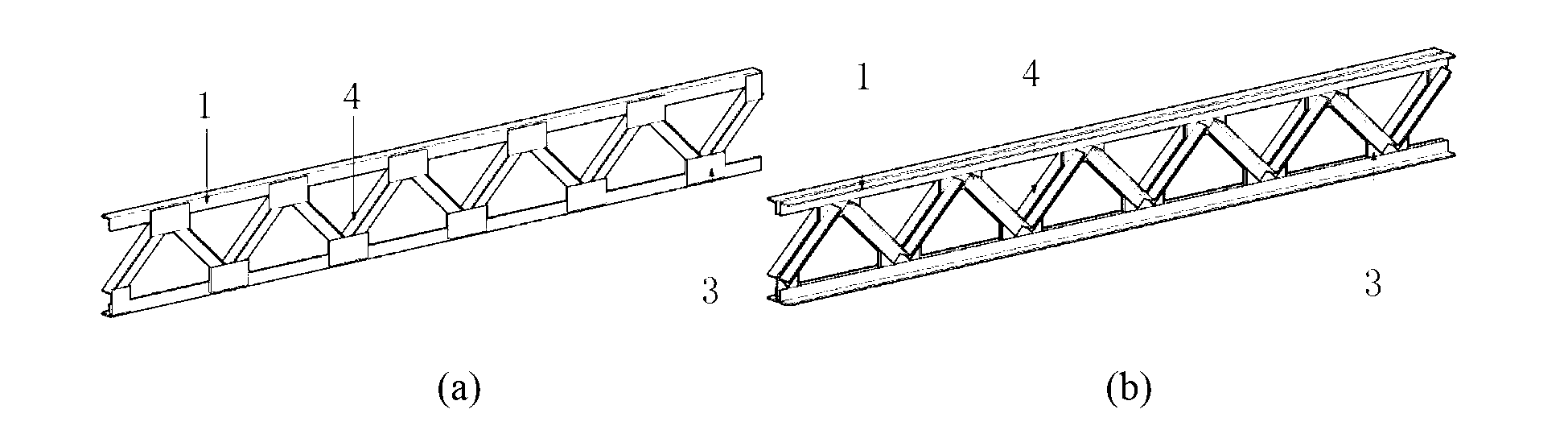

ActiveCN103276803AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

A hollow irregular column multi-layer high-rise assembling steel structure system relates to the technical field of engineering and comprises assembling truss plates and assembling flange columns. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. The assembling truss plates and the assembling flange columns are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:镇江电力设计院有限公司

Energy-saving and environment-friendly material and preparation method of energy-saving and environment-friendly material

The invention discloses an energy-saving and environment-friendly material. The energy-saving and environment-friendly material is prepared from the following raw materials in parts by weight: 40 to 60 parts of waste plastic, 10 to 20 parts of straw powder, 3 to 8 parts of glass fiber, 6 to 10 parts of calcium carbonate powder, 1 to 2 parts of nano titanium dioxide, 1 to 2 parts of nano silver ion, 2 to 6 parts of calcium stearate, 0.5 to 1 part of a flame retardant, 1 to 3 parts of an adhesive and 2 to 4 parts of a lubricant. The energy-saving and environment-friendly material provided by the invention not only has good stability, weather resistance and mechanical properties, but also has good heat preservation property, antibacterial property, anti-ageing property and flame-retarding property; the energy-saving and environment-friendly material takes the waste plastic as a main raw material and wastes are utilized, so that recycling of resources is realized; the straw powder is used as a main filling so that environment pollution and resource waste problems are effectively reduced; energy saving and environment friendliness are realized; a preparation method of the energy-saving and environment-friendly material is simple and the preparation cost is low; the obtained material can be widely applied to daily life, industrial buildings and other fields, is safe and environmentally friendly and is worthy of being popularized.

Owner:MOBAO CO LTD

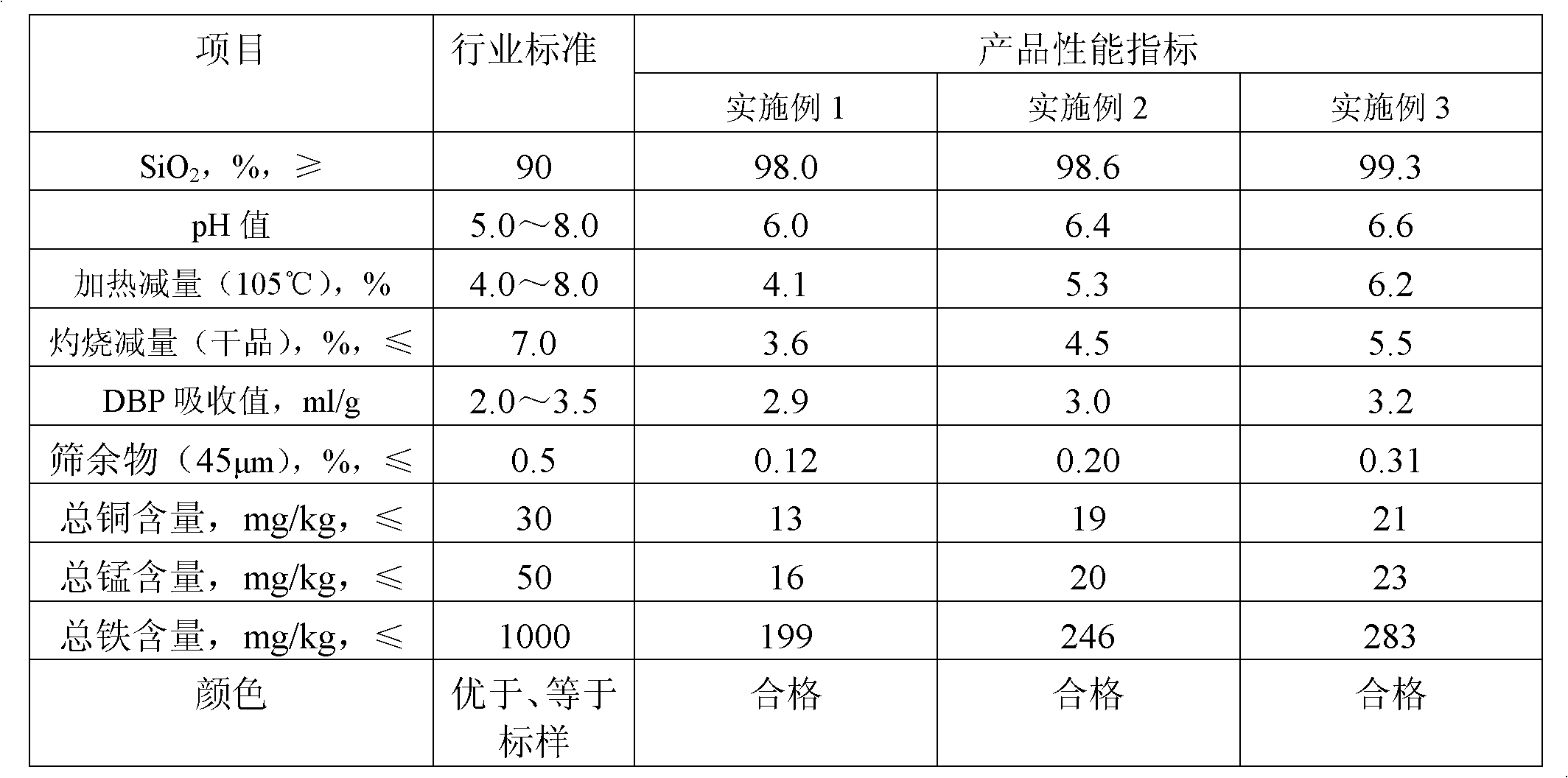

Method for preparing high dispersing white carbon black with ammonia precipitation method

The invention belongs to the field of chemical industry, particularly relates to a method for preparing high dispersing white carbon black with ammonia precipitation method. The method comprises the following steps of: (1) simultaneously adding ammonium hydrogen carbonate, water glass solution and dispering agent to a reaction kettle in a certain proportion, and quickly heating till the temperature of 70-90 DEG C; (2) carrying out heat preservation and stirring, controlling the stirring speed to be 60-100 rpm, simultaneously discharging ammonia gas in the reaction process, and obtaining loose precipitate white carbon black after finishing the reaction; (3) mixing the ammonia gas generated in the reaction and the smoke gas carbon dioxide generated in the process of preparing the water glass solution and simultaneously absorbing with water, and obtaining ammonium hydrogen carbonate solution after the reparation; (4) filtering the obtained precipitate white carbon black after the reaction under the condition of vacuum, wherein the filtrate is recycled to prepare sodium carbonate, and obtaining the high dispersing white carbon black after washing, drying, crashing and filtering the filter cake. The method is simple in technology and environment-friendly, thereby reducing the production cost and improving the product performance; and the quality is stable and reliable.

Owner:廖险峰

Hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system

The invention relates to a hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system and belongs to the technical field of structural engineering. The hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system comprises assembling truss plates, assembling flange columns and steel plate shear walls. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. On the basis of the steel frame structure, steel plate shear wall members are connected with the truss beams or the columns in the frame structure beam plate layers to be used as lateral load resistance members. The assembling truss plates, the assembling flange columns and steel plate shear wall members are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:BEIJING UNIV OF TECH

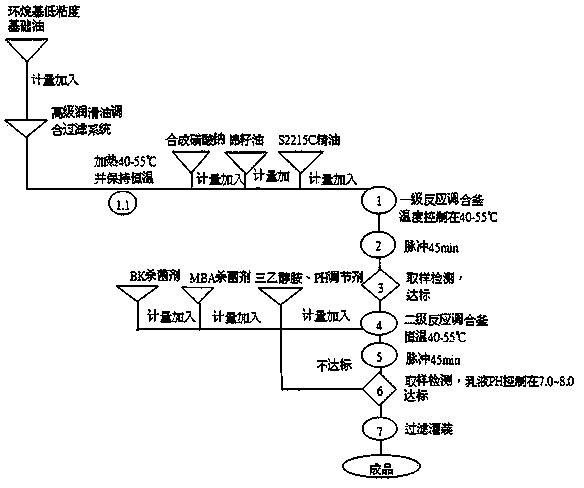

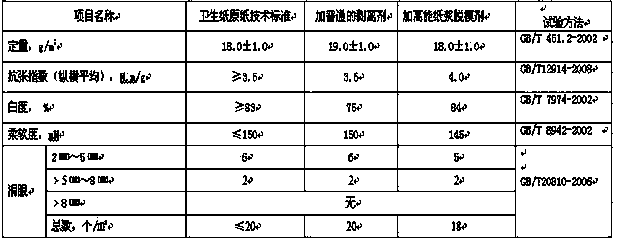

High-energy paper pulp release agent and production method thereof

ActiveCN103774495AComprehensive ability to reduce pHBoosts pH synthesisNon-fibrous pulp additionSulfonateEmulsion

The invention provides a high-energy paper pulp release agent. The preparation method comprises the following steps: by taking cycloalkyl low viscosity base oil and Enable460M synthesized sodium sulfonate as fundamental research, treating through an advanced lubricating oil blending and filtering system; then compounding various additives such as a BK hexahydro-triazine bactericide, an MBM bactericide, T-405 vulcanized cottonseed oil and S2215C universal emulsified oil; stirring; finally adopting a triethanolamine to assist acid-base balance modulation so as to synthesize the high-energy paper pulp release agent. The product can be directly applied to paper pulp and further can be prepared to an emulsion for spraying a cylinder. The high-energy paper pulp release agent is low in cost, harmless to a human body and environment-friendly, and can be used for solving the problem of break, hair slip and powder fall of paper in the papermaking process in the paper industry, and reducing the cylinder adhering phenomenon in papermaking. The smoothness and glossiness of paper can be improved to a greater extent without affecting the strength of paper, and the paper quality is improved. Meanwhile, the high-energy paper pulp release agent has a good lubricating and protecting effect on a wrinkling scraper of a dryer, so that the service life of the scraper is prolonged.

Owner:广西飞日能源集团有限公司

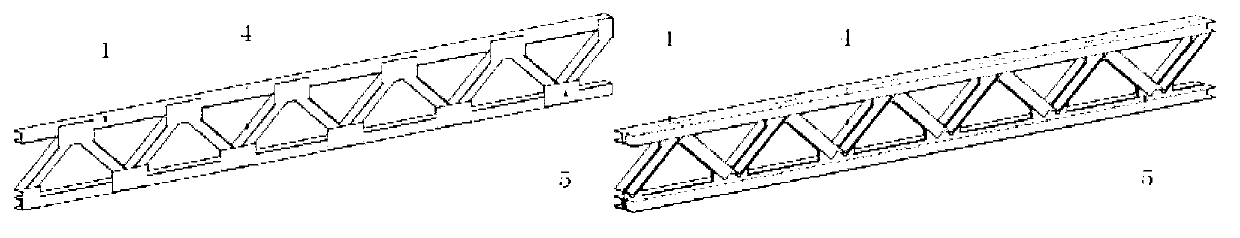

Industrialized assembly type multi-high-rise steel specially shaped column frame structure system

InactiveCN103276802AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

The invention provides an industrialized assembly type multi-high-rise steel specially shaped column frame structure system and relates to the technical field of structure engineering. The industrialized assembly type multi-high-rise steel specially shaped column frame structure system comprises assembly type truss plates and assembly type specially shaped columns. Each assembly type truss plate comprises a lattice type truss girder provided with a channel steel web member and a floor plate. Each assembly type truss plate is prefabricated in a factory and is mutually spliced with a flange plate of one assembly type specially shaped column through a girder end sealing plate of the assembly type truss plate at a construction site. The assembly type specially shaped columns are spliced among floors in site through bolts so that a multi-layer truss plate steel frame structure can be formed. The assembly type truss plates and the assembly type specially shaped columns are all prefabricated in the factory and assembled through bolts at the construction site.

Owner:BEIJING UNIV OF TECH

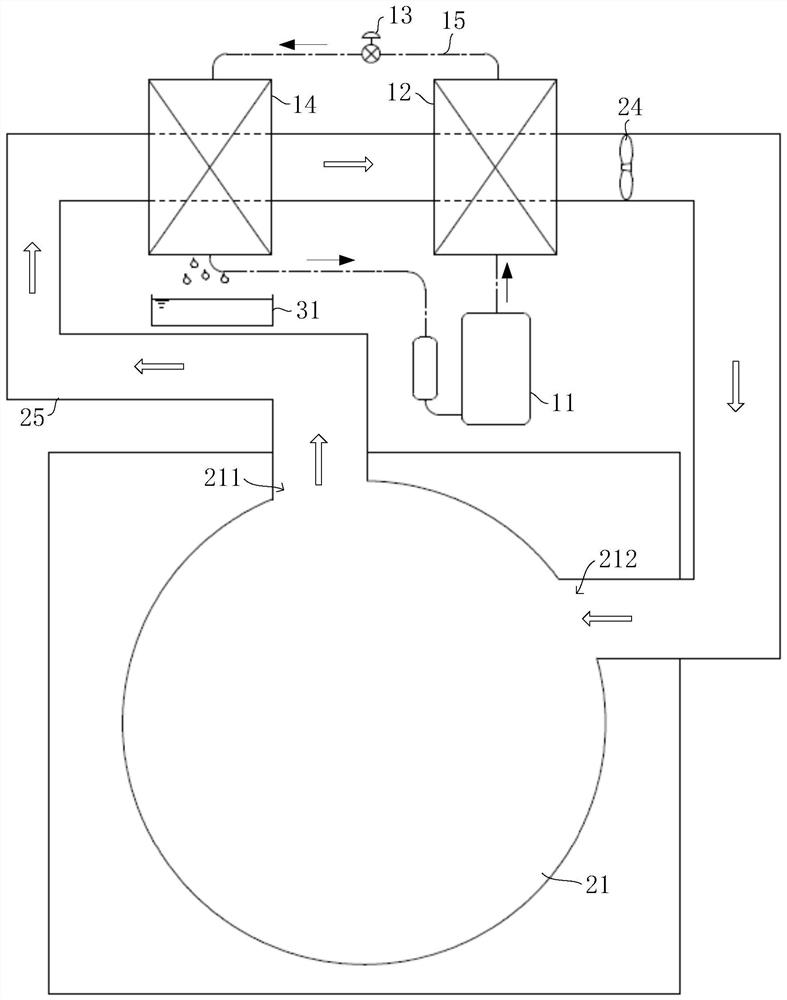

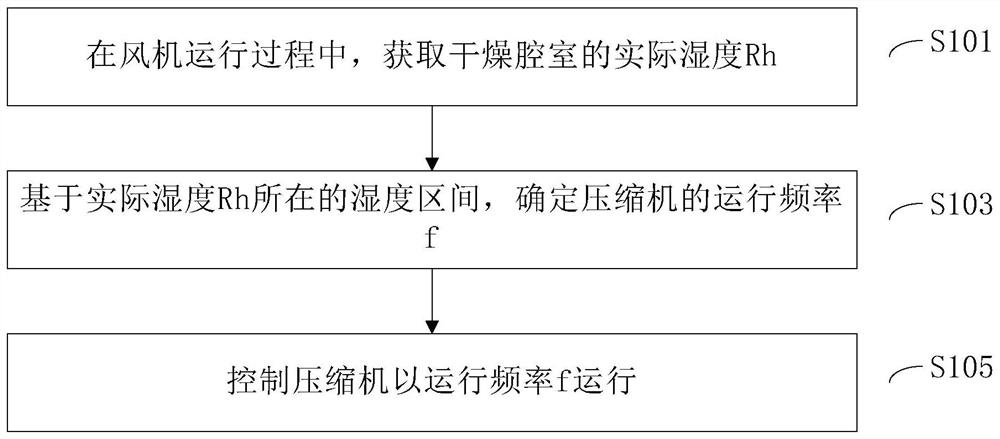

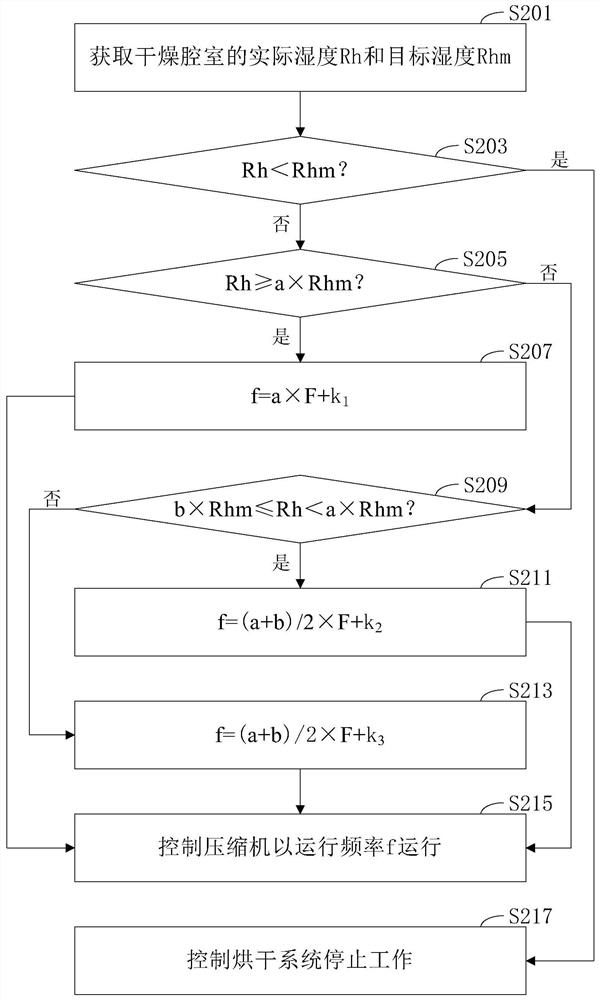

Drying control method of drying system

ActiveCN112227043AImprove applicabilityMaintain dehumidification performanceTextiles and paperLaundry driersEngineeringProcess engineering

The invention relates to the technical field of clothes treatment, in particular to a drying control method of a drying system. The problems that an existing drying control method is long in drying time and high in energy consumption are solved. To achieve the purpose, the drying control method comprises the steps that in the operation process of a draught fan, the actual humidity Rh of a drying cavity is obtained; based on the humidity interval where the actual humidity Rh belongs, the operation frequency f of a compressor is determined; and the compressor is controlled to operate at the operation frequency f, wherein the actual humidity Rh is in direct proportion to the operation frequency f. According to the drying control method of the drying system, the drying energy consumption can be considered while the drying efficiency is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

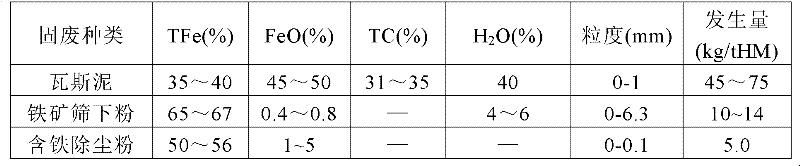

Iron-containing solid byproduct of iron making by smelting reduction and manufacturing method thereof

The invention relates to an iron-containing solid byproduct of iron making by smelting reduction and a manufacturing method thereof. The byproduct comprises the following components in percentage by weight: 20-75% of dry basis of gas mud, 20-75% of dry basis of iron ore minus undersize powder, 1-5% of dedusting powder dry basis, 10-30% of binding agent and 8-15% of water. The byproduct and the manufacturing method provided by the invention finally realize the reutilization of smelted ironmaking sludge, can manufacture the iron-containing product conglomerations for smelting reduction, reduce the molten iron cost, and reduce environmental pollution.

Owner:XINJIANG BAYI IRON & STEEL

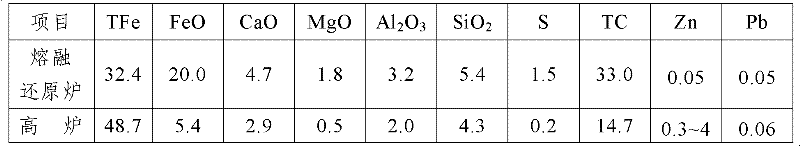

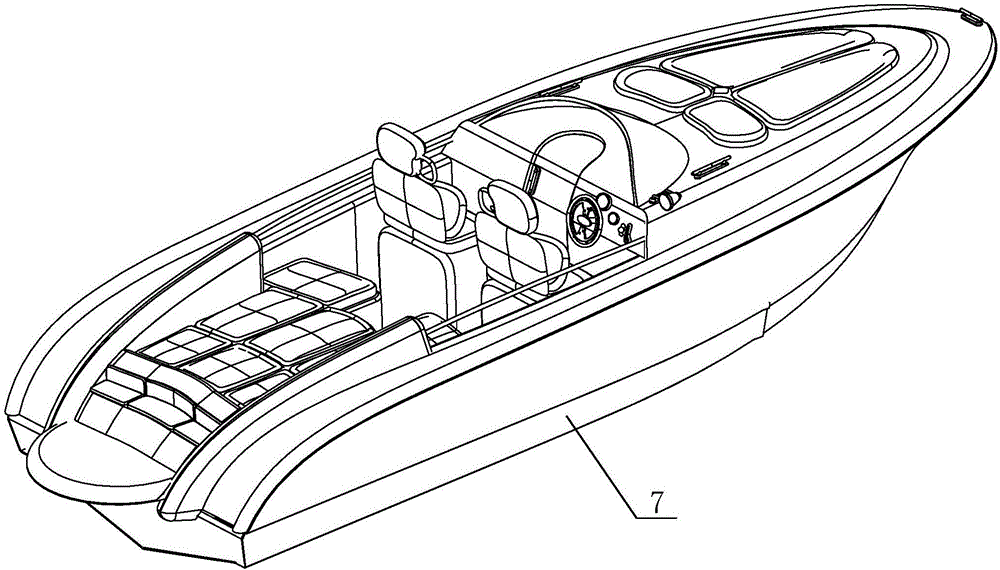

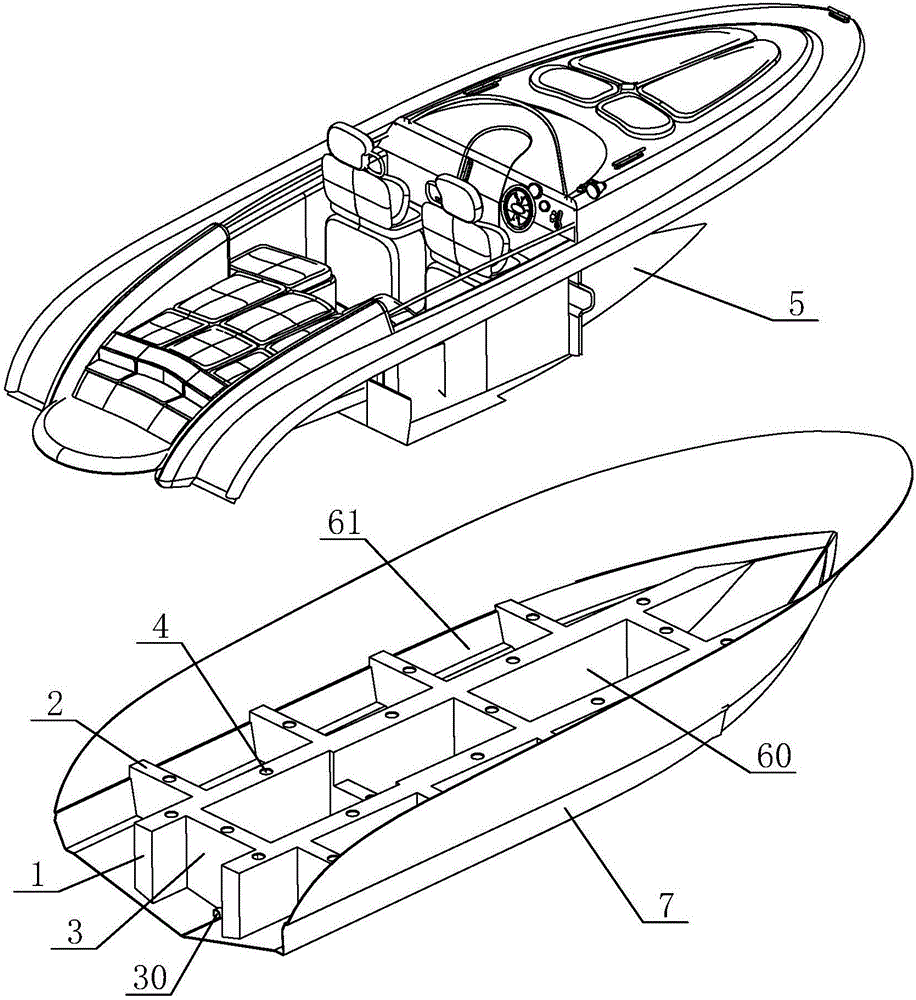

Manufacturing process for anti-sinking fiber reinforced plastic ship

ActiveCN106585873AGood weather resistanceReduce structural strengthNon-magnetic metal hullsVessel partsFiberAdhesive

The invention discloses a manufacturing process for an anti-sinking fiber reinforced plastic ship. The process comprises a series of process steps of mold treatment, ship bottom pasting, ship bottom molding, ship bottom material injection, ship bottom demolding, keel mounting, keel packing, ship bottom side edge packing, ship bottom cleaning, deck mounting and ship part assembling. The ship manufactured through the process has the following advantages that firstly, a keel structure is low in weight and high in strength, the safety is improved while the weight of a ship body is lowered; secondly, corrosion of moisture to the keel structure can be resisted, and the service life is prolonged; and thirdly, due to the fact that a ship bottom and the keel structure are bound firmly through a structural adhesive, decks with foaming fillers can be used as temporary first-aid tools after the ship body is fractured and scattered and replace life rings, and persons falling into water are prevented from drowning.

Owner:山东双一游艇有限公司

Method for depolymerizing waste polyester bottle

ActiveCN102532591AReduce the possibilityHigh yieldOrganic compound preparationPlastic recyclingSodium bicarbonateIce water

The invention provides a method for depolymerizing a waste polyester bottle, comprising the following steps of: adding the waste polyester bottle, ethylene glycol, sodium bicarbonate and distilled water into a high-temperature and high-pressure reaction kettle according to a certain proportion and reacting at a temperature of 170-200 DEG C for 15-40 minutes to depolymerize the waste polyester bottle into sodium terephthalate, ethylene glycol and other byproducts; then, adsorbing by active carbon and de-coloring; acidifying by hydrochloric acid, and cooling and crystallizing by ice water; filtering, washing and drying to obtain terephthalic acid; and carrying out rotary evaporation on a filtering solution to obtain the ethylene glycol to be repeatedly utilized. According to the method for depolymerizing the waste polyester bottle, by utilizing a mixed reaction system, the depolymerization temperature is reduced, the reaction time is shortened, the energy source consumption is reduced, the equipment investment is reduced, the depolymerization rate of PET (Polyethylene Terephthalate) reaches to be more than 99% and the yield of the target product, namely terephthalic acid, is more than 94%.

Owner:CENT SOUTH UNIV

Tin inlay mold and method for producing tin inlay technique pattern

InactiveCN101486072AMeet the scaleSatisfy industrializationDecorative surface effectsFoundry mouldsCompression moldingMolding machine

The invention relates to a method for producing handicraft articles, in particular to a method for manufacturing a tin-embedded die and a tin-embedded technological pattern. The tin-embedded die is made of silica gel. The step for manufacturing the tin-embedded technological pattern comprises the following steps: manufacturing a stone die, engraving the stone die according to layout work, and arranging a liquid casting flow passage; melting passivated tin into a tin liquid; injecting the tin liquid into the stone die, and taking out a pattern after solidification; removing redundant parts of the pattern, and using sand paper to grind the surface of the pattern; manufacturing a master die; manufacturing a silica gel die blank; placing the master die on the surface of the silica gel die blank, and placing the silica gel die blank on a press molding machine for heating and compression molding; taking out the master die from a silica gel die after cooling, and obtaining the silica gel die; melting passivated tin into a tin liquid; and injecting the tin liquid into the silica gel die, taking out the pattern after the tin liquid is solidified, and obtaining the tin-embedded technological pattern after edging. The method has the advantages that due to adoption of the silica gel die, the finely chiseled master die can be preserved and used permanently after compression molding; die turnover for a plurality of times is not required; and the method can meet the requirements of scale and industrialization of the handicraft articles.

Owner:谷伟

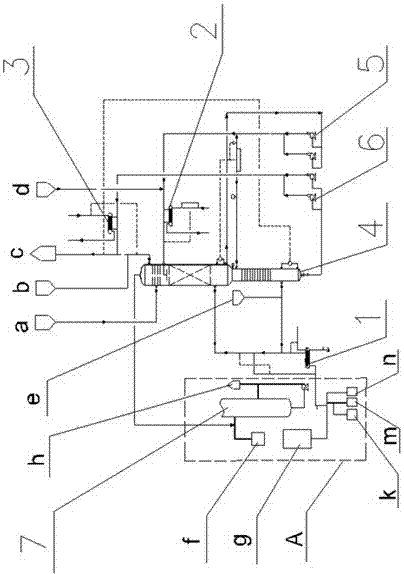

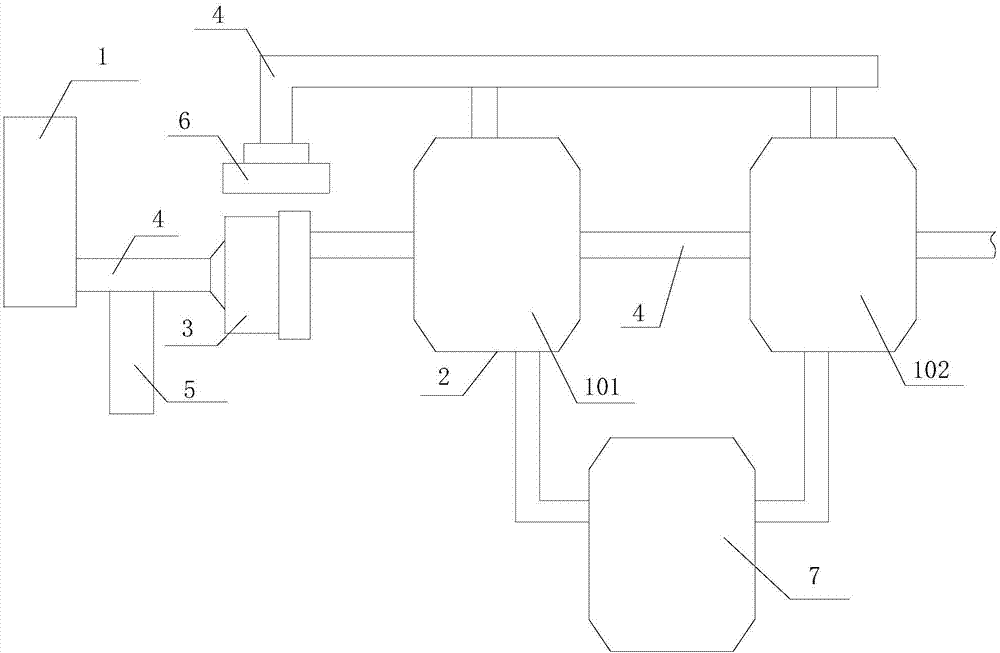

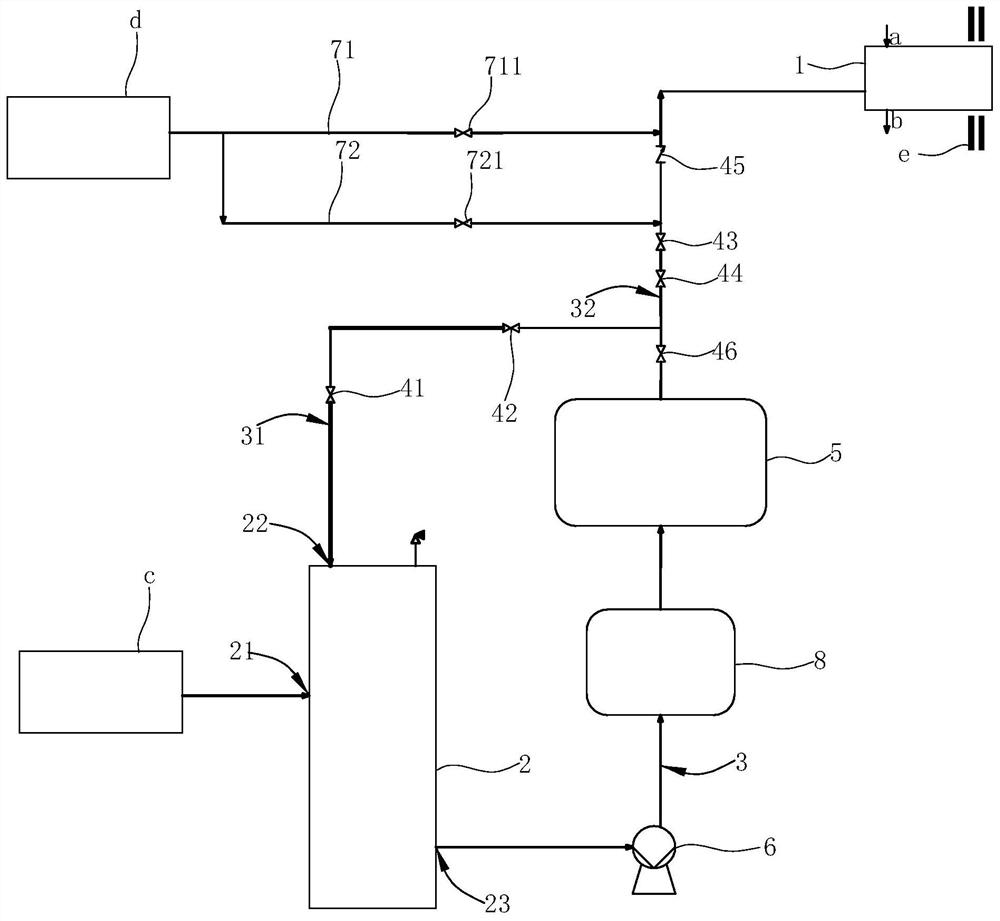

Reduction purification technology for nitric acid in production of coal produced glycol

InactiveCN106904714AEmission reductionLess recyclingWater contaminantsWater/sewage treatmentGas phaseHydrogenation reaction

The invention relates to a reduction purification technology of nitric acid in production of coal produced glycol. A coal produced glycol technology mainly comprises coal gasification, purification and separation, coupling reaction, regeneration reaction and hydrogenation reaction. According to the technology, a nitric acid purification system is arranged in rear of a regeneration technology of an original system (A); in the original system (A), after a gas phase material (g) from the top of a DMO removal tower is treated through the nitric acid purification system, the content of nitric acid in discharge liquor is smaller than 0.5 percent. The technology solves the problems in the prior art, and provides a nitric acid reduction purification technology which fundamentally solves the problem of reduction purification of nitric acid in production of coal produced glycol, reduces the nitrogen source loss and nitric acid consumption in coupling reaction, solves the problems, such as wastewater treatment, in a coal produced glycol project, and is good in equipment treatment capacity and energy-saving effect in the same operation condition and technical condition control, high in device reliability, convenient to operate, safe and reliable, and easy to maintain.

Owner:XINJIANG TIANZHI CHENYE CHEM +1

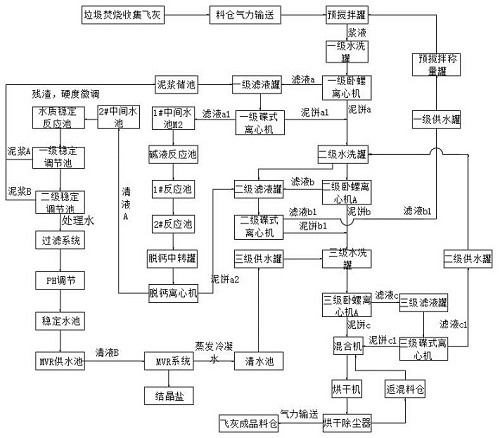

Domestic garbage incineration fly ash water washing chlorine-removing and waste water desalination and reuse process system

InactiveCN111822490AReduce disposal costsAchieve recyclingSolid waste disposalTransportation and packagingWater desalinationCentrifugation

The invention relates to the technical field of waste incineration fly ash treatment, and discloses a domestic garbage incineration fly ash water washing chlorine-removing and waste water desalinationand reuse process system. A process comprises the steps of step 1, collecting fly ash from waste incineration and transport the fly ash to a pre-mixing tank for mixing through a seven mile conveyingdevice of a silo to obtain slurry; and step 2, washing the slurry obtained in step 1 through a primary water washing tank, and then centrifuging by a primary horizontal centrifuge, and then producingmud cake a and filtrate a after centrifugation. By combining multi-stage elution systems to give full play to the unique advantages of water washing chlorine-removing for the resource utilization of the fly ash and the recycling of heavy metals, and to simultaneously realize the efficient removal of pollutants such as chloride ions and heavy metal ions. The system can reduce the cost of fly ash disposal, reduce heavy metal pollution, and realize the harmless and resource utilization of fly ash. The system has low energy consumption, low investment and low operating costs, and is convenient inuse, mild in operating conditions, low in operating costs and high in recovery rates.

Owner:宋仁贵

Industrialized assembly type special-shaped column steel structure frame-eccentric support system

InactiveCN103276796AIncrease net heightGuarantee the construction qualityBuilding constructionsAbnormal shapedFloor slab

The invention provides an industrialized assembly type special-shaped column steel structure frame-eccentric support system and belongs to the technical field of structural engineering. The industrialized assembly type special-shaped column steel structure frame-eccentric support system comprises assembly type truss plates, assembly type columns and eccentric support members. Each assembly type truss plate comprises lattice truss beams and floor slabs and is prefabricated in a factory, and the assembly type truss plates and beam-column joints of the assembly type columns are spliced through beam-end seal plates in a construction site, and the assembly type columns are spliced among layers in the site through bolts to form a multiple-layer truss plate steel frame structure. Based on the truss plate steel frame structure, the eccentric support members serve as lateral force resisting members and are connected with the truss beams in the assembly type truss plates and the bottoms or the tops of the assembly type columns. The assembly type truss plates, the assembly type columns and the eccentric support members are prefabricated in the factory and are assembled in the construction site through bolts.

Owner:BEIJING UNIV OF TECH

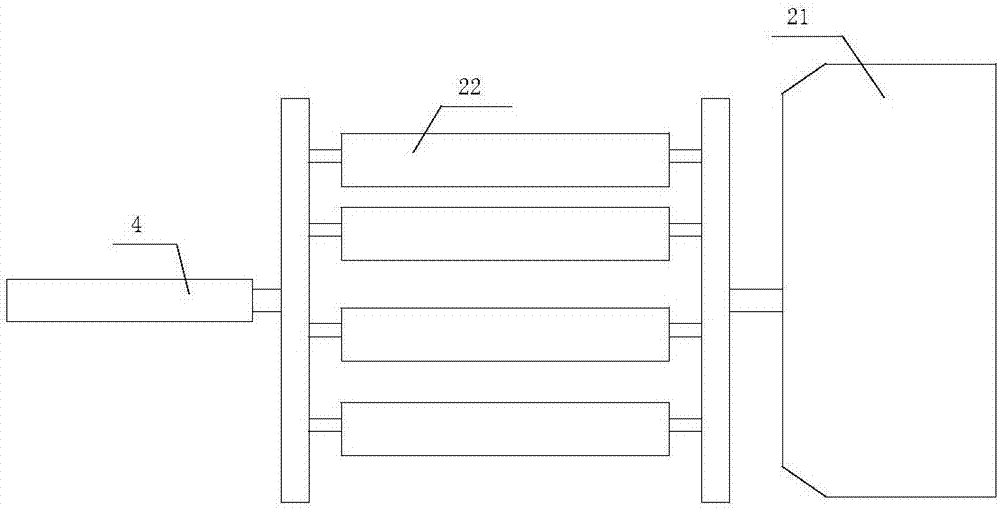

High-efficiency air distribution system for garbage incinerator and application method thereof

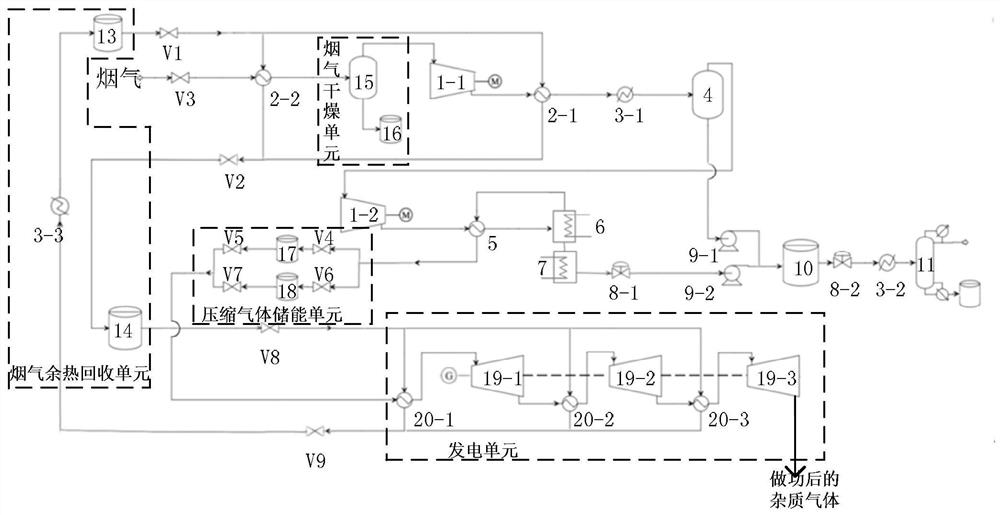

ActiveCN107355796AEffective lossAvoid wastingSteam engine plantsIncinerator apparatusWaste heat recovery unitElectronic systems

The invention discloses a high-efficiency air distribution system for a garbage incinerator and an application method thereof. The high-efficiency air distribution system comprises a flue gas heat exchanger, at least two waste heat power generation units and a booster pump. The two adjacent waste heat power generation units are connected in series through a gas guide pipe to form a power generation subsystem. The waste heat power generation units in each power generation subsystem are called the first-stage power generation unit and the second-stage power generation unit from front to back in sequence, wherein the first-stage power generation unit communicates with the booster pump through a gas guide pipe. The booster pump communicates with the flue gas heat exchanger through a gas guide pipe. Each waste heat power generation unit comprises an organic rankine cycle power generation device and air eddy pipes. The application method of the high-efficiency air distribution system comprises the steps of equipment layout and waste heat recovery. By adopting the high-efficiency air distribution system for the garbage incinerator and the application method thereof, on one hand, waste heat of tail gas can be effectively recycled, and resource waste is avoided, and on the other hand, application of a traditional cooling system can be effectively reduced while the waste heat of the tail gas is recycled.

Owner:海诺尔环保产业股份有限公司

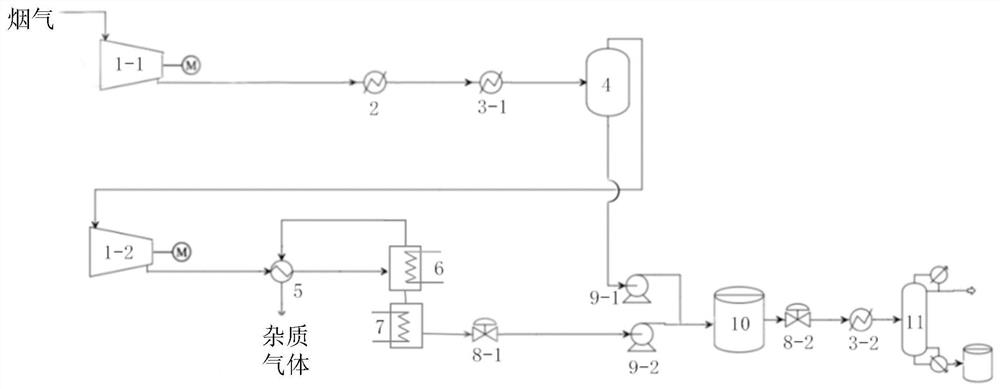

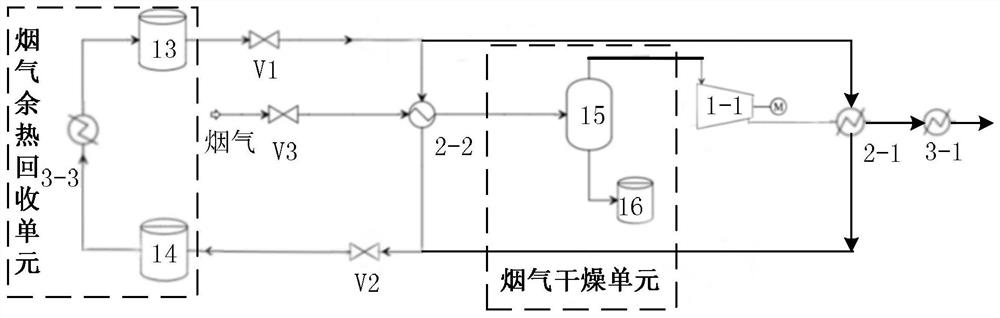

Flue gas carbon dioxide trapping and purifying system and method

PendingCN113175687AGuaranteed capture rateCaused by pollutionSolidificationLiquefactionFlue gasResidual carbon

The invention discloses a flue gas carbon dioxide trapping and purifying system and method, and relates to the field of flue gas pollutant purification treatment. The problems that when carbon dioxide in low-concentration flue gas is captured in the prior art, energy consumption is high when a physical separation method is adopted, and environmental pollution exists when a chemical absorption method is adopted are solved. After flue gas is cooled twice through a cold water heat exchanger set and a second refrigerant heat exchanger in sequence, low-temperature physical separation of carbon dioxide is conducted on low-concentration carbon dioxide flue gas through a carbon dioxide separator, liquid carbon dioxide and mixed gas are separated out, residual carbon dioxide gas in the mixed gas is further purified, and therefore, the purification of the low-concentration carbon dioxide flue gas is realized. The flue gas carbon dioxide trapping and purifying system and method is mainly used for purifying flue gas pollutants.

Owner:HARBIN INST OF TECH

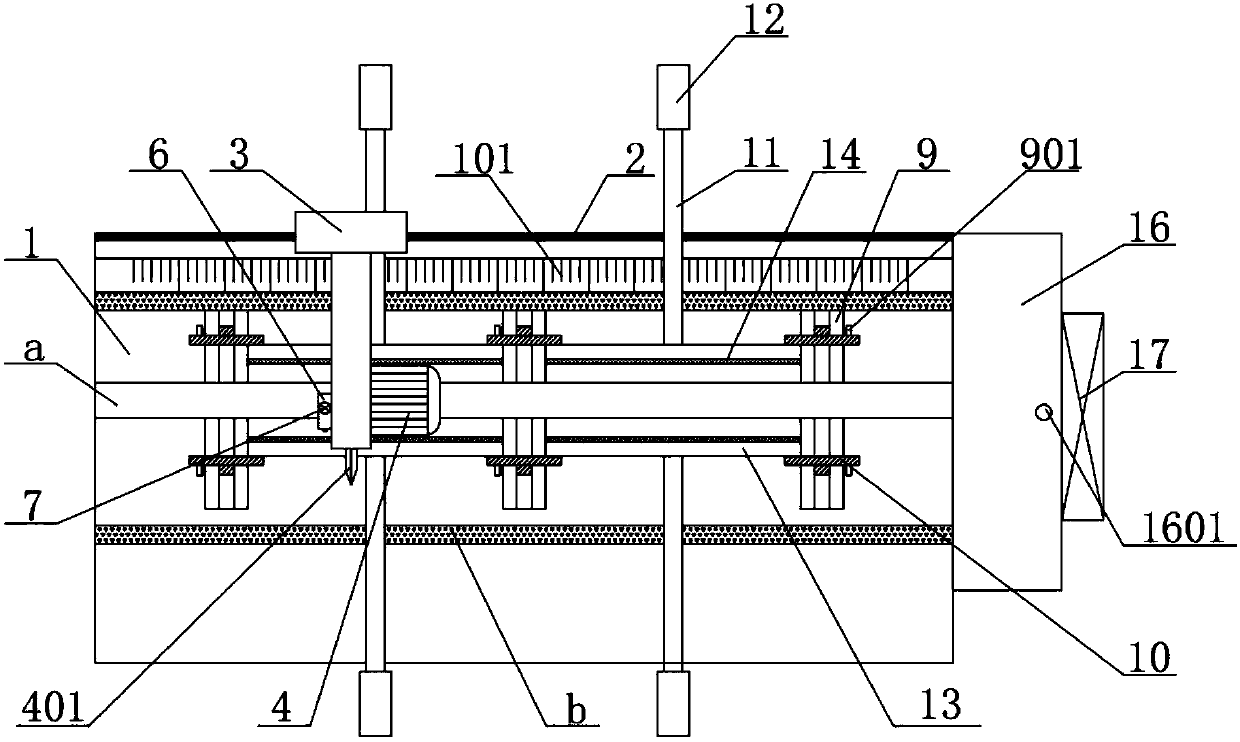

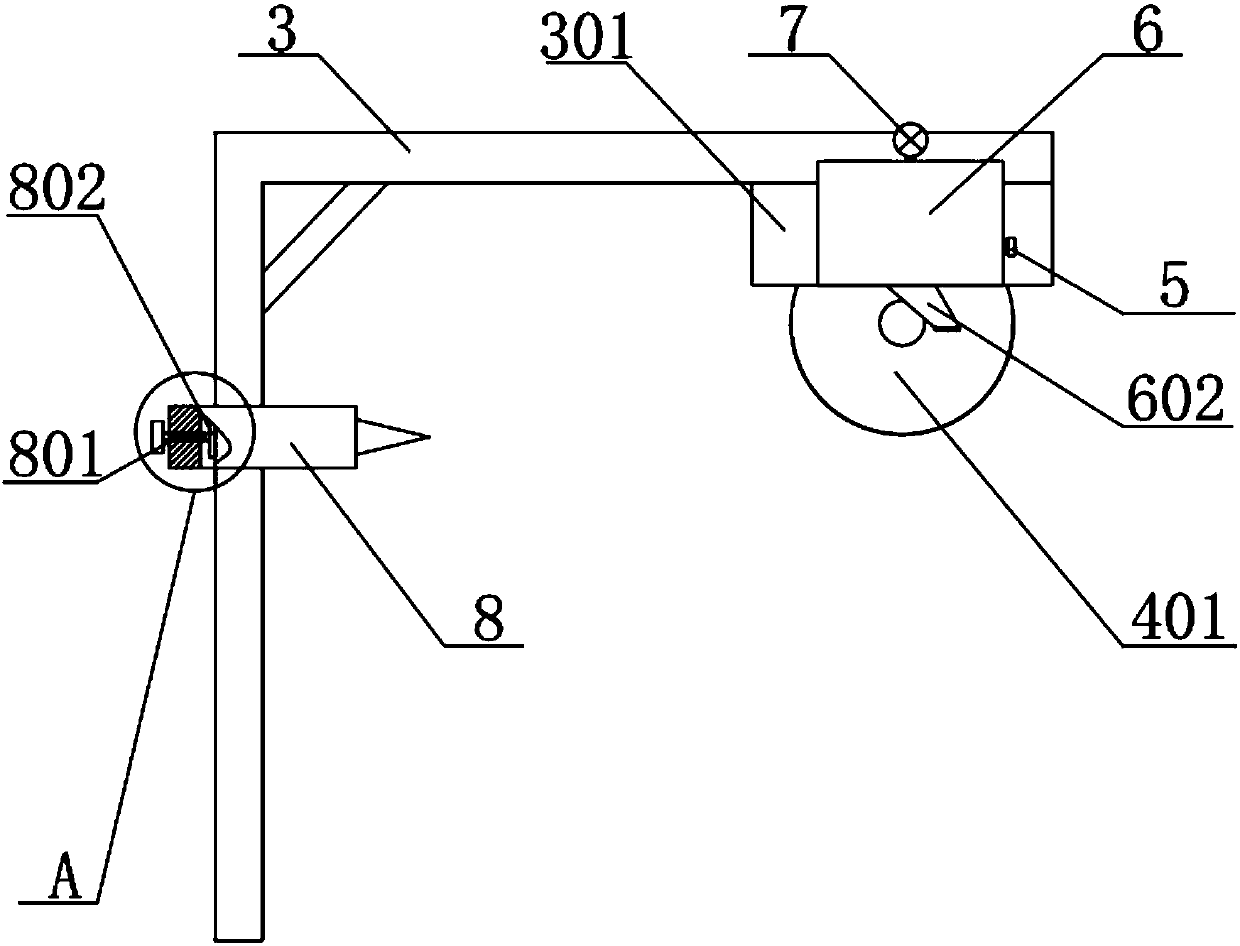

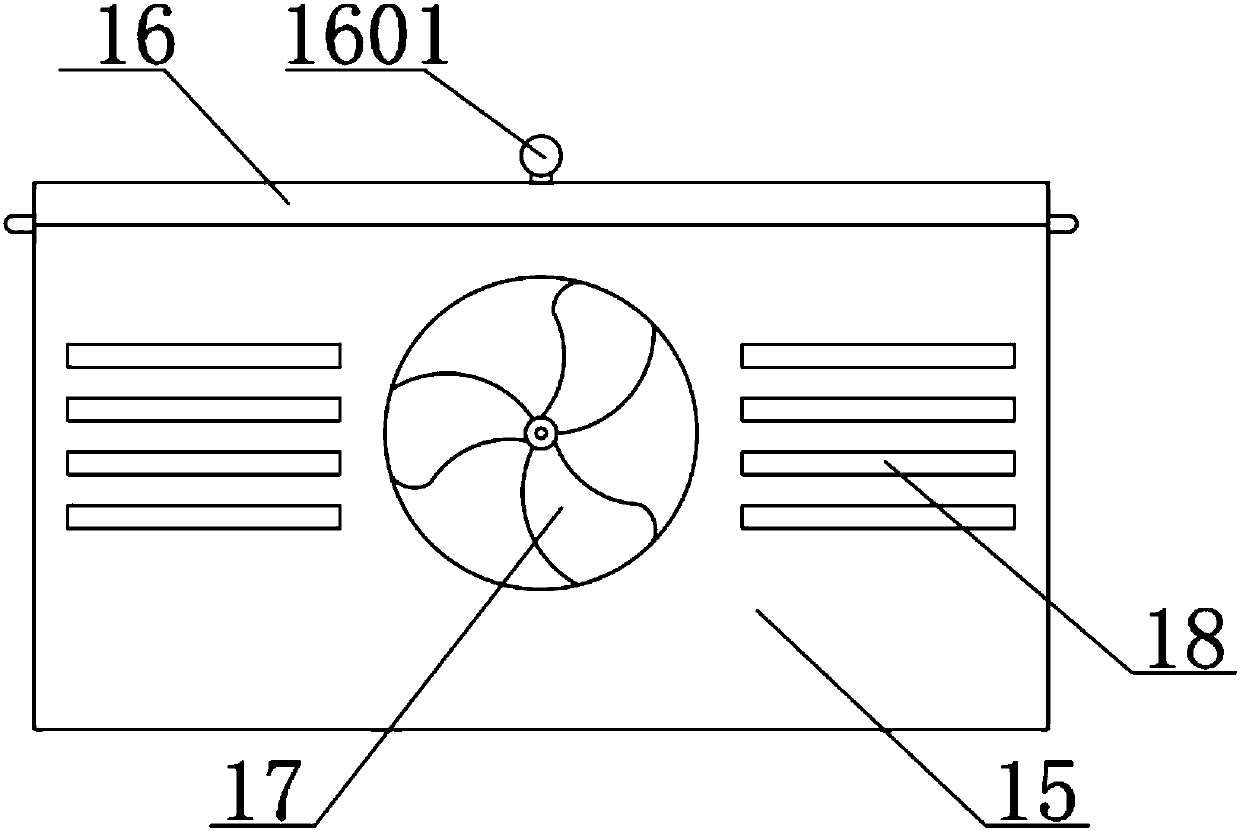

Heat-pump drying room and technology for honeysuckle flowers

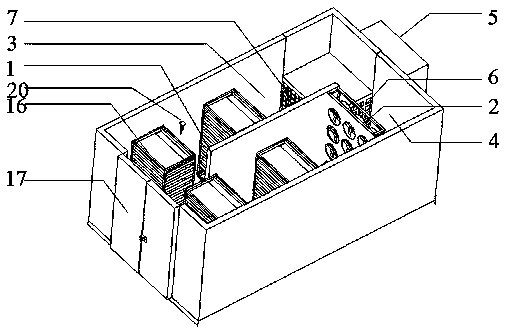

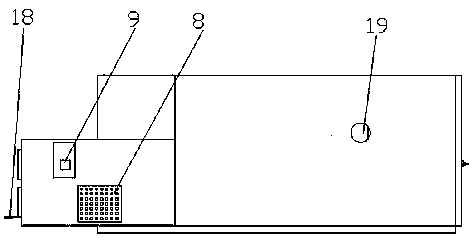

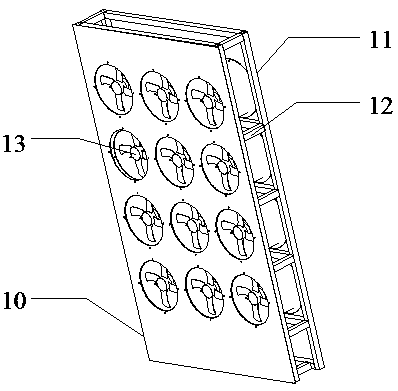

PendingCN110986515AReasonable structural designGuaranteed stabilityFluid heatersDrying gas arrangementsThermodynamicsMechanical engineering

The invention discloses a heat-pump drying room and technology for honeysuckle flowers. The drying room comprises a drying room body; a separating wall is arranged in the drying room body; an axial-flow fan frame is arranged between the separating wall and the inner wall of the drying room body; the inside of the drying room body is divided by the separating wall and the axial-flow fan frame intoa drying room air flue circulating cavity and a heat collection room; the drying room air flue circulating cavity communicates with the heat collection room; and an air-source heat pump is arranged outside the drying room body. According to the drying room and technology, the multi-period and multi-level dehumidification and drying method is adopted, and reserving of the appearances and the drug properties of honeysuckle flowers is guaranteed to the maximum extent.

Owner:河南天赫伟业能源科技有限公司

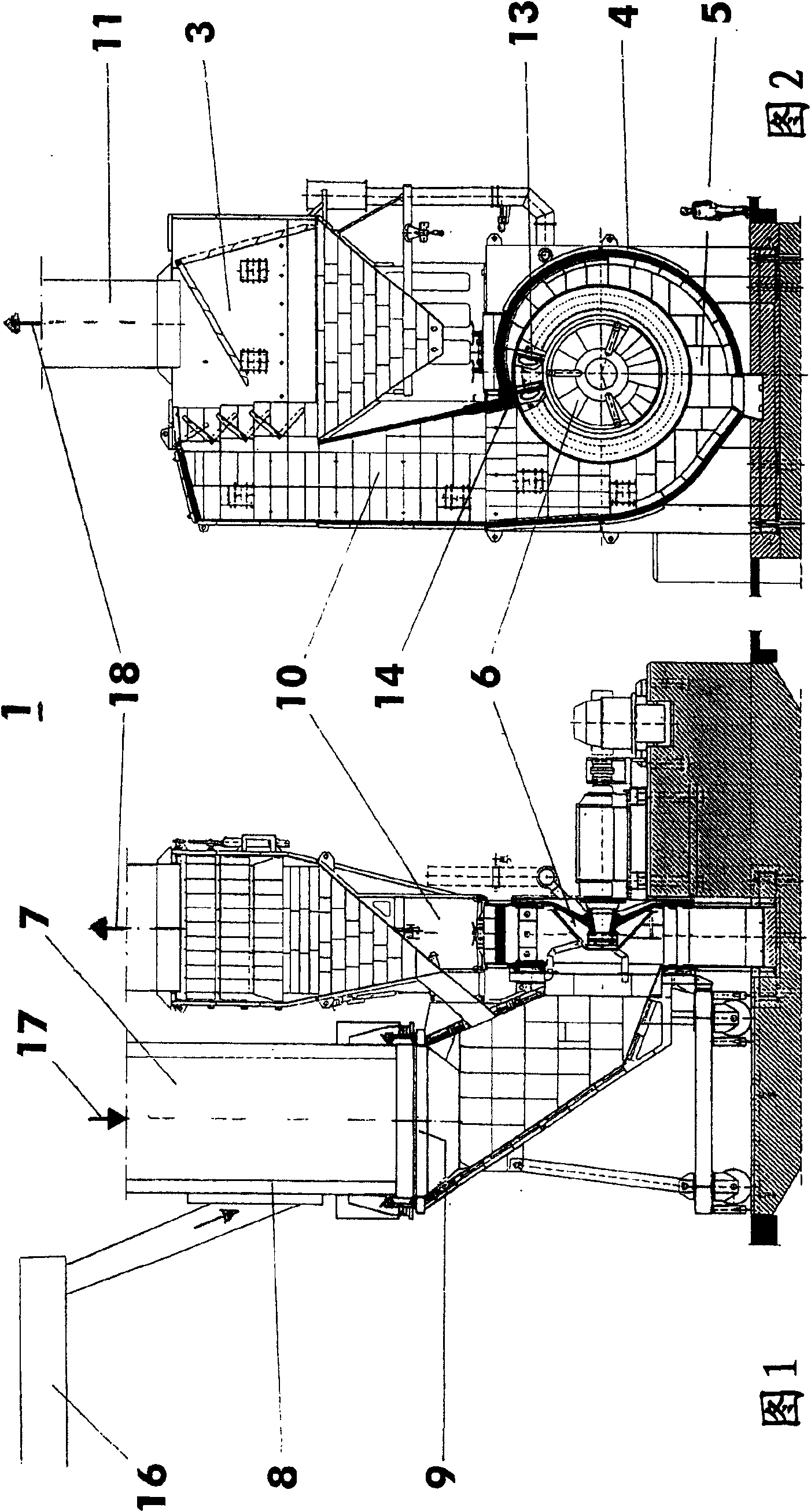

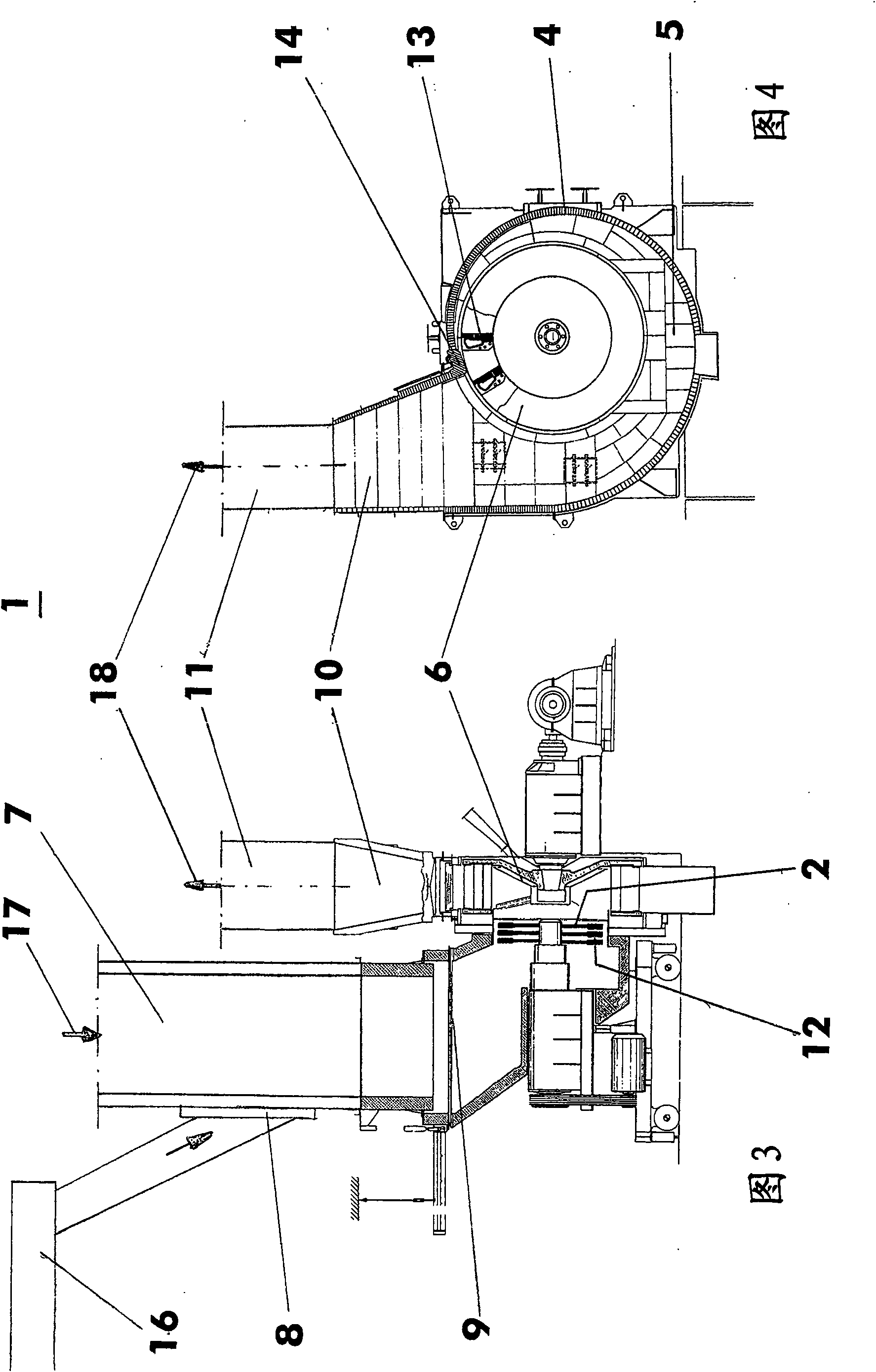

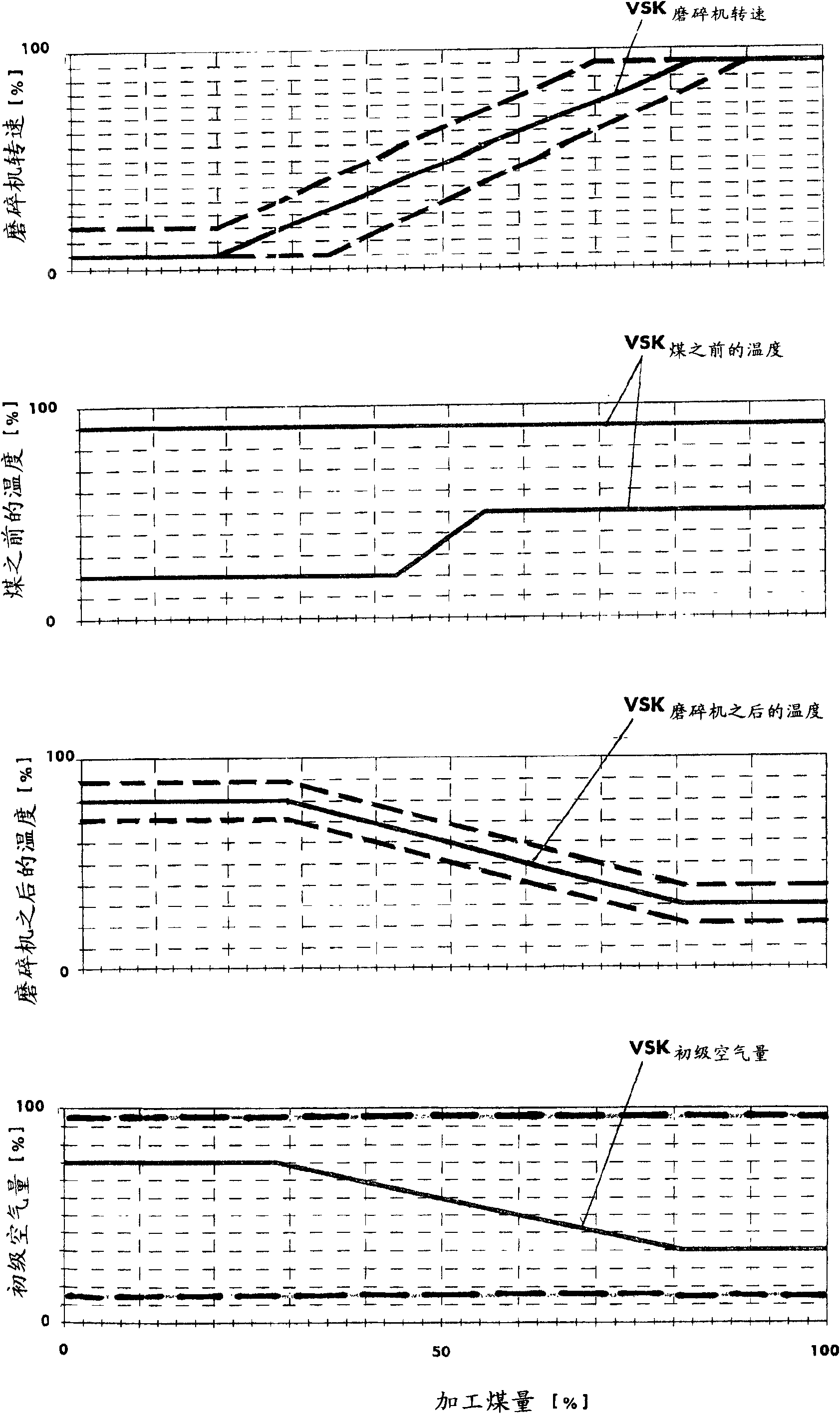

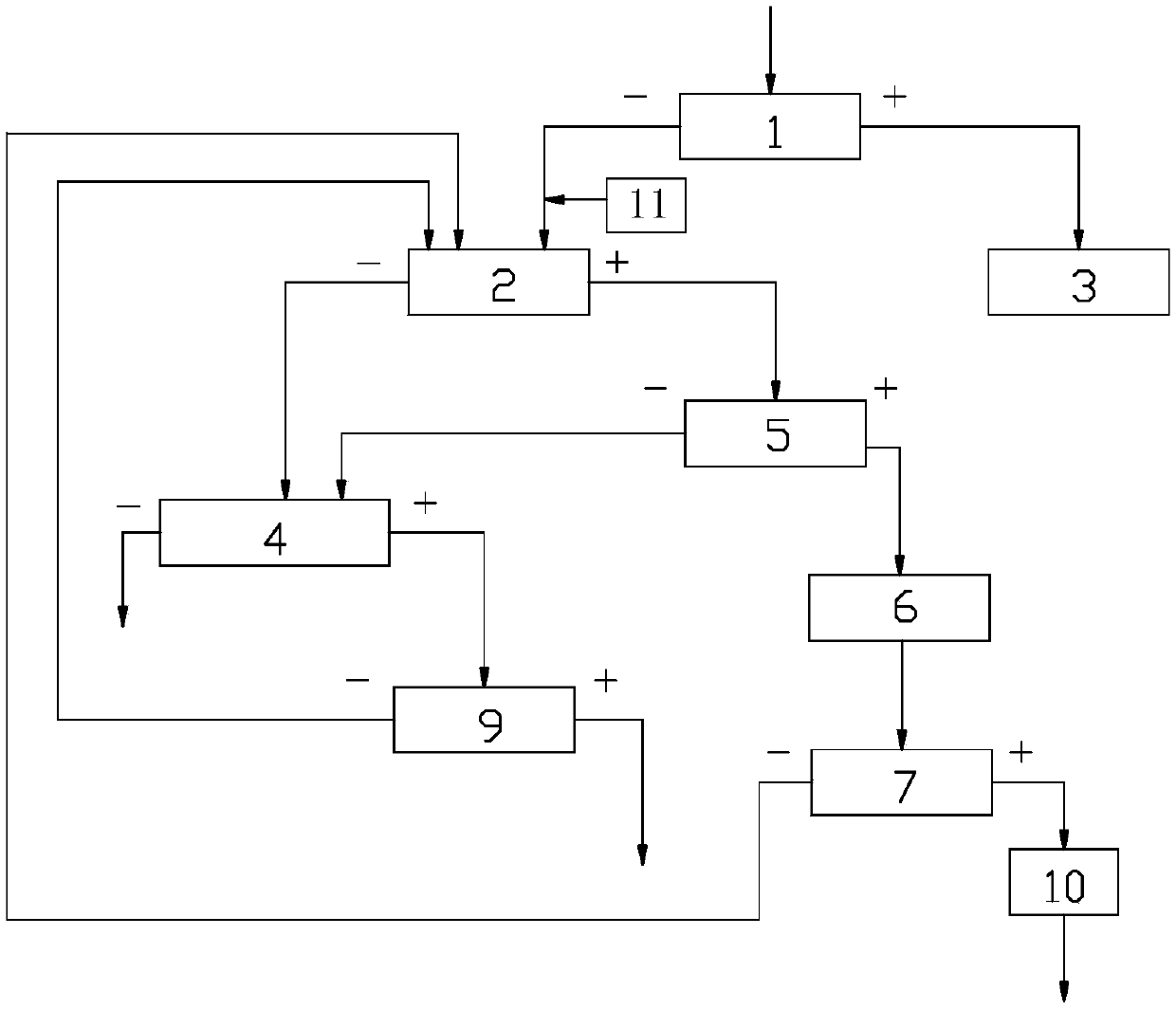

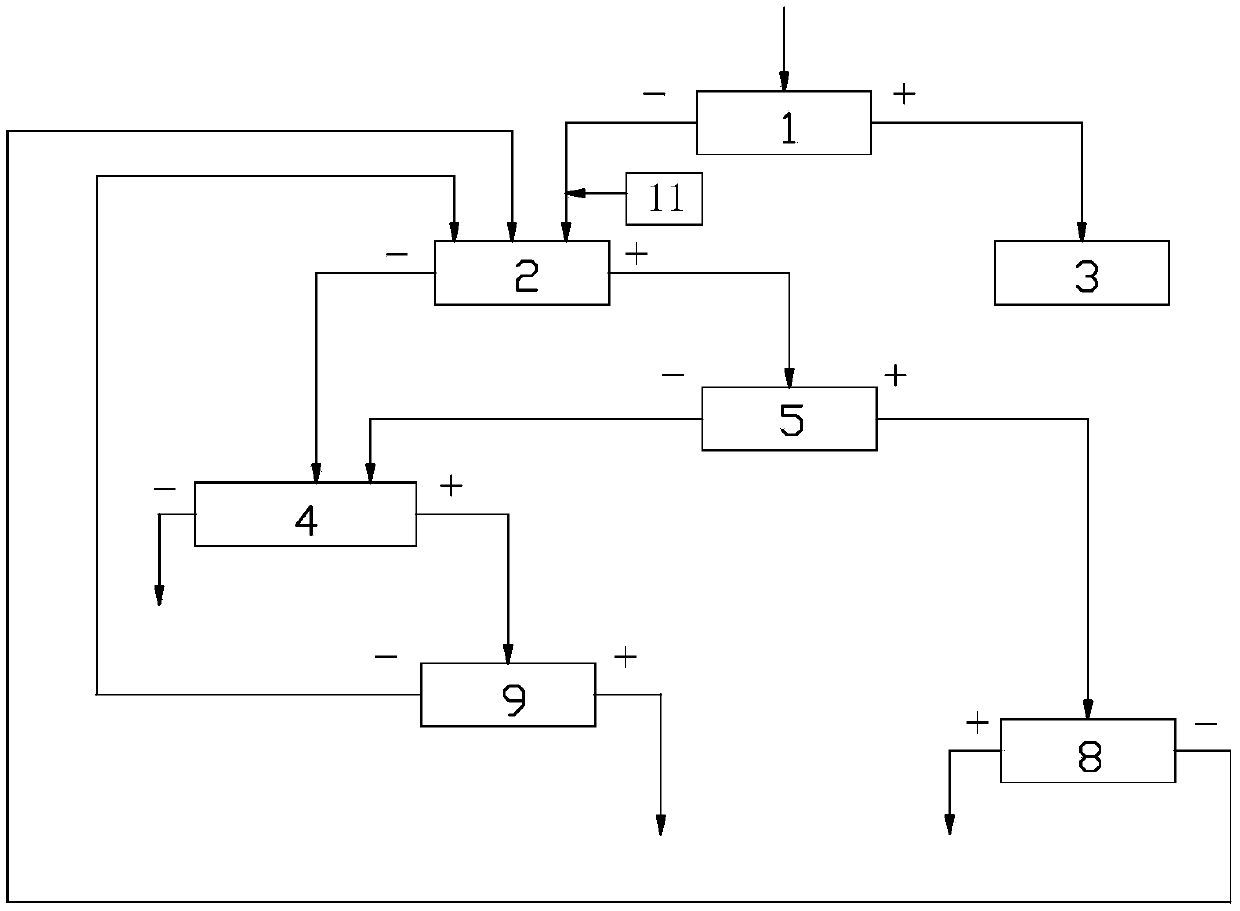

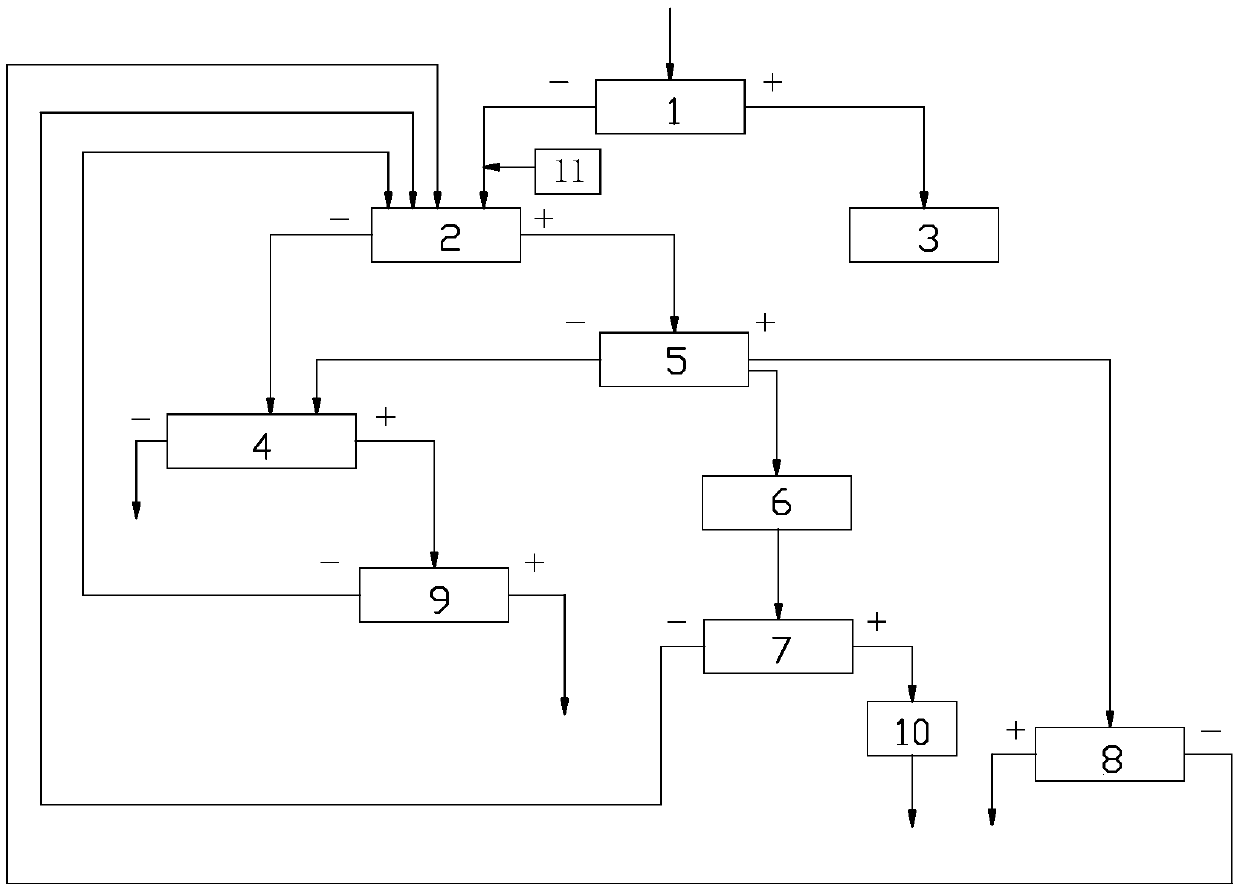

Method and assembly for regulating the grind drying procedure of a coal dust ventilator mill

The present invention provides a method for controlling grind drying procedure of a coal dust ventilator mill, in particular a method for controlling grind drying procedure for brown coal, wherein the method controls at least parameters such as milling speed, temperature after milling and primary air quantity, which involves pre-control curves (VSK[grind rotation speed]) for controlling the milling speed, pre-control curves (VSK[temperature after milling]) for controlling the temperature after milling and pre-control curves (VSK[primary air quantity]) for controlling the primary air quantity, where the pre-control curves (VSK[grind rotation speed], VSK[temperature after milling], VSK[primary air quantity]) are determined depending on coal throughput. The pre-control curve (VSK[grind rotation speed]) of the milling speed is corrected depending on a state of wear (V[IST]) of a mill-tool of a coal dust fan mill. An independent claim is also included for an arrangement for controlling a pulverized drying process of raw lignite, wherein the corresponding curves have minimum curves and maximum curves.

Owner:GENERAL ELECTRIC TECH GMBH

System and method for extracting and recovering fine coal slime from coal slime

The invention discloses a system and a method for extracting and recovering fine coal slime from coal slime. The system comprises a classification cyclone, a coarse coal slime sorting system, a first-stage concentrator, a second-stage concentrator, a dewatering device, a laminated screen and a dewatering and drying device; and the method comprises the following steps (1) system coal slime water isclassified through the classification cyclone; (2) classified overflow is settled and classified through the first-stage concentrator; (3) the coal slime is subjected to secondary grading through thelaminated screen; (4) screen residues are dewatered and dried to obtain the fine coal slime; and (5) the high-ash fine coal slime is subjected to overflow flocculation sedimentation separation so asto obtain the discharged coal slime. The system and the method have the advantages of low investment, high efficiency, simple process and good economic benefits. If 6 million tons of raw coal is washed annually, after the fine coal slime is recovered according to the method, the discharged coal slime is about 600-650 thousand tons, and the recovered low-ash coarse particle fine coal slime is about350-400 thousand tons, the resource waste is greatly reduced, the resource utilization rate is improved, and meanwhile, the amount of waste coal slime is greatly reduced.

Owner:鄂尔多斯市中钰泰德煤炭有限公司 +1

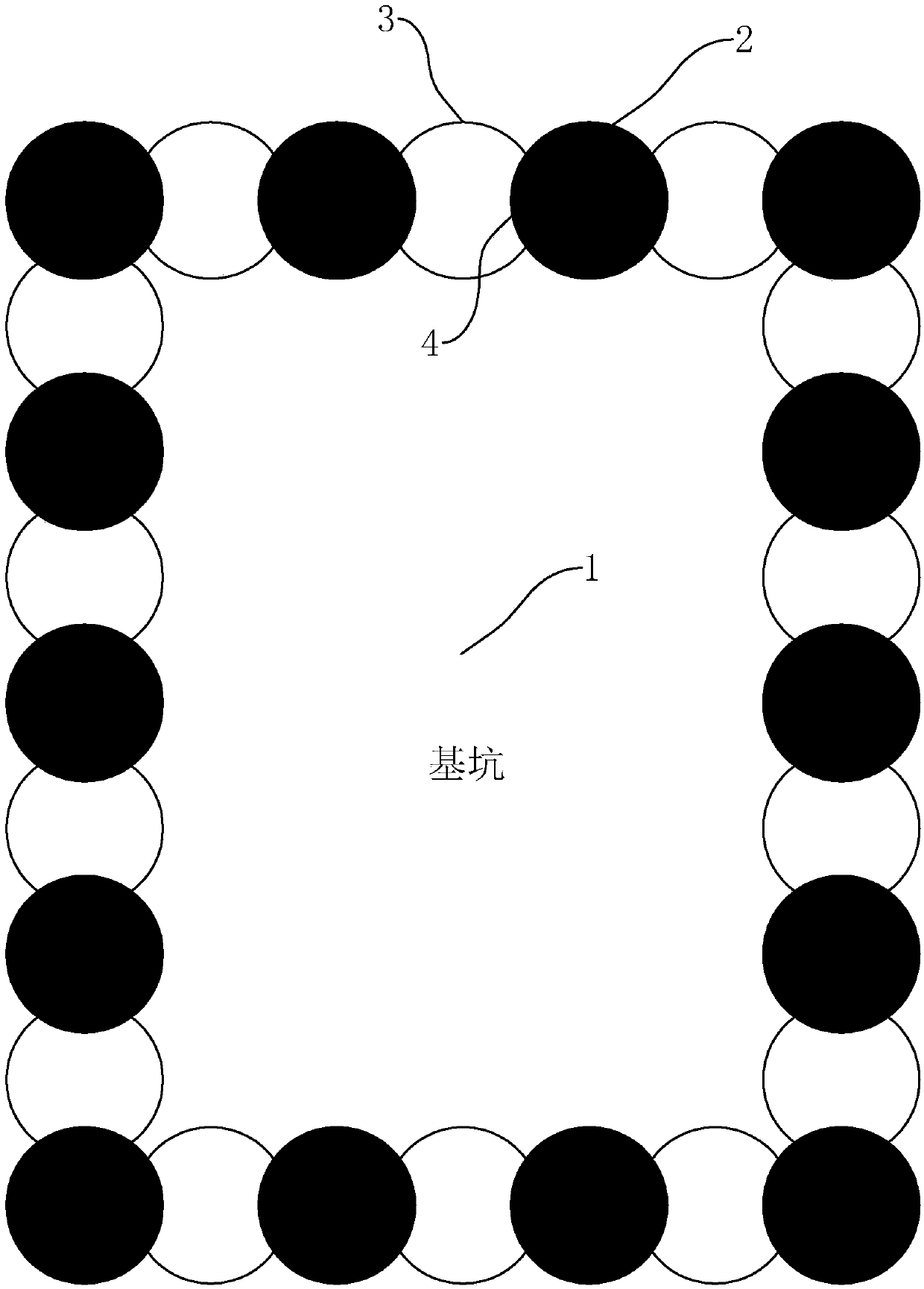

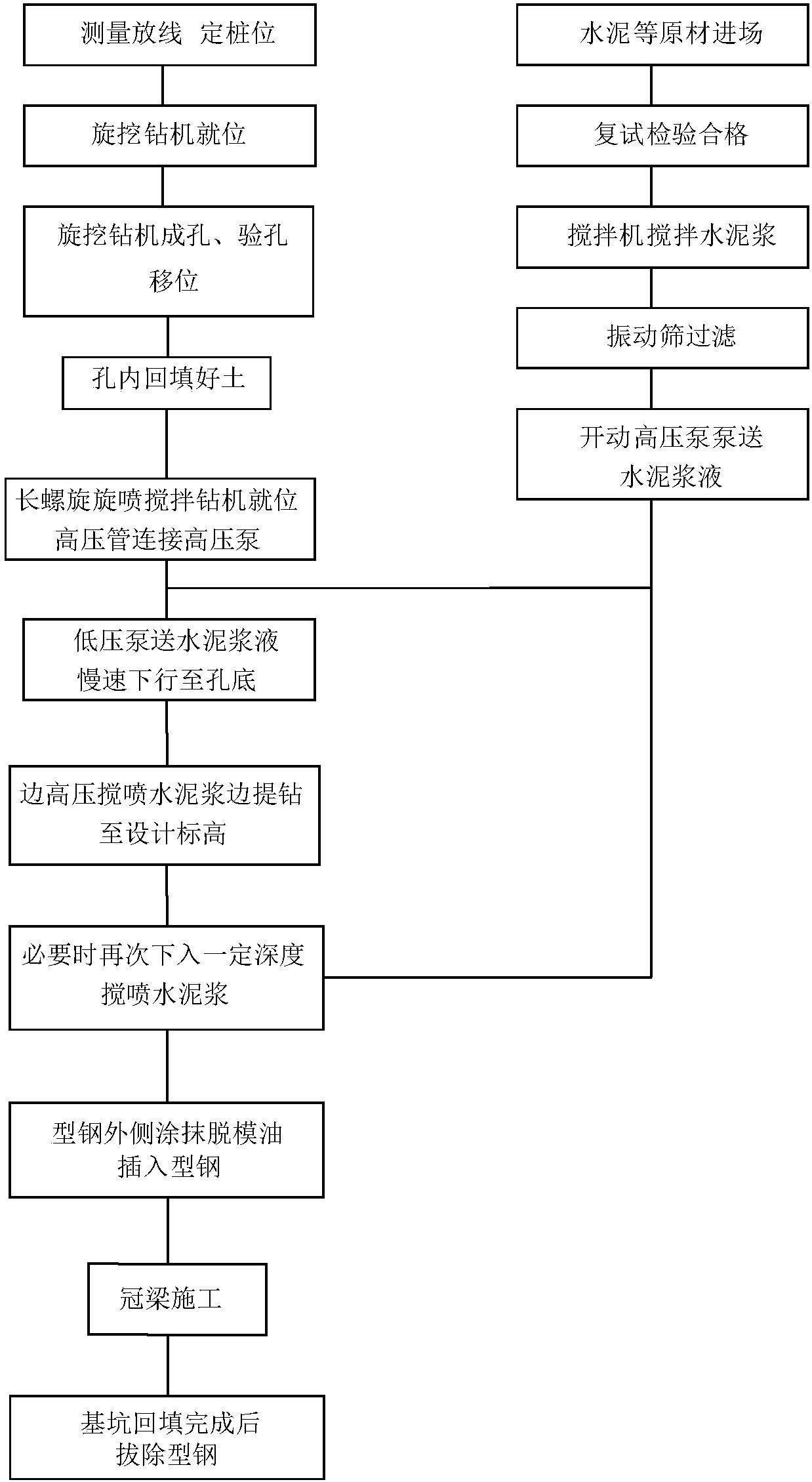

Construction method of profile steel and mixing-jetted cement soil curtain support pile

InactiveCN107700508AImprove reliabilityMinimize Disturbance and DisruptionExcavationsBulkheads/pilesEngineeringWaterstop

The invention discloses a construction method of a profile steel and mixing-jetted cement soil curtain support pile. According to key points of the technical scheme, the construction method comprisesthe following construction steps that survey and setting out are performed; a rotary drilling rig is arranged in place; drilling is performed; holes are filled with soil, and slurry is mixed outside the holes; a long auger rotary-jetting stirring drilling jig is arranged in place; cement soil pile mixing-jetting construction is performed; profile steel is inserted into piles; top beam constructionis performed; and the profile steel is pulled out. The method is applicable to construction on hard pan and gravel layers; the support pile after construction is completed achieves the combined effect of water stopping and supporting, and the inserted profile steel can be recycled, so that sources are saved, and the environment is protected; and the mixing-jetted support pile is independent of undisturbed soil, and is good in pile forming quality.

Owner:北京建材地质工程有限公司 +2

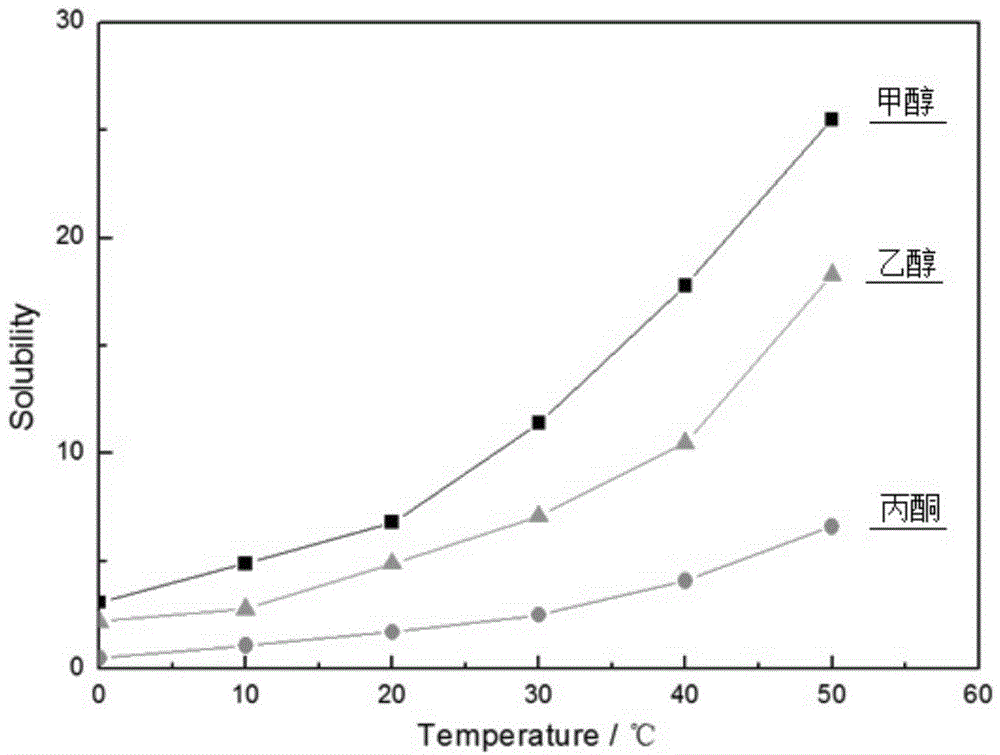

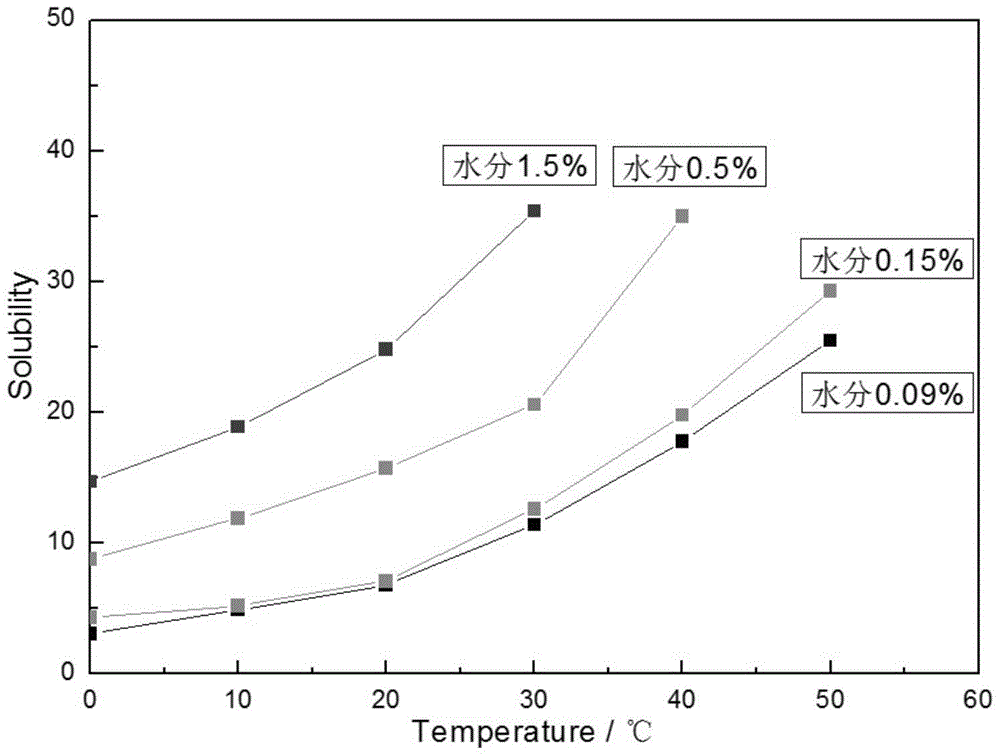

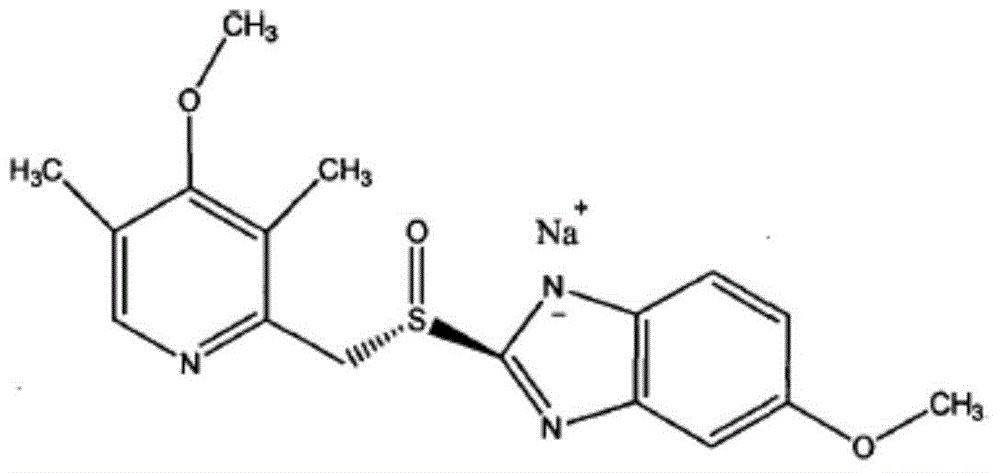

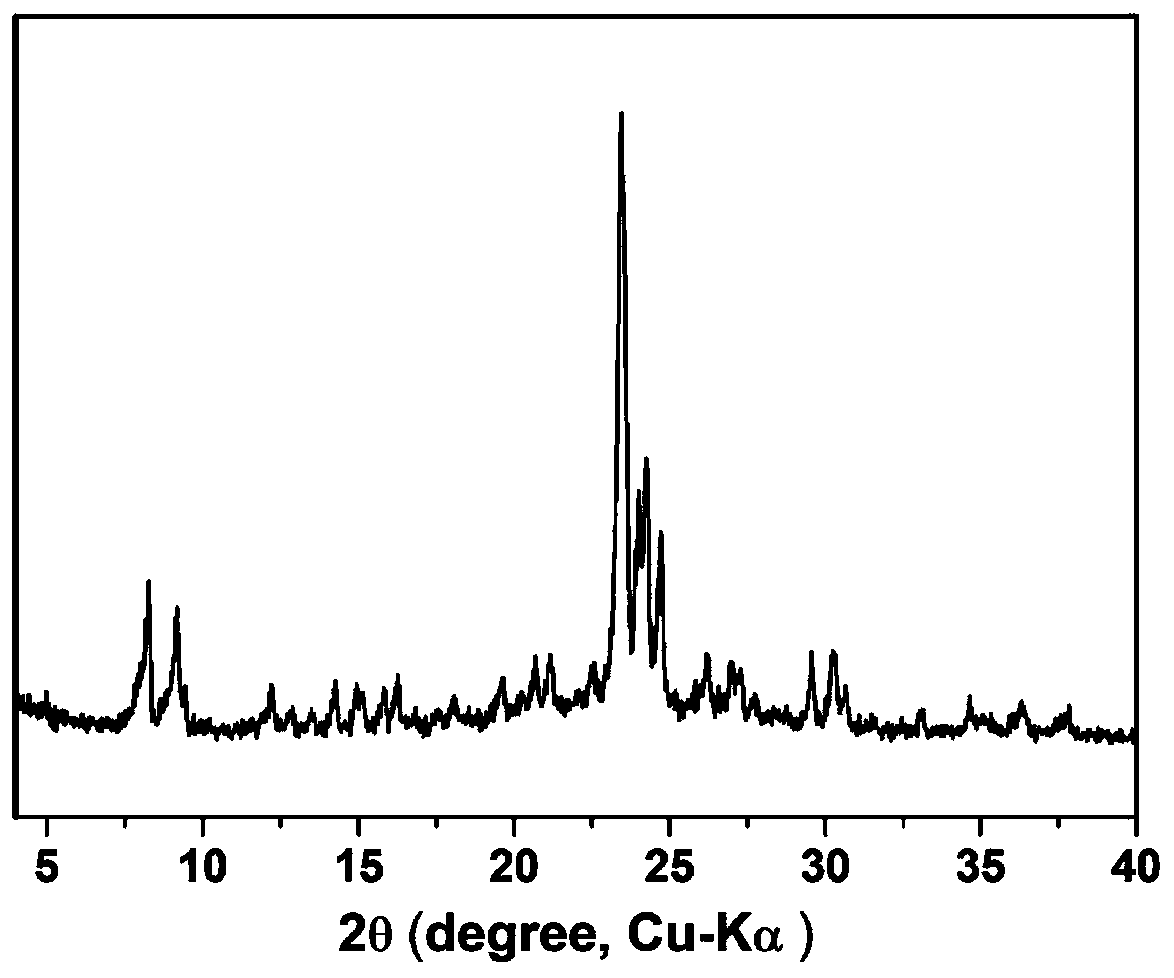

Preparation method of esomeprazole sodium

The invention relates to a preparation method of esomeprazole sodium. The preparation method comprises the following steps: dissolving esomeprazole free acid in a benign solvent in azeotropy with the water, adding sodium hydroxide to form salt, dehydrating through distillation azeotropy to reduce the water content in a solution system to be less than 0.2%, and cooling for crystallizing, thereby obtaining the esomeprazole sodium with high yield. The preparation method is simple in operation, the process yield is greatly promoted, the obtained product has high purity, the excellent single solvent is adopted, and the industrialization can be easily realized.

Owner:JIANGSU ZHONGBANG PHARMA

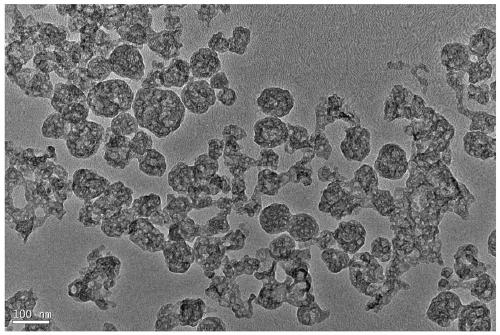

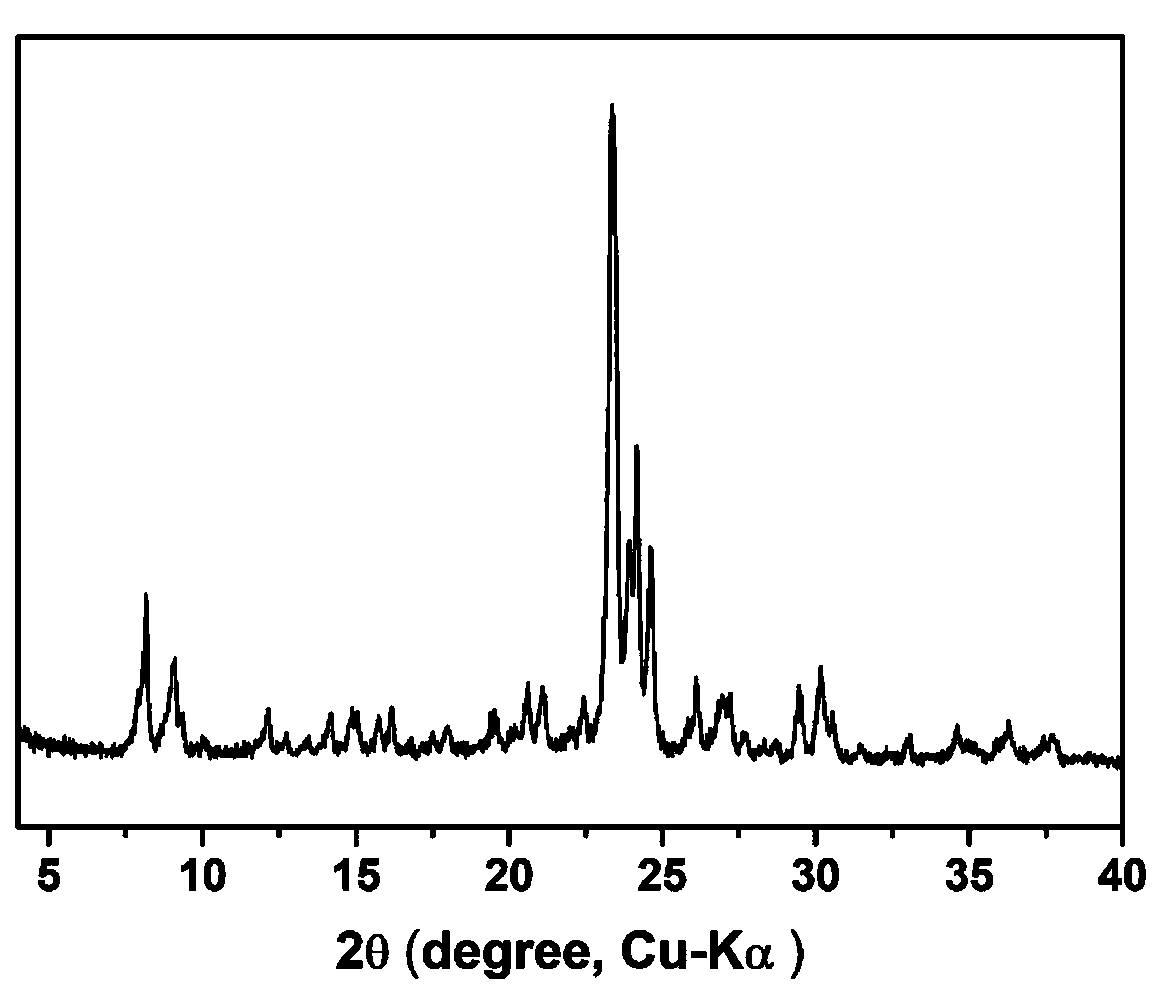

Method for directly preparing meso-porous molecular sieves by hydrothermal process in system using meso-porous silica as silicon source precursor without meso-porous template

InactiveCN109721078AHigh crystallinityIncreased mesopore volumePentasil aluminosilicate zeolitePorous substrateTetramethylammonium bromide

A method for directly preparing meso-porous molecular sieves in situ by a hydrothermal process in a system using meso-porous silica as a silicon source precursor without a meso-porous template belongsto the technical field of preparation of molecular sieves. Molecular sieve crystals are formed and grown on a meso-porous substrate with tetrapropylammonium hydroxide, tetraethylammonium hydroxide, tetrapropylammonium bromide and tetraethylammonium bromide as a micro-porous template and the meso-porous silica as the silicon source to synthesize the meso-porous molecular sieves having a good crystallization degree, a high micro-pore specific surface area, a large external specific surface area and a large micro-pore volume. The ZSM-5 and Beta molecular sieves synthesized in the invention havea large meso-porous volume, greatly improve the mass transfer rate in the field of molecular sieve catalysis, and have a broad industrial prospect.

Owner:JILIN UNIV

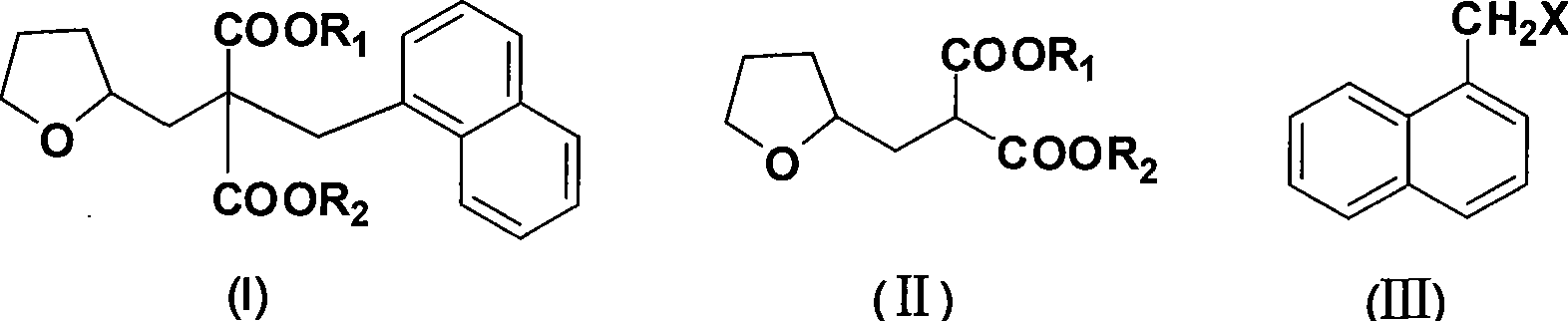

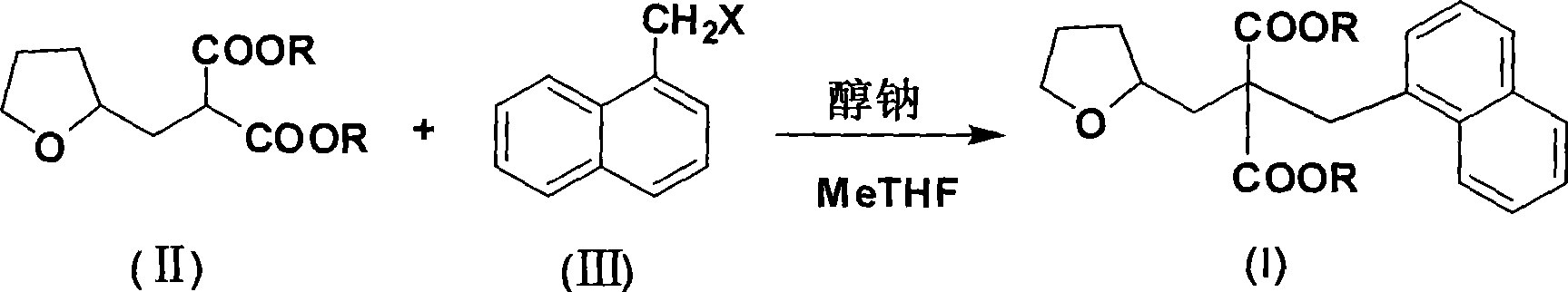

Synthetic method of diethyl naphthylmethyl-tetrahydrofurfurylmalonate

ActiveCN101381350AConducive to stratificationHigh reaction yieldOrganic chemistryMalonateAfter treatment

The invention discloses a method for synthesizing menaphthyl tetrahydrofuryl ethyl malonate as shown in a formula (I). The synthesis method is as follows: sodium alkoxide is added into a 2-methyl tetrahydrofuran solution of the menaphthyl tetrahydrofuryl ethyl malonate as shown in a formula (II) in batch at a temperature of between 20 and 45 DEG C; after addition, the mixture is heated and refluxed for 0.5 to 2 hours, and 1-methylnaphthalene halide as shown in a formula (III) is slowly dripped into the mixture at a temperature of between 80 and 100 DEG C; the mixture is subjected to reflux reaction for 0.5 to 2 hours; and the menaphthyl tetrahydrofuryl ethyl malonate is obtained after after-treatment of a reaction liquid. Compared with the prior art, the method has the advantages that the menaphthyl tetrahydrofuryl ethyl malonate adopts a green solvent, namely 2-methyl tetrahydrofuran as a reaction solvent and is also directly taken as an extracting solvent; and the method has high yield of reaction products and high recovery rate of the solvent, is environment-friendly, and has good industrial application prospect.

Owner:浙江清和新材料科技有限公司

Pulverized coal gasification device and process method for blending combustion of organic wastewater

ActiveCN112226248ARealize processingAchieve recyclingWaste based fuelGasification processes detailsThermodynamicsCombustion

The invention relates to a pulverized coal gasification device and a process method for blending combustion of organic wastewater. The pulverized coal gasification device comprises a gasification furnace, the gasification furnace is provided with an interface capable of installing an ignition burner, the pulverized coal gasification device is characterized in that the pulverized coal gasificationdevice also comprises a wastewater nozzle, and the wastewater nozzle can also be installed on the interface. The original function of the interface is that the interface is used for installing an ignition burner and the wastewater nozzle at present, a gasification furnace does not need to be modified, a special waste liquid inlet does not need to be formed in the gasification furnace, and therefore the original connector of the gasification furnace is fully utilized to be combined with the newly-added waste water nozzle to atomize waste water.

Owner:SINOPEC NINGBO ENG +2

Automatic clean wood sawing machine

InactiveCN107738322AReduce wasted timeImprove work efficiencyGripping devicesClamping devicesScrapElectric heating

The invention relates to the technical field of mechanical equipment, in particular to an automatic cleaning sawmill, comprising a fixed plate, and a horizontally arranged arc-shaped groove is provided at the central position of the end surface of the fixed plate, and the two sides of the arc-shaped groove are symmetrical A waste chute is provided, and a support plate is provided between the arc-shaped groove and the waste chute, and the support plates are arranged in pairs, clamping blocks are slidably connected between the support plates, and a second support plate is spirally connected to one side of the support plate. Two locking screws, in the present invention, through the set clamping block and the second locking screw, it is convenient to control the distance between the clamping blocks, and can clamp wood with different diameters, which has wide applicability and has a large market Foreground, at the same time, the waste chips can be cleaned through the cleaning device, which is convenient and quick to clean. At the same time, the cleaned wood chips can be directly pushed into the steam drying box, and dried and dried by fans and electric heating wires, which has huge economical advantages. Benefits and broad market prospects, it is worth popularizing and using.

Owner:WUXI AOTU AUTOMATION TECH CO LTD

Energy-saving environment-protecting method for steel and iron plant sintering

The invention discloses an energy-saving environment-protecting method for steel and iron plant sintering. The energy-saving environment-protecting method for steel and iron plant sintering comprises the following steps that (1) solid fuel consumption is reduced by adopting thick bed sintering; (2) solid fuel consumption is reduced through recycling production and the burning effect and performance of solid fuels improvement; (3) the burning effect and performance of solid fuels are improved; (4) the temperature of a sintering material can be improved through hot returning ores and quick lime and hot gas sintering and by injecting steam through a drum mixer before the fuels are mixed, and thus waste heat can be utilized; (5) energy consumption of ignition is reduced by applying an energy-saving type igniter and by means of the method of preheating combustion air; (6) electricity consumption is reduced by reducing air leakage and by adopting a frequency conversion technology; and (7) waste heat is recycled by applying a waste heat boiler and by adopting a waste heat boiler and a waste gas sintering technology. Energy saving and environment protection of the sintering process is actually achieved through the energy-saving environment-protecting method for steel and iron plant sintering provided by the invention.

Owner:HARBIN HONGTIAN RUIDA TECH

Distribution-network operation multifunctional combination tool

InactiveCN107069536AReduce replacement costsEliminate all kinds of defectsApparatus for overhead lines/cablesEngineeringMultiple function

The invention discloses a multifunctional combination tool for distribution network operation, which includes an operating head and an insulating rod. The bottom of the operating head is connected with a fixing column, the fixing column is provided with an external thread, the top of the insulating rod is provided with a groove, and the inner sleeve of the groove is Connected with a threaded sleeve, the threaded sleeve is provided with internal threads, and a fixing device is connected between the side wall of the groove and the threaded sleeve to prevent the threaded sleeve from moving in the groove. , high-branch saws, posting clips for pole numbers and shovel blades, the invention realizes the integration of multiple functions through the separate operating head, threaded sleeve and insulating rod, carries a set of tools, and eliminates various defects It has excellent performance in terms of mechanical strength and practicability, effectively reduces the number and weight of equipment carried by operation and maintenance personnel, reduces the burden on operation personnel, meets the work needs of front-line operation and maintenance personnel, and improves work enthusiasm and work efficiency. At the same time reduce operation and maintenance costs.

Owner:ZHUJI POWER SUPPLY BUREAU +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com