Domestic garbage incineration fly ash water washing chlorine-removing and waste water desalination and reuse process system

A technology for domestic waste incineration and process system, which is applied in the field of domestic waste incineration fly ash water dechlorination and its wastewater desalination and reuse process system, and can solve the problems of vicious competition, potential safety hazards, and random flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

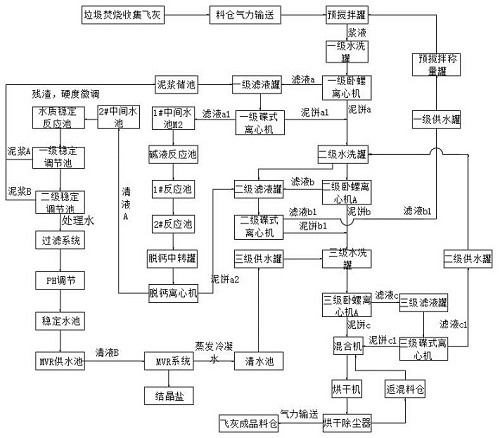

[0024] A technical system for washing and dechlorination of domestic waste incineration fly ash and its waste water desalination and reuse, comprising the following steps:

[0025] 1. Collect the fly ash produced by garbage incineration and transport it to the pre-mixing tank through the seven-mile conveying device in the hopper to get the slurry;

[0026] 2. Wash the slurry obtained in step 1 through a primary washing tank, and then centrifuge through a primary horizontal centrifuge to produce mud cake a and filtrate a after centrifugation. The mud cake a is transported to the next step, and the filtrate a is passed through the primary filtrate tank Treat with a first-stage butterfly centrifuge to obtain mud cake a1 and filtrate a1, mud cake a1 is transported to the next step, and filtrate a1 is processed again;

[0027] three. The mud cake a and mud cake a1 obtained in step 2 are transported to the secondary water washing tank for water washing, and then centrifuged through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com