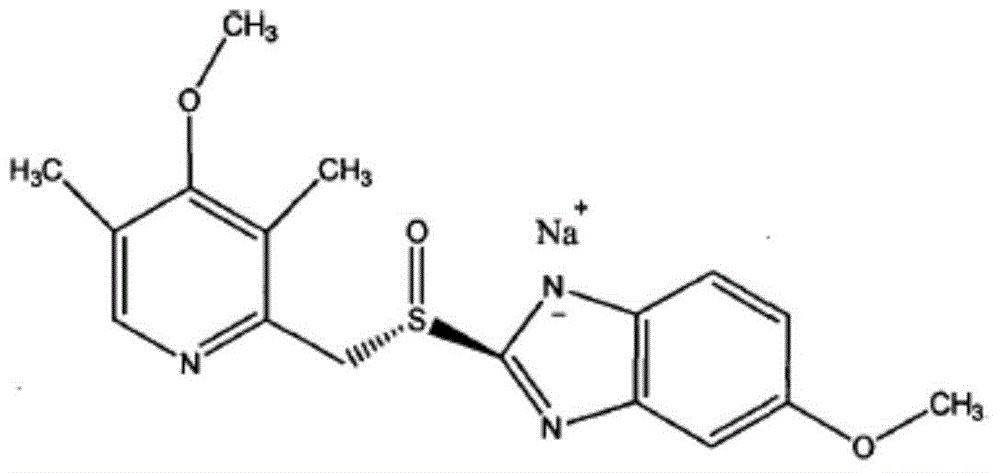

Preparation method of esomeprazole sodium

A technology of esomeprazole sodium and a benign solvent, which is applied in the field of preparation of esomeprazole sodium, can solve problems such as low yield and difficult solvent recovery, and achieve high yield, improved operability, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of esomeprazole free acid

[0027] In the present invention, the preparation method of esomeprazole free acid adopts the disclosed general synthetic method of present WO94 / 27988, and the method is as follows:

[0028] 30kg of toluene, 5kg of D-(-)-diethyl tartrate, 40kg of 5-methoxy-2-[[(4-methoxy-3,5-dimethyl-2-pyridine Base) methyl] sulfenyl] -1H-benzimidazole, stir and heat up to 60±, then add 3.0kg tetraisopropyl titanate and 2.2kg N,N-diisopropylethylamine, keep stirring for 30 minutes, Want to add 26kg cumene hydroperoxide dropwise in the still, and react at room temperature for 1 hour after the dropwise addition is completed. Sodium bicarbonate, extracted with 200kg dichloromethane, after the extraction was completed, the dichloromethane layer was dried by adding 5kg anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain 32kg brown viscous oil, which was esomeprazole free acid, HPLC The analytical chemical purity is 99...

Embodiment 1

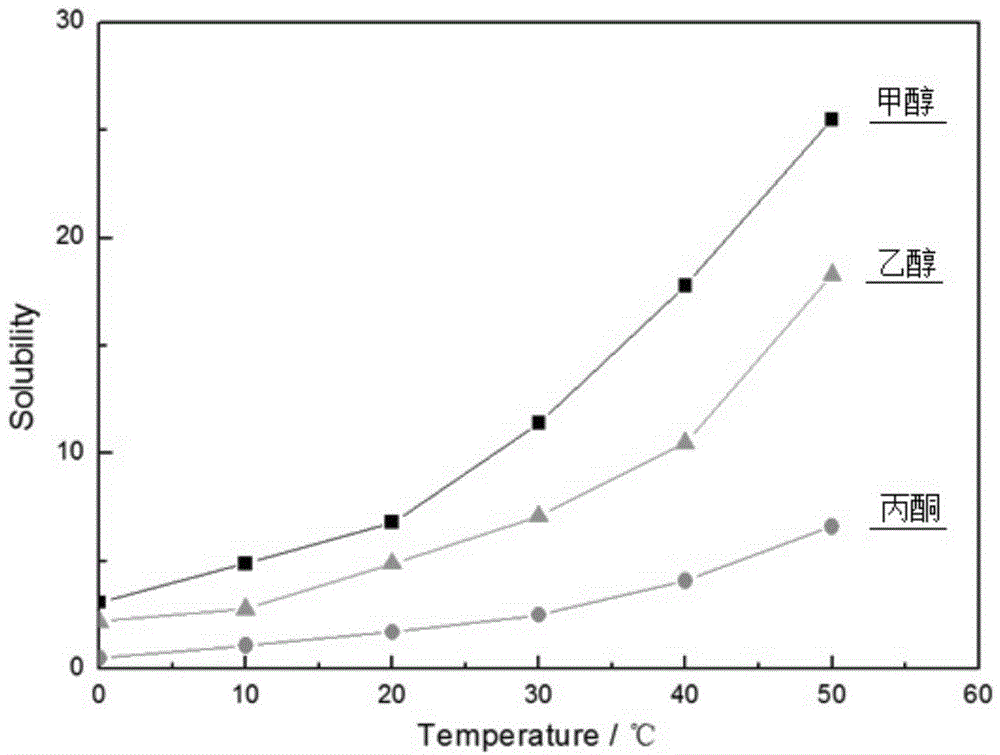

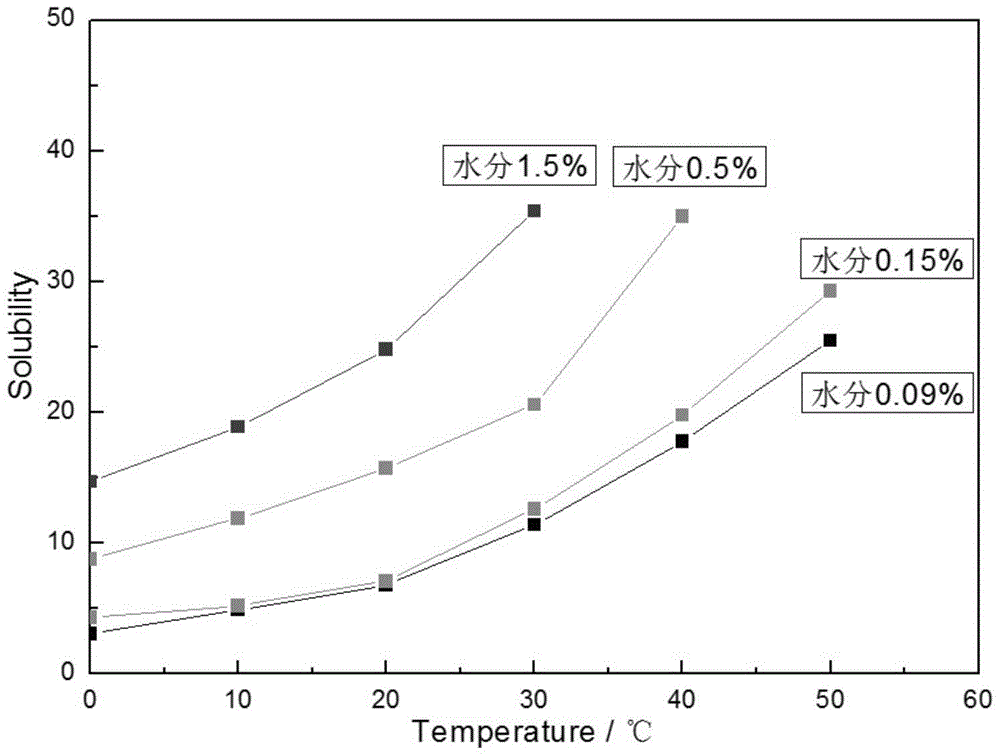

[0030] Preparation of esomeprazole sodium

[0031] Put 5 kg (14.5 mol) of esomeprazole and 25 kg of methanol into the reaction kettle, stir and dissolve at room temperature, slowly add 0.57 kg (14.4 mol) of sodium hydroxide to the kettle, complete the addition, and stir for 0.5 hours to react. After the reaction is completed, the reaction solution is concentrated under reduced pressure at 40°C until the water content is ≤0.15%. After the concentration is completed, a large amount of white solids are precipitated in the kettle, and the temperature in the kettle is slowly reduced to 0±5, stirred for 2 hours, filtered, and vacuum-dried to obtain Exome The finished product of prazole sodium is 4.5kg, and the yield is 84.9%.

Embodiment 2

[0033] Preparation of esomeprazole sodium

[0034] 5kg (14.5mol) esomeprazole, 50kg isopropanol are dropped into reactor, at room temperature, in stirring and dissolving, slowly in kettle, add 0.57kg (14.4mol) sodium hydroxide, add complete, stirring reaction 0.5 hour. After the reaction is completed, the reaction solution is concentrated under reduced pressure at 40°C until the water content is ≤0.15%. After the concentration is completed, a large amount of white solids are precipitated in the kettle, and the temperature in the kettle is slowly reduced to 0±5, stirred for 2 hours, filtered, and vacuum-dried to obtain Exome The finished product of prazole sodium is 4.8kg, and the yield is 90.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com