Reduction purification technology for nitric acid in production of coal produced glycol

A coal-to-ethylene glycol, purification process technology, applied in chemical instruments and methods, natural water treatment, water pollutants, etc., to achieve the effects of convenient operation, good device reliability, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

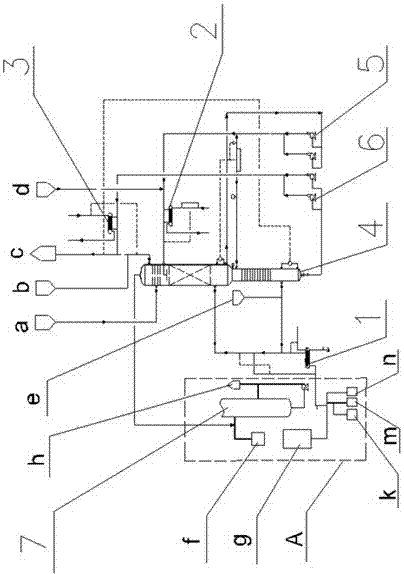

[0037] Refer to attached figure 1 , this example

[0038] The described nitric acid reduction and purification process in the production of coal-to-ethylene glycol, the coal-to-ethylene glycol process mainly includes coal gasification, separation and purification, coupling reaction, regeneration reaction, hydrogenation reaction, etc., in the original system (A) After the regeneration process, a nitric acid reduction and purification system is installed; in the original system (A), the gas phase material (g) from the top of the DMO removal tower is treated by the nitric acid reduction and purification system, and the nitric acid content of the effluent is 0.4%.

[0039] Another embodiment is different in that the content of nitric acid in the effluent after being treated by the nitric acid reduction purification system is <0.3%.

[0040] The difference of another embodiment is that the nitric acid reduction and purification system described in it includes a tower inlet preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com