Flue gas carbon dioxide trapping and purifying system and method

A carbon dioxide and flue gas technology, applied in liquefaction, refrigeration and liquefaction, climate sustainability, etc., can solve the problems of environmental pollution and high energy consumption by chemical absorption, improve energy utilization, reduce carbon capture energy consumption, The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

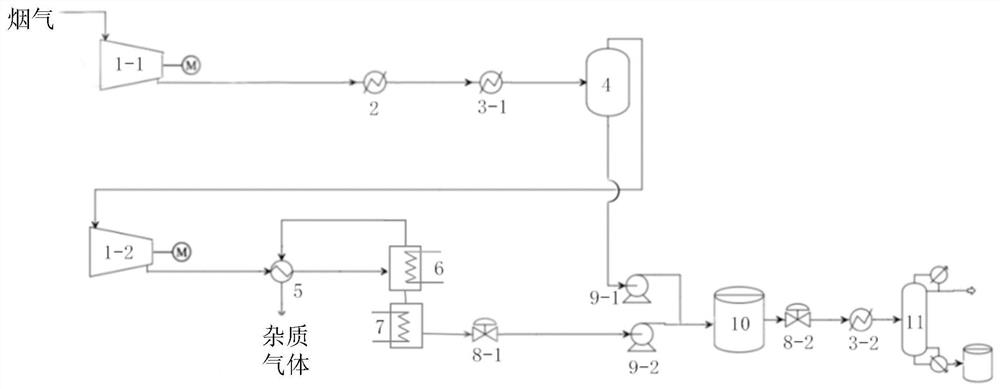

[0063] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a flue gas carbon dioxide capture and purification system described in this embodiment includes a first air compressor 1-1, a second air compressor 1-2, a cold water heat exchanger group 2, a first refrigerant Heat exchanger 3-1, second refrigerant heat exchanger 3-2, carbon dioxide separator 4, gas heat exchanger 5, desublimator 6, sublimator 7, first pressure regulating valve 8-1, second regulator Pressure valve 8-2, first booster pump 9-1, second booster pump 9-2, carbon dioxide storage tank 10 and rectification tower 11;

[0064] The air inlet of the first air compressor 1-1 is used to receive flue gas;

[0065] The flue gas output by the first air compressor 1-1 is sent to the carbon dioxide Separator 4;

[0066] The carbon dioxide separator 4 is used to separate the carbon dioxide in the flue gas, and output the liquid carbon dioxide and the mixed gas;

[0067] The l...

specific Embodiment approach 2

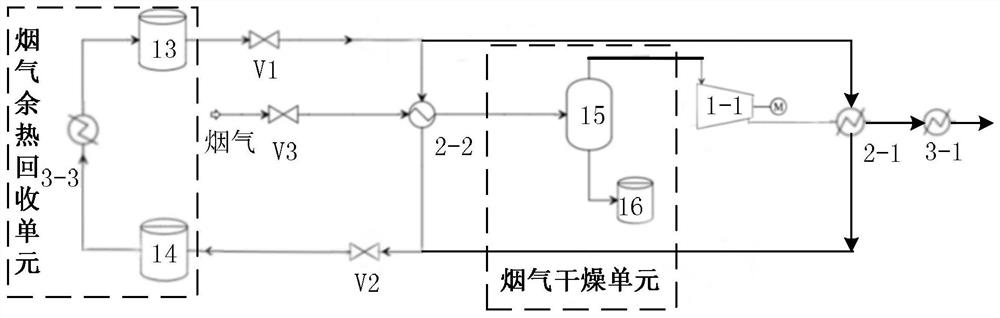

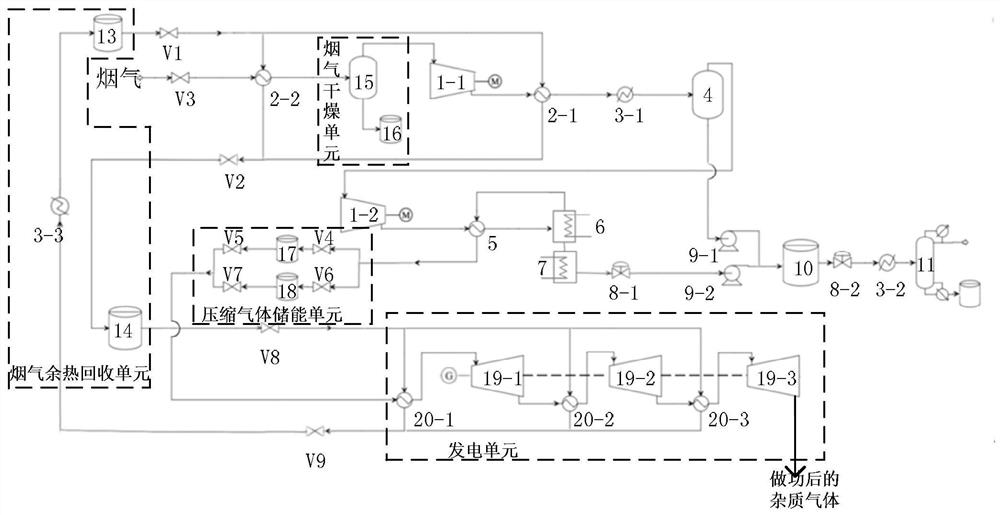

[0078] Specific implementation mode two: the following combination Figure 1 to Figure 3 To illustrate this embodiment, this embodiment will further describe a flue gas carbon dioxide capture and purification system described in Embodiment 1. The purification system also includes a flue gas waste heat recovery unit and a flue gas drying unit;

[0079] The flue gas drying unit is used to dry the flue gas before sending it to the first air compressor 1-1;

[0080] The flue gas waste heat recovery unit is used to pass cooling water into the cold water heat exchanger group 2 to cool down the flue gas, recover the waste heat of the flue gas through the cooling water, and recycle the cooling water after recovering the waste heat of the flue gas.

[0081] In this embodiment, drying the flue gas through the flue gas drying unit can recover most of the moisture in the flue gas for recycling, which is of great significance for the construction of generating units in water-scarce areas a...

specific Embodiment approach 3

[0082] Specific implementation mode three: the following combination figure 2 and image 3 Describe this embodiment. This embodiment will further describe a flue gas carbon dioxide capture and purification system described in Embodiment 2. The cold water heat exchanger group 2 includes a first cold water heat exchanger 2-1 and a second cold water heat exchanger device 2-2;

[0083] The flue gas waste heat recovery unit includes a low-temperature water storage tank 13, a high-temperature water storage tank 14 and a third refrigerant heat exchanger 3-3;

[0084] The flue gas drying unit includes a gas-liquid separator 15 and a water storage tank 16;

[0085] The first cold water heat exchanger 2-1 is arranged on the pipeline between the first air compressor 1-1 and the first refrigerant heat exchanger 3-1;

[0086] The low-temperature water storage tank 13 is used to provide cooling water for the first cold water heat exchanger 2-1 and the first cold water heat exchanger 2-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com