A dust removal method for coke transportation system

A transportation system, coke technology, applied in the direction of dust removal, transportation and packaging, cleaning methods and utensils, etc., can solve the problems of large area occupied by the dust collector, easy blockage of horizontal pipes, large air volume and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

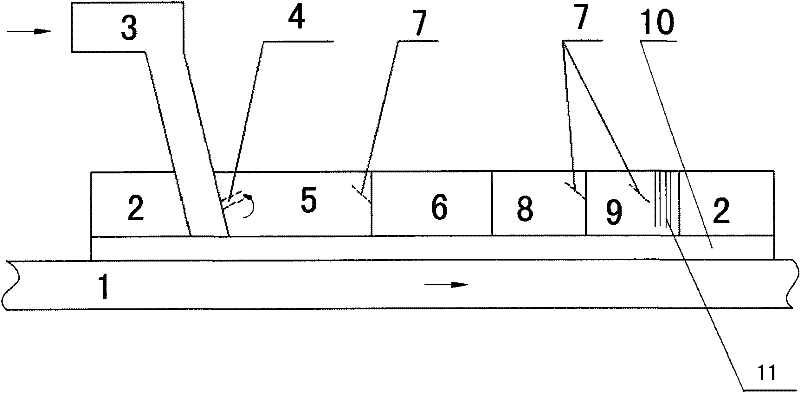

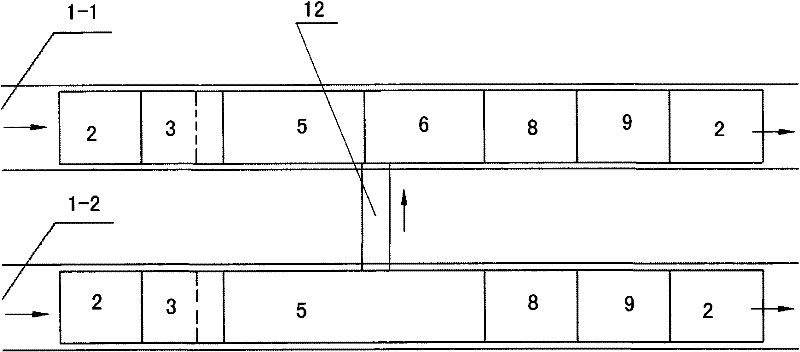

[0027] see figure 1 , 2 , the first position of the belt conveyor 1 is sealed with a sealed chamber 2, followed by a dust removal chamber 5, a dust-gas separation chamber 8 and a circulating dust reduction chamber 9 after the station of the drop pipe 3, and the upper part of each chamber is provided with an inclined folding plate 7, and the angle between the folding plate 7 and the horizontal direction is 15°-45°, and the chambers are connected into one body through the connector 10. First of all, for the rising dust gas falling into the dust removal chamber 5 from the discharge pipe 3, it is redirected by the inclined folding plate 7 on the top, causing turbulent flow and causing the large particles to settle; while the fine dust is transported by the belt conveyor 1 at the discharge port. And the movement of the material generates a slight negative pressure, so that the fine dust flows back to the lower end of the discharge pipe 3 through the return pipe 4, and finally most...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com