High-energy paper pulp release agent and production method thereof

A release agent and pulp technology, applied in the direction of papermaking, textiles and papermaking, non-fiber pulp addition, etc., can solve the problems of easy release, achieve the effects of reducing pollution, good lubrication and protection, and improving paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

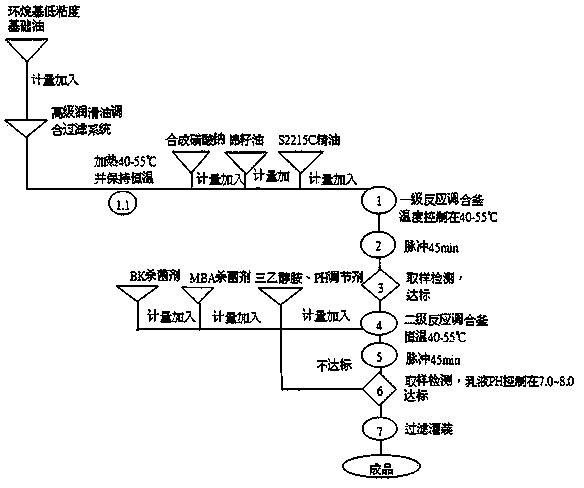

Method used

Image

Examples

Embodiment 1

[0036] First, measure each raw material base oil and additives. 70.0kg of naphthenic low-viscosity base oil enters the advanced blending and filtering system and transfers to the first-stage reaction blending kettle, and heats to 40-55°C for pulse stirring for 30-45 minutes to make the sample Heating evenly, then add 12.0kg of Enable460M synthetic sodium sulfonate, 8.0kg of S2215C general-purpose emulsified olein, and 5.0% of T-405 vulcanized cottonseed oil in order of integration, and the sampling test reaches the standard. Transfer to the secondary reaction blending kettle at a constant temperature of 40-55°C, add 2.0kg of BK hexahydro-triazine fungicide, 1.0% kg of MBM fungicide, etc. in sequence while pulse stirring, and carry out a new process through the advanced lubricating oil blending and filtering system. Compound, stir and mix evenly, take a sample and observe the transparency of the sample to meet the standard, and test the pH value of the emulsion of the test sampl...

Embodiment 2

[0038] Base oil Naphthenic low-viscosity base oil 85.5kg, Enable460M synthetic sodium sulfonate 6.0kg, S2215C general-purpose emulsified olein 5.0kg, T-405 vulcanized cottonseed oil 2.0kg, BK hexahydro-triazine fungicide 0.5kg, MBM sterilization Agent 0.5kg, the addition amount of triethanolamine 0.5kg etc., main configuration process is with embodiment 1.

Embodiment 3

[0040] Base oil Naphthenic low-viscosity base oil 80.0kg, Enable460M synthetic sodium sulfonate 9.0kg, S2215C general-purpose emulsified olein 6.5kg, T-405 vulcanized cottonseed oil 3.5kg, BK hexahydro-triazine fungicide 1.0kg, MBM sterilization Agent 0.5kg, triethanolamine 1.5kg etc., main configuration process is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com