Construction method of profile steel and mixing-jetted cement soil curtain support pile

A construction method and a technology for supporting piles, which are applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems that are not involved, cannot reach the design depth, and cannot do what they want, so as to reduce disturbance and damage, improve the occlusal effect, easy chiseling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

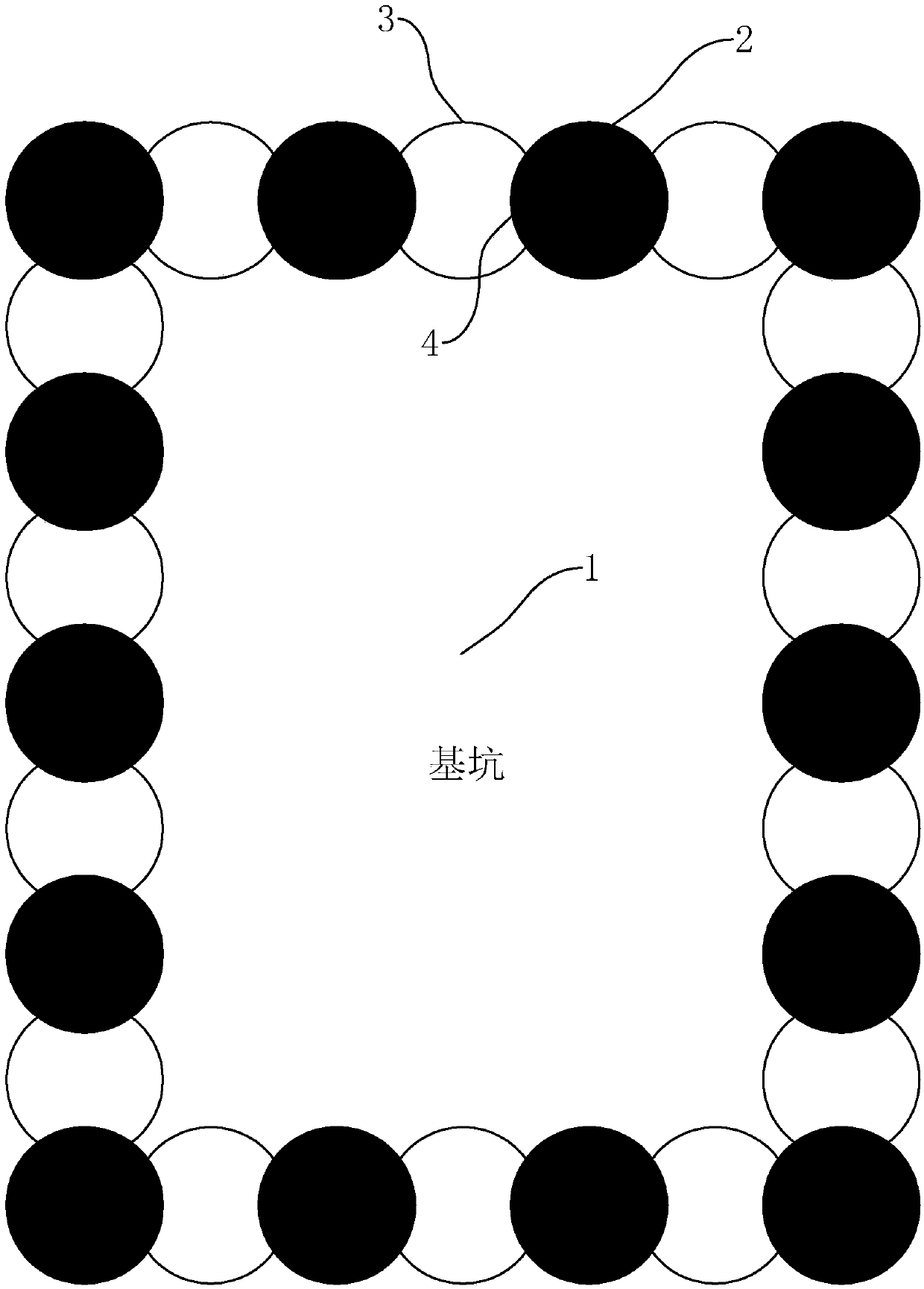

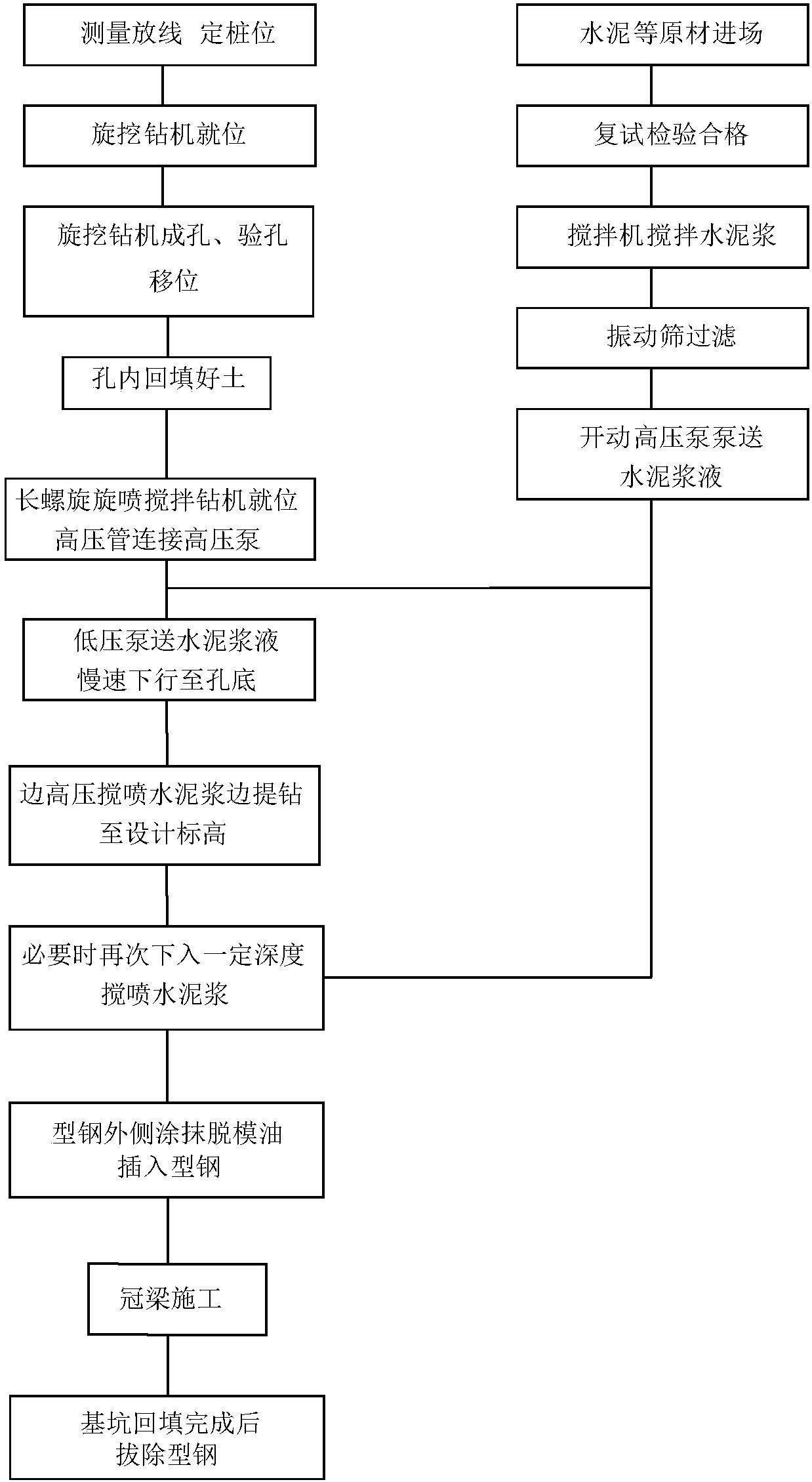

[0042] like figure 2 Shown, a kind of construction method of section steel mixing and spraying cement-soil curtain curtain support pile, comprises the following construction steps:

[0043] Step a, measurement and setting out: measure and set out on a flat site, insert wooden sticks or steel bar sticks at the released pile positions for identification; in addition, make leading piles next to the pile positions so that they can be reviewed at any time when there is a deviation in the pile positions; leading piles It is two identification piles that form a straight line with the center of the pile position. The usual method for leading piles is to drill a deep hole on the ground with a steel drill or a hole puncher, and pour white lime powder into it;

[0044] Step b, the rotary drilling rig is in place: the operator controls the movement of the drilling rig according to the released pile position to ensure that the drilling axis is in place, and uses the self-contained device ...

Embodiment 2

[0054] The difference from Embodiment 1 is that in step i, when the ground space is narrow and the special lifting machine has no operating space, the section steel is pre-lifted with a jack, and after reaching a certain height, such as after pulling out 1m, use a tower crane or The crane pulls up the whole section steel for recycling.

[0055] In addition, in order to further improve the reliability of the water-stop curtain, after the construction of the support piles is completed, with the excavation of the foundation pit, detachable anchor rods are implemented layer by layer on the inner wall of the foundation pit, and the net is hung with shotcrete. When the foundation construction is completed and the backfilling of the fertilizer tank of the foundation pit reaches the height of the anchor bolts, the anchor bolts are removed layer by layer for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com