Method and assembly for regulating the grind drying procedure of a coal dust ventilator mill

A drying process, mill technology, applied in the direction of grain processing, etc., can solve the problems of deterioration of conveying conditions, deterioration of grinding conditions and combustion conditions, increase gas/solid circulation, etc., and achieve the effect of high conveying stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

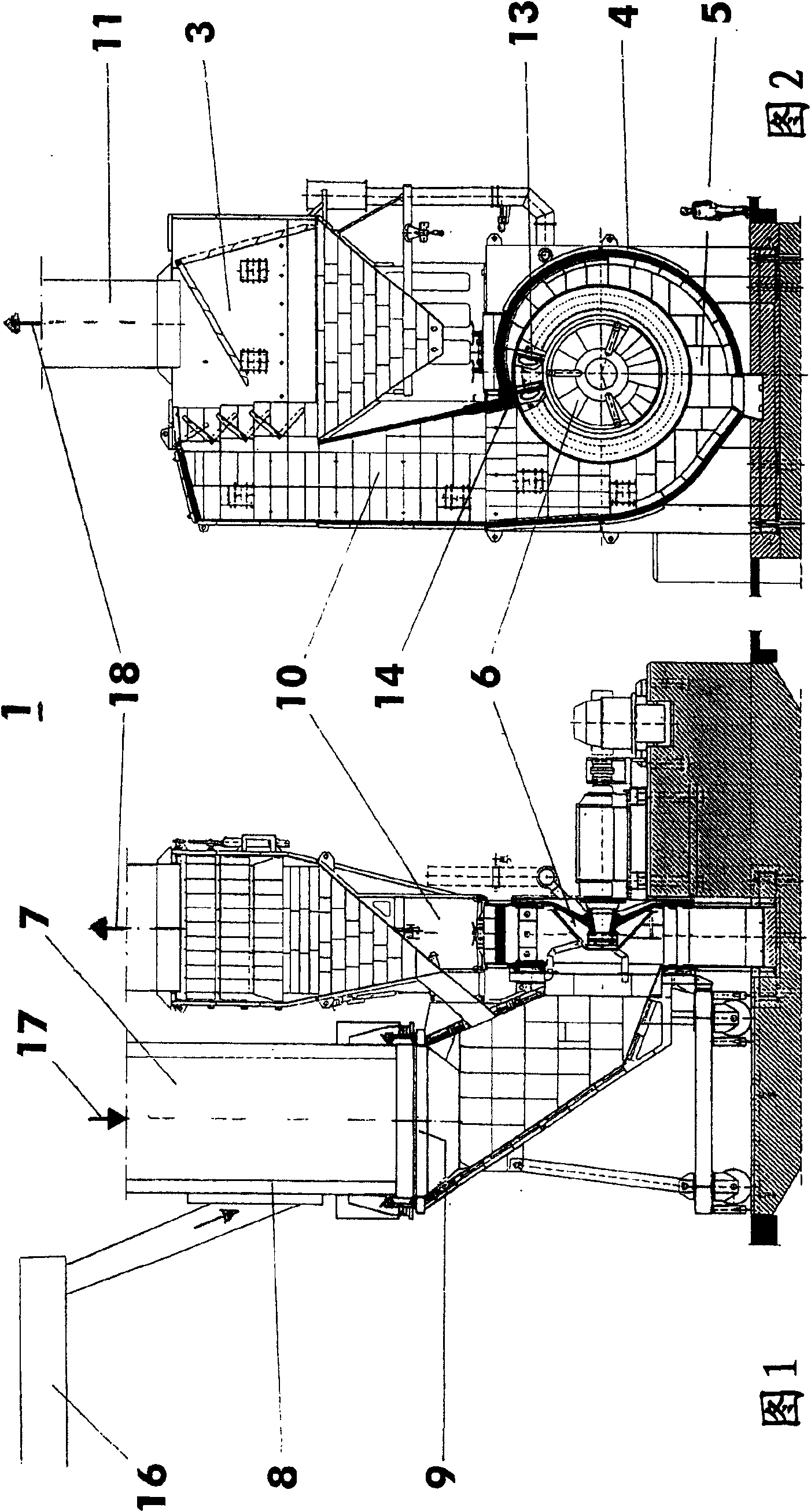

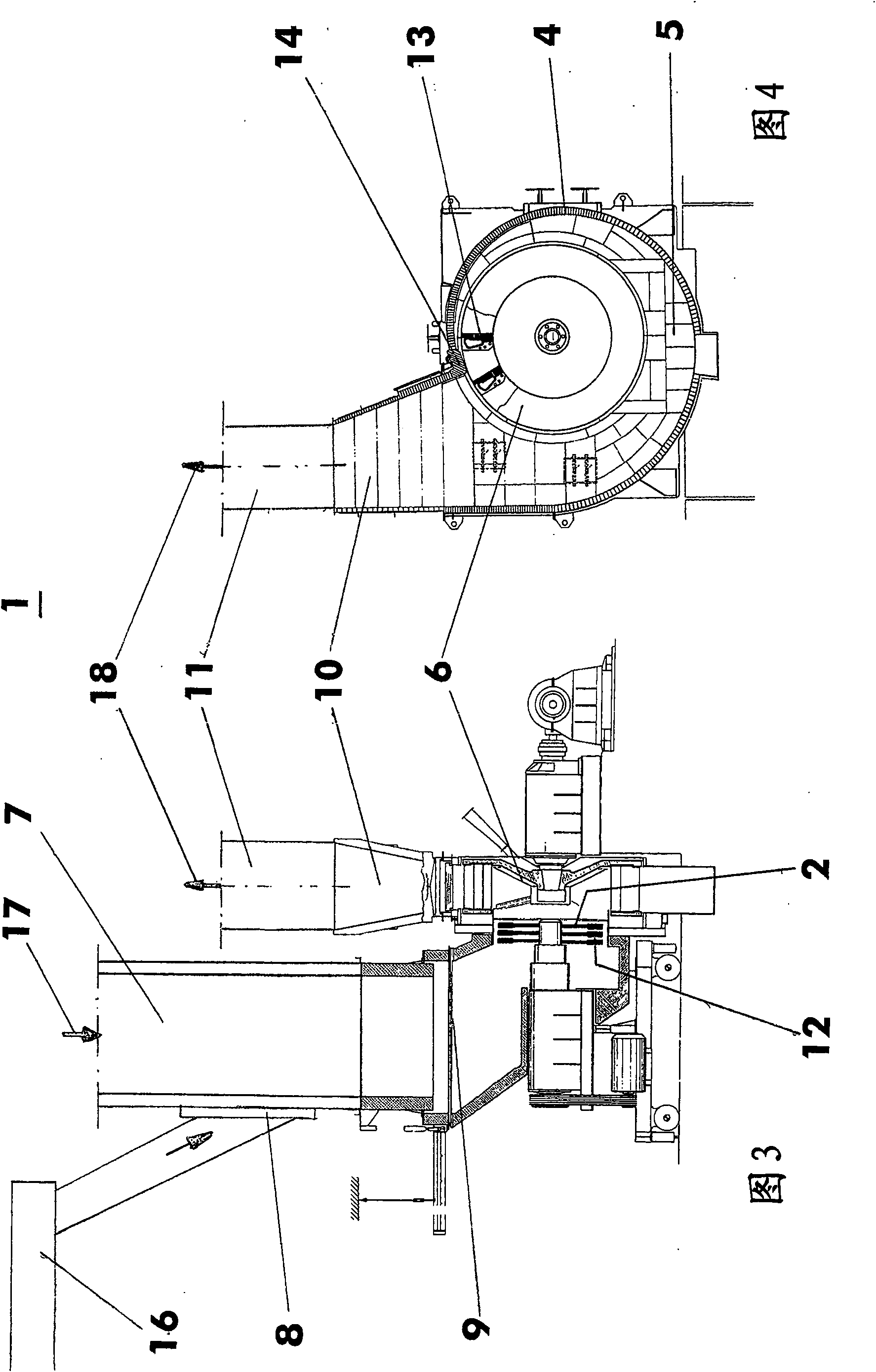

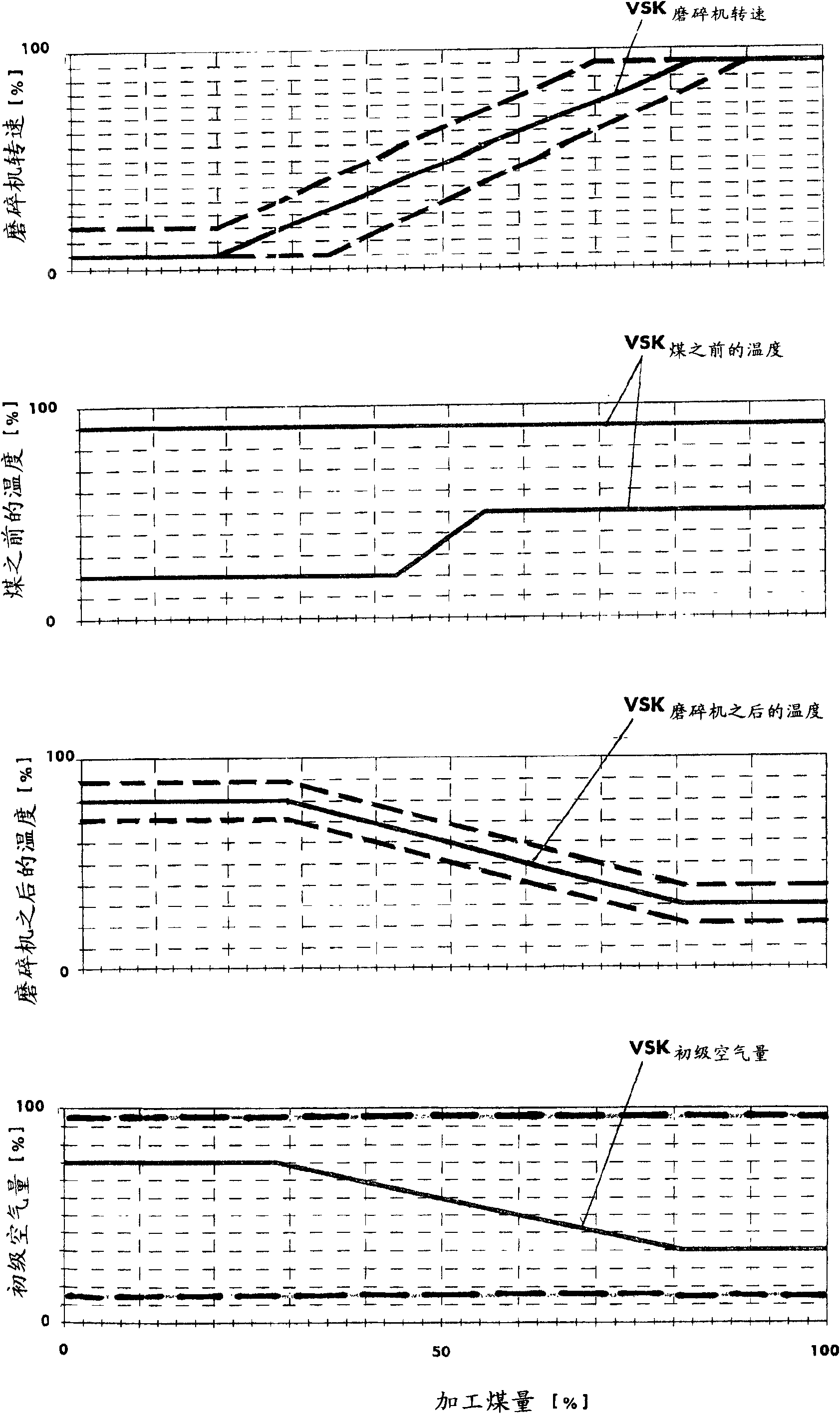

[0028] figure 1 and 2 A pulverized-coal pulverized-air mill 1 with a separator 3 is schematically shown, in which the method according to the invention is used. In such a blast mill 1, raw fuel, in particular raw lignite, from a coal bunker (not shown) is passed through a feeding device 16, such as a coal feeder, a bunker unloading device or another feeding mechanism , and enters the flue gas-suction shaft 7 via the coal inlet 8, from which the raw fuel reaches the pulverizer 1 via the pulverizer inlet 9. The raw fuel is dried in a blast or impact mill 1 and comminuted or ground by grinding means 13 , 14 . In order to achieve the drying, combustion exhaust gases or flue gases are sucked by the blast mill 1 from the upper region of the combustion chamber, not shown, of the steam generator of the power plant fired with fuel from the mill 1 , in which the combustion The exhaust gas is conveyed to the pulverizer 1 via the flue gas suction shaft 7 respectively. The combustion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com