Patents

Literature

37results about How to "Eliminate emission pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

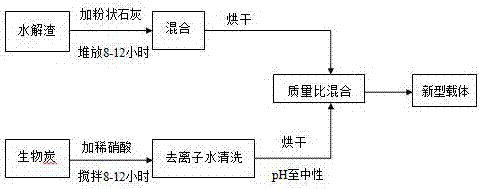

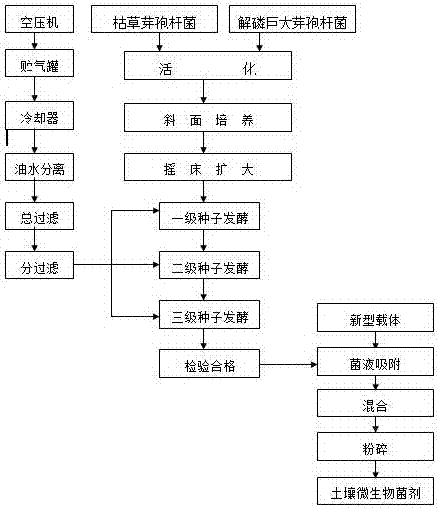

Microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof

InactiveCN106867945AIncrease resistanceImprove enrichment capacityBacteriaContaminated soil reclamationMicroorganismResource utilization

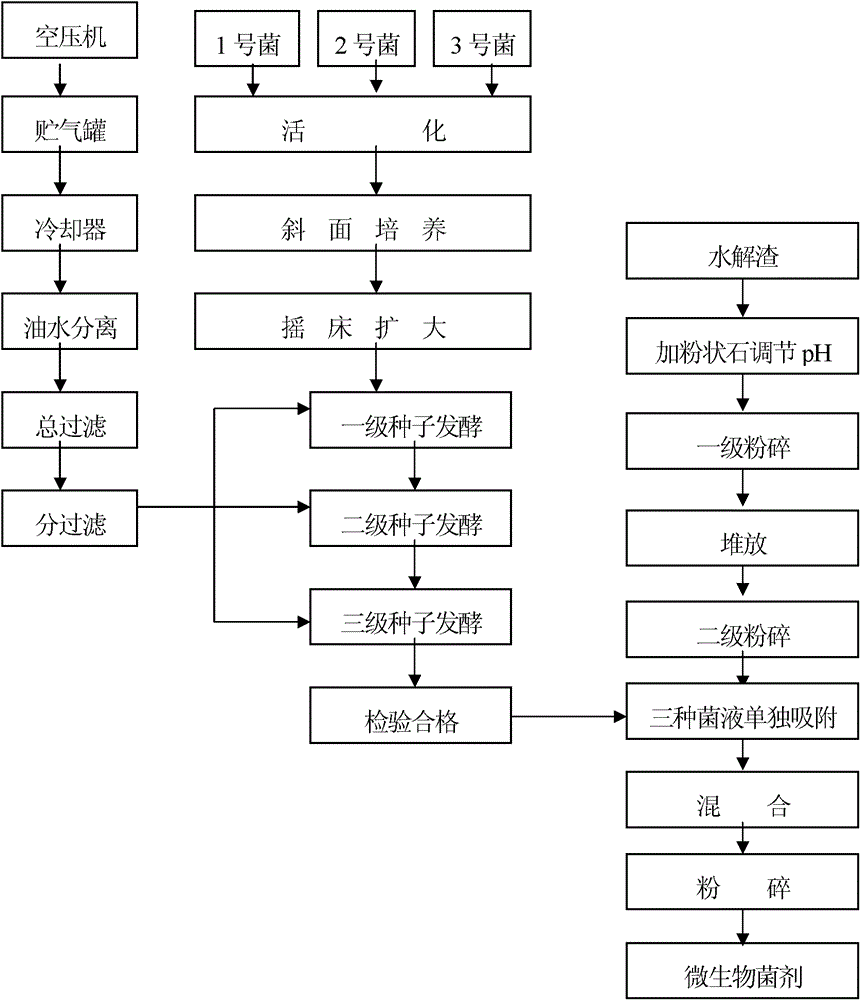

The invention discloses a microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof. A preparing method comprises the steps of fermentation and adsorption of strains. Specifically, bacteria solutions obtained after fermentation of bacillus megateriumvar.phosphaticum and bacillus subtilis LVLE-14 are mixed in proportion, then adsorption is conducted by means of a special adsorption carrier, and then mixing and smashing are conducted to obtain the microorganism passivator. The adsorption carrier comprises hydrolysis residues and biochar which are mixed and smashed according to a certain mass ratio. By the adoption of the microorganism passivator for repairing heavy metal pollution of soil, the content of available heavy metals in soil can be effectively reduced, and the number of microbial populations and plant yield are increased greatly. The method for repairing heavy metal pollution of soil by means of the microorganism passivator is in-situ repair, operation is easy, the cost is low, and industrialized implementation can be easily achieved; furthermore, the repairing effect is good, soil fertility can not be damaged, and the utilization rate of resources can be increased.

Owner:SHANGHAI LVLE BIO TECH

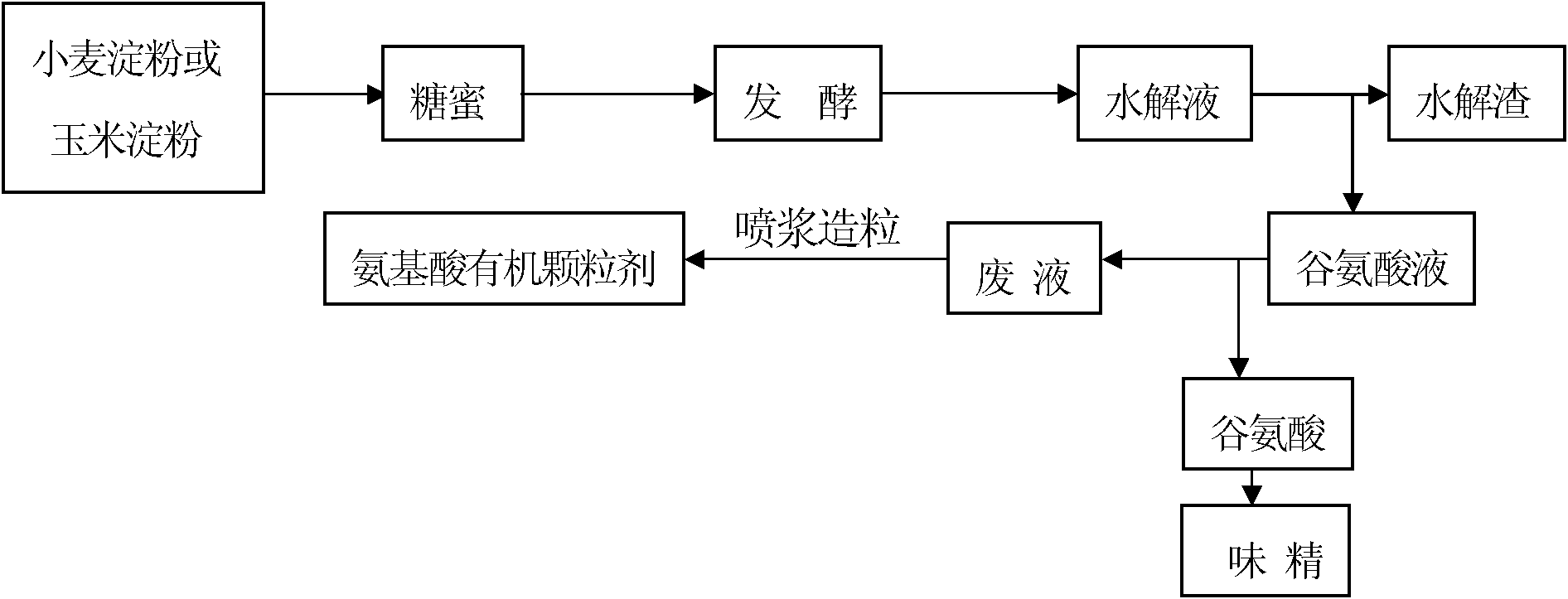

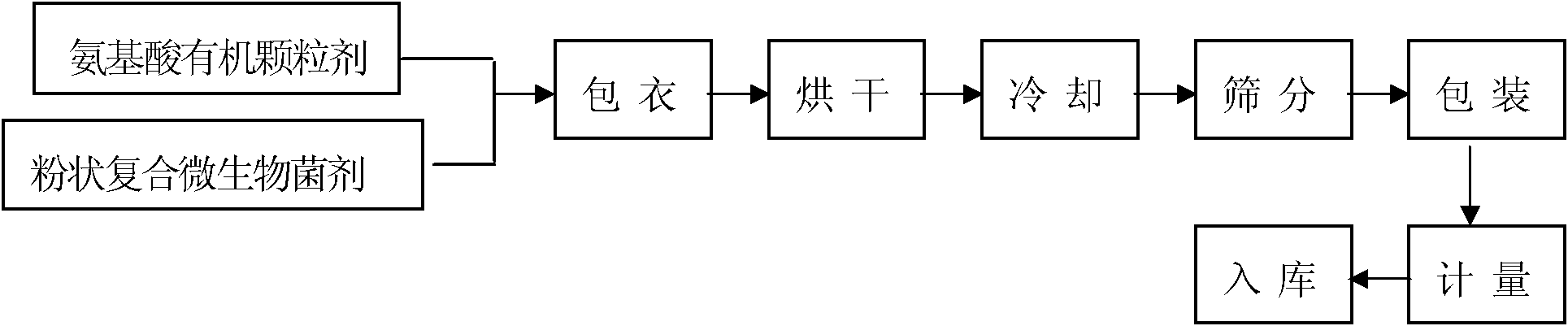

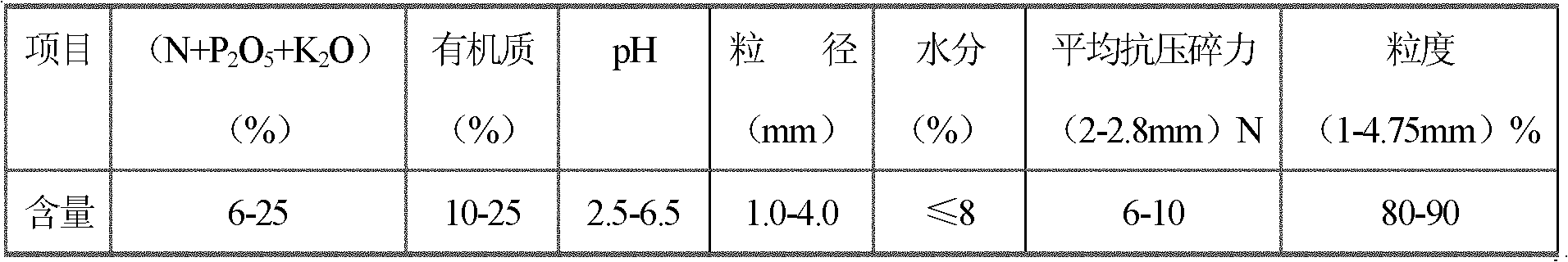

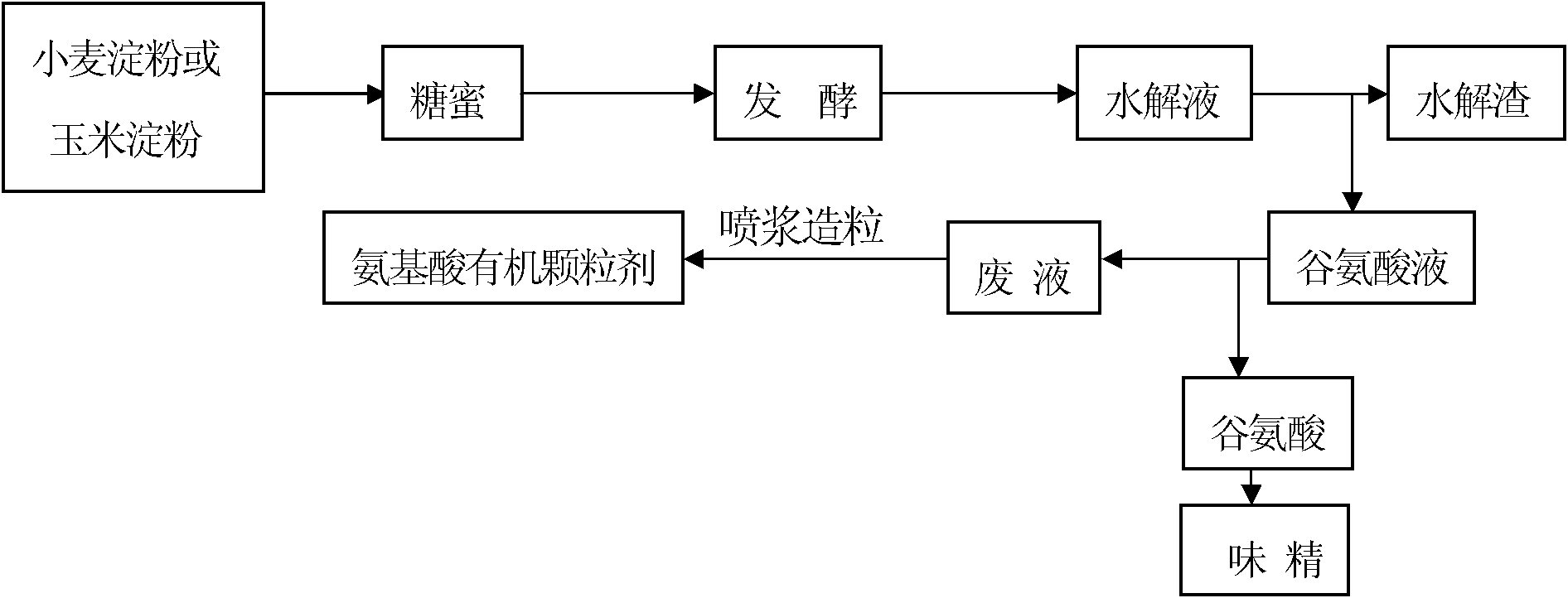

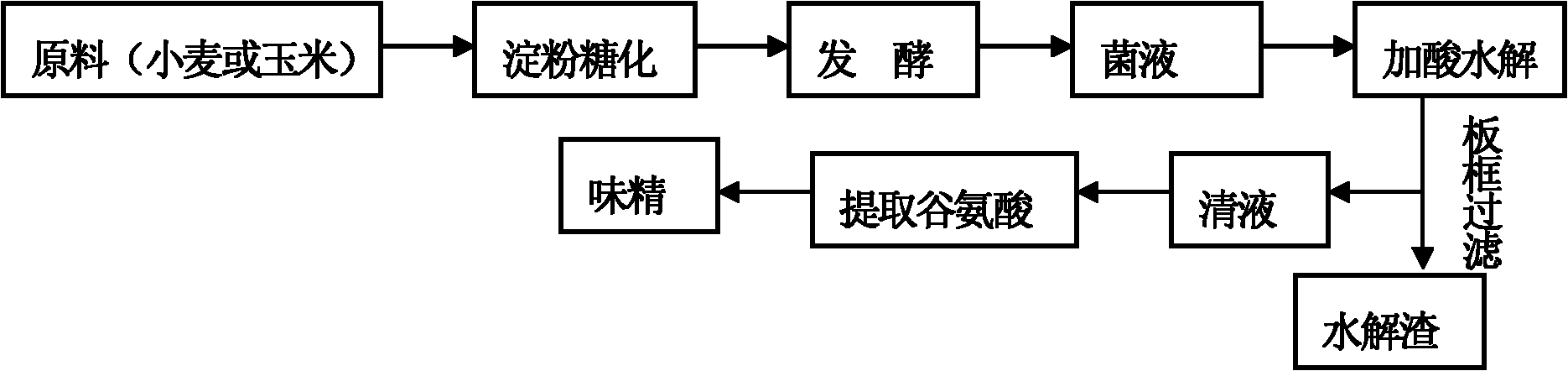

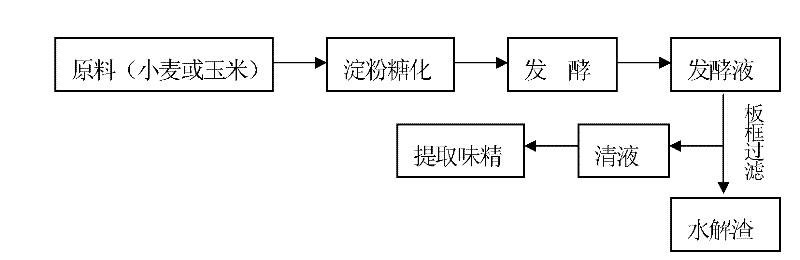

Production method of amino acid complex microorganism fertilizer

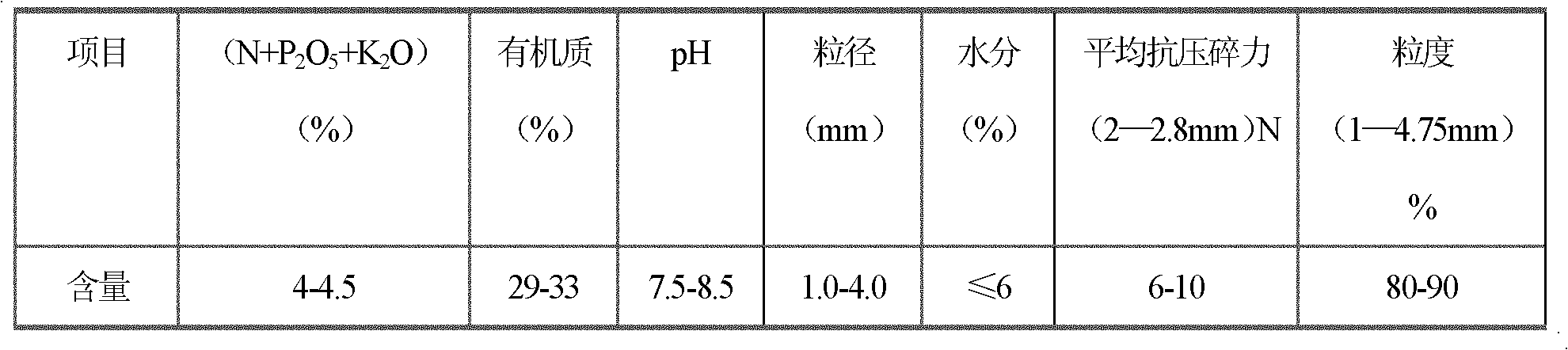

ActiveCN102040407ASolve ball problemSolve solubilityOrganic fertilisersSpray GranulationMicroorganism

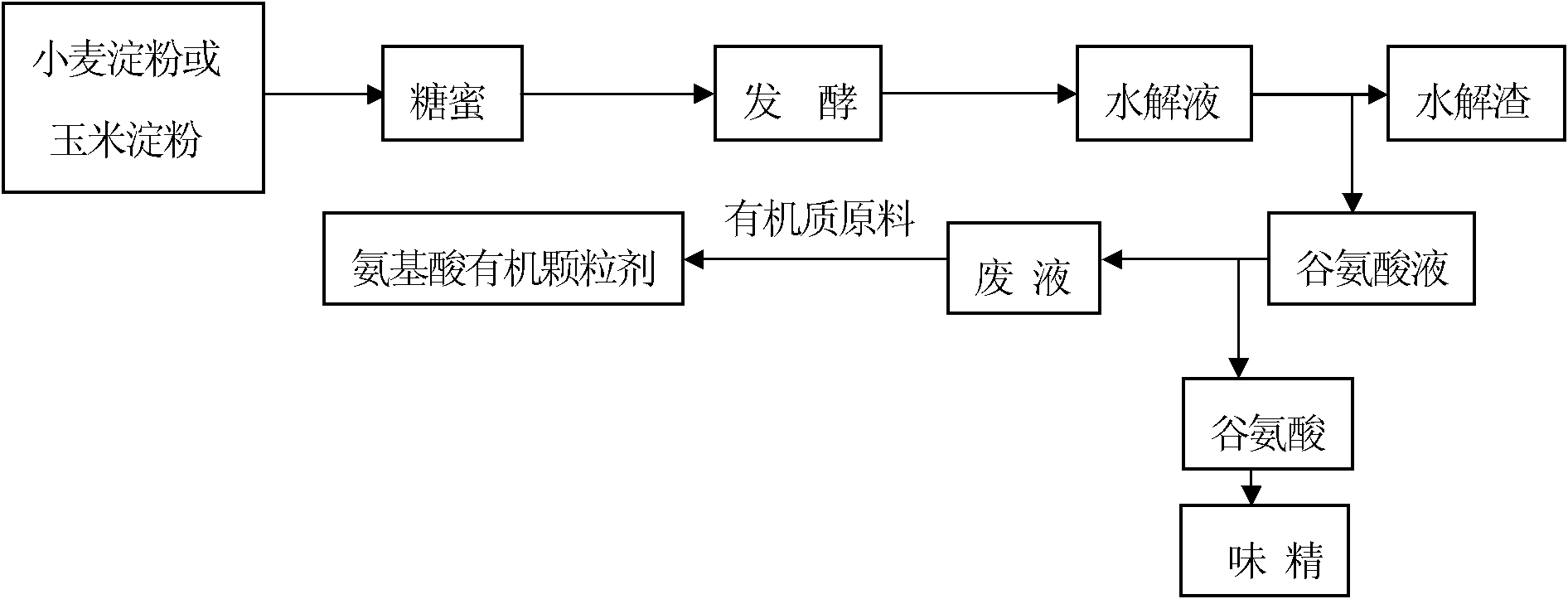

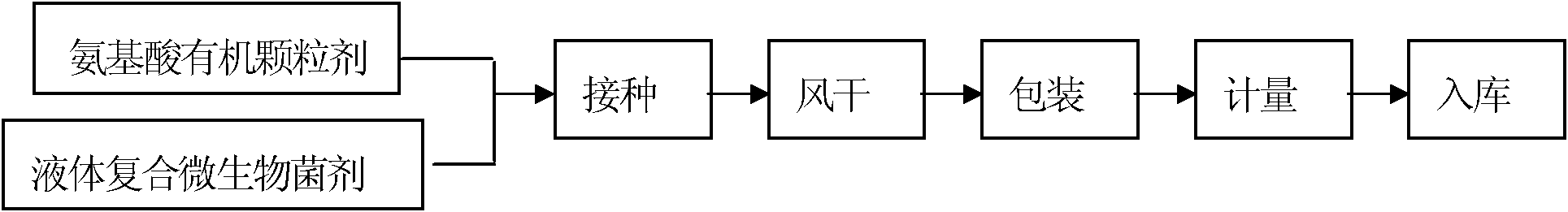

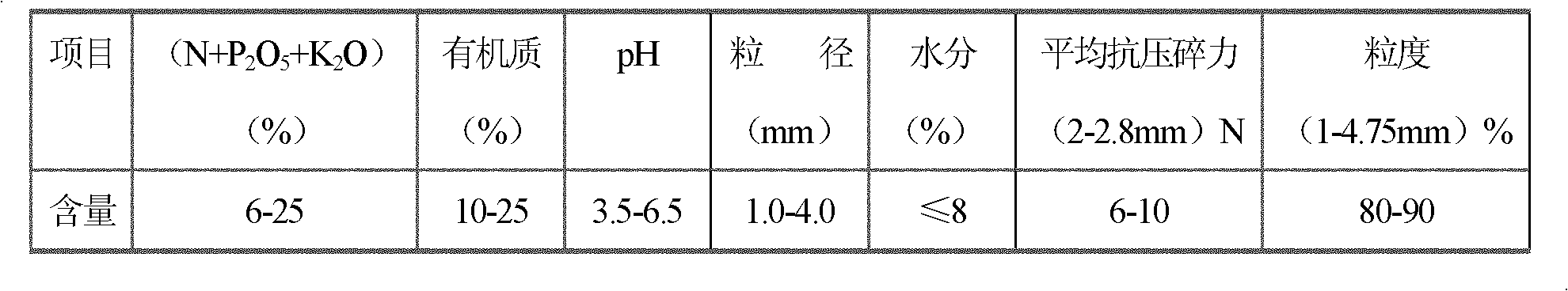

The invention provides a production method of an amino acid complex microorganism fertilizer, in particular to a method for producing an amino acid complex microorganism fertilizer by using amino acid organic granules. The method comprises the following steps: preparing solid inoculant; pelleting amino acida liquid waste into organic granules; compounding the organic granules with solid powders; when compounding, adding powdery inoculant which accounts for 5-15% of the finished product complex microorganism fertilizer at weight ratio; and mixing, pelleting and drying, wherein the material temperature in a drying cylinder is not higher than 80 DEG C. The production method provided by the invention breaks the normal procedure and is divided into two steps of pelleting of the organic granules and the package of the organic granules, as well as ensures viable count in the complex microorganism fertilizer. The production method of the complex microorganism fertilizer provides a new process which realizes the breakthrough of the process from powder pelleting by a disc and a roller to spraying granulation, thus improving commodity and effectiveness of the complex microorganism fertilizer and laying a foundation for popularization.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

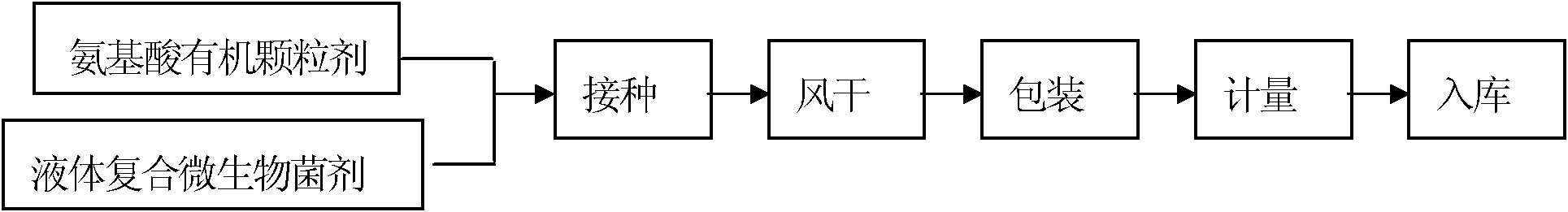

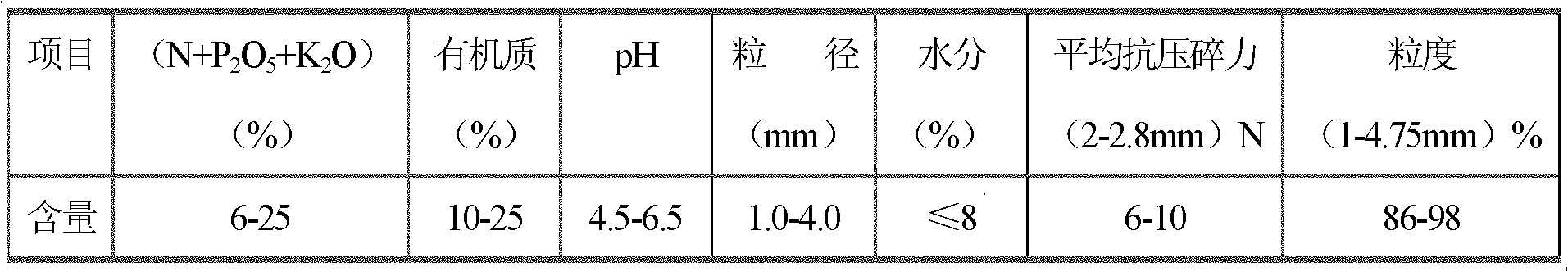

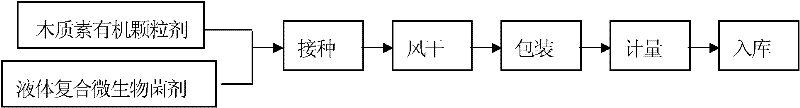

Method for producing compound microbial fertilizer from amino acid organic granules

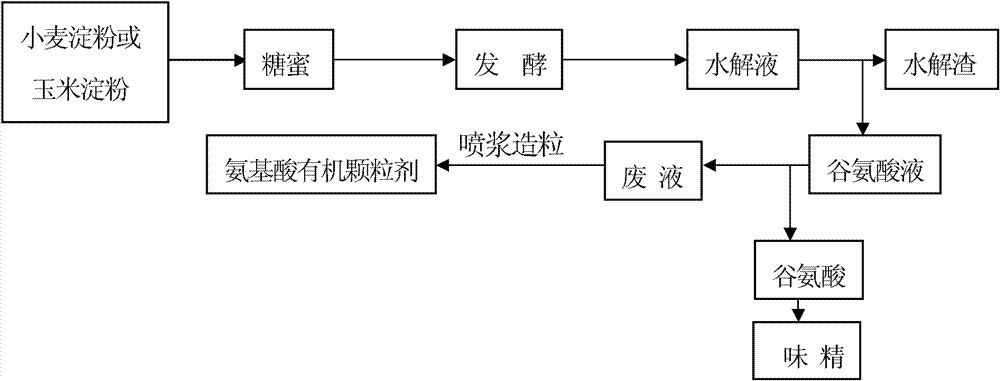

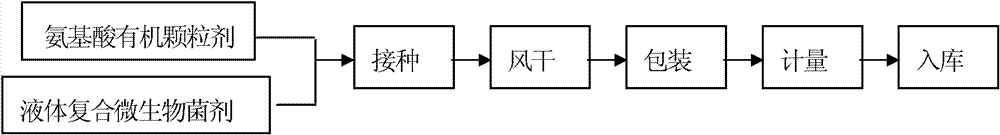

InactiveCN102040406ASimplify the steps of dryingSolve ball problemOrganic fertilisersFertilizer mixturesMicrobial agentSlurry

The invention provides a method for producing compound microbial fertilizer from amino acid organic granules, in particular to a method for producing compound microbial fertilizer by adopting slurry spraying and granulating processes, comprising the following steps: preparing liquid microbial agent, granulating waste amino acid solution into organic granules, and compounding the organic granules with the liquid compound microbial agent, wherein the liquid compound microbial agent is uniformly absorbed on the surfaces of the amino acid organic granules, and fermentation liquid accounts for 0.5-1.5wt% of the finished product of the compound microbial fertilizer. According to the invention, the normal method for producing the compound microbial fertilizer is improved, a novel method for producing the granular compound microbial fertilizer by two steps of granulating waste amino acid solution into organic granules and absorbing the liquid compound microbial agent by the amino acid organic granules is provided, and the number of viable bacteria in the compound microbial fertilizer is ensured. The production of the compound microbial fertilizer by the slurry spraying and granulating processes breaks through the production of the powdery compound microbial fertilizer by the disc and roller granulating process, thus a good foundation is laid for improving the commodity value, effectiveness and large-area popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

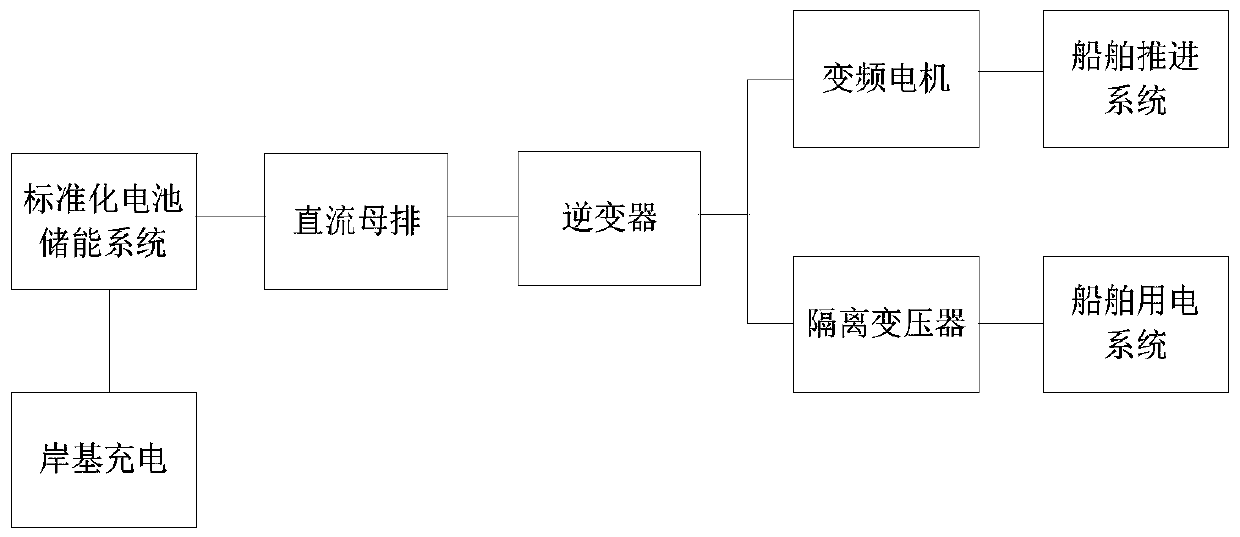

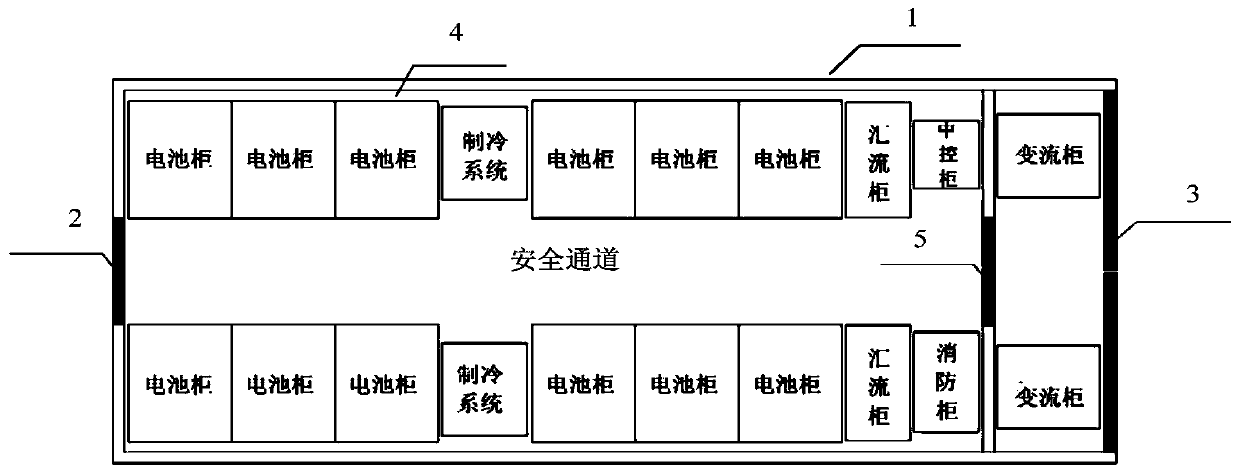

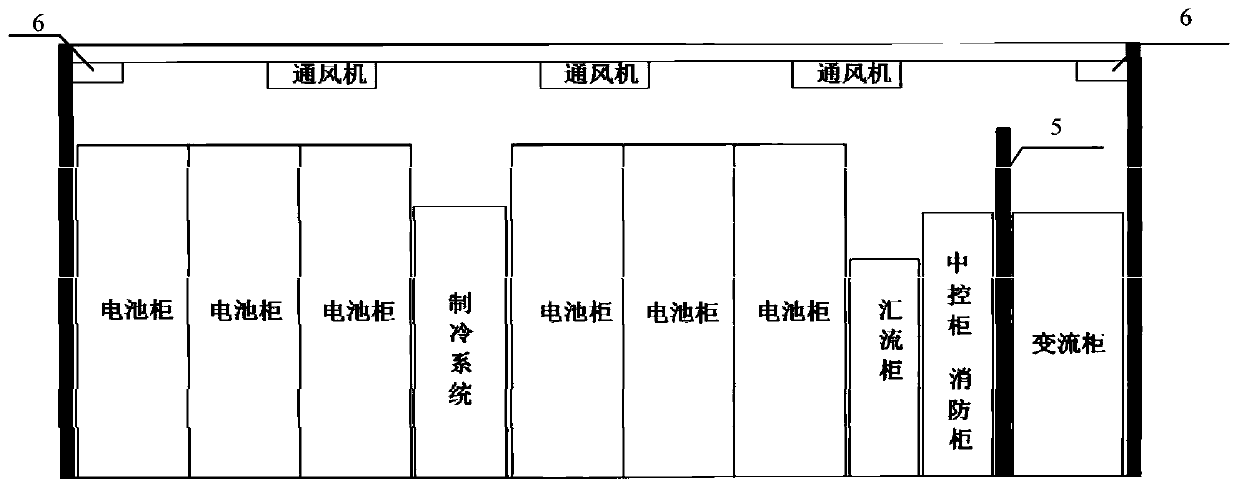

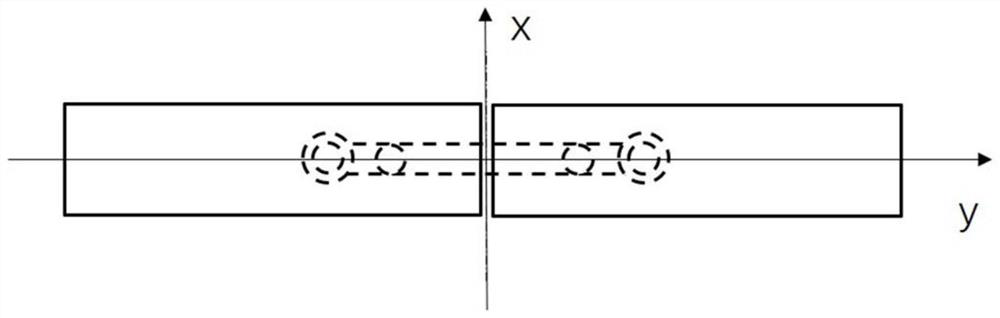

Inland river container ship system based on standardized battery energy storage system

PendingCN110481748ASave spaceNo noise pollutionAuxillariesPropulsion power plantsAutomotive engineeringDistribution power system

The invention discloses an inland river container ship system based on a standardized battery energy storage system, and relates to the technical field of ships; the system includes: a standardized battery energy storage system and a ship power distribution system. The standardized battery energy storage system comprises a container body adopting a standard freight container size, and battery cabinets, a refrigeration system, a confluence cabinet, a converter cabinet, a central control cabinet and a fire-fighting cabinet which are arranged in the container body; the battery cabinets are connected into the confluence cabinet in parallel, the confluence cabinet outputs the confluence to the converter cabinet after confluence, and the standardized battery energy storage system is connected with a direct-current busbar of the ship power distribution system through the converter cabinet for power output and supplies power to a ship propulsion system and a ship power utilization system. Thestandardized battery energy storage system takes the standard freight container as a carrier, so that the cabin arrangement space is saved, and shore-based charging or direct replacement can be carried out on the standardized battery energy storage system; and internal equipment can realize mutual communication, so that the safety of the internal equipment and the environment is ensured, and the goal of 'zero emission' of the ship is achieved while sufficient power of the ship is met.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

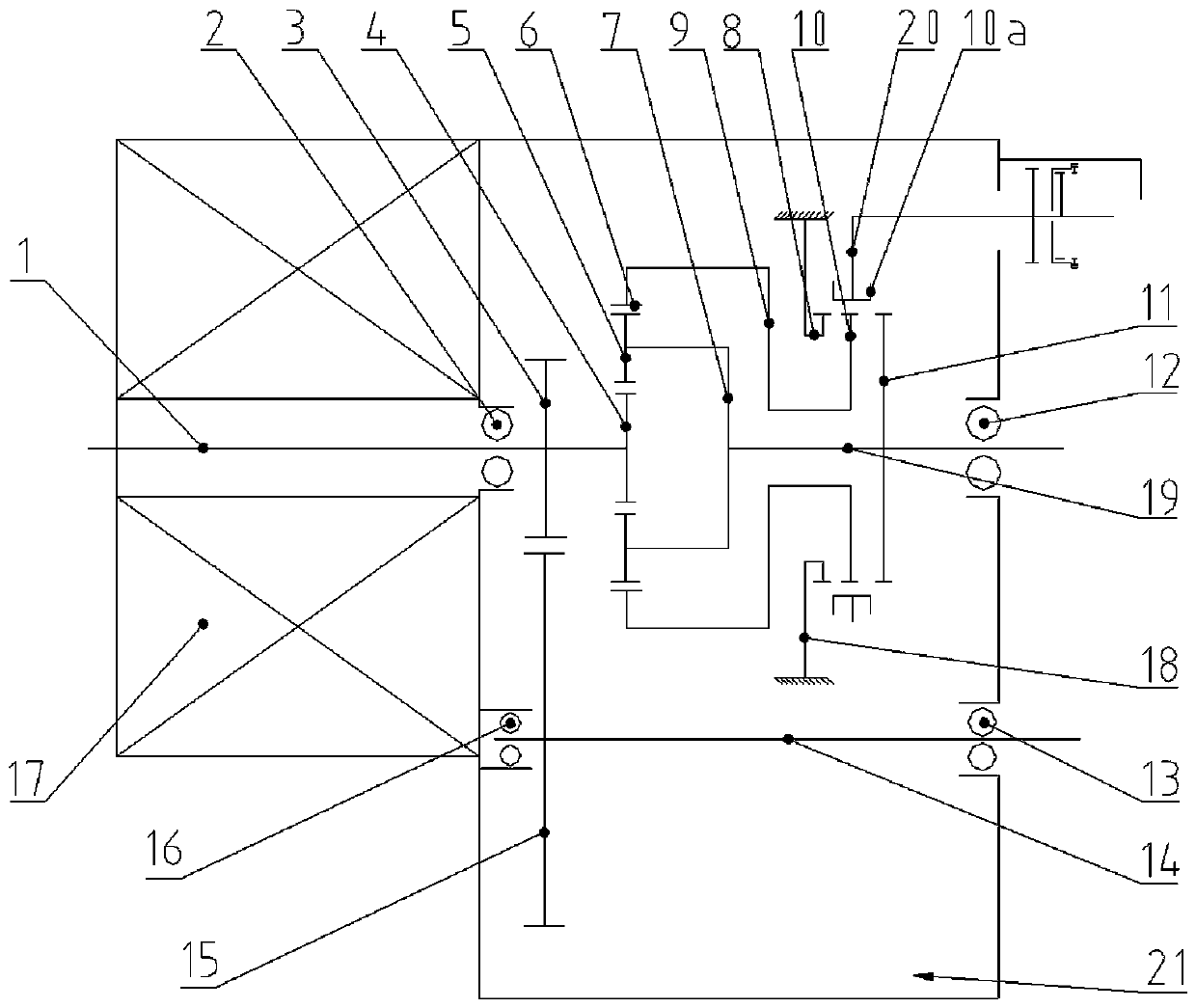

Two-gear planet row transmission of pure electric vehicle

InactiveCN107906174AEliminate emission pollutionReduce manufacturing costControlled membersToothed gearingsLow speedGear wheel

The invention discloses a two-gear planet row transmission of a pure electric vehicle. An input shaft, fixed with a sun gear, is supported in a transmission shell; one end of the input shaft outwardsextends to connect with a motor rotor; an output shaft is supported in the transmission shell; a planet carrier is fixedly arranged on the output shaft; the sun gear is engaged with a planet gear supported on the planet carrier; a low-speed gear tooth hub is fixedly arranged in the transmission shell; a high-speed gear tooth hub is fixedly arranged on the output shaft; a transmission hub idly sleeves the output shaft; an inner gear ring is arranged at one end of the transmission hub for engaging with the planet gear; the other end of the transmission hub is in spline fit with a synchronizer; ajoint sleeve of the synchronizer can axially move to join the synchronizer with the low-speed gear tooth hub or joint the synchronizer with the high-speed gear tooth hub for power transfer; a takeoffoutput shaft is supported in the transmission shell; a takeoff driven gear is fixedly arranged on the takeoff output shaft; a takeoff driving gear is fixedly arranged on an input shaft; and the takeoff driving gear is engaged with the takeoff driven gear to transfer takeoff output power. The transmission is compact in structure, and can realize takeoff output.

Owner:QIJIANG GEAR TRANSMISSION

Zero discharging system for cement kiln clinker cooling machine waste gas

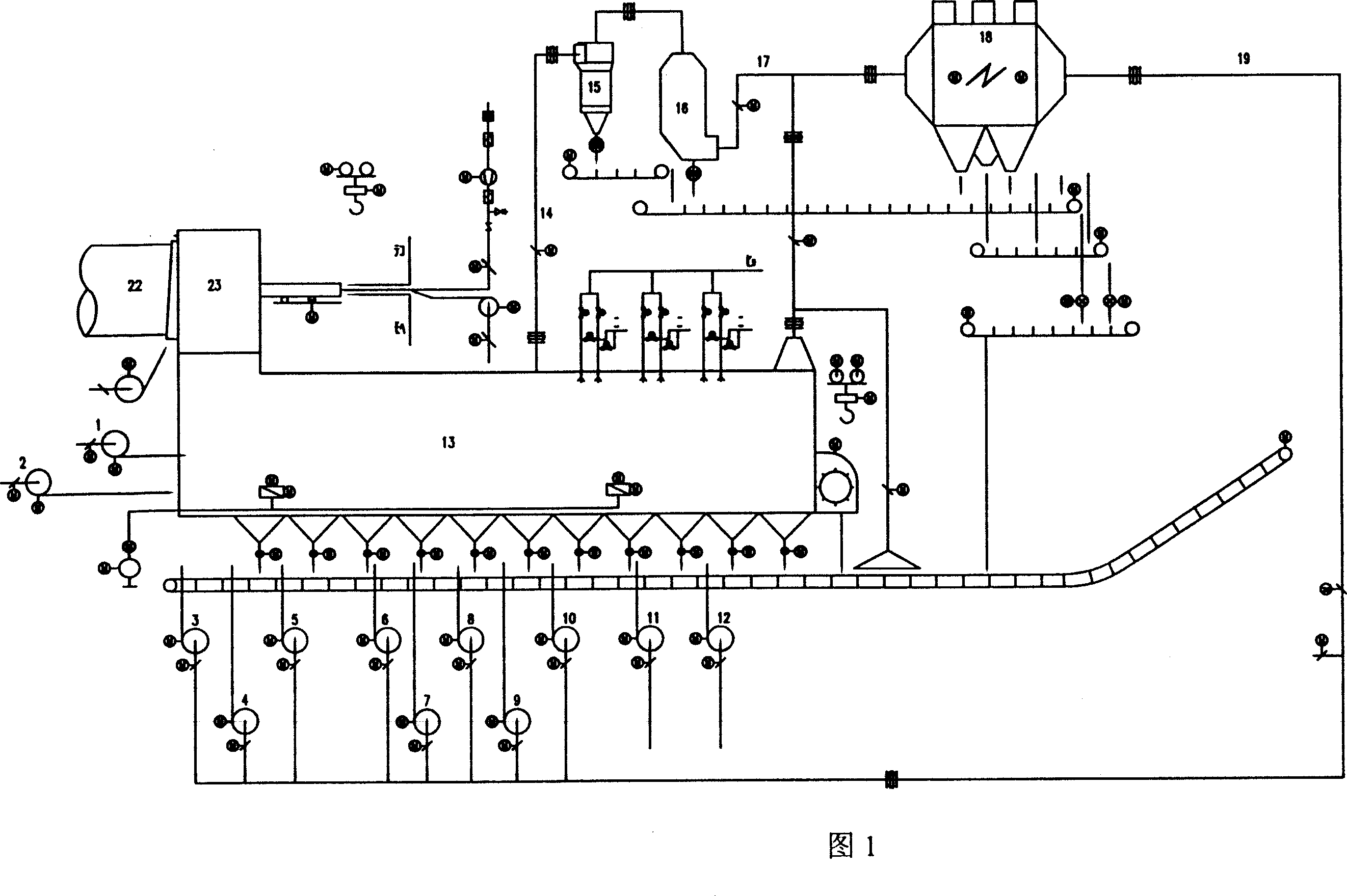

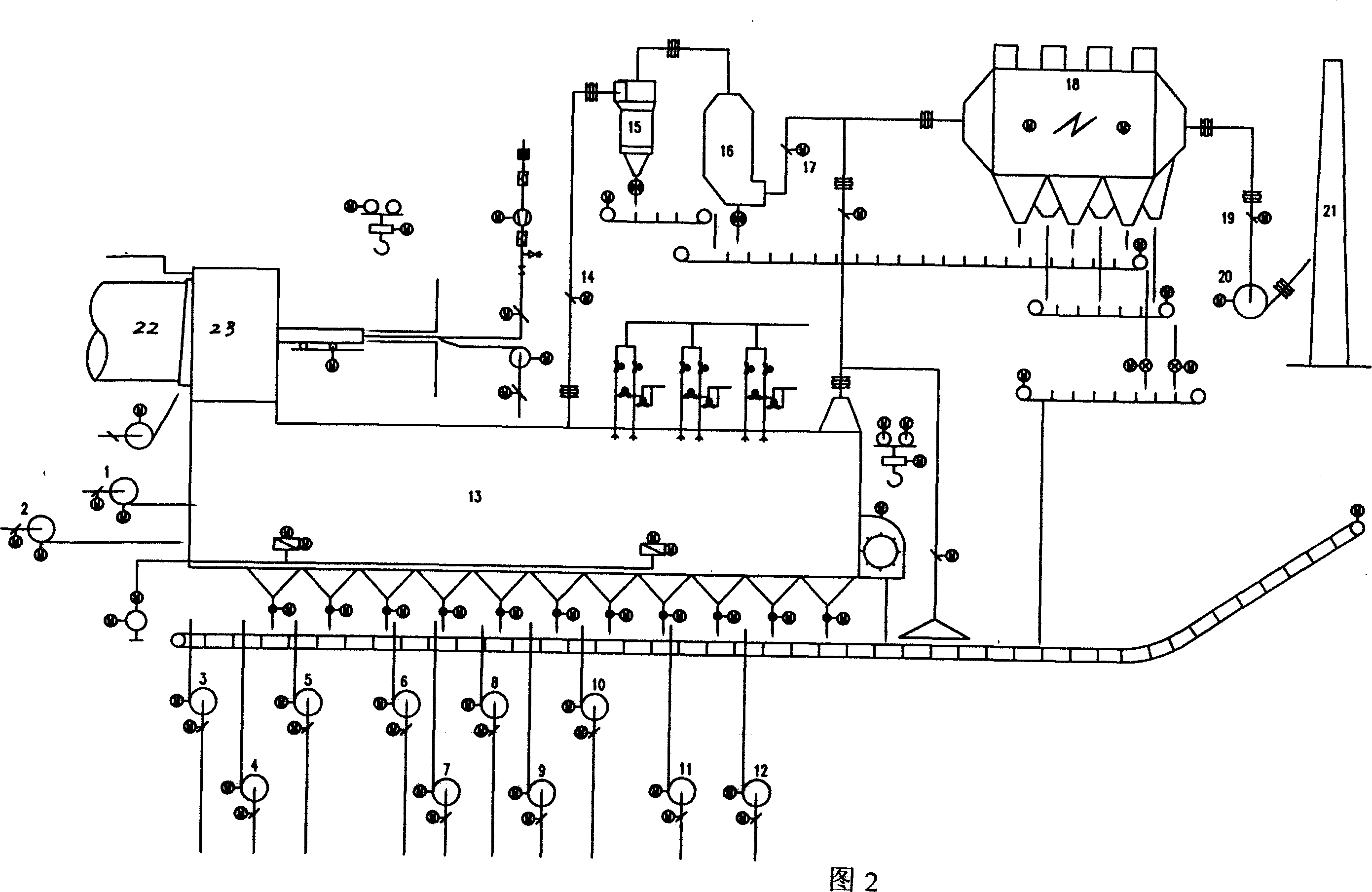

InactiveCN1945184AEliminate emission pollutionIncrease temperatureRotary drum furnacesFurnace coolingExhaust fumesEngineering

The present invention is zero discharging clinker cooling machine system of cement kiln has one comb type cooling machine with comb type cooling bed connected to the clinker outlet of rotary cement kiln, cooling blowers below the comb type cooling bed, hot blast outlet of the comb type cooling machine connected to the inlet of the rotary kiln, pre-duster connected to the hot blast outlet of the comb type cooling machine via pipeline, afterheat boiler connected to the outlet of the pre-duster, and duster with inlet connected through pipeline to the outlet of the afterheat boiler and outlet connected via pipeline to the inlets of partial blowers. The present invention has the advantages of no waste gas exhaust, relaxed requirement on dedusting apparatus, no environmental pollution, and raised afterheat utilization.

Owner:南京圣火环境科技有限公司

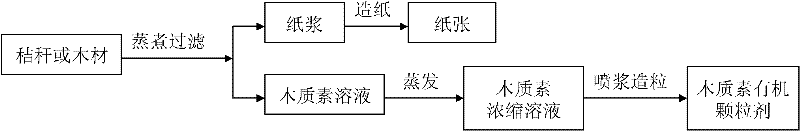

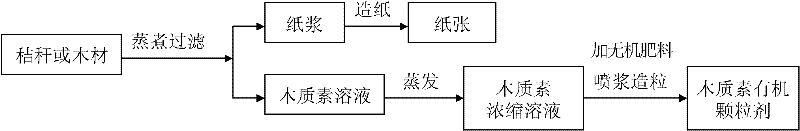

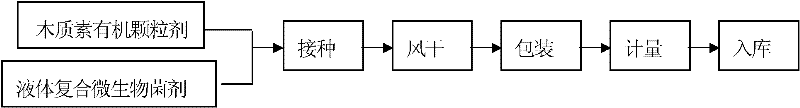

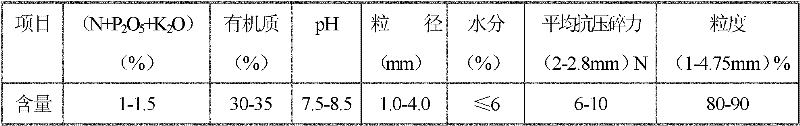

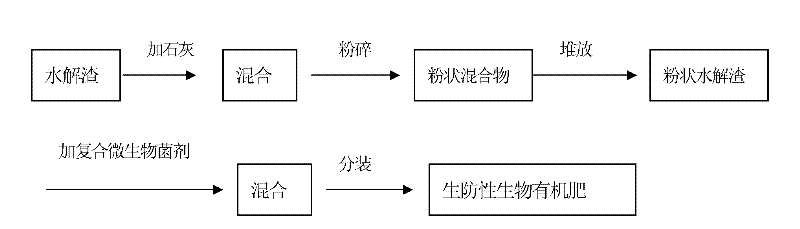

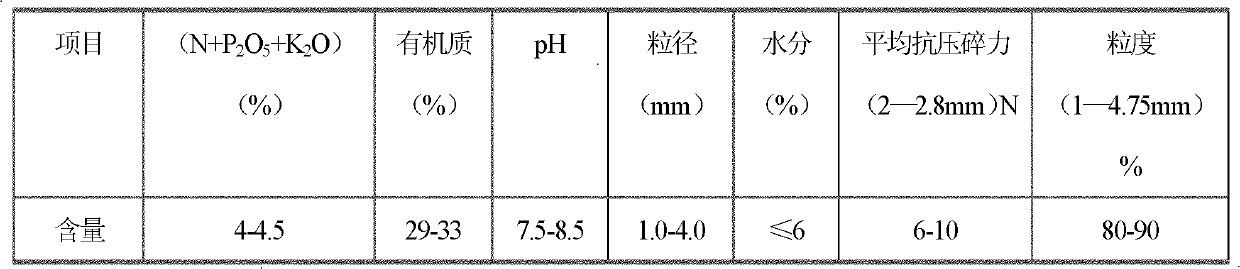

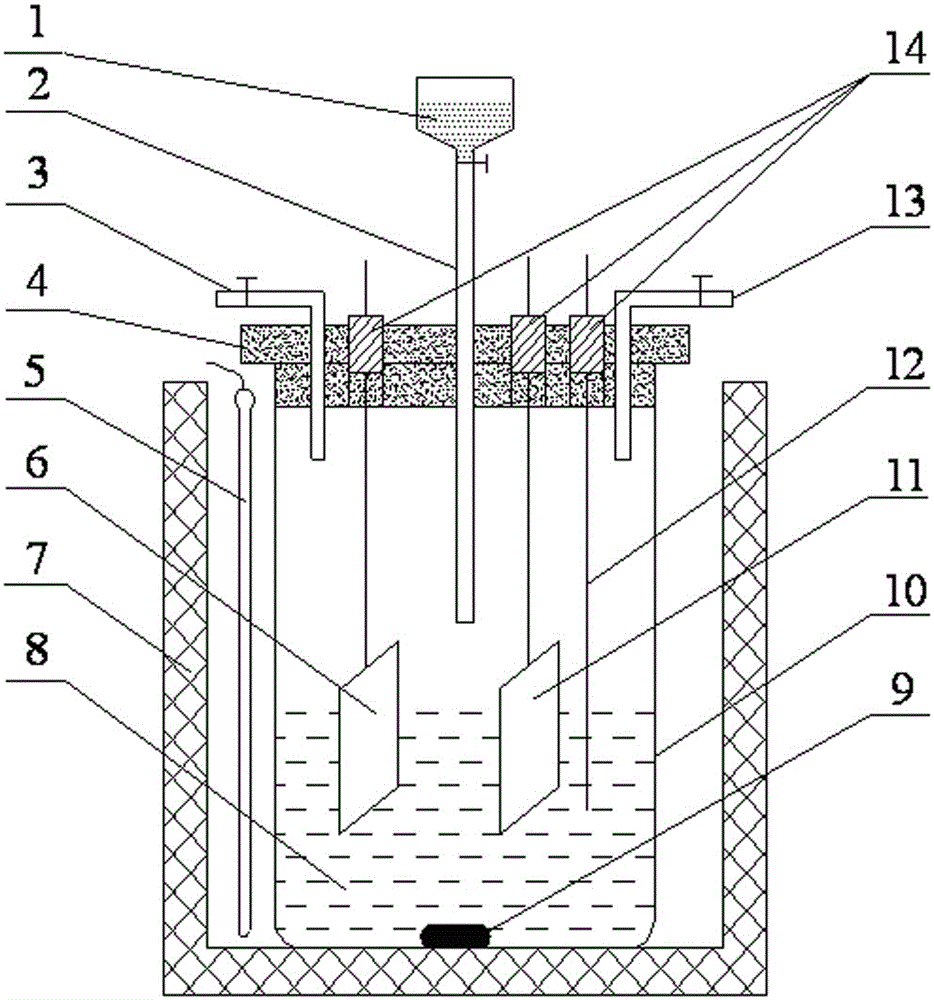

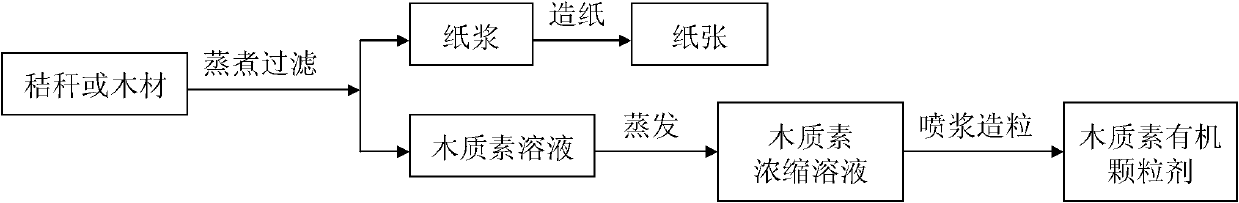

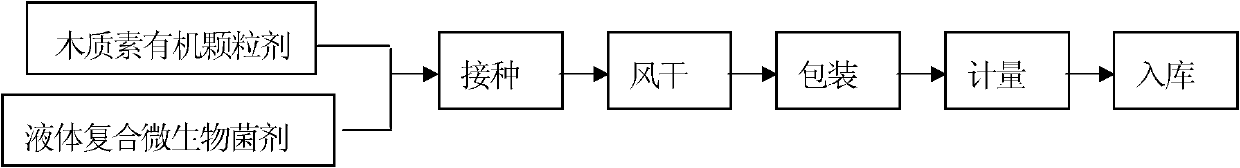

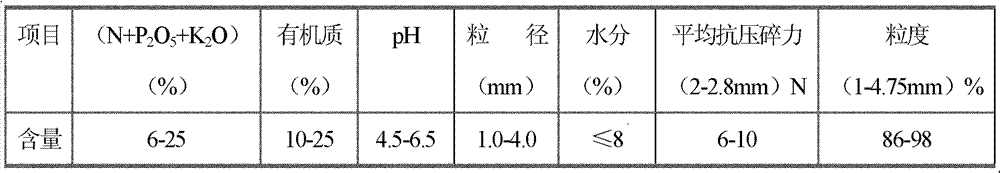

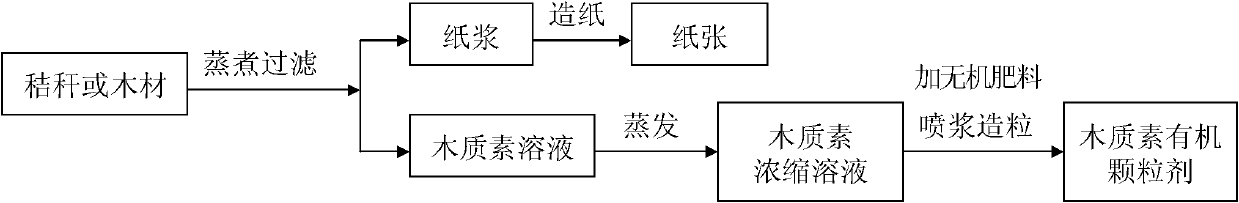

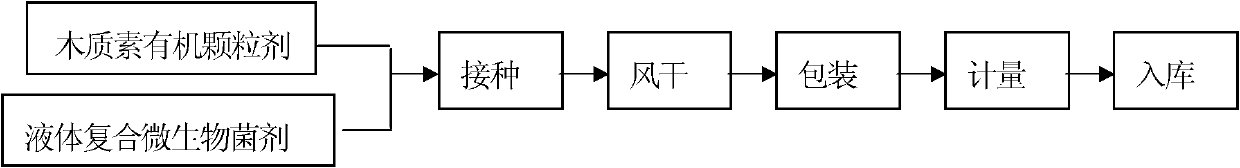

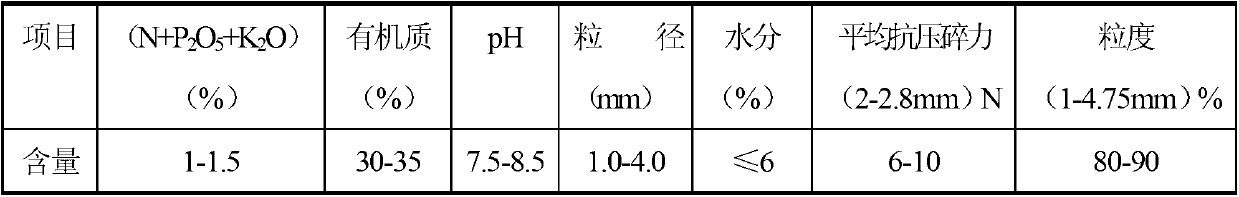

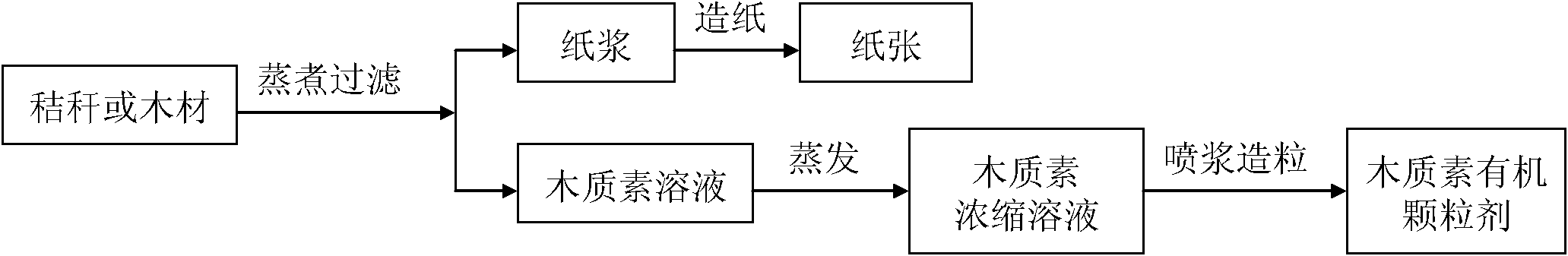

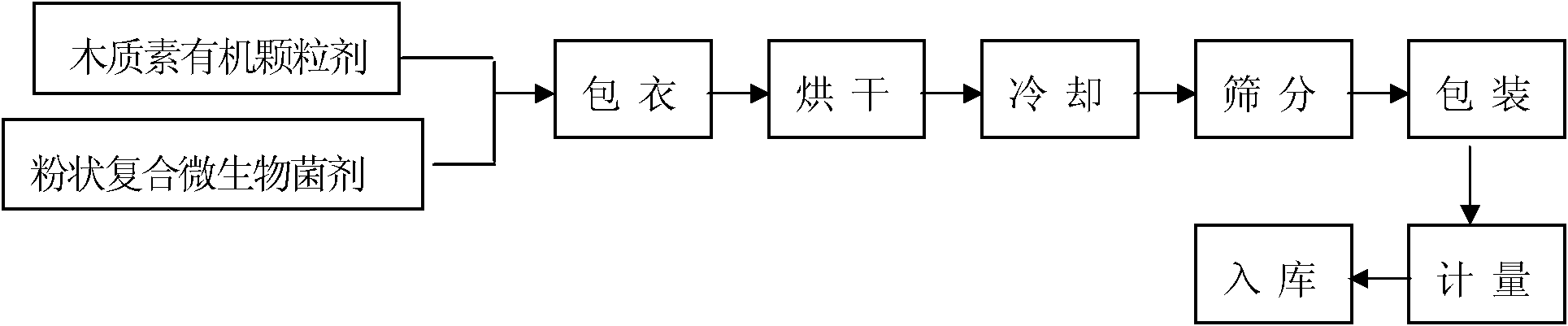

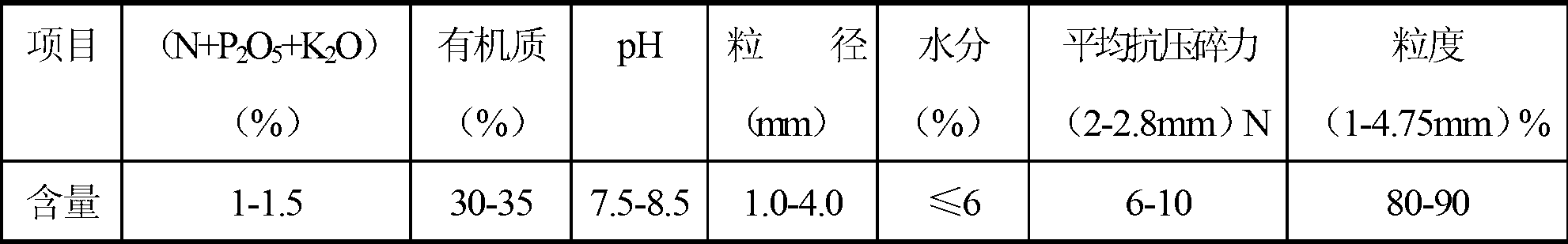

Method for producing bio-organic fertilizer by using lignin organic granules

InactiveCN102442847AFully reuseEliminate emission pollutionOrganic fertilisersFertilizer mixturesParticulatesSpray Granulation

The invention provides a method for producing a bio-organic fertilizer by using lignin organic granules. The method provided by the invention comprises steps of: preparing a liquid inoculant, preparing a lignin black liquor into an organic particulate agent by spraying granulation, and compounding the organic granules and the liquid composite inoculant, wherein the liquid composite inoculant which accounts for 0.5-1.5% of the weight of the finished product composite microbial fertilizer is added. The production of the bio-organic fertilizer can be completed by bacterial liquid permeation intoorganic particles and the technical requirement of the product can be reached without drying. According to the invention, routines are broken by creative introduction of the spraying granulation method into the biological fertilizer granulation technology. The production method of the particulate bio-organic fertilizer is divided into two steps of spraying granulation of the organic granules and organic granule wrapping or inoculant adsorption. In the meanwhile, a certain activity of the bio-organic fertilizer is maintained. According to the bio-organic fertilizer product, the breakthrough from a powder form to spray particles is realized, thus laying a foundation for the extensive popularization of the bio-organic fertilizer.

Owner:北京世纪大德环保科技有限公司

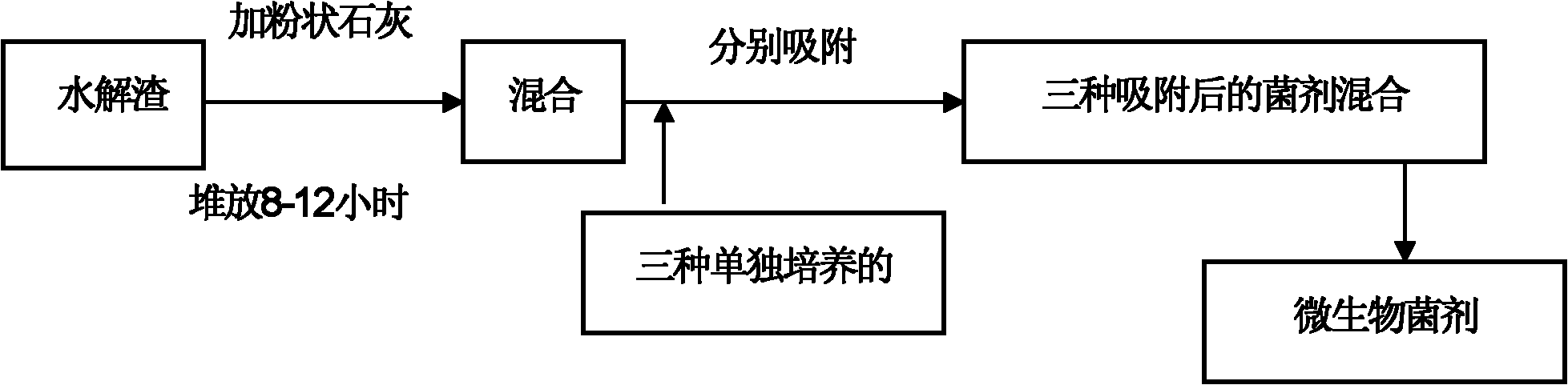

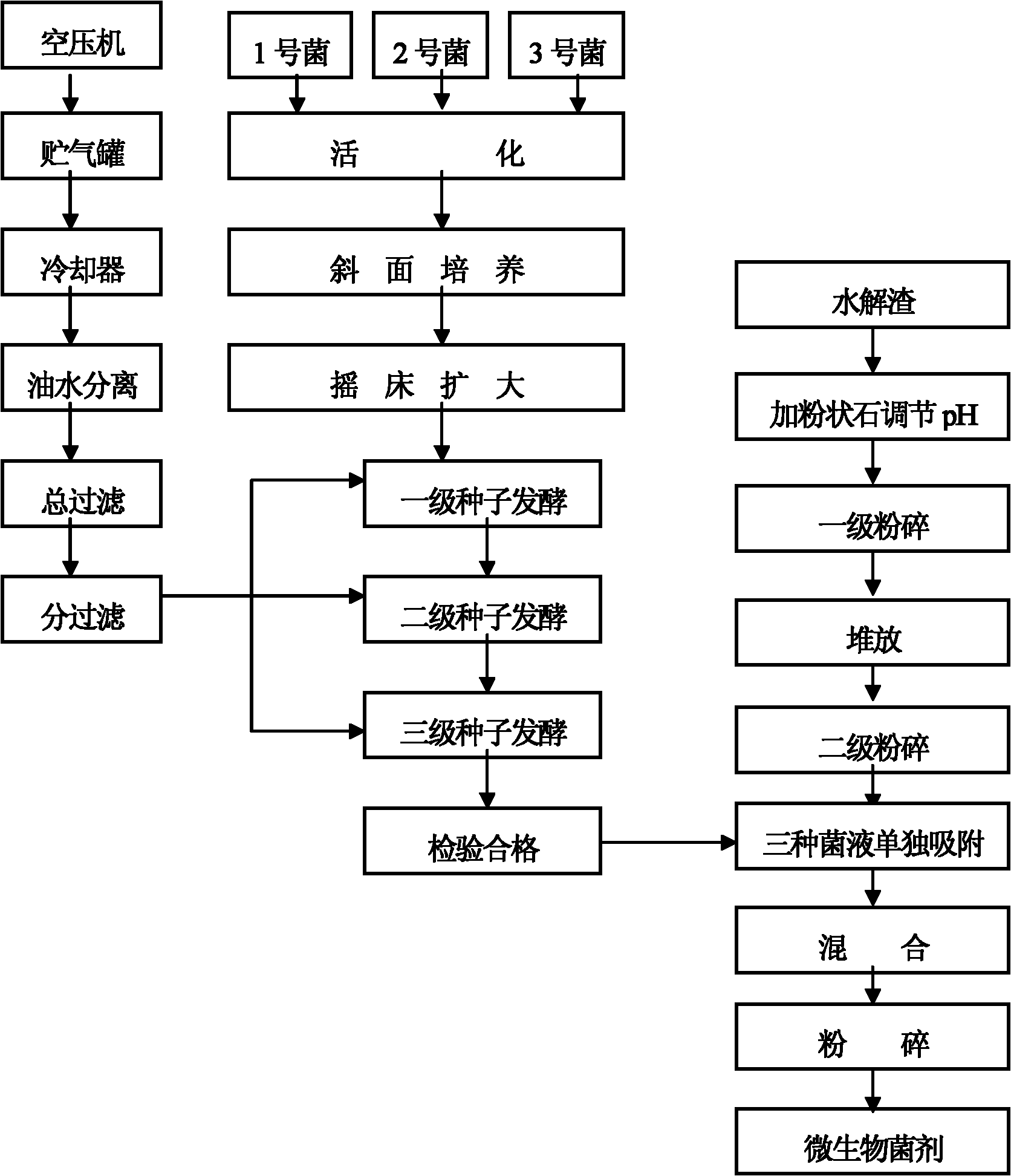

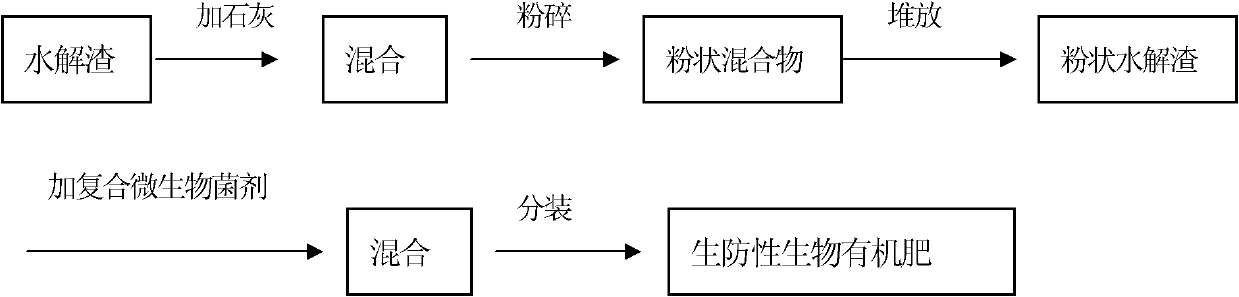

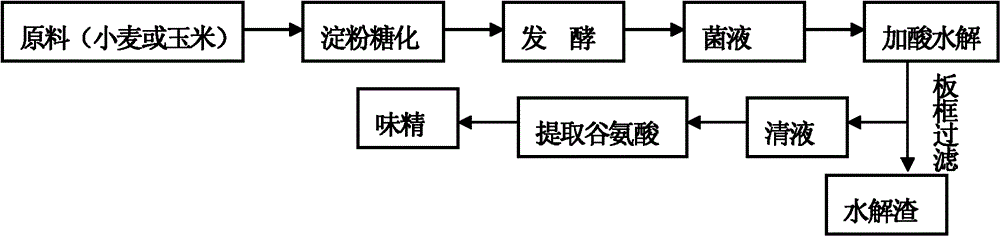

Production method of microbial inoculum

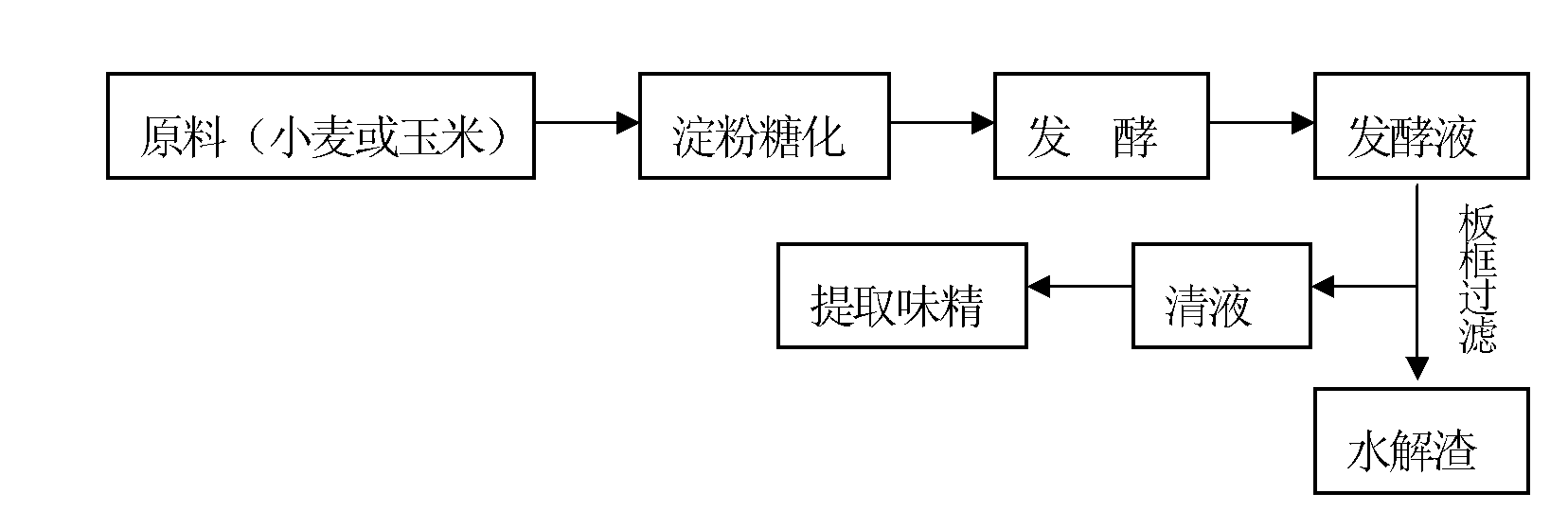

ActiveCN102174443AShort storage timePromote growthBacteriaMicroorganism based processesMicroorganismBacillus megaterium

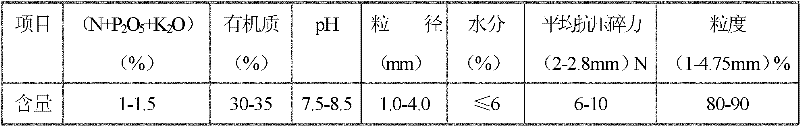

The invention provides a production method of microbial inoculum and the method contains the fermentation and adsorption of the strain. The method comprises the following steps: utilizing treated hydrolysis residue as a bacterium solution adsorption medium to absorb the fermented bacterium solution of one or more of Bacillus subtilis, Bacillus megaterium and Bacillus mucilaginous krassilm, wherein the weight ratio of the bacterium solution to the hydrolysis residue is 0.3:(2-4); and then mixing and crushing, thus obtaining the microbial inoculum. The invention provides a new powdery microbial inoculum adsorption carrier, and the carrier contains various nutrients for microbial growth, is favorable for microbial proliferation and growth and is environmentally-friendly and low in price.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Method for producing compound microbial fertilizer with microbial inoculum permeation and adsorption method

ActiveCN102442859AFlat surfaceHigh technical contentFertiliser formsFertilizer mixturesSpray GranulationBlack liquor

The invention provides a method for producing a compound microbial fertilizer with a microbial inoculum permeation and adsorption method. The method comprises the following steps of: preparing a liquid microbial inoculum; preparing a lignin black liquor into organic granules by performing spraying granulation; and compounding the organic granules with a liquid compound microbial inoculum, whereinthe l inoculum; preparing a lignin black liquor into organic granules by performing spraying granulation; and compounding the organic granules with a liquid compound microbial inoculum is added in anamount of 0.5-1.5 percent by weight based on the total weight of a finished compound microbial fertilizer. Production of the compound microbial fertilizer is completed with a method for making a bacterial liquid permeate into the organic granules, and the technical requirements of a product can be met without drying. In the invention, a new path is opened, the convection is broken, a production method of a granular compound microbial fertilizer is partitioned into an organic granule granulating step and an organic granule coating step, a certain viable count in the compound microbial fertilizer is ensured simultaneously, breakthrough of a compound microbial fertilizer product from powdery granules to spraying granulation granules is realized, and foundations are laid for large-scale popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

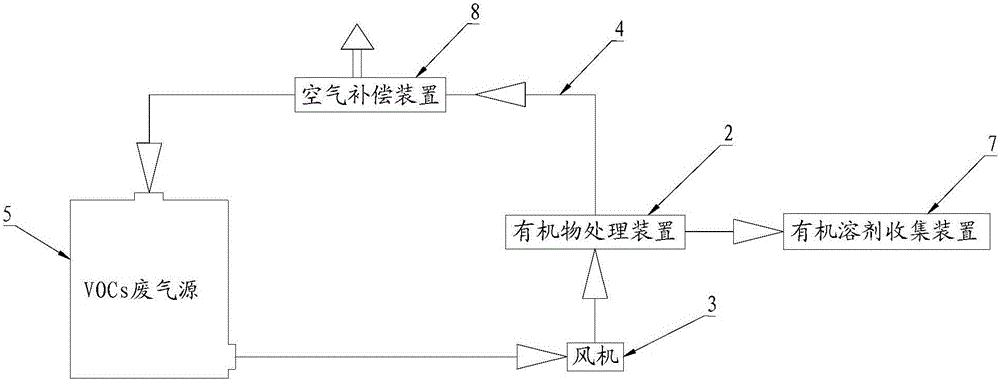

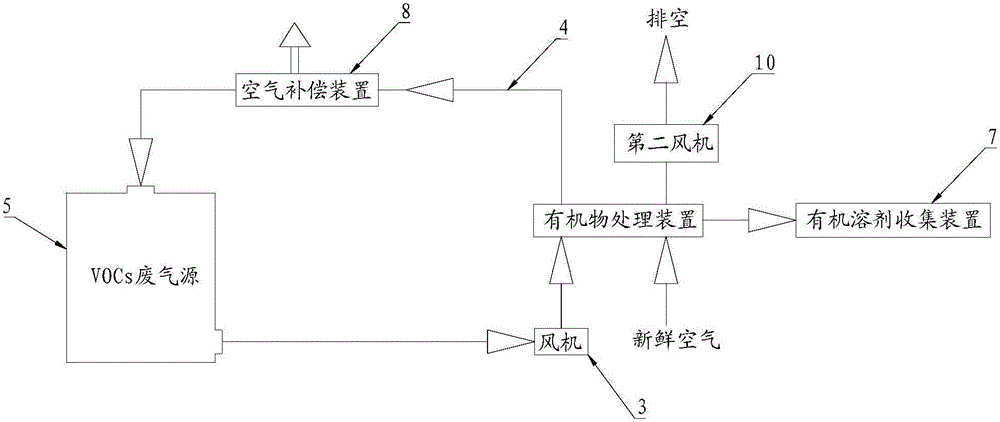

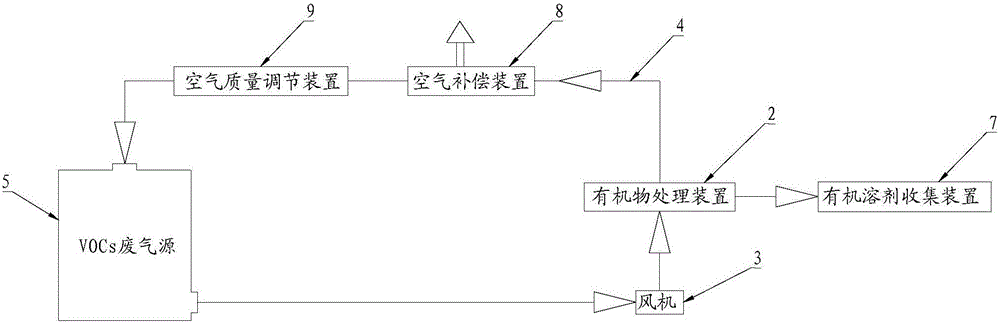

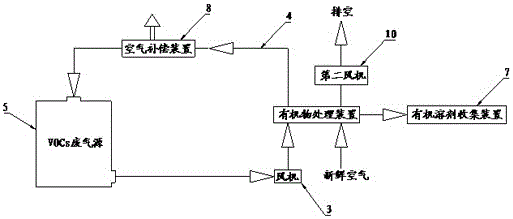

Zero discharge treatment method of VOCs waste gases

InactiveCN105854504AEliminate emission pollutionEasy to handleDispersed particle separationIncinerator apparatusExhaust fumesCombined method

The invention relates to a zero discharge treatment method of VOCs waste gases. The method comprises the following steps: treating organic matters, namely carrying out organic matter treatment on waste gases generated by VOCs waste gas sources, wherein the organic matter treatment adopts one or a combination of more of an assimilation recycling method, an adsorption recycling method, a condensation recycling method, an incineration method, a catalytic incineration method, a plasma method and a biological method to remove VOCs in the waste gases; recycling exhaust gases, namely returning the waste gases subjected to the organic matter treatment to the VOCs waste gas sources. With the adoption of the zero discharge treatment method of the VOCs waste gases, zero discharge of the VOCs waste gases is realized, the technical problem of the zero discharge of the VOCs waste gases which is desired to be solved but cannot be solved by environmental protection equipment manufacturing enterprises over the years is overcome, and emission pollution of the VOCs waste gases to the environment is completely eliminated; the whole treatment process is simple and easy to operate and high in treatment efficiency, requires less equipment, has low energy consumption of the equipment, well meets requirements of modern enterprises on energy saving and emission reduction, improves requirements of production benefits and has great significance on saving resources and reducing costs.

Owner:蔡祥雨

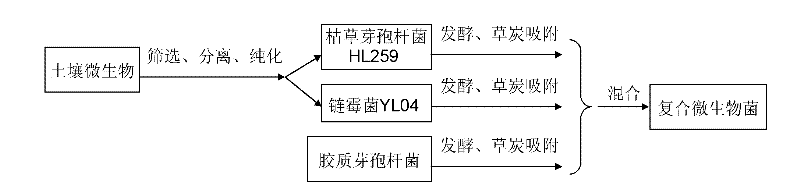

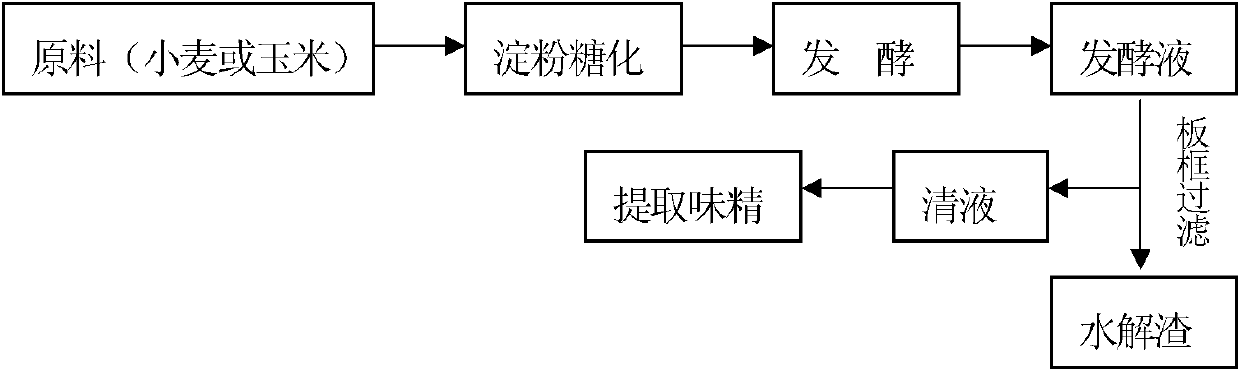

Bio-control bio-organic fertilizer and production method thereof

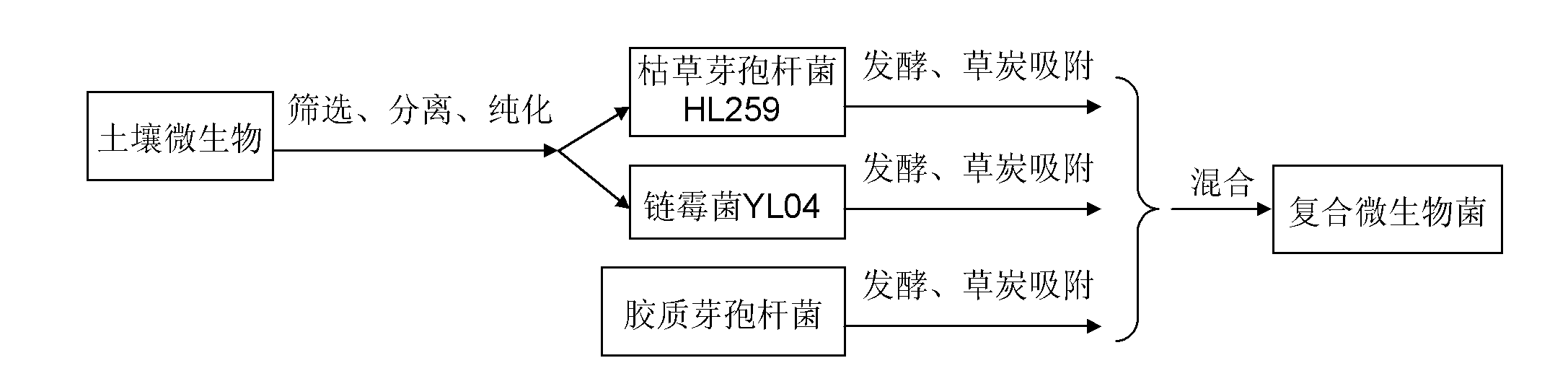

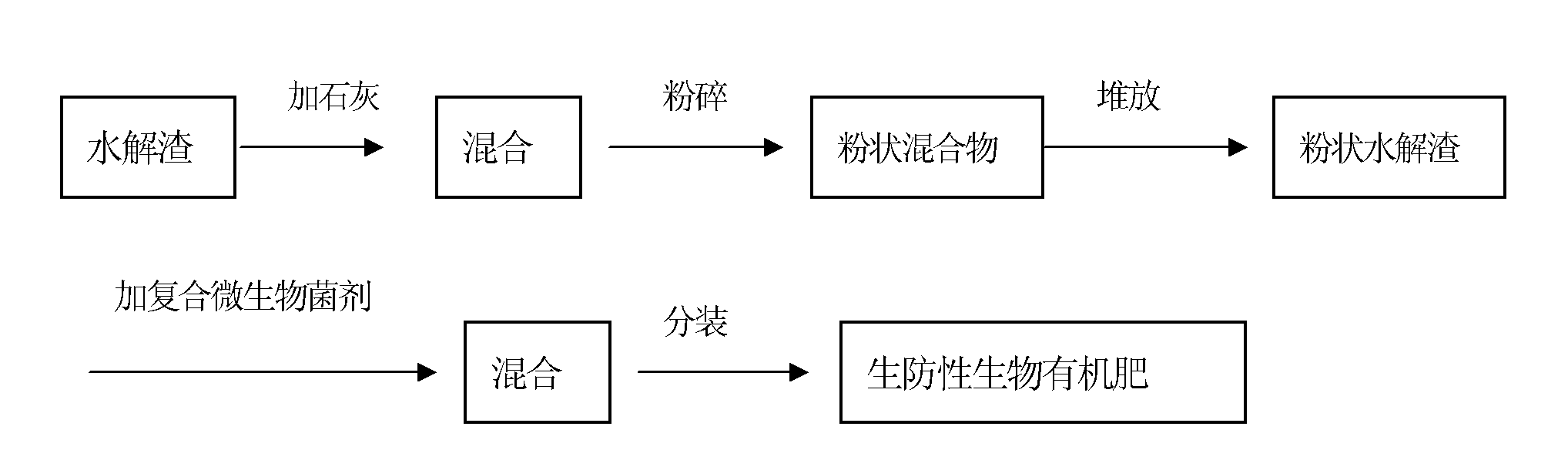

ActiveCN102180709AEliminate emission pollutionThorough governanceClimate change adaptationBioloigcal waste fertilisersDiseasePlant disease

The invention provides a production method of a bio-control bio-organic fertilizer. A microbial inoculum is independently fermented by bio-control bacillus subtilis HL259, bacillus mucilaginosus krassilnikov, and bio-control streptomyces sp. YL04 strains which are mixed according to a mass proportion of 4-5 : 2.5-3.5 : 1-2 after absorption by using an adsorption medium, and then hydrolysis residue and complex microbial community are mixed to obtain the bio-organic fertilizer. The bio-control bio-organic fertilizer can significantly improve the efficiency of bio-fertilizers, has obvious prevention and control effects on diseases of crops, greatly reduces the diseased seedling rate, and can more comprehensively provide nutrients required for crop growth to improve crop yield.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

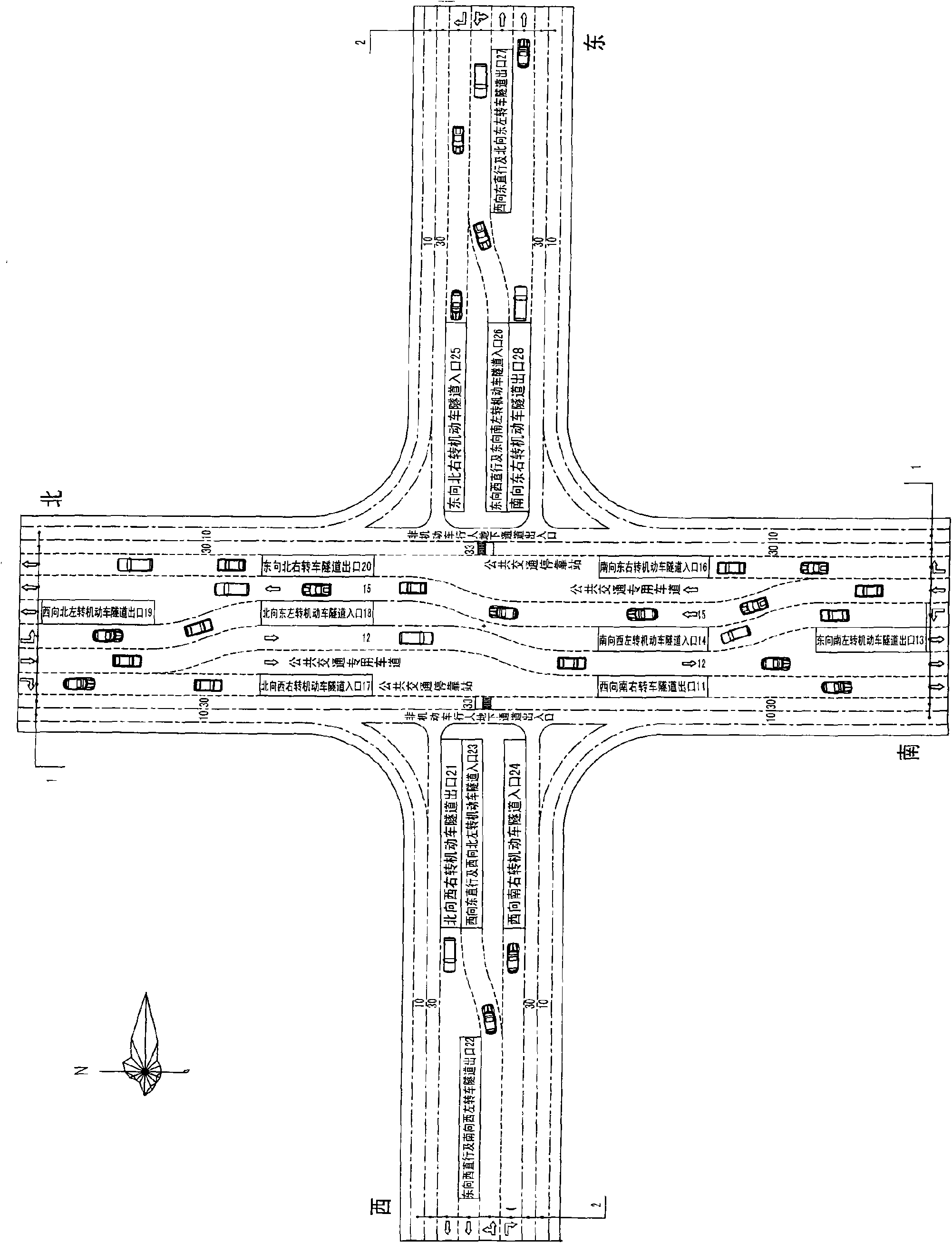

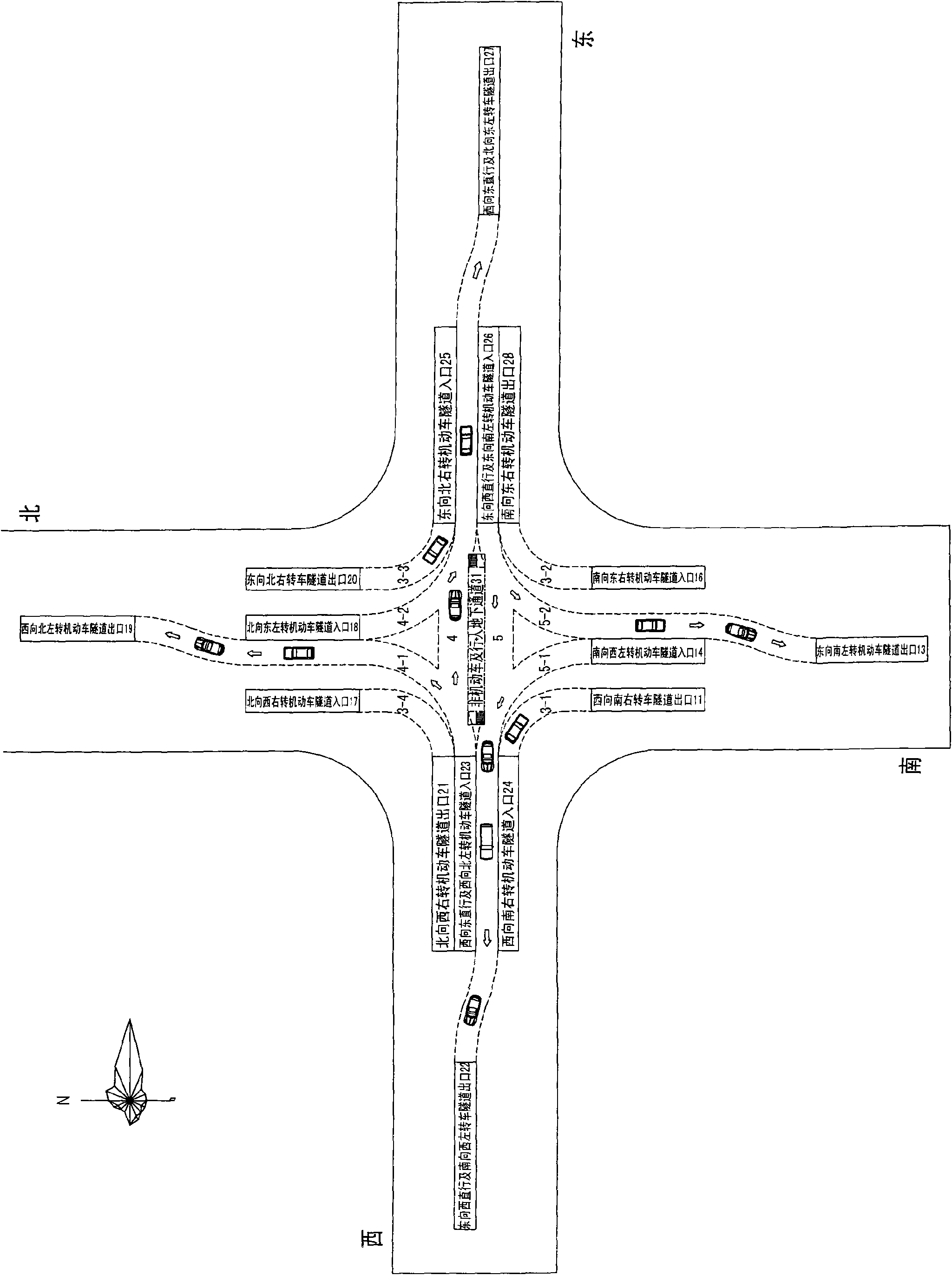

Full-communication and full-orientation three-dimensional traffic system

The invention relates to a full-communication and full-orientation three-dimensional traffic system. In the invention, a main lane (1) takes a carfax as a centre; pedestrian passageways (10) and non-motor lanes (30) are arranged at both sides of the main lane (1); the south end of the main lane (1) sequentially comprises the pedestrian passageway (10), the non-motor lane (30), a motor tunnel exit(11) turning right from west to south, a motor lane (12) going straight from north to south and a motor tunnel exit (13) turning left from east to south from west to east. The invention overcomes theshortcoming that frequent traffic jams for long time exist in the prior road traffic systems. In the invention, motors, non-motors and pedestrians take different roads, thereby completely solving thedifficult problem of scrambling road, greatly reducing the occurrence of traffic accidents and fully embodying the concept of harmonious development.

Owner:王晓京

Engine

InactiveCN101240781ASimple structureLess consumablesPropulsion partsMachines/enginesHydraulic cylinderNet force

An engine belongs to power generating machine without consuming energy sources and discharging contamination. Car body is equispaced with a set of crunode in transverse direction, in which two symmetrical crunode is on piston of crank-connecting rod mechanism, flexibility piece bypasses each crunode, two end of it connect two identical piston of hydraulic cylinder, each piston is communicated with oil recess between hydraulic cylinder shell cover and closed into hydraulic system by a little piston, weight acts on booster input end, larger force of output end is on little piston, hydraulic-oil of hydraulic system produces pressure and compels two piston tend to mobile for tensing flexibility piece, every crunodes are subjected to both sides tension force of flexibility piece, starting motor or car body running rear-wheel spindle drives bent shaft, composite force between tension force of upper crunode of piston which is against car body direction of motion component force and reciprocating mass inertia force of piston side rod acts on crankshaft bearing after crank-connecting rod mechanism converting, component force along car body direction of motion is constant smaller than that of crunode, both tension force composite force of flexibility pieces which is summation or difference of component force is power driving car body moving.

Owner:曹世善

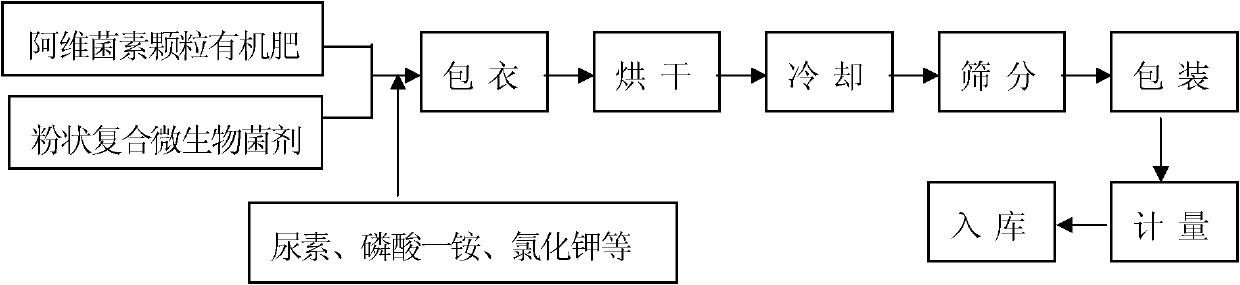

Method for producing compound microbial fertilizer by microbial inoculum packing method

ActiveCN102040434BReduce manufacturing costSolve the production processFertilizer mixturesAgricultural engineeringAbamectin

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

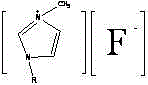

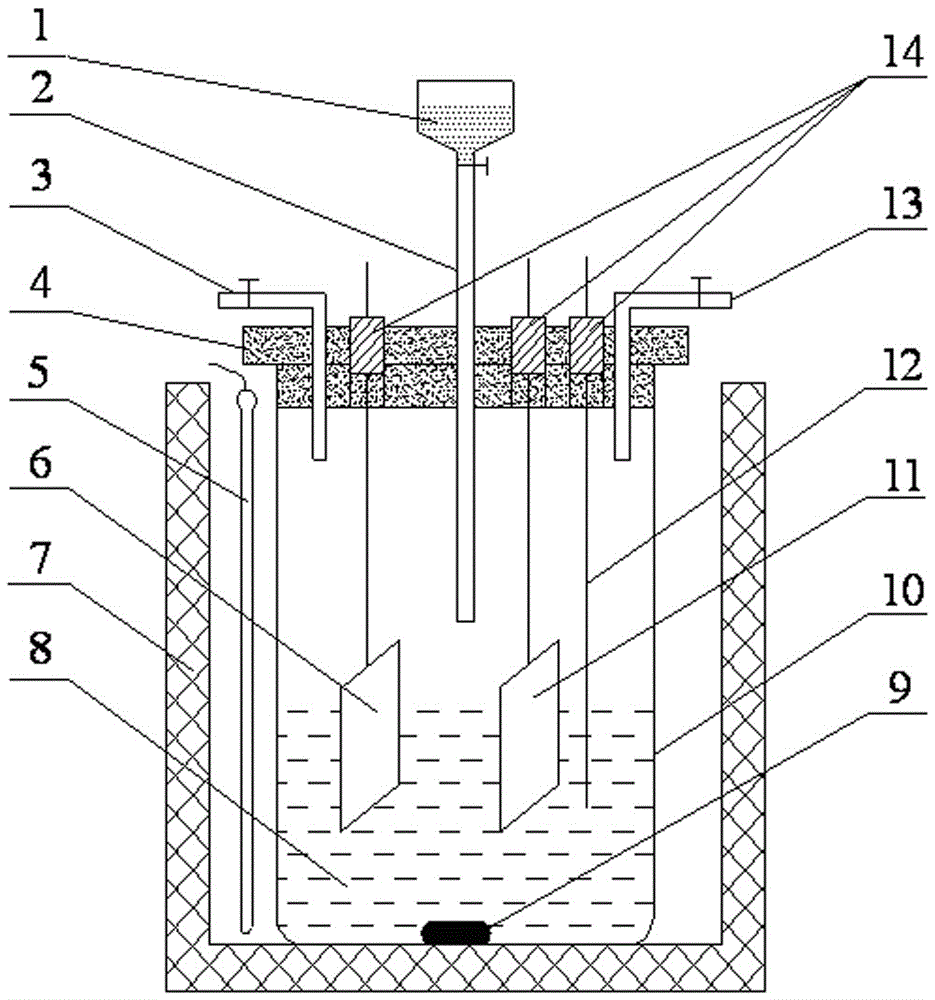

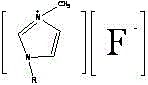

Method for preparing high-purity silicon thin film by electrolyzing SiO2 at low temperature through ionic liquid

ActiveCN105040020AEliminate emission pollutionShort processElectrolysis componentsHydrofluoric acidSilicon membrane

The invention provides a method for preparing a high-purity silicon thin film by electrolyzing SiO2 at a low temperature through ionic liquid. The method includes the following steps that (1) the raw materials, namely, the fluorinated imidazole ionic liquid, cryolite, a hydrofluoric acid solution and silicon dioxide, of an electrolyte are prepared; (2) the electrolyte is prepared in an electrolytic cell, and silicon dioxide is electrolyzed under the inert gas circulation and stirring condition; (3) silicon dioxide is supplemented in the electrolysis process; (4) working electrodes are replaced every 1-2 h; and (5) a silicon film is peeled off, washed and dried. According to the method, silicon electro-deposition can be conducted at a low temperature, and obtained silicon is high in purity; the technical reserve is provided for environment-friendly preparation of low-cost and low-pollution solar-grade silicon thin films.

Owner:NORTHEASTERN UNIV

A kind of all-aqueous plastic flexographic printing ink and preparation method thereof

The invention provides full water-based plastic flexible printing ink. The full water-based plastic flexible printing ink is prepared by the following raw materials by weight: 35-70 parts of printing ink connection materials, 25-50 parts of color paste, 1-10 parts of a flatting agent, 1-10 parts of a defoamer, 1-8 parts of wax emulsion, and 5-20 parts of deionized water. The color paste is prepared by mixing the following raw materials by weight: 20-55 parts of printing ink resin, 20-50 parts of organic pigments, 1-8 parts of a wetting dispersant, 1-6 parts of the defoamer, and 20-40 parts of the deionized water. The full water-based printing ink has abroad application range, and has environment-friendly feature compared with the normal water-based printing ink, and is capable of greatly reducing the pollutant residue and volatility gases on the surface of a printed matter, and realizing the zero release of VOC in the printing ink products. The full water-based printing ink has the characteristics of good adhesive force, rub resistance, scratch resistance, weather resistance, water resistance, chemical resistance, resistance and so on, and the high-speed flexible printing is more than 150 m / min.

Owner:中国印刷科学技术研究院有限公司

Method for producing bio-organic fertilizer by using lignin organic granules

InactiveCN102442847BFully reuseEliminate emission pollutionOrganic fertilisersFertilizer mixturesSpray GranulationParticulates

The invention provides a method for producing a bio-organic fertilizer by using lignin organic granules. The method provided by the invention comprises steps of: preparing a liquid inoculant, preparing a lignin black liquor into an organic particulate agent by spraying granulation, and compounding the organic granules and the liquid composite inoculant, wherein the liquid composite inoculant which accounts for 0.5-1.5% of the weight of the finished product composite microbial fertilizer is added. The production of the bio-organic fertilizer can be completed by bacterial liquid permeation intoorganic particles and the technical requirement of the product can be reached without drying. According to the invention, routines are broken by creative introduction of the spraying granulation method into the biological fertilizer granulation technology. The production method of the particulate bio-organic fertilizer is divided into two steps of spraying granulation of the organic granules and organic granule wrapping or inoculant adsorption. In the meanwhile, a certain activity of the bio-organic fertilizer is maintained. According to the bio-organic fertilizer product, the breakthrough from a powder form to spray particles is realized, thus laying a foundation for the extensive popularization of the bio-organic fertilizer.

Owner:北京世纪大德环保科技有限公司

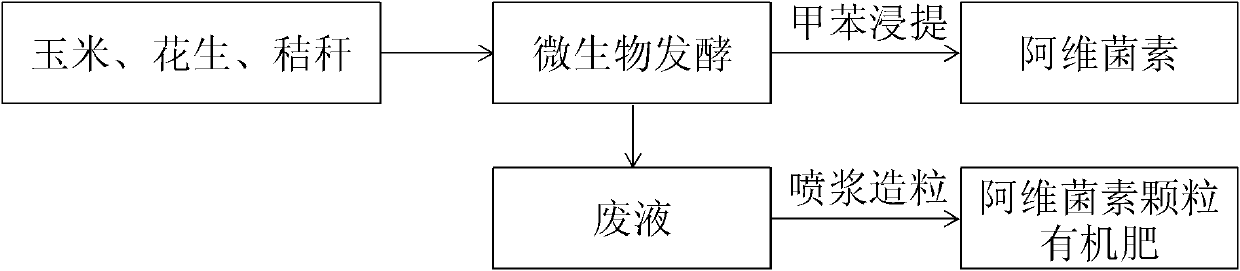

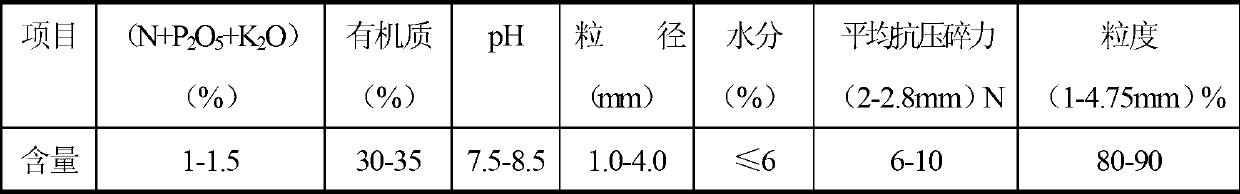

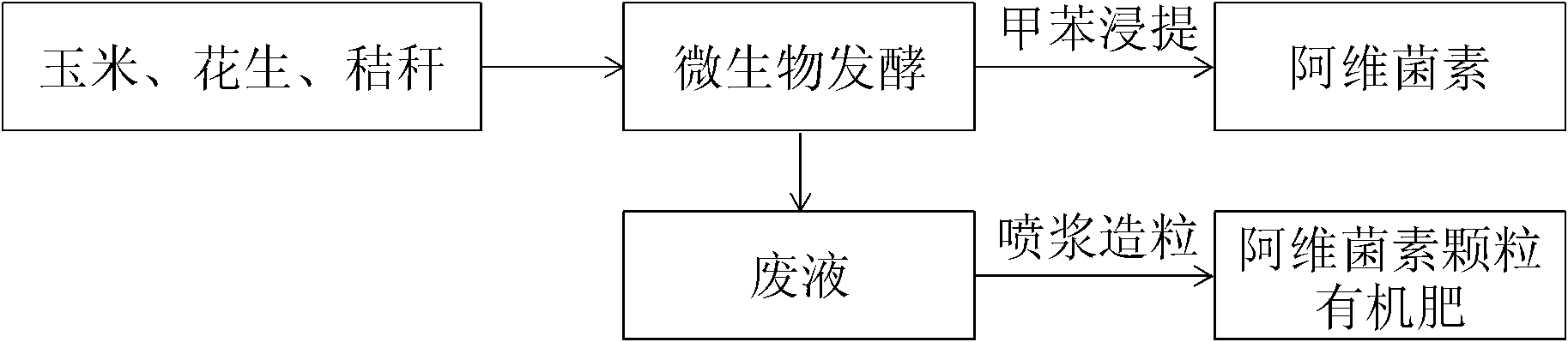

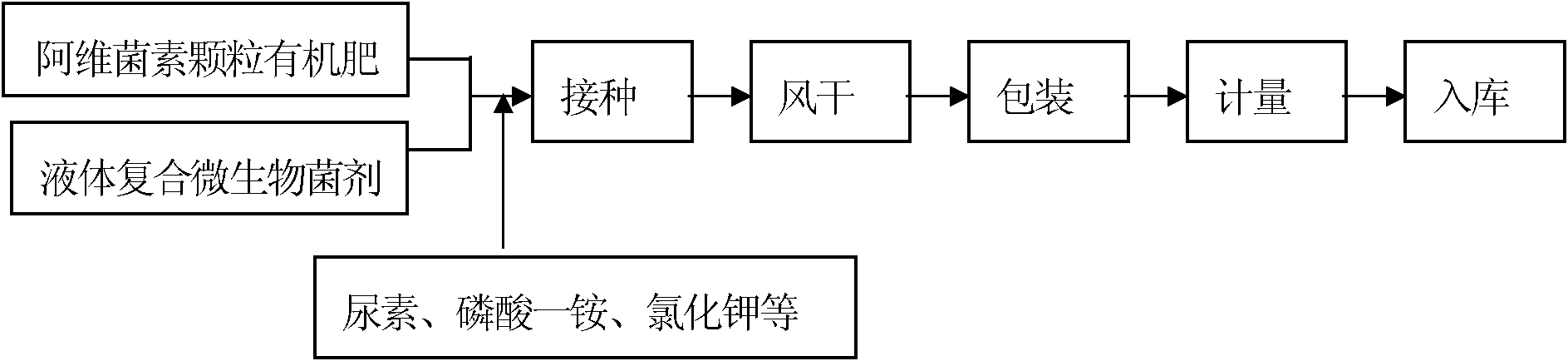

Method for producing compound microbial fertilizer with insecticidal effect

InactiveCN102040430BReduce manufacturing costSolve the production processFertilizer mixturesMicrobial agentBiofertilizer

The invention provides a method for producing a compound microbial fertilizer with insecticidal effect, comprising the following steps: preparing liquid microbial agent; adding waste abamectin liquid to inorganic fertilizer, and granulating the inorganic fertilizer into granular organic fertilizer; compounding the granular organic fertilizer and the liquid microbial agent which is 0.5-1.5 percent of the weight of the finished product of the compound microbial fertilizer; and airing or drying. The invention breaks the normal method for producing the compound microbial fertilizer and provides a novel method for producing the granular compound microbial fertilizer by granulating the inorganic fertilizer into the organic fertilizer and coating the liquid microbial agent by the granular organic fertilizer. The powdery compound microbial fertilizer is replaced by the granular compound microbial fertilizer, and the granular compound microbial fertilizer has a certain activity, thus a good foundation is laid for popularizing the granular compound microbial fertilizer on a large scale. The invention also provides a method for recycling the waste abamectin liquid.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Method for producing compound microbial fertilizer from amino acid organic granules

InactiveCN102040406BReduce manufacturing costSolve the production processOrganic fertilisersFertilizer mixturesMicrobial agentSlurry

The invention provides a method for producing compound microbial fertilizer from amino acid organic granules, in particular to a method for producing compound microbial fertilizer by adopting slurry spraying and granulating processes, comprising the following steps: preparing liquid microbial agent, granulating waste amino acid solution into organic granules, and compounding the organic granules with the liquid compound microbial agent, wherein the liquid compound microbial agent is uniformly absorbed on the surfaces of the amino acid organic granules, and fermentation liquid accounts for 0.5-1.5wt% of the finished product of the compound microbial fertilizer. According to the invention, the normal method for producing the compound microbial fertilizer is improved, a novel method for producing the granular compound microbial fertilizer by two steps of granulating waste amino acid solution into organic granules and absorbing the liquid compound microbial agent by the amino acid organic granules is provided, and the number of viable bacteria in the compound microbial fertilizer is ensured. The production of the compound microbial fertilizer by the slurry spraying and granulating processes breaks through the production of the powdery compound microbial fertilizer by the disc and roller granulating process, thus a good foundation is laid for improving the commodity value, effectiveness and large-area popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Bio-control bio-organic fertilizer and production method thereof

ActiveCN102180709BEliminate emission pollutionThorough governanceClimate change adaptationBioloigcal waste fertilisersDiseaseHydrolysis

The invention provides a production method of a bio-control bio-organic fertilizer. A microbial inoculum is independently fermented by bio-control bacillus subtilis HL259, bacillus mucilaginosus krassilnikov, and bio-control streptomyces sp. YL04 strains which are mixed according to a mass proportion of 4-5 : 2.5-3.5 : 1-2 after absorption by using an adsorption medium, and then hydrolysis residue and complex microbial community are mixed to obtain the bio-organic fertilizer. The bio-control bio-organic fertilizer can significantly improve the efficiency of bio-fertilizers, has obvious prevention and control effects on diseases of crops, greatly reduces the diseased seedling rate, and can more comprehensively provide nutrients required for crop growth to improve crop yield.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

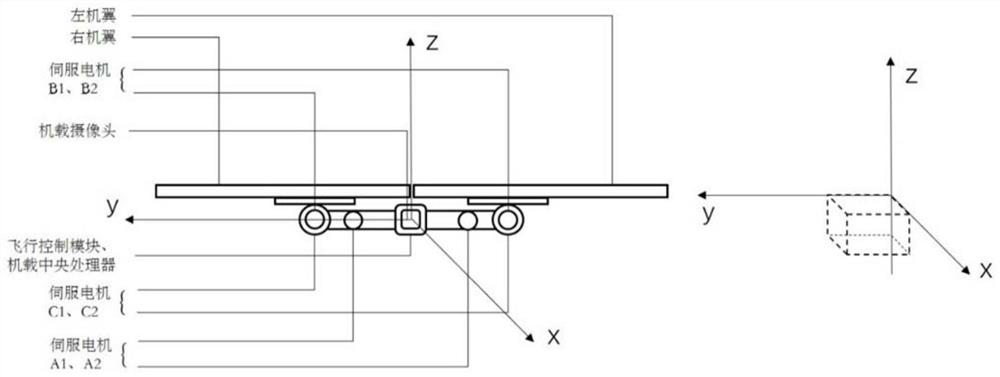

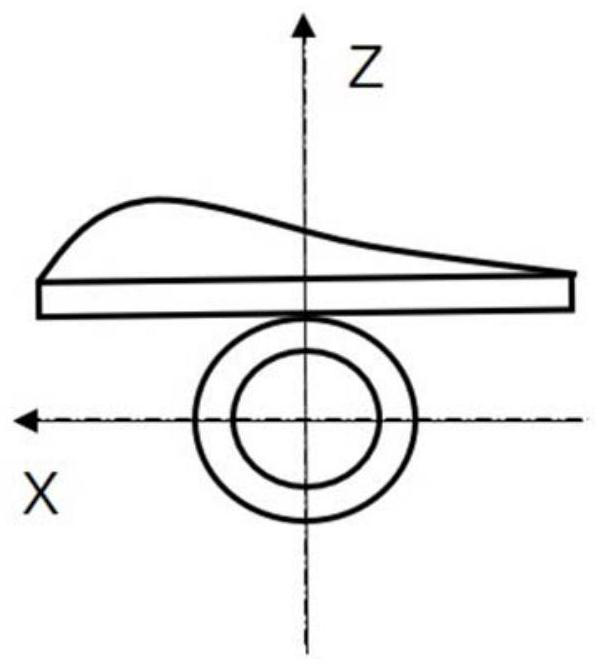

A bladeless aircraft capable of adapting to the environment based on electroaerodynamics and its control method

ActiveCN111142565BWith self-balancing functionNo consumptionPosition/course control in three dimensionsFly controlFlight vehicle

The invention discloses a bladeless aircraft based on an electro-aerodynamic adaptive environment and a control method thereof, comprising a wing, a frame, a flight control module, an airborne central processing unit, an airborne camera, a servo motor group and a power components. The bladeless aircraft is powered by the ion generator. The control method of the aircraft is divided into two parts, one is the control method of the self-evolution of the aircraft and the adaptive environment; the other is the control method of the aircraft motion. The control method of self-evolution and self-adaptive environment is to establish the control rule set and iterate continuously to realize the self-stabilization of the aircraft during flight. The attitude of the aircraft is controlled by three sets of servo motors. Under the three-dimensional model of the space, the angles of the aircraft's wings rotating around the three axes are controlled to change the movement direction of the aircraft. The invention has a self-balancing function under various motion conditions, and has no liquid fuel consumption, thereby eliminating the noise and emission pollution of the driving aircraft.

Owner:ZHEJIANG UNIV

Low-temperature electrolysis of sio using ionic liquids 2 Method for preparing high-purity silicon thin film

ActiveCN105040020BEliminate emission pollutionShort processElectrolysis componentsSilicon oxideSilicon thin film

A method for producing high-purity silicon thin films by low-temperature electrolysis of SiO2 using ionic liquids. The following steps are followed: (1) Prepare electrolyte raw materials such as fluorinated imidazole ionic liquid, cryolite, hydrofluoric acid solution and silicon dioxide; (2) The electrolyte is made in the electrolytic cell, and the silicon dioxide is electrolyzed under inert gas circulation and stirring conditions; (3) Add silicon dioxide during the electrolysis process; (4) Replace the working electrode every 1 to 2 hours; (5) Remove the silicon dioxide The film peels off, washed and dried. The method of the invention can electrodeposit silicon at low temperature, and the obtained silicon has high purity; it provides technical reserves for the green preparation of low-cost, low-pollution solar-grade silicon thin films.

Owner:NORTHEASTERN UNIV LIAONING

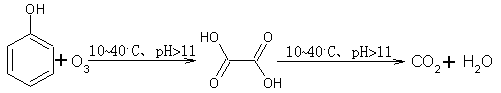

Method using ozone for treating phenol in car washing wastewater

InactiveCN102701420AEliminate emission pollutionReduce or even eliminate emission pollutionWater contaminantsWater/sewage treatment by oxidationChemistryPhenols

The invention relates to a method for treating phenol in car washing wastewater. Reaction conditions are achieved by means of detection of car washing wastewater temperatures, pH (potential of hydrogen) and phenol concentration and adjustment of the car washing wastewater temperatures and the pH, and flow rate of the car washing wastewater entering a mixer is determined to enable low ozone consumption on the premise of complete treatment of the phenol in the car washing wastewater, so that low-consumption purification of the car washing wastewater is achieved.

Owner:XIAN FEISIDA AUTOMATION ENG

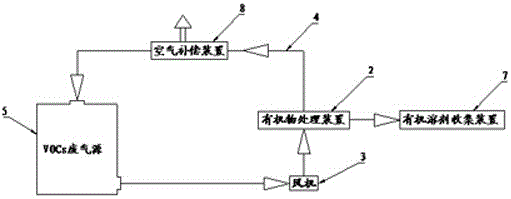

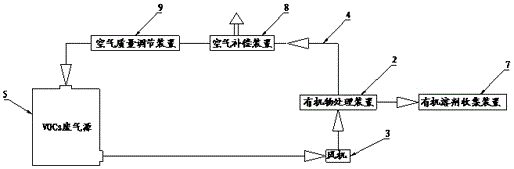

A vocs waste gas treatment device

ActiveCN104436979BEliminate emission pollutionEasy to handleDispersed particle separationDirt cleaningOrganic solventEnvironmental engineering

The invention relates to a VOCs waste gas treatment device. The VOCs waste gas treatment device comprises a VOCs waste gas source, an organic matter treatment device, a fan and an exhaust recovering pipeline, wherein the organic matter treatment device and the exhaust recovering pipeline are sequentially connected, a gas inlet end of the organic matter treatment device is connected with a waste gas emission outlet pipeline of the VOCs waste gas source, a gas outlet end of the exhaust recovering pipeline is connected with a fresh air inlet end pipeline of the VOCs waste gas source, a closed circulating loop is formed by the VOCs waste gas source, the organic matter treatment device and the exhaust recovering pipeline, the fan is arranged on the closed circulating loop, and the organic matter treatment device is also connected with an organic solvent collecting device pipeline. The VOCs waste gas treatment device provided by the invention realizes zero emission of VOCs waste gas, and thoroughly eliminates the pollution of VOCs waste gas emission to the environment; and the whole treatment process is simple and easy to operate, high in treatment efficiency, less in required equipment, and low in energy consumption of equipment, and well meets the requirements of modern enterprises for energy conservation and emission reduction, and improvement of production effectiveness, thus being of great significance for saving resources and lowering cost.

Owner:FUJIAN TIANLANG ENVIRONMENTAL PROTECTION EQUIP

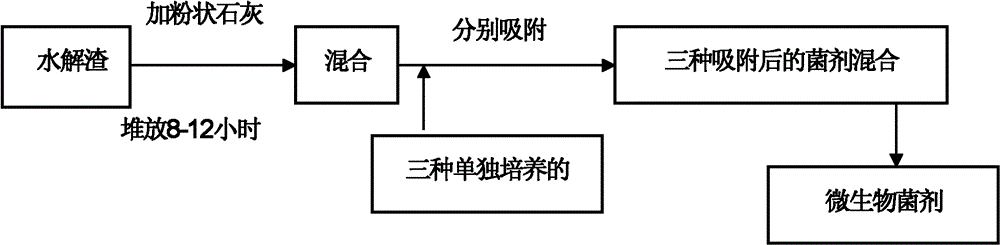

Biological control composite microbial agent, fertilizer and production method of fertilizer

ActiveCN102173950BEliminate emission pollutionThorough governanceFertilizer mixturesMicrobial agentSlag

The invention provides a biological control composite microbial agent. The biological control composite microbial agent is prepared by the following steps of: fermenting biological control bacillus subtilis HL259, bacillus mucilaginosus Krassilnikov and biological control streptomyces sp. YL04 strains respectively; adsorbing the materials by using an adsorbing medium; and mixing the materials according to the mass ratio of the fermenting biological control bacillus subtilis HL259 to the bacillus mucilaginosus Krassilnikov to the biological control streptomyces sp. YL04 of 4-5:2.5-3.5:1-2. Theinvention also provides a composite microbial fertilizer produced by using the microbial agent and hydrolytic slag and a production method thereof. The biological control composite microbial fertilizer can effectively improve manurial effect, has obvious effect of preventing and controlling diseases of crops, greatly reduces seedling disease rate, comprehensively provides nutrients required by growth of the crops and increases yield of the crops.

Owner:SHANGHAI LVLE BIO TECH

Method using ozone for purification treatment of alkyl sulfate sodium salt

InactiveCN102701407AEliminate emission pollutionReduce or even eliminate emission pollutionWater contaminantsWaste water treatment from vehicle washingDecompositionChemistry

The invention relates to a method using ozone for purification treatment of alkyl sulfate sodium salt. The alkyl sulfate sodium salt is completely decomposed to water, Na+, SO42- and dischargeable carbon dioxide by means of pollutant concentration detection and reaction temperature adjustment so that the shortages of residual pollution and the like of existing technical methods are overcome, and efficient treatment of pollutants can be achieved by computing the ozone amount required by complete decomposition of the alkyl sulfate sodium salt and adjusting and controlling openness of a water outlet valve and ozone feeding flow rate.

Owner:XIAN FEISIDA AUTOMATION ENG

Production method of microbial inoculum

ActiveCN102174443BSolve the production processReduce manufacturing costBacteriaMicroorganism based processesMicroorganismBacillus megaterium

The invention provides a production method of microbial inoculum and the method contains the fermentation and adsorption of the strain. The method comprises the following steps: utilizing treated hydrolysis residue as a bacterium solution adsorption medium to absorb the fermented bacterium solution of one or more of Bacillus subtilis, Bacillus megaterium and Bacillusmucilginosus krassilm, wherein the weight ratio of the bacterium solution to the hydrolysis residue is 0.3:(2-4); and then mixing and crushing, thus obtaining the microbial inoculum. The invention provides a new powdery microbial inoculum adsorption carrier, and the carrier contains various nutrients for microbial growth, is favorable for microbial proliferation and growth and is environmentally-friendly and low in price.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Production method of granular bioorganic fertilizer

ActiveCN102050644BReduce manufacturing costSolve the production processClimate change adaptationBioloigcal waste fertilisersSpray GranulationOrganic matter

Owner:SHANGHAI LVLE BIO TECH

Method for producing compound microbial fertilizer with microbial inoculum permeation and adsorption method

ActiveCN102442859BEliminate emission pollutionHigh particle strengthFertiliser formsFertilizer mixturesSpray GranulationBlack liquor

The invention provides a method for producing a compound microbial fertilizer with a microbial inoculum permeation and adsorption method. The method comprises the following steps of: preparing a liquid microbial inoculum; preparing a lignin black liquor into organic granules by performing spraying granulation; and compounding the organic granules with a liquid compound microbial inoculum, whereinthe l inoculum; preparing a lignin black liquor into organic granules by performing spraying granulation; and compounding the organic granules with a liquid compound microbial inoculum is added in anamount of 0.5-1.5 percent by weight based on the total weight of a finished compound microbial fertilizer. Production of the compound microbial fertilizer is completed with a method for making a bacterial liquid permeate into the organic granules, and the technical requirements of a product can be met without drying. In the invention, a new path is opened, the convection is broken, a production method of a granular compound microbial fertilizer is partitioned into an organic granule granulating step and an organic granule coating step, a certain viable count in the compound microbial fertilizer is ensured simultaneously, breakthrough of a compound microbial fertilizer product from powdery granules to spraying granulation granules is realized, and foundations are laid for large-scale popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Method for producing bio-organic fertilizer by performing spraying granulation

InactiveCN102442846BFully reuseEliminate emission pollutionFertiliser formsOrganic fertilisersSpray GranulationOrganic fertilizer

The invention provides a method for producing a bio-organic fertilizer by performing spraying granulation. The method comprises the following steps of: preparing a solid inoculant; granulating a lignin waste liquor into organic granules; compounding the organic granules with solid powder, wherein a powdery inoculant is added in an amount of 5-15 percent by weight based on the total weight of a finished compound microbial fertilizer; and mixing, granulating and drying under the condition that the material temperature in a drying barrel is not higher than 80 DEG C. In the invention, a new path is opened, the convection is broken, a production method of a granular compound microbial fertilizer is partitioned into an organic granule granulating step and an organic granule coating step, a certain viable count in the compound microbial fertilizer is ensured simultaneously, breakthrough of a compound microbial fertilizer product from powdery and disc-drum granulation to a spraying granulation process is realized, and foundations are laid for enhancing the commodity, effectiveness and area popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com