A vocs waste gas treatment device

A waste gas treatment device and a technology of a treatment device, which are applied in the direction of air quality improvement, dust removal, and separation of dispersed particles, can solve the problems that the treatment limit of the treatment system and method is difficult to meet the requirements of emission standards, residual VOCs, and non-standard emissions, etc., to achieve Meet the effects of energy saving and emission reduction, low equipment energy consumption, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

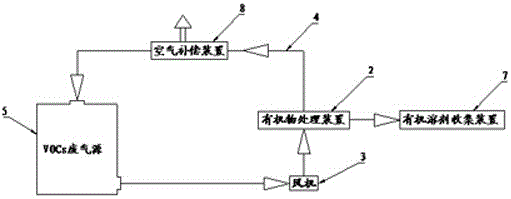

[0038] Please refer to figure 1 As shown, the VOCs exhaust gas treatment system of the present embodiment 1 includes an organic matter treatment device 2 for removing VOCs, a fan 3, and a tail gas recovery pipeline 4, and the organic matter treatment device 2 is an existing absorption recovery method, adsorption recovery One or more of the devices used in the method, condensation recovery method, incineration method, catalytic incineration method, plasma method or biological method.

[0039] The organic matter treatment device 2 and the tail gas recovery pipeline 4 are connected sequentially, and the gas inlet end of the organic matter treatment device 2 and the gas outlet end of the tail gas recovery pipeline 4 are respectively connected with the VOCs waste gas source 5, and the VOCs waste gas source 5, organic matter The processing device 2 and the exhaust gas recovery pipeline 4 form a closed loop (exhaust gas circulation system), and the fan 3 is arranged on the closed loo...

Embodiment 2

[0050] When the organic matter treatment device 2 is an adsorption recovery device including an adsorption tank, and the organic matter treatment method is to adsorb VOCs:

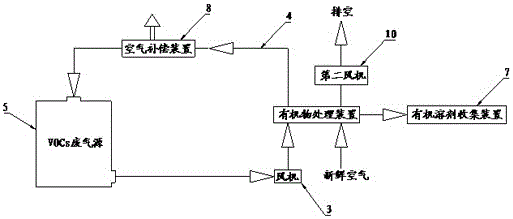

[0051] Please refer to figure 2 As shown, on the basis of Embodiment 1, the VOCs exhaust gas treatment system of Embodiment 2 also includes an adsorption system, a desorption system, a condensation system and a separation system of the adsorption recovery method, and the dehumidification of the adsorption tank of the second fan 10, cooling system.

[0052] The second fan 10 is connected to the adsorption tank of the organic matter treatment device 2, and a cooling and dehumidification channel is opened on the adsorption tank, one end of the cooling and dehumidification channel is connected to the second fan 10, and the other end of the cooling and dehumidification channel is connected to the outside world Pass.

[0053] Please continue to refer to figure 2 Shown, the VOCs waste gas treatment method of...

Embodiment 3

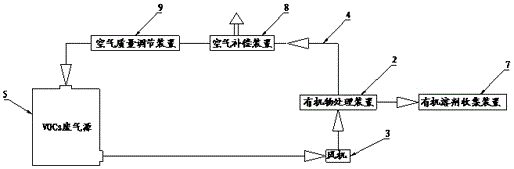

[0058] When the organic matter treatment device 2 is an organic matter treatment device 2 used to absorb or incinerate VOCs, and the organic matter treatment method is to absorb or incinerate VOCs:

[0059] can be used as figure 1 For the VOCs waste gas treatment system shown, the treatment method can refer to the description in Example 1.

[0060] The difference between this embodiment 3 and embodiment 2 is that the second blower fan 10 is not included, because there will be no intermittent temperature rise and water in the desorption process of the adsorption recovery method in the organic matter treatment device 2 for absorbing or incinerating VOCs. Steam is a problem, so there is no need for cooling and removal of water vapor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com